Adjustable rotor coiling mould

An adjustable, winding die technology, used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of increased man-hours, energy and material consumption, inaccurate positioning, low mold utilization, etc., to improve the mold Utilization rate, safe and reliable positioning, convenient adjustment and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

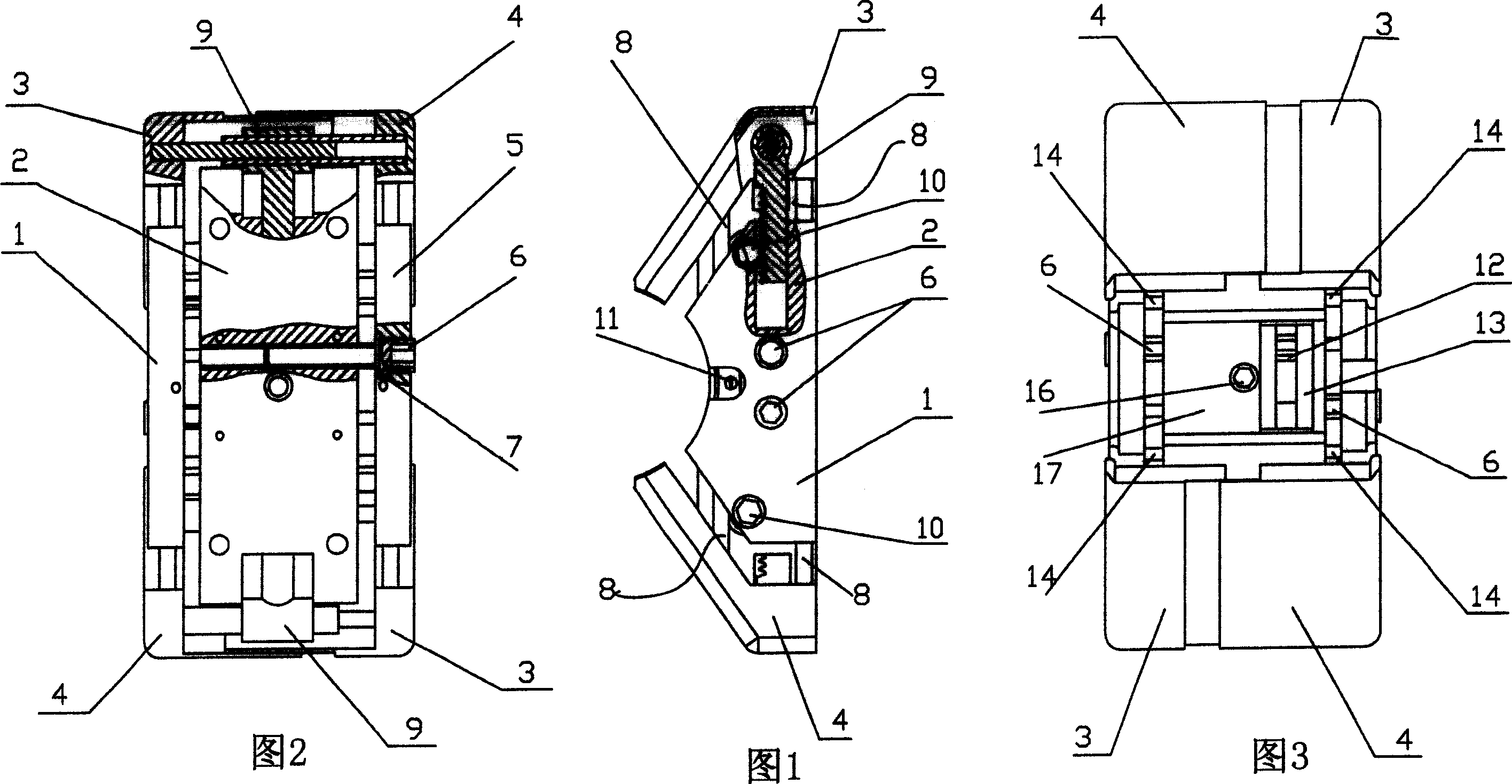

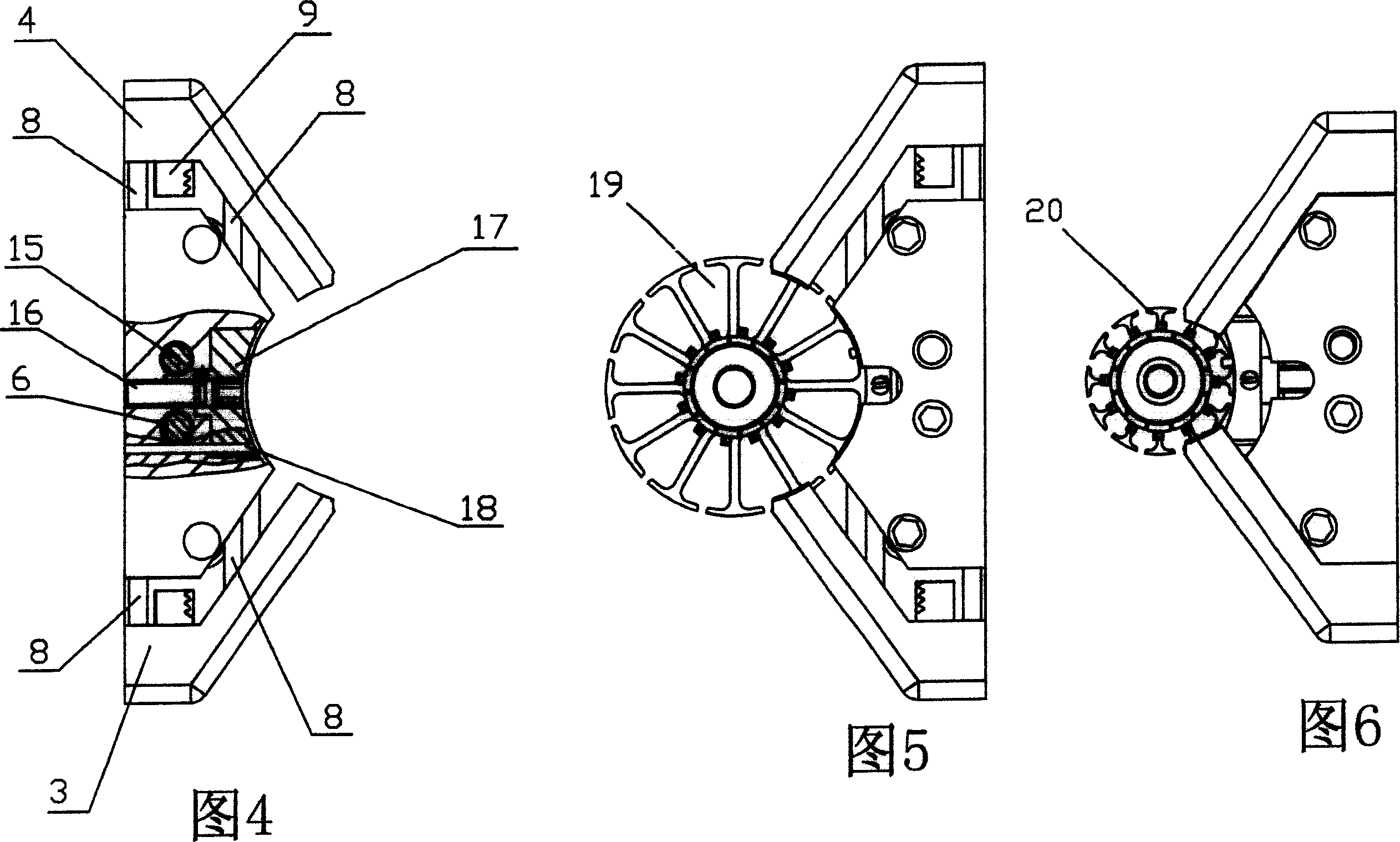

[0022] Figures 1 to 6 show the schematic structure of the adjustable rotor winding die. Structural features and working principles of the adjustable rotor winding die.

[0023] Description of structural features: The adjustable rotor winding die includes the mold body 2, wherein: the upper and lower end surfaces of the mold body 2 are respectively equipped with a set of first model surface 3 and second model surface 4 that are linked in the upper and lower directions and can be adjusted in the front and rear directions; The first model surface 3 and the second model surface 4 are equipped with four first guide columns 8 for up and down displacement, and are respectively linked with the first end plate 1 and the second end plate 5; the mold body 2 is symmetrically installed with rotation Functional gear shaft 10, the gear shaft 10 is engaged w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com