Method of producing exhaust-gas carrying devices, in particular exhaust-gas cleaning devices

A technology for cleaning device and exhaust gas, applied in the direction of exhaust device, muffler device, separation method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

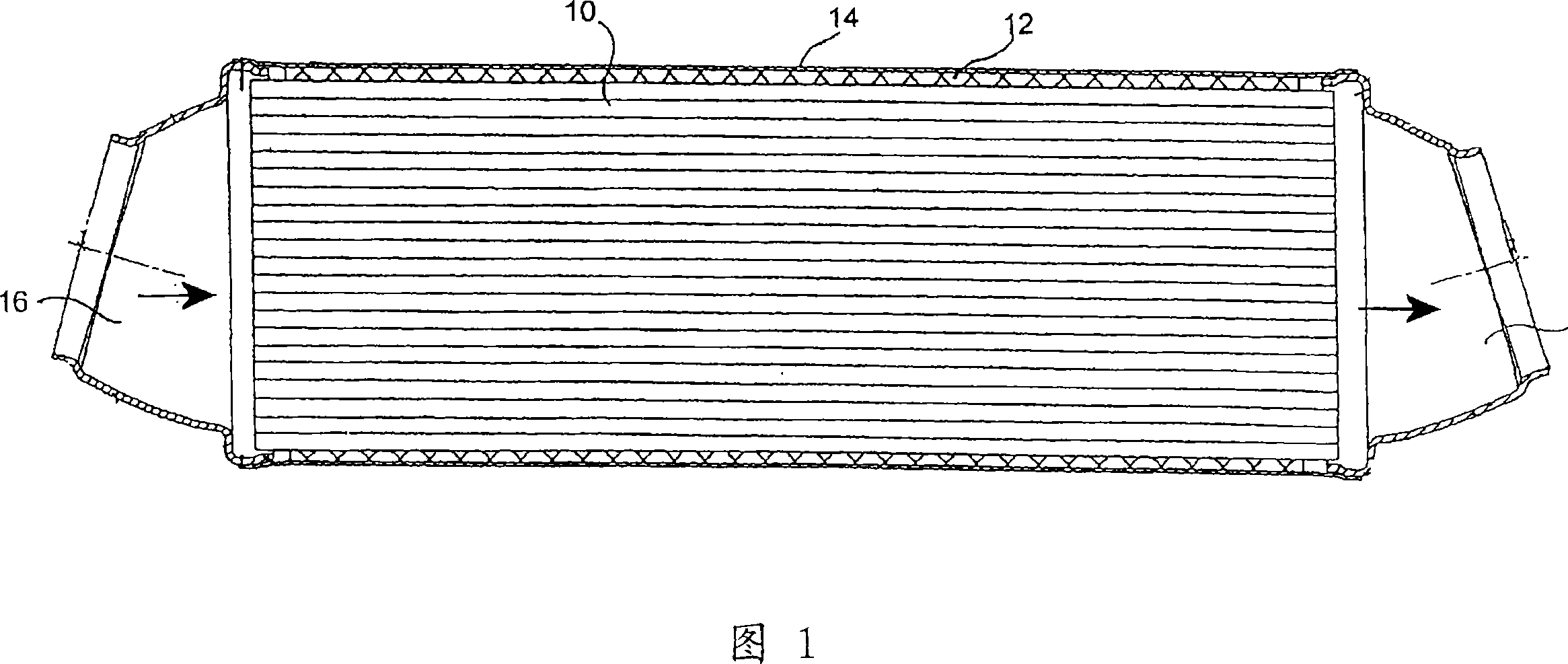

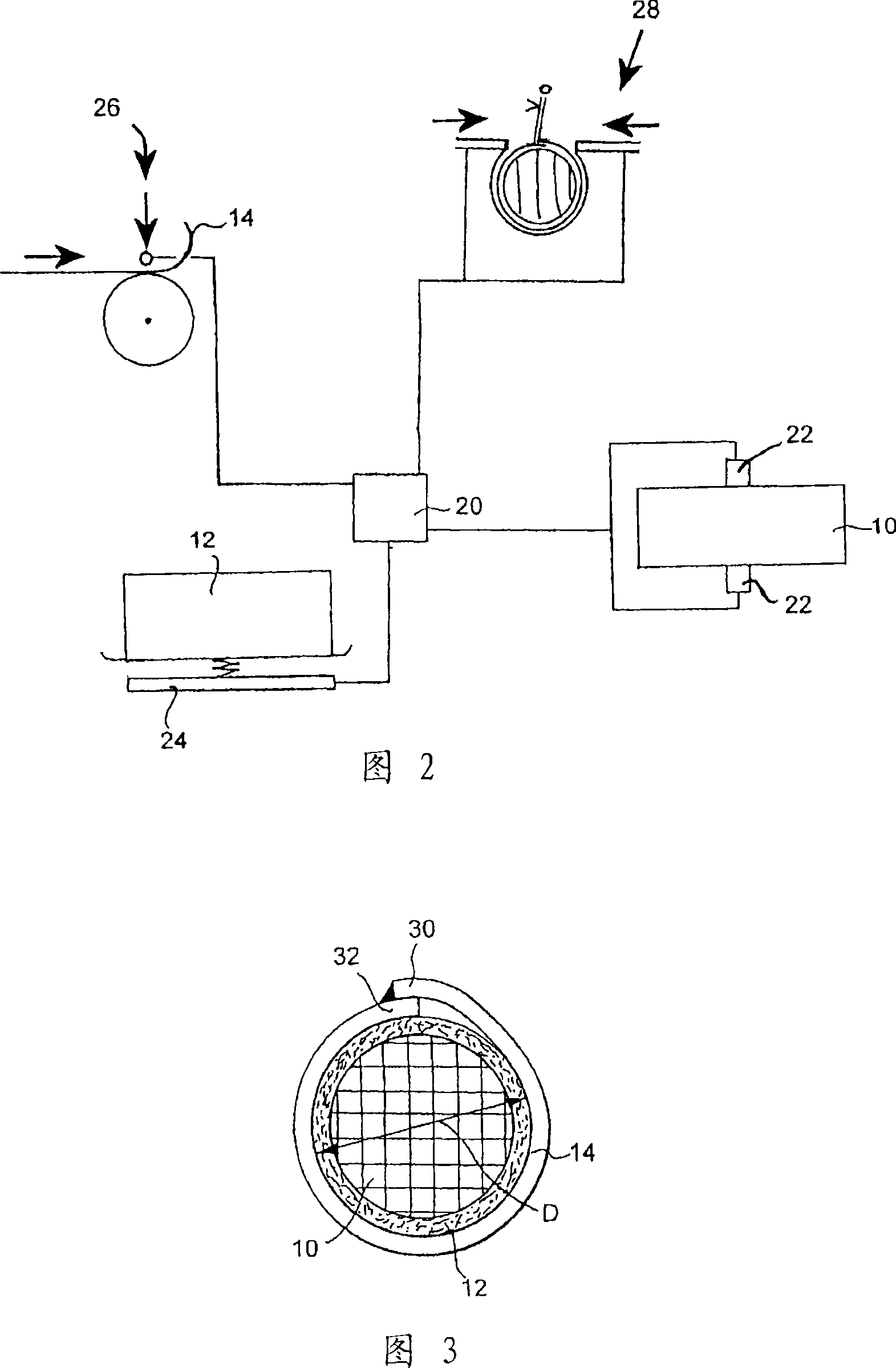

[0033] FIG. 1 illustrates an exhaust gas carrying device in the form of a vehicle exhaust gas cleaning device and accommodated in a motor vehicle. The vehicle exhaust gas cleaning device is an exhaust gas catalytic converter, or a diesel particle filter, or a combination of the two.

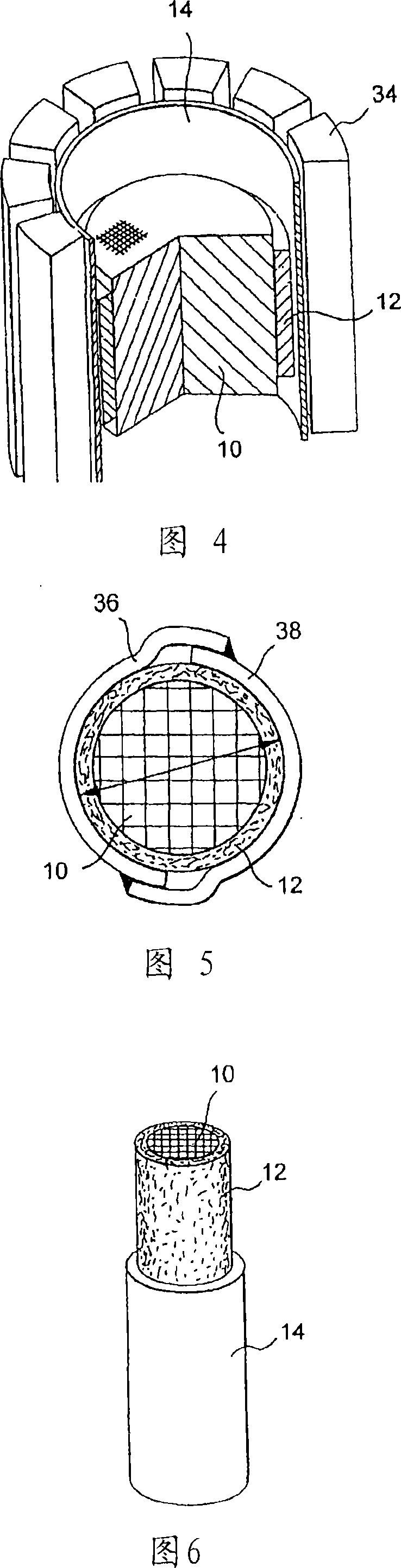

[0034] The core of the exhaust gas cleaning device is an elongated cylindrical substrate 10 comprising, for example, a ceramic substrate or a wrapped, corrugated plate or other catalytic carrier or filter material with or without coating . The substrate 10 may have a cylindrical cross-section or a non-circular cross-section. To simplify illustration, a cylindrical cross section is shown in each figure. The substrate is surrounded by a liner 12 , wherein the liner 12 serves as an elastic compensating element between the substrate 10 and the outer cover 14 . The housing 14 is designed with a low wall thickness, in particular it is made of sheet metal. An inlet funnel 16 and an outlet funnel 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com