Patents

Literature

65results about How to "Short arm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

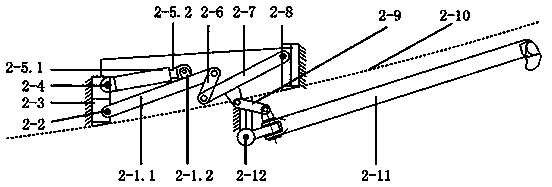

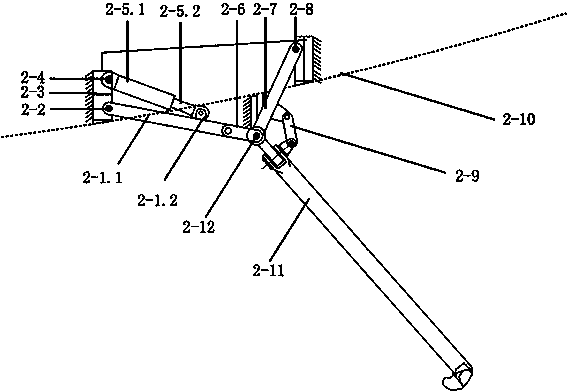

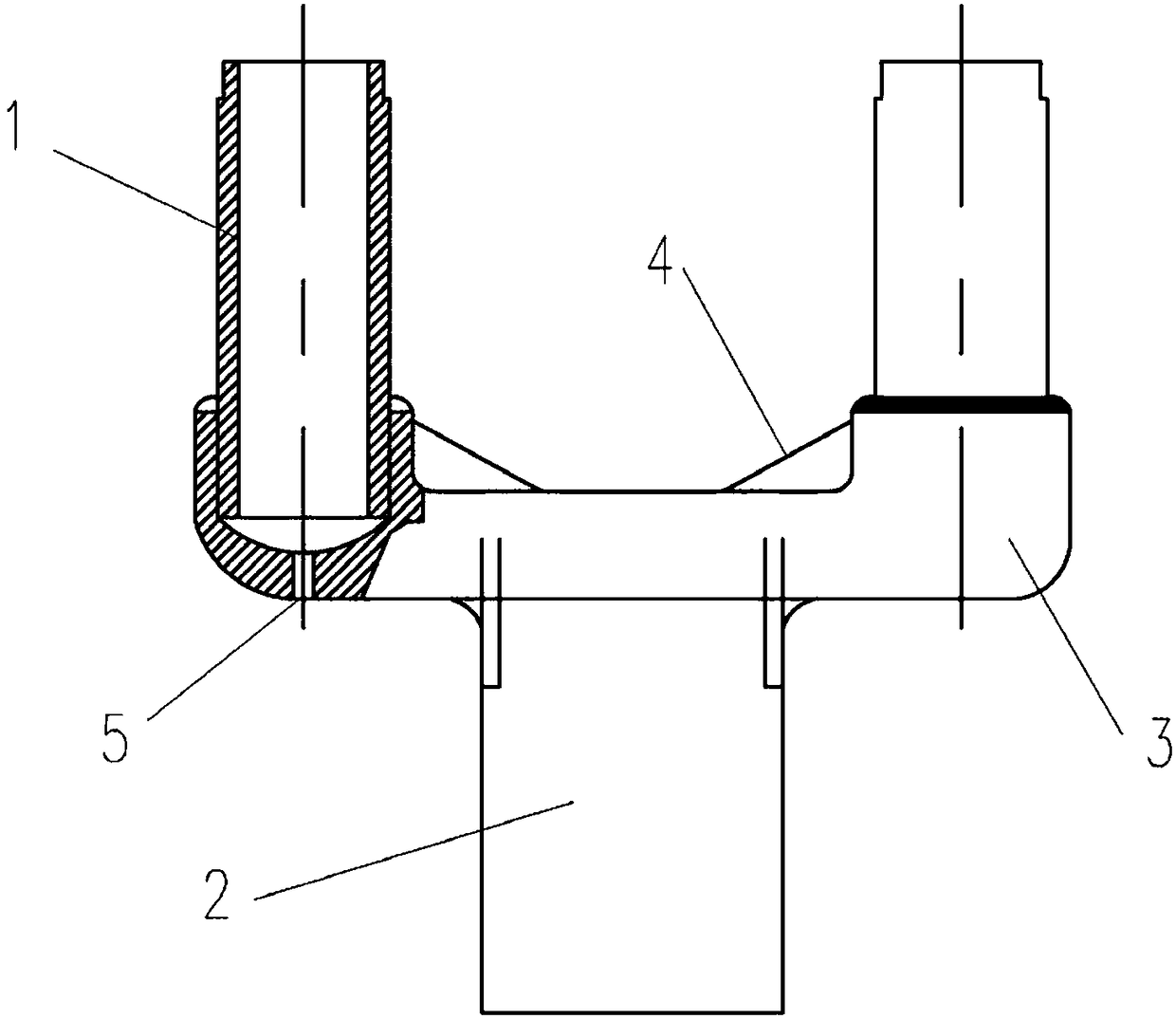

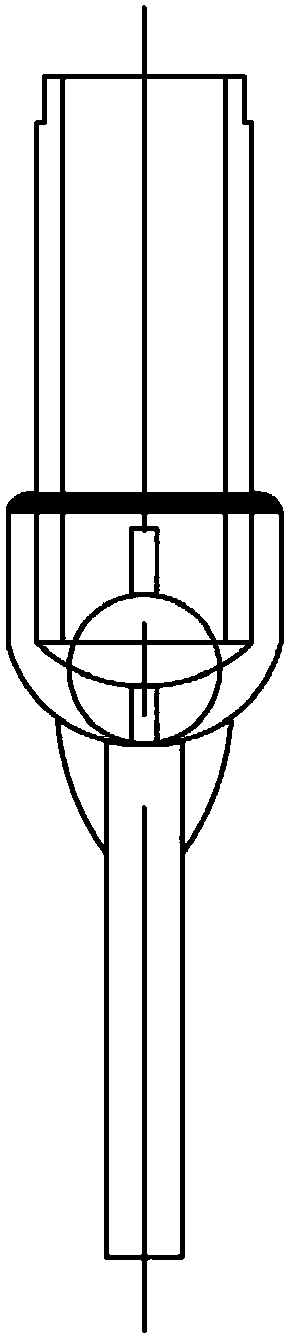

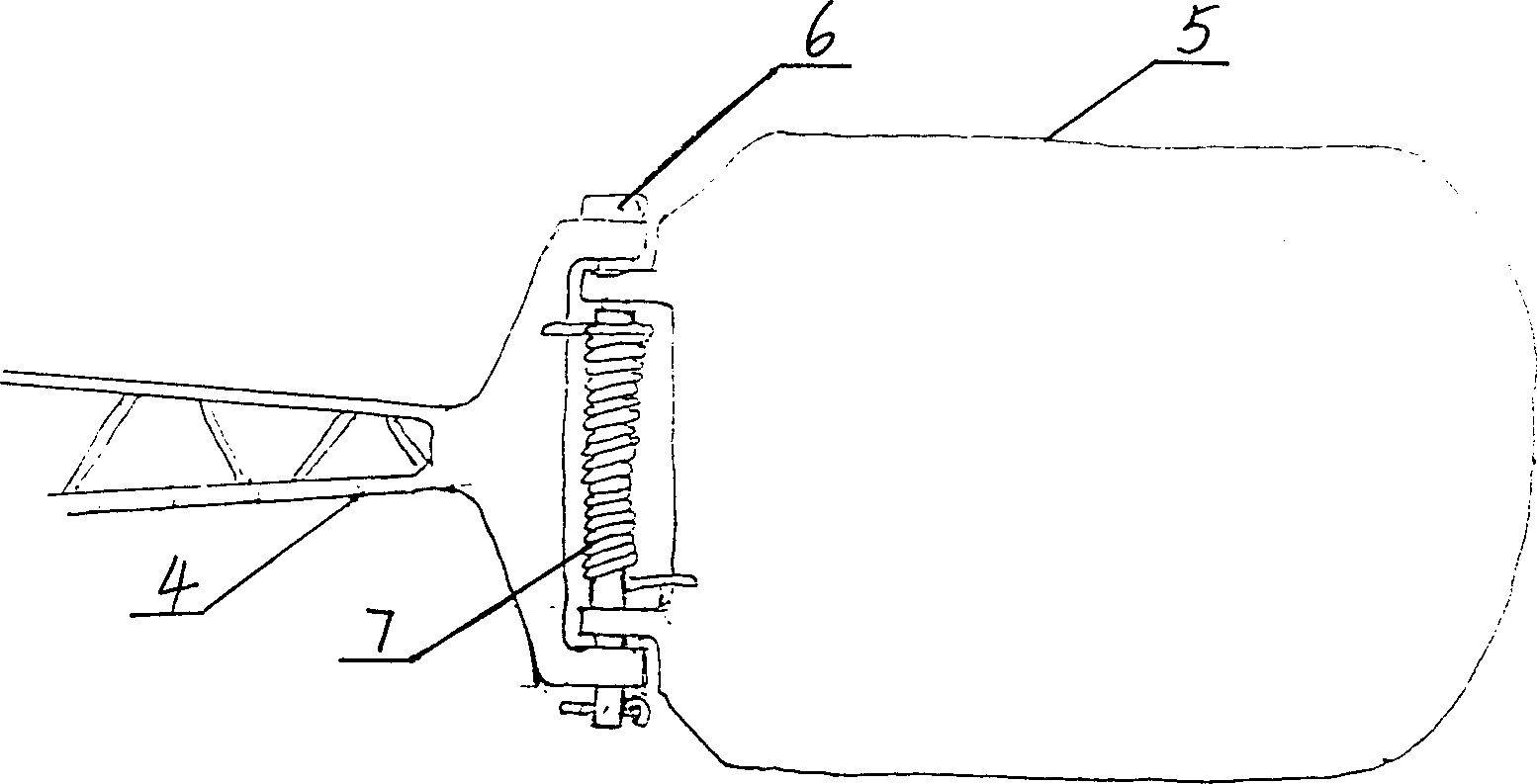

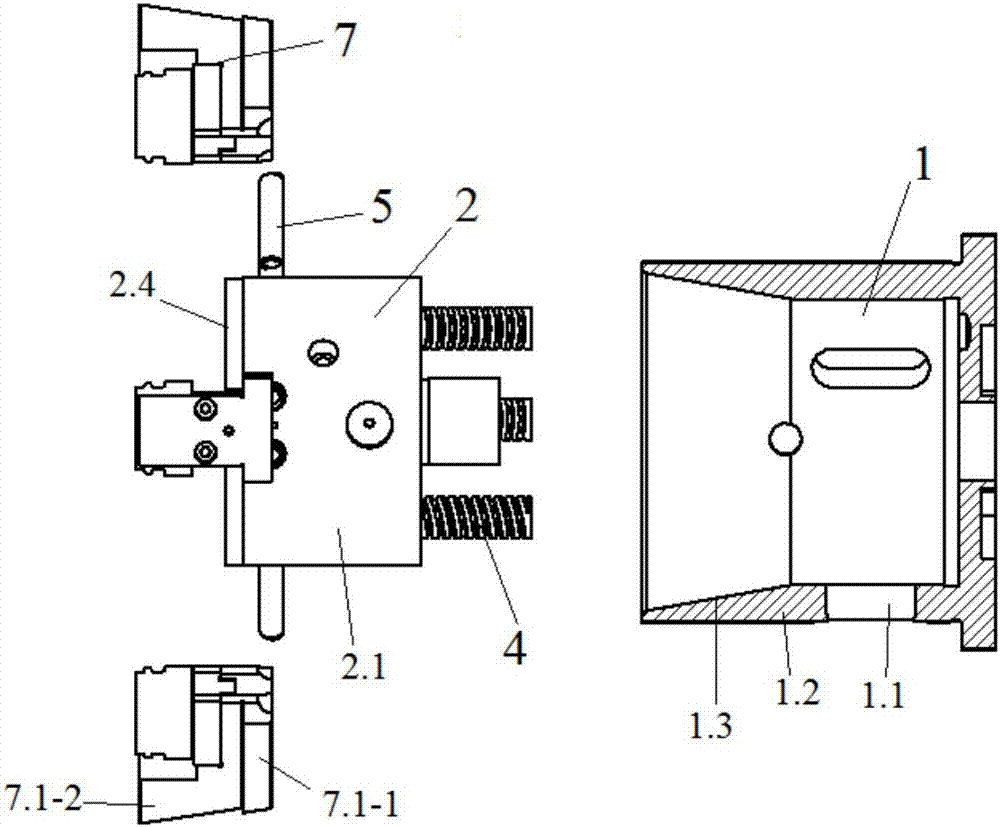

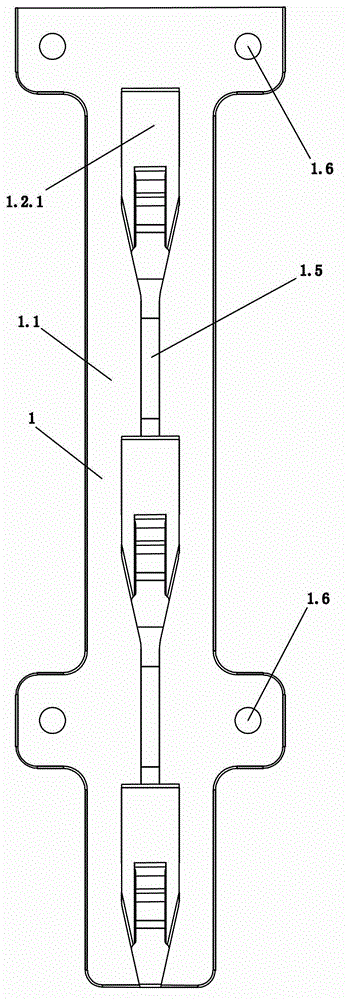

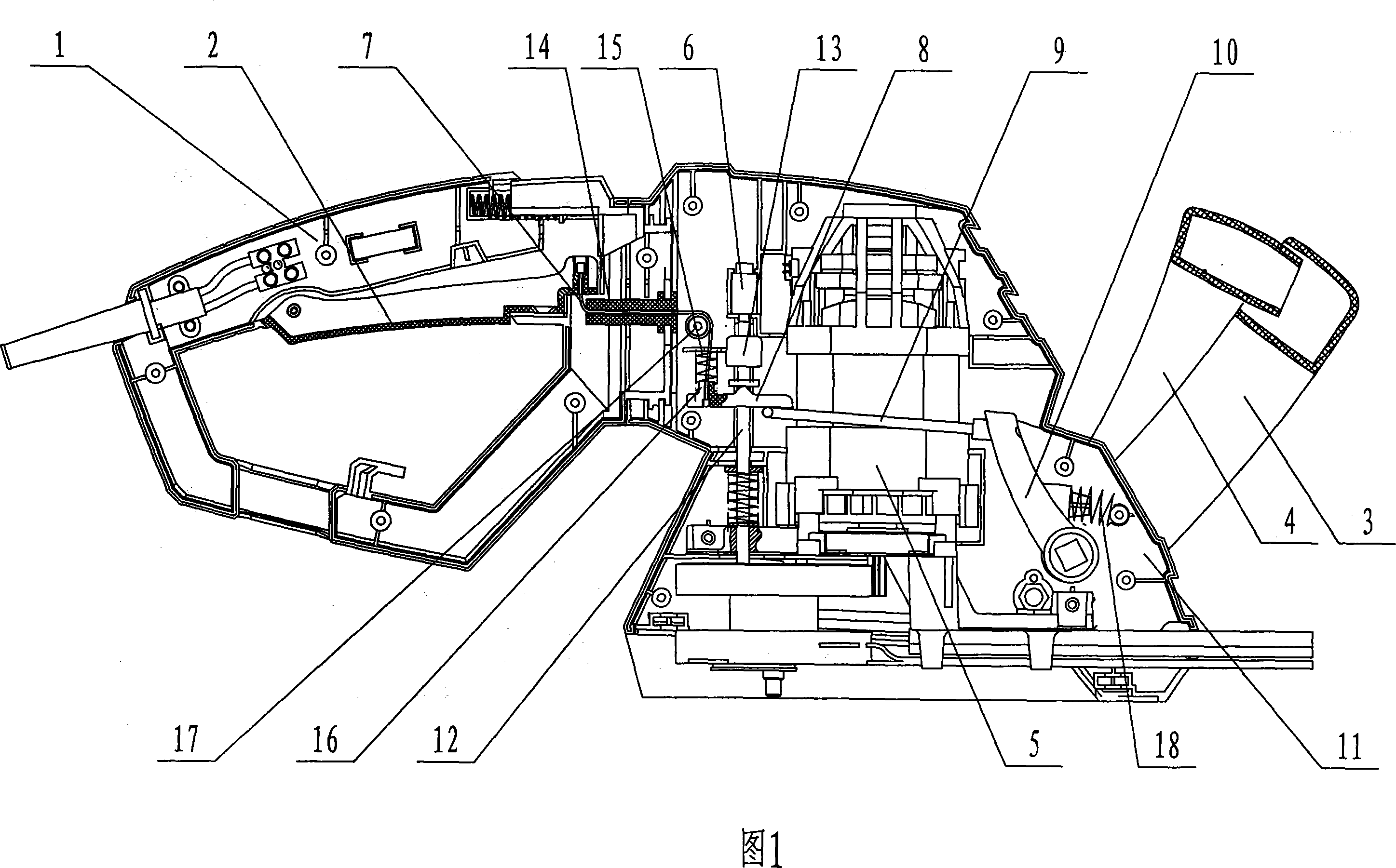

Arresting hook retracting and releasing mechanism

ActiveCN104176246AReduced strength requirementsShort action distanceArrester hooksPull forceUpper joint

The invention relates to an arresting hook retracting and releasing mechanism, belonging to the technical field of aircraft manufacturing. The arresting hook retracting and releasing mechanism comprises a connecting rod I, an upper joint, a fixed rotating shaft I, a rotating shaft support, a fixed rotating shaft II, an actuator cylinder, an expansion link, a connecting rod II, a connecting rod III, a fixed rotating shaft III, a connecting rod IV, an aircraft body surface, an arresting hook and a fixed rotating shaft IV; a transmission mechanism can enable the arresting hook to be released and retracted stably, the mechanism is reliable, and the actuator cylinder can realize long force arm by a short actuating distance; in addition, when the arresting hook is released to a working position, the connecting rod I 2-1.1, the connecting rod II 2-6, the connecting rod III 2-7 and a shipboard aircraft fixed structure form a triangular force-bearing structure, pulling force generated by arresting during aircraft landing is directly dispersed to an aircraft body structure by a connecting rod mechanism, and therefore, the strength requirement on the actuator cylinder can be reduced.

Owner:JIANGXI HONGDU AVIATION IND GRP

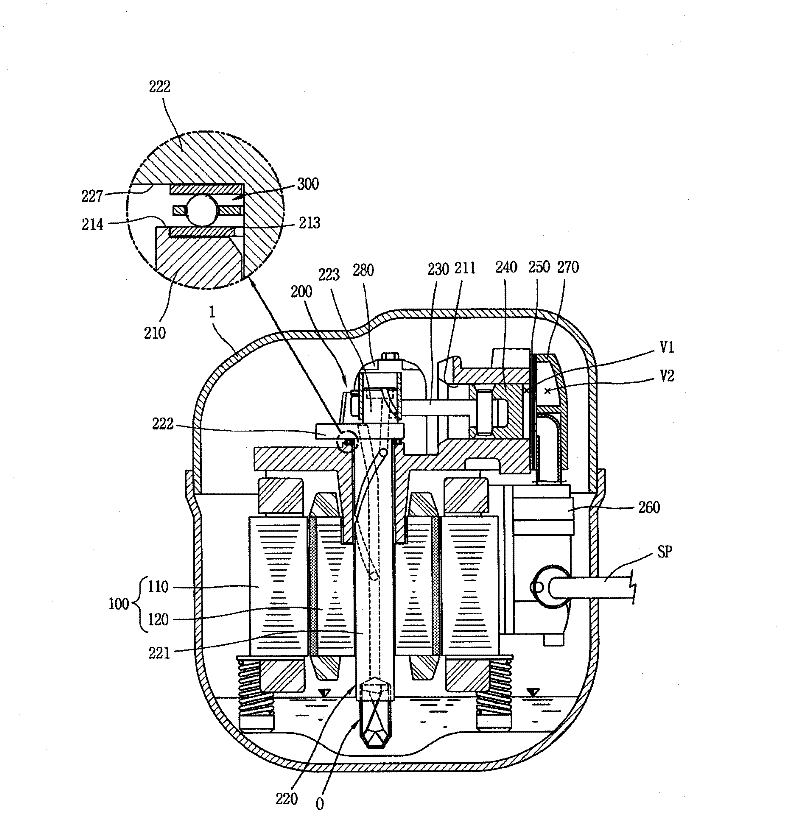

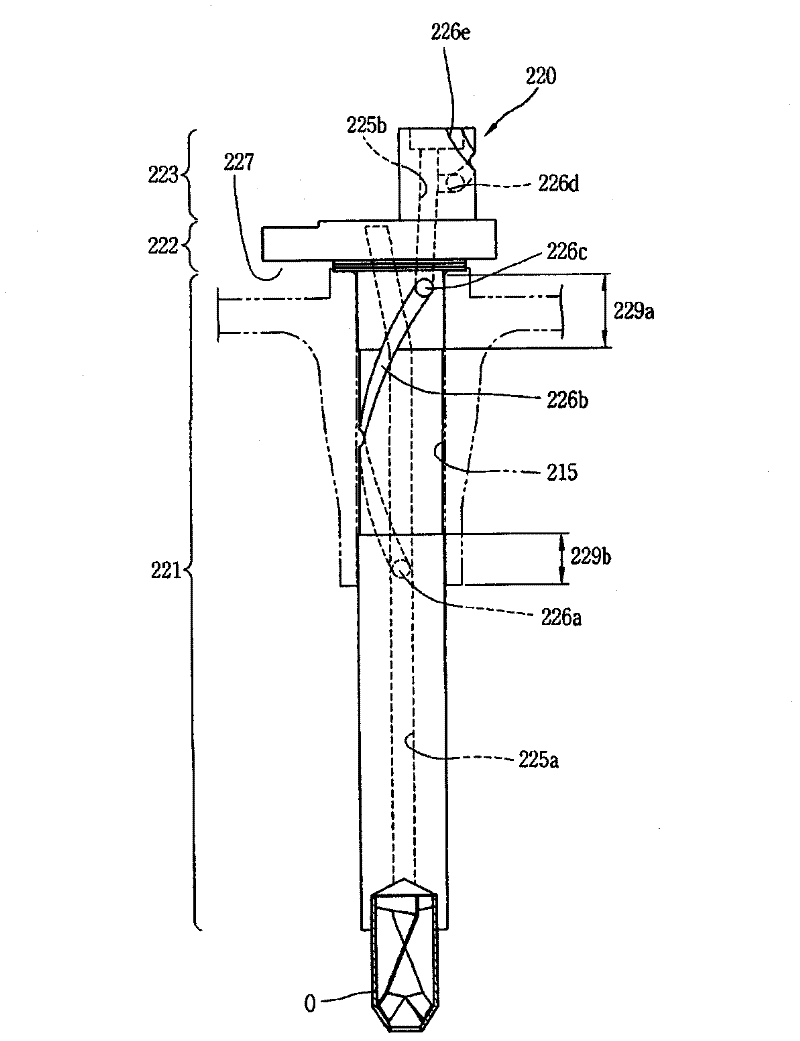

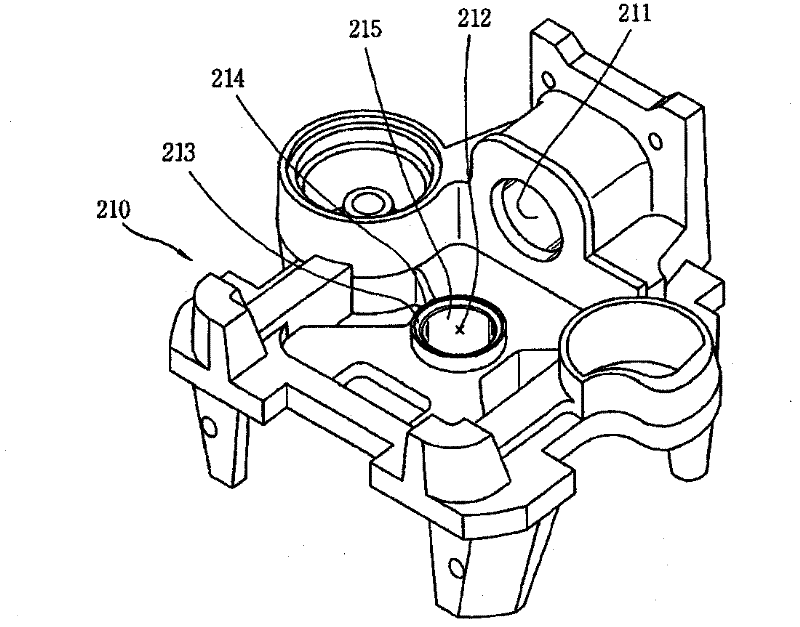

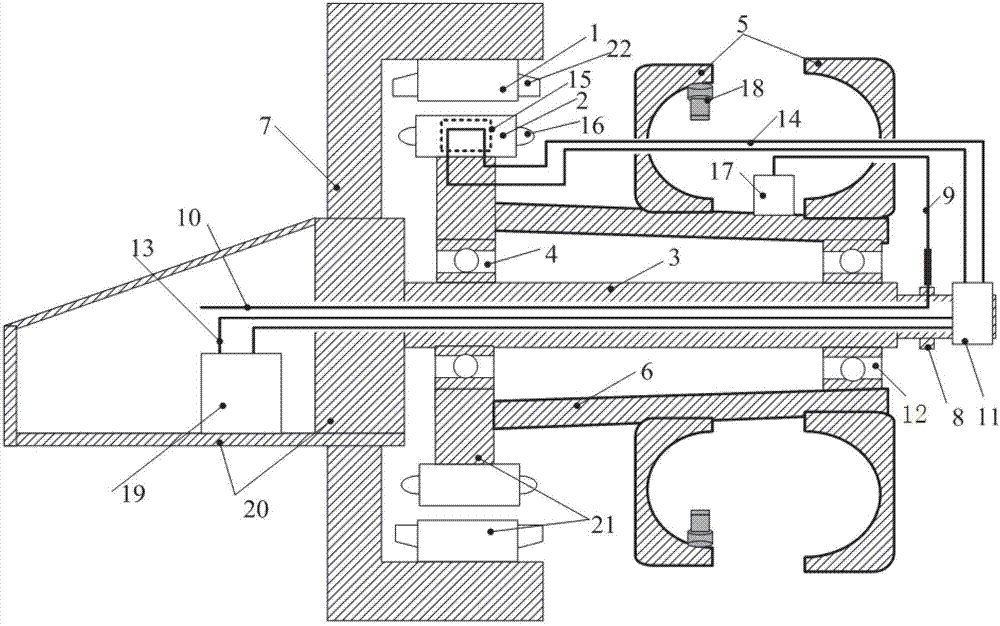

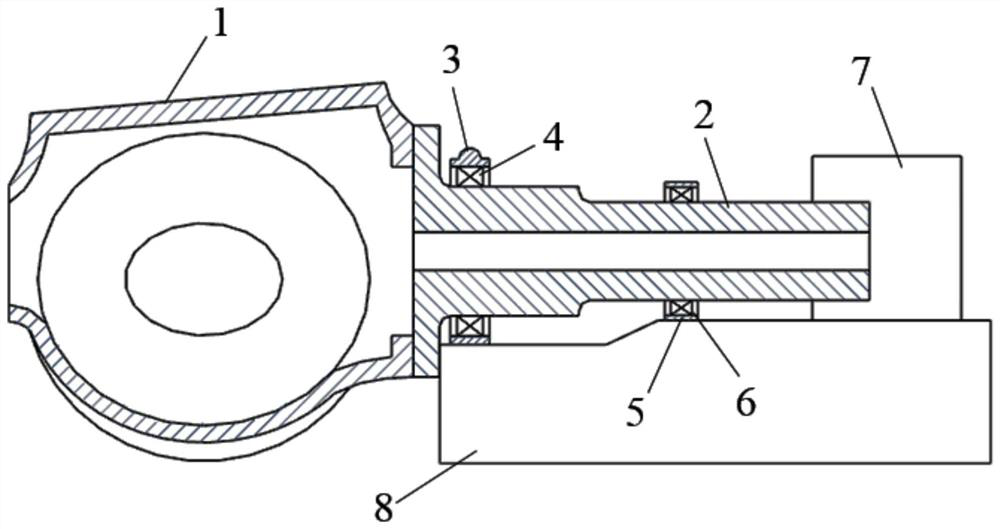

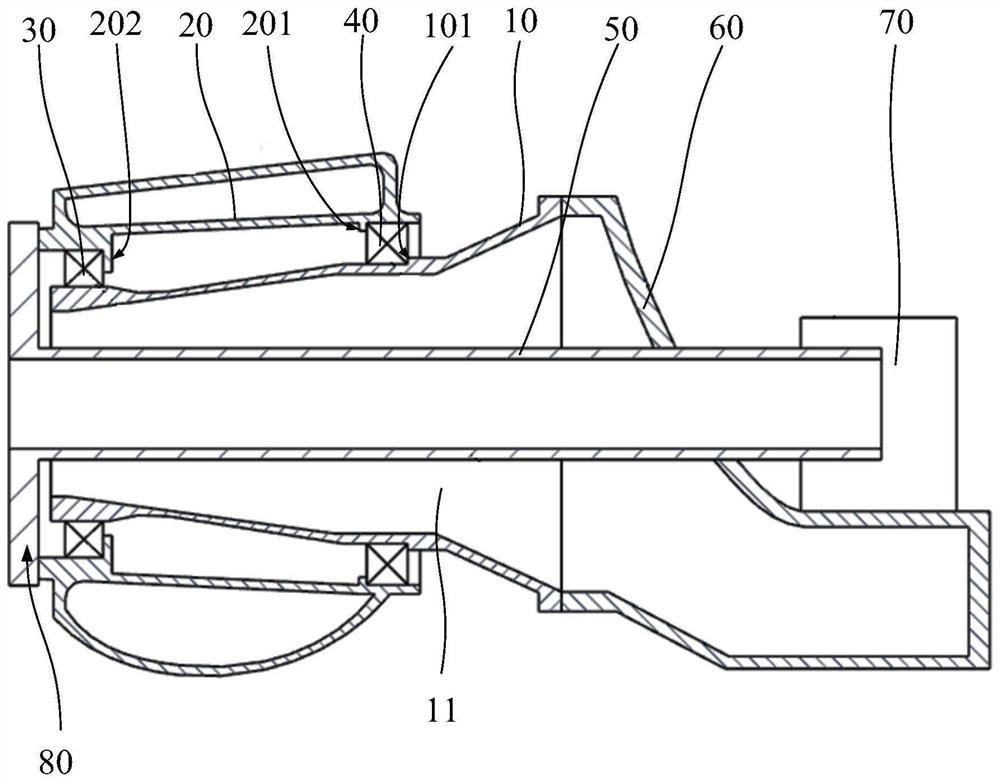

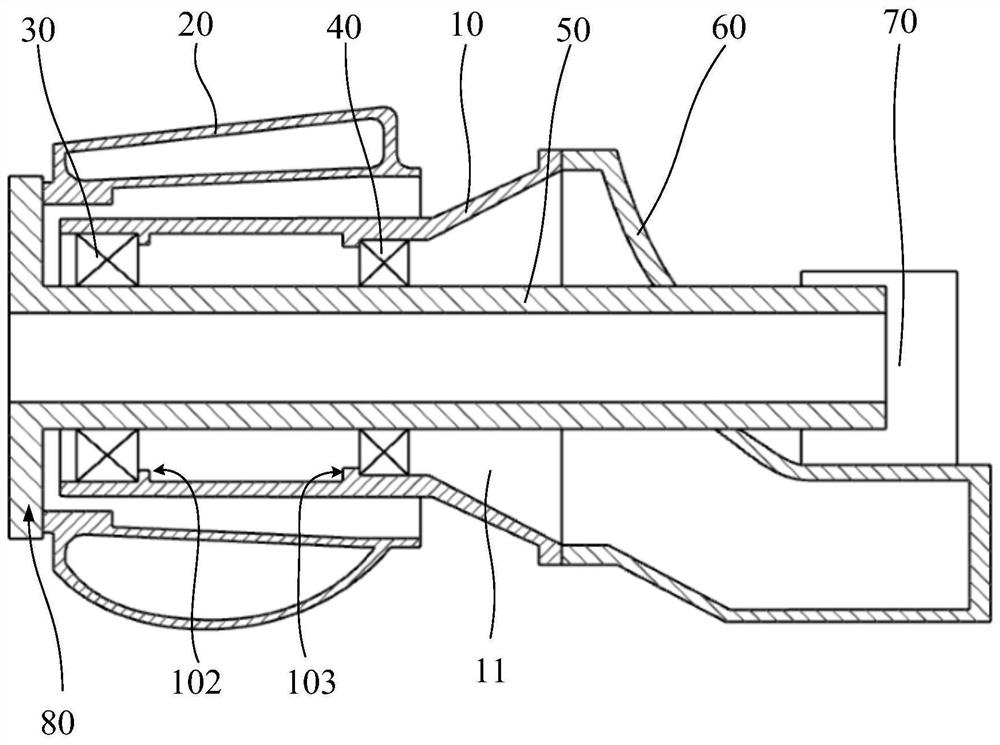

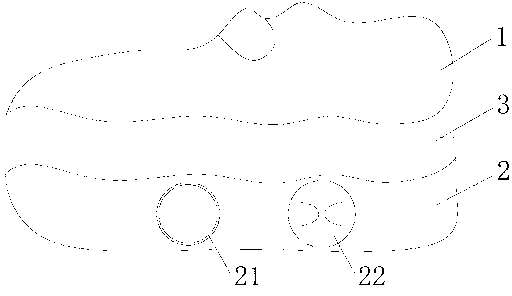

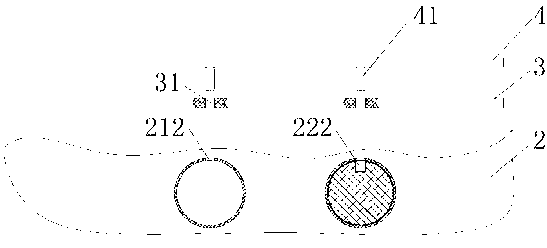

Reciprocating compressor and refrigeration device with the reciprocating compressor

ActiveCN102272453AImprove efficiencyEasy to installPositive displacement pump componentsMulti-stage pumpsBall bearingEngineering

Disclosed are a reciprocating compressor and a refrigerating apparatus having the same, a ball bearing (300) can be easily stably installed between thrust surfaces (213, 227) of a cylinder block (210) and a crank shaft (220) so as to enhance efficiency of the compressor. Also, a ball bearing (300) can be installed by being inserted into thrust surfaces (213, 227) so to shorten a moment arm that much, thereby decreasing a frictional loss at a journal bearing surface (215), resulting in an energy efficiency of the reciprocating compressor and the refrigerating apparatus having the same. In addition, as an oil hole (226c) of the crank shaft (220) is veiled by the journal bearing surface (215) of the cylinder block (210), even if a ball bearing (300) is employed, oil leaked between the thrust surfaces (213, 227) can be reduced, thereby further enhancing the efficiency of the compressor and the refrigerating apparatus having the same.

Owner:LG ELECTRONICS INC

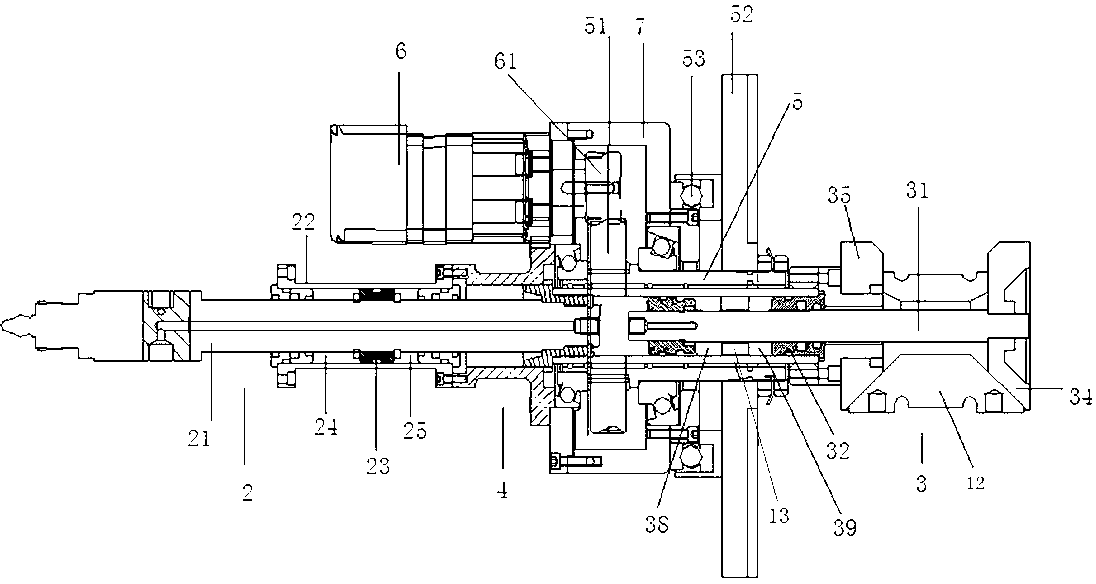

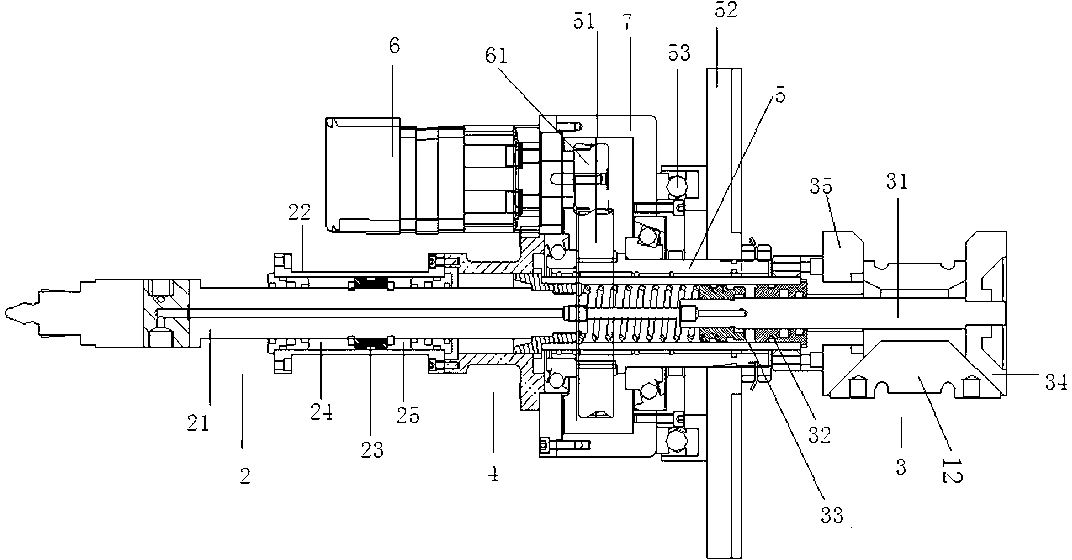

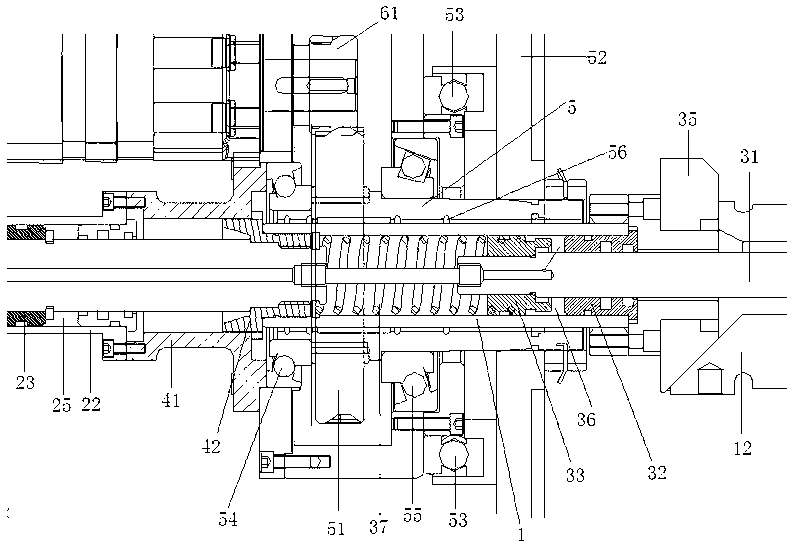

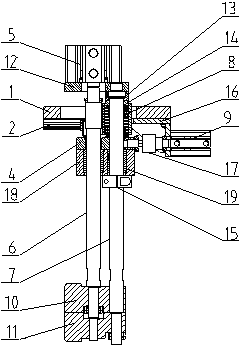

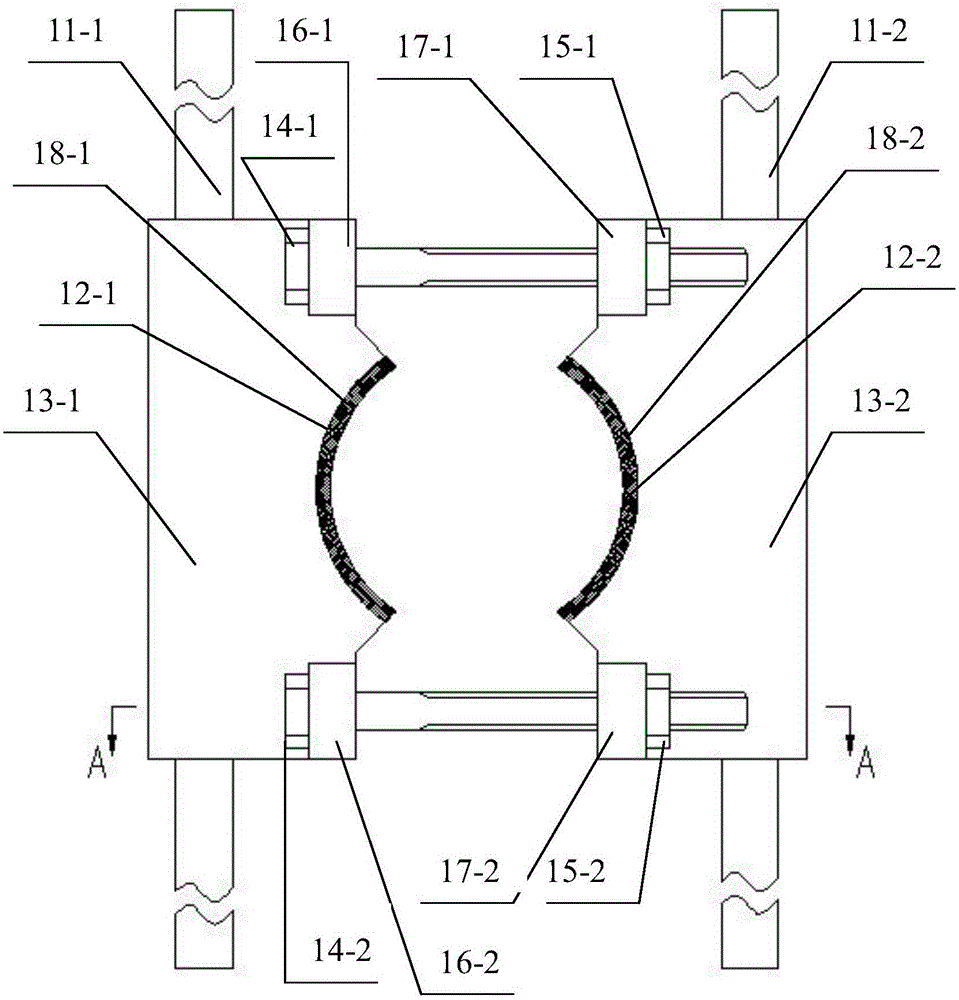

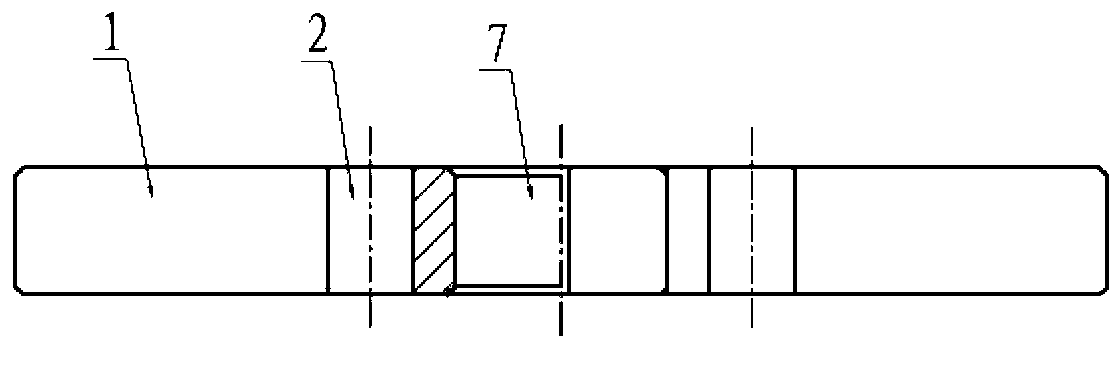

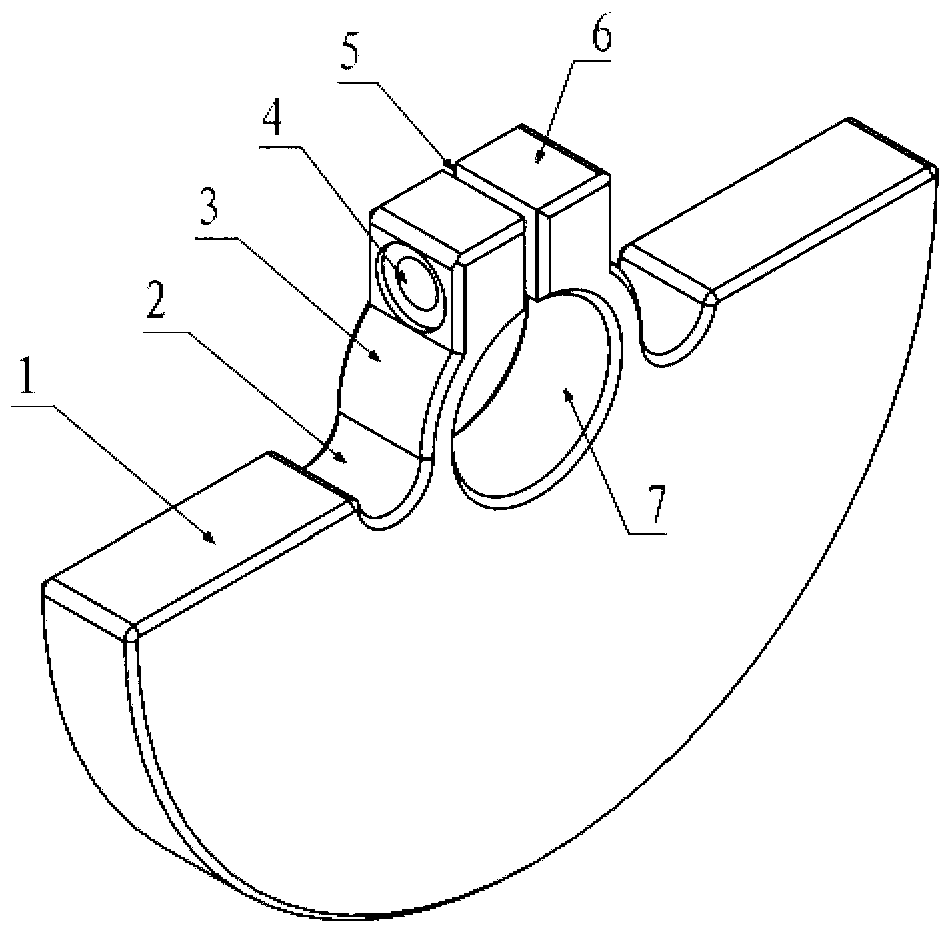

Pipeline facing machine

InactiveCN102962521APlay the role of supporting the chassisTake full advantage ofFeeding apparatusPositioning apparatusPower outputEngineering

The invention relates to a pipeline facing machine, which comprises a main supporting shaft and an enclosure, wherein the main supporting shaft is provided with a main shaft sleeve; the main shaft sleeve is movably connected with the main supporting shaft via a bearing; the main shaft sleeve is provided with a transmission gear and a cutterhead; a hydraulic cutting and feeding device and a hydraulic expansion device are respectively arranged on two ends of the main supporting shaft; a driving device is meshed with the transmission gear via a power output gear; the driving device is fixedly arranged on the enclosure; and the enclosure is movably connected with the main shaft sleeve via a main enclosure supporting bearing. According to the pipeline facing machine disclosed by the invention, the facing machine and the a pipeline can be fixed and the cutterhead can be fed and retracted by the hydraulic expansion device and the hydraulic cutting and feeding device, the automatic degree and the manpower labor intensity are improved, and the pipeline facing machine has the advantages of high expansion speed, big expansion force, stability in feeding, compact equipment structure, small volumesize, wide pipeline applicable range and convenience in carrying. According to a proper device, one person can easily finish installing and disassembling the machine on the pipeline.

Owner:上海油威液压成套设备有限公司

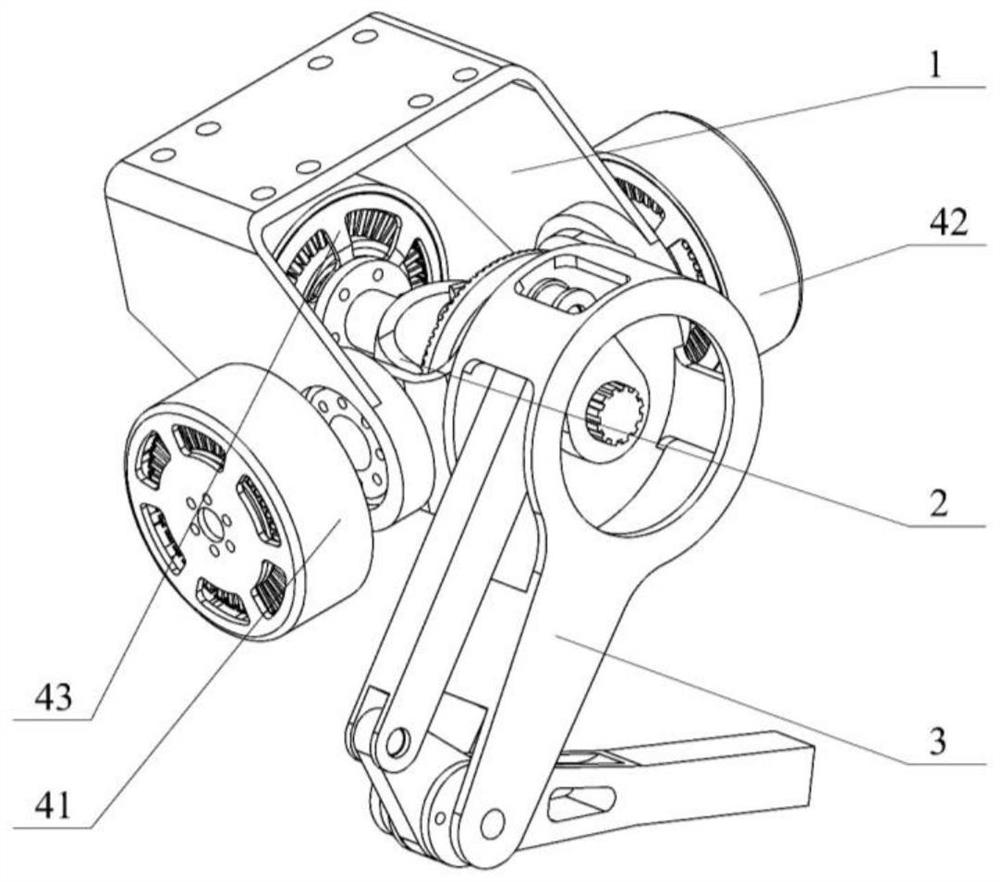

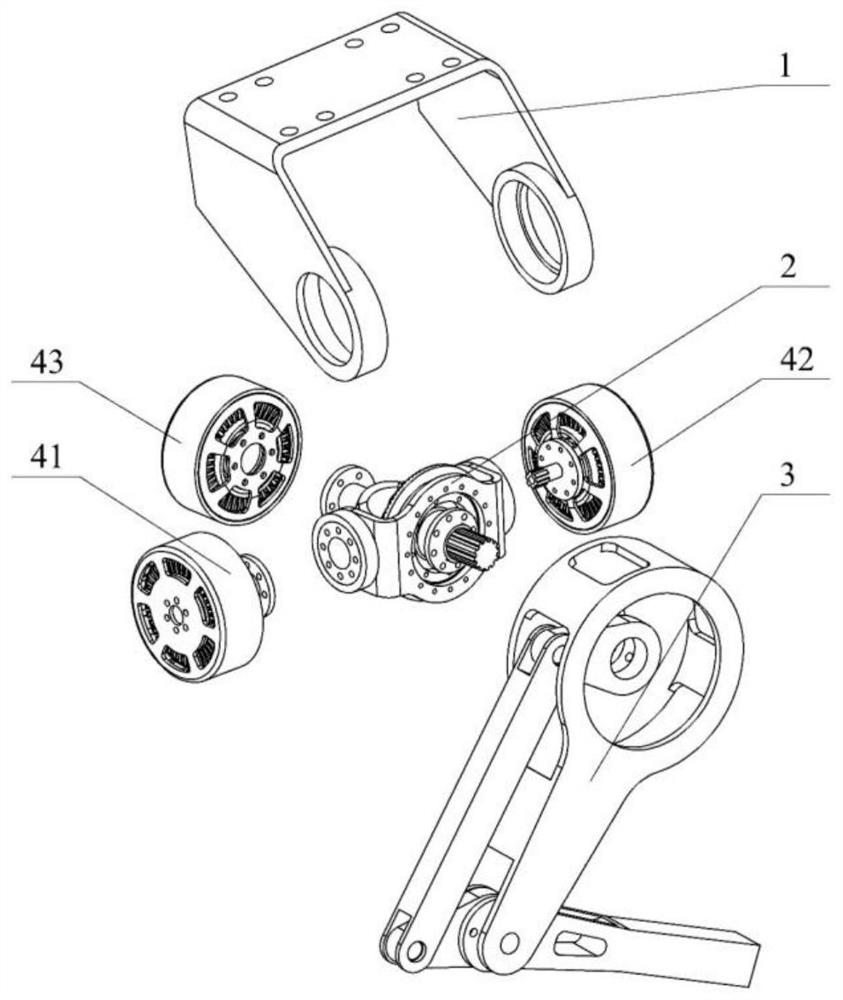

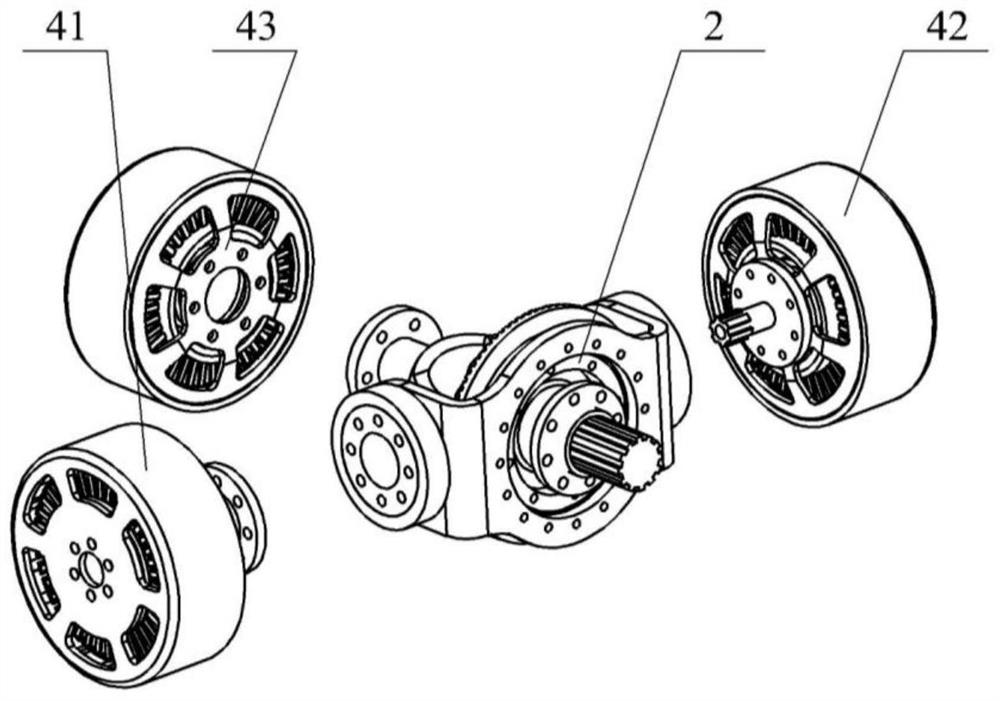

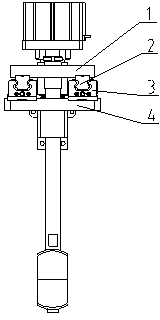

Low-inertia and high-load-bearing leg structure and foot type robot applying same

The invention belongs to the related technical field of robots, and discloses a low-inertia and high-load-bearing leg structure and a foot type robot applying the same. The leg structure comprises a crotch connector, a pelvis assembly, a knee joint motor, a hip joint motor, a side-sway joint motor and leg connecting rods, the crotch connector is connected with stators of the three motors at the same time, rotors of the three motors are connected with the pelvis assembly, the side-sway joint motor is coaxially opposite to the hip joint motor, the axis of the knee joint motor is perpendicular to the axes of the two motors, the hip joint motor drives the thigh connecting rod to rotate, the knee joint motor drives the shank connecting rod to rotate, and the side swing joint motor drives the leg connecting rod to swing laterally, so that outward swing and inward retraction of the legs of the robot and flexion and extension of the thighs and the shanks are achieved. According to the robot, the three joint motors are connected to the robot body and the pelvis assembly in parallel for power distribution, so that the inertia of the legs is reduced, the rigidity of the legs is enhanced, and the bearing and dynamic response capabilities are improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

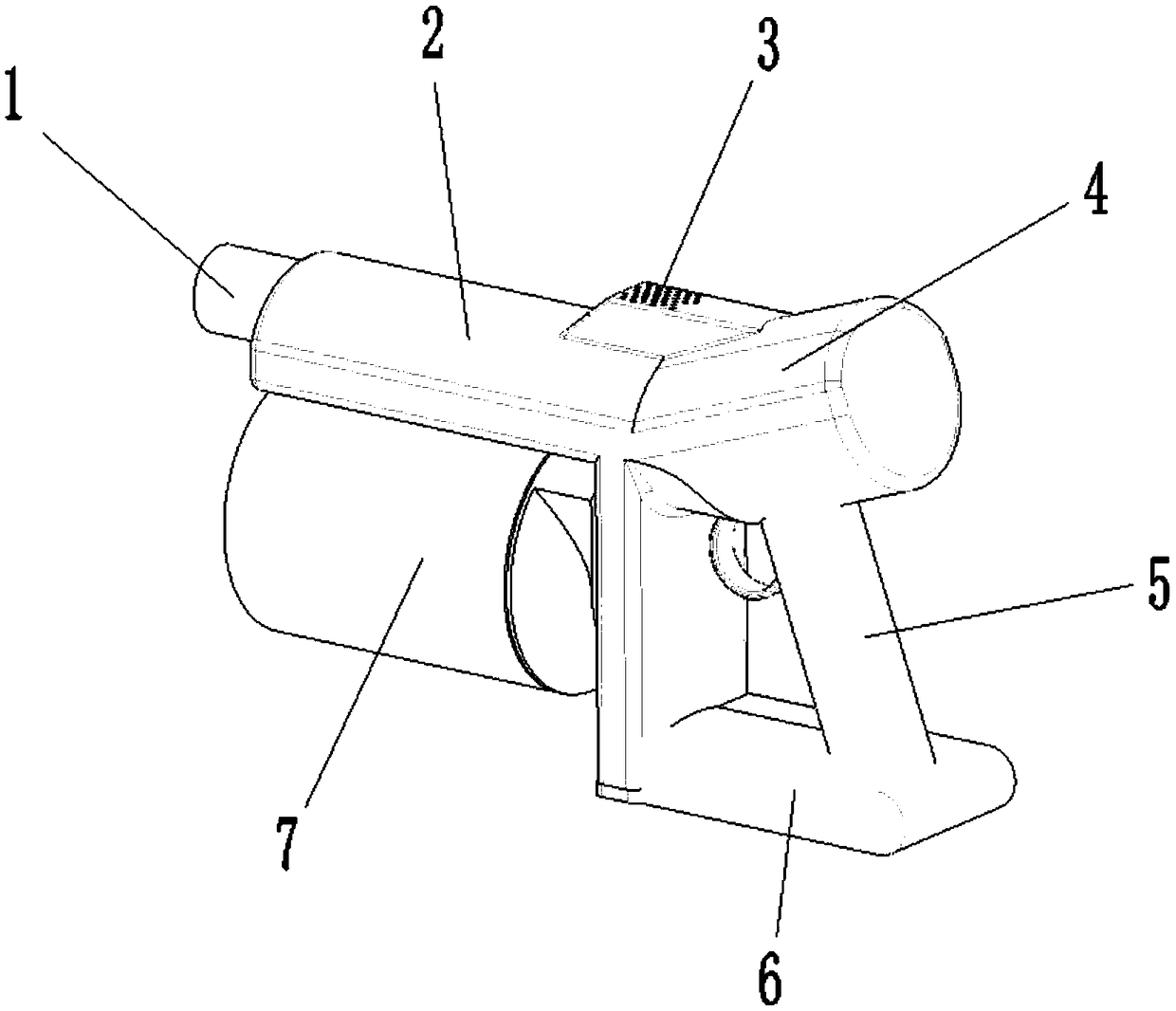

Hand-held vacuum cleaner

InactiveCN108903781AOptimize structure layoutImproved gripSuction filtersSuction handlesHand heldEngineering

The invention provides a hand-held vacuum cleaner, which comprises a mounting shell, a dust cup, a handle, a motor, a battery and an air inlet pipe mounted on the mounting shell. The dust cup is arranged parallel to the air inlet pipe axis and is positioned below the air inlet pipe; the motor located at the top of the dust cup is inclined with respect to the air inlet pipe axis, and the end thereof is upturned; the handle is arranged below the motor, the handle extends obliquely outward with respect to the dust cup from the motor position, and the battery is arrange at the end. By improving the structural layout of the hand-held vacuum cleaner, the invention can move the center of gravity of the whole machine to the handle position to the maximum extent, so as to shorten the force arm fromthe hand-held position to the center of gravity position of the whole machine in the normal use state of the user, and improve the gripping experience of the user. At the same time, it is convenientto set the air outlet of the motor.

Owner:GREE ELECTRIC APPLIANCES INC

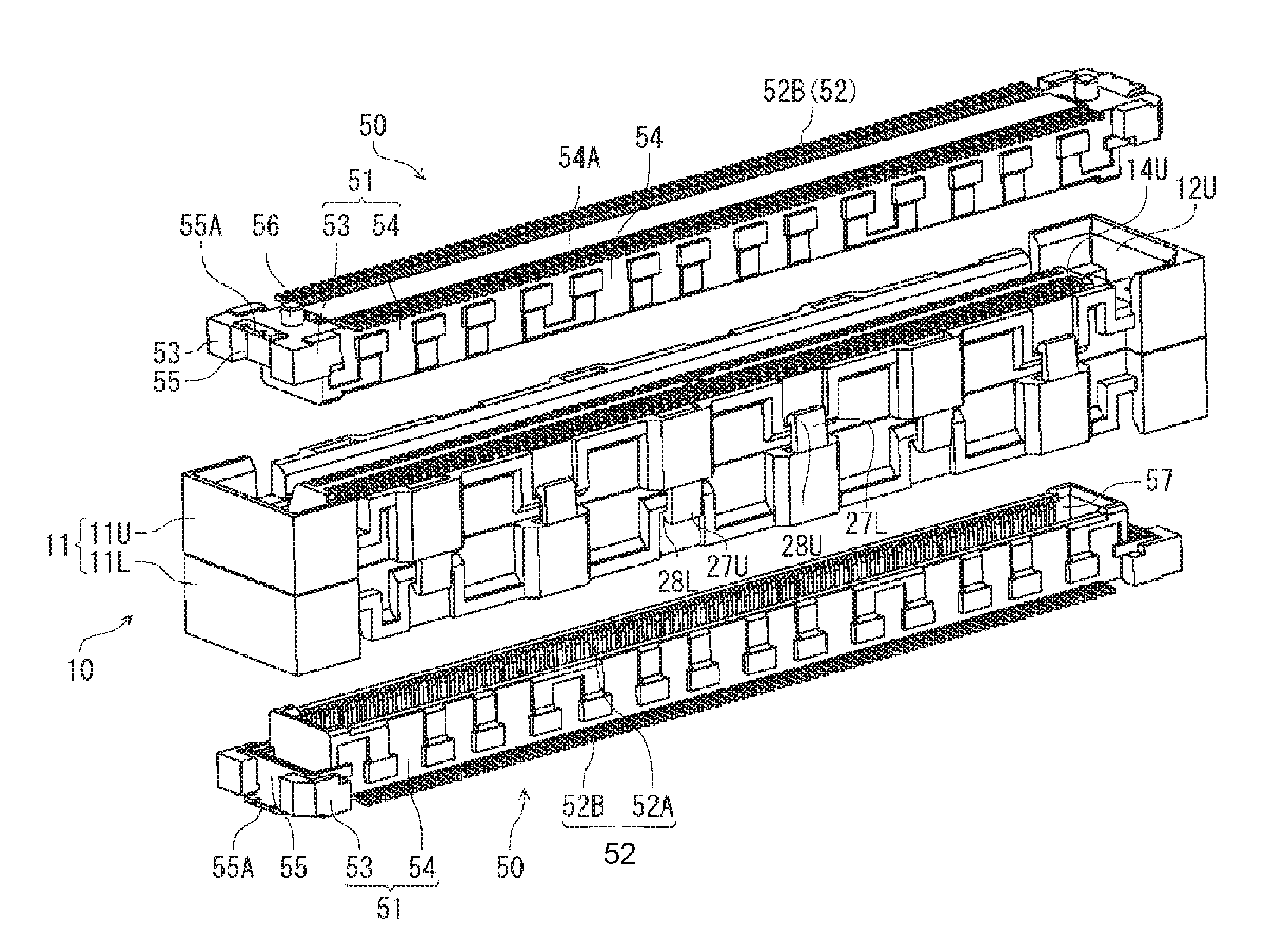

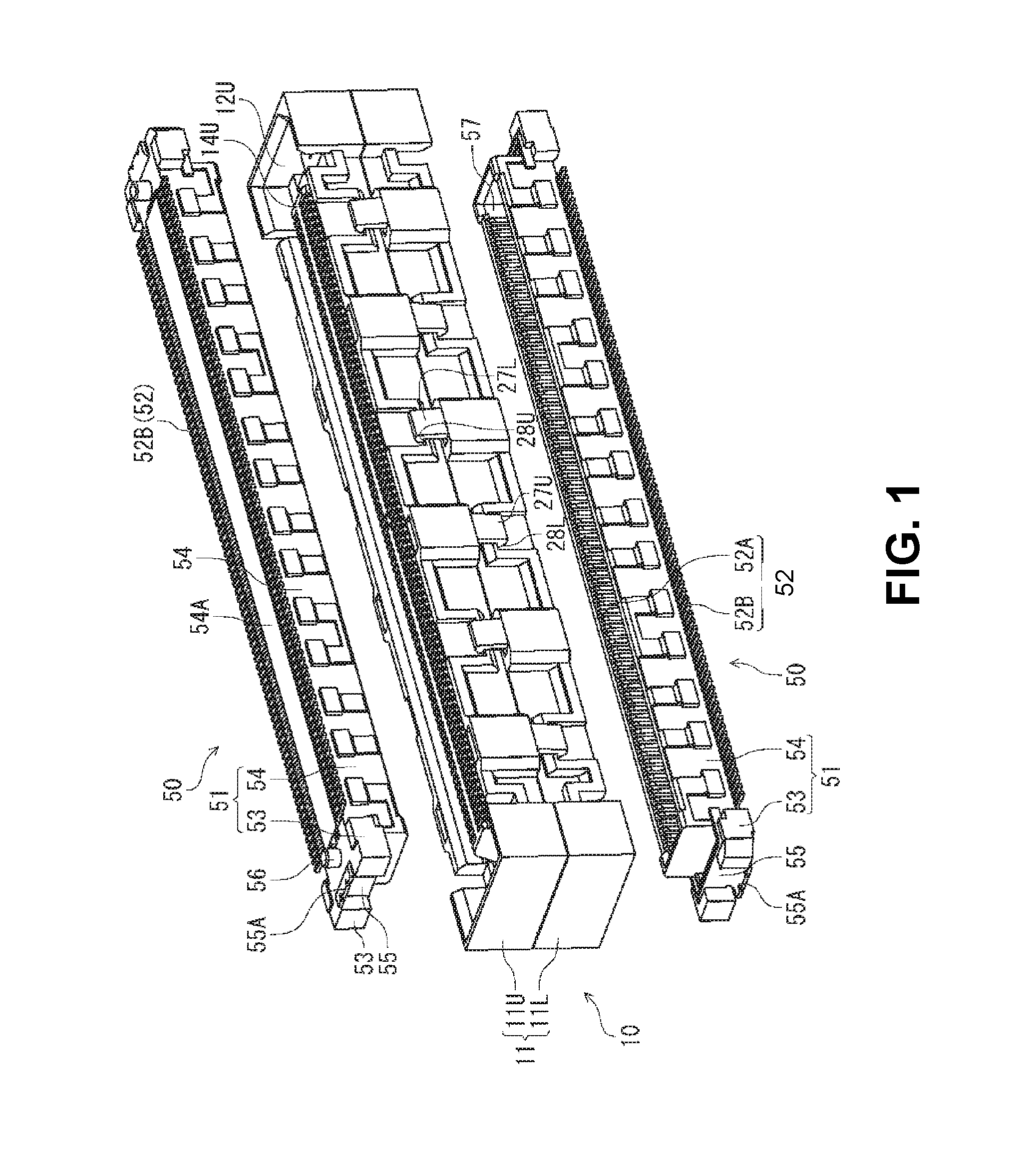

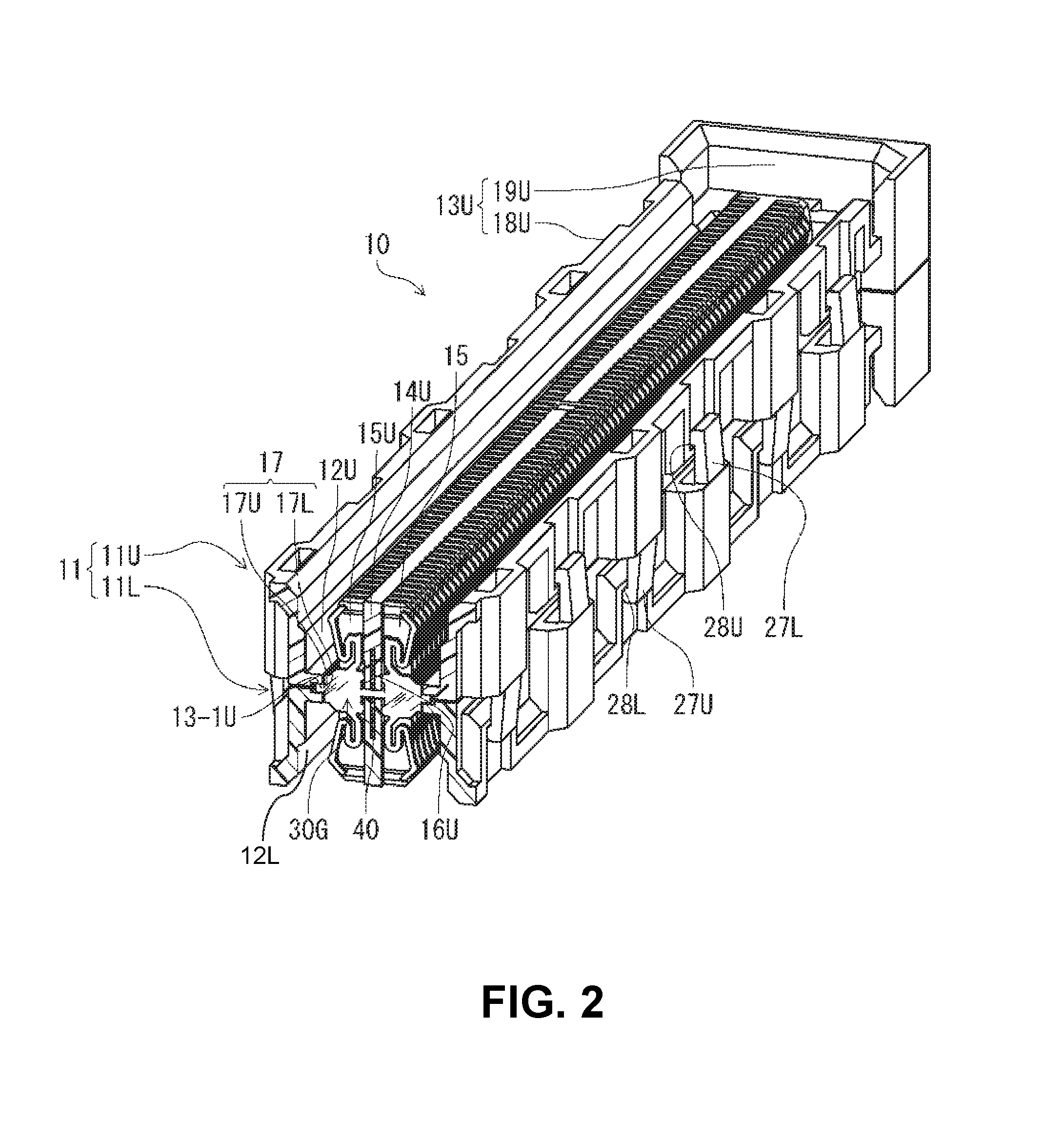

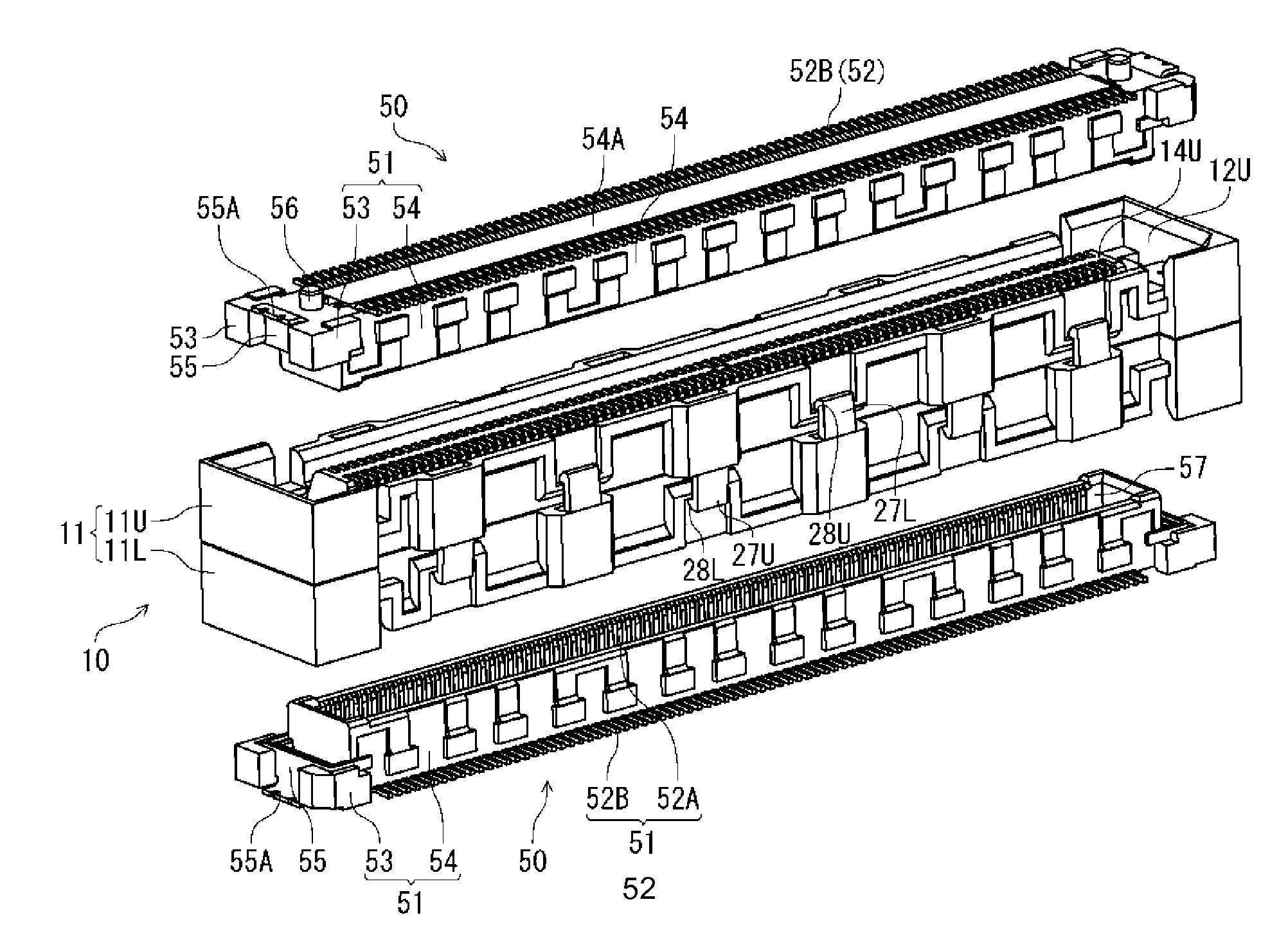

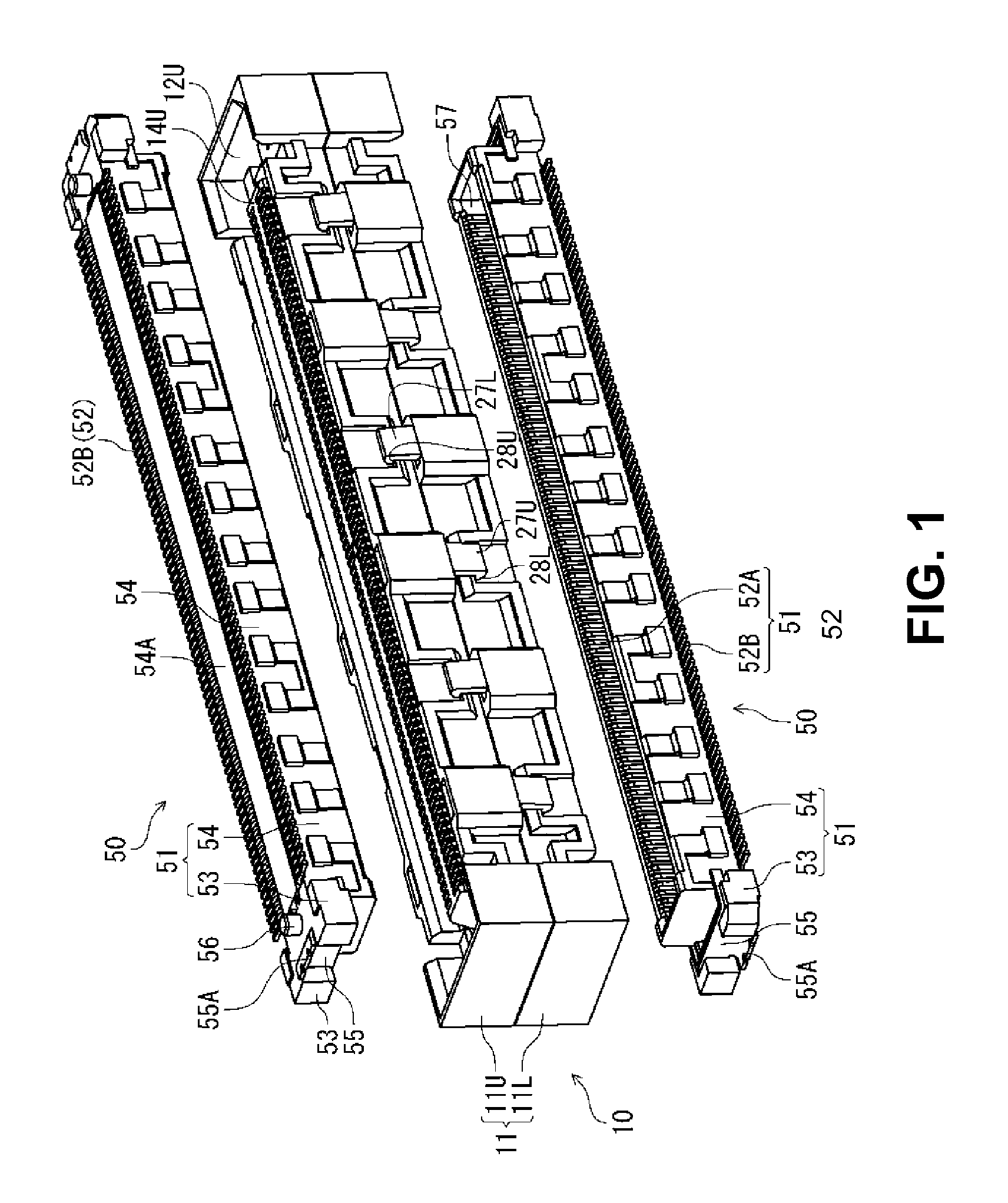

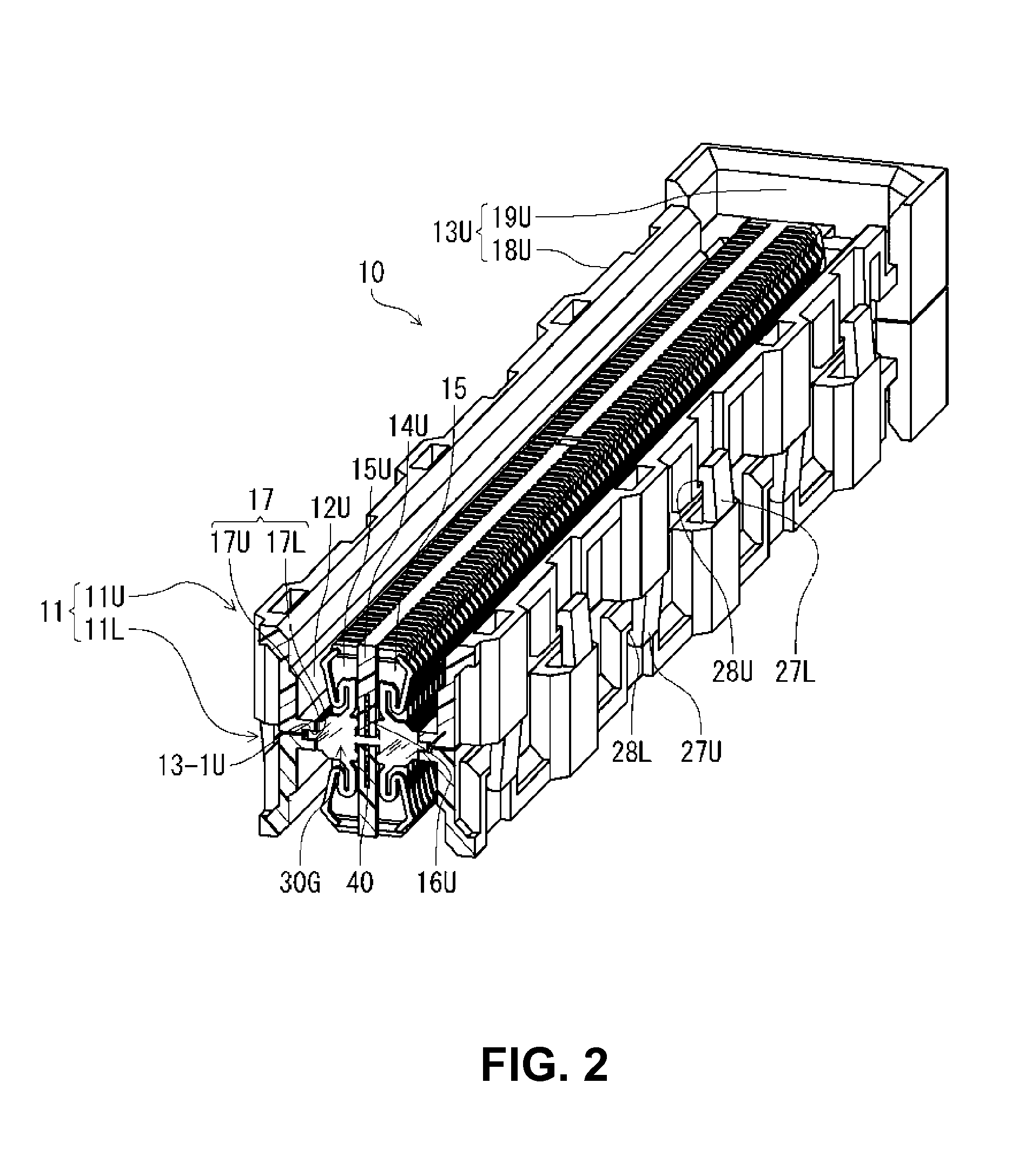

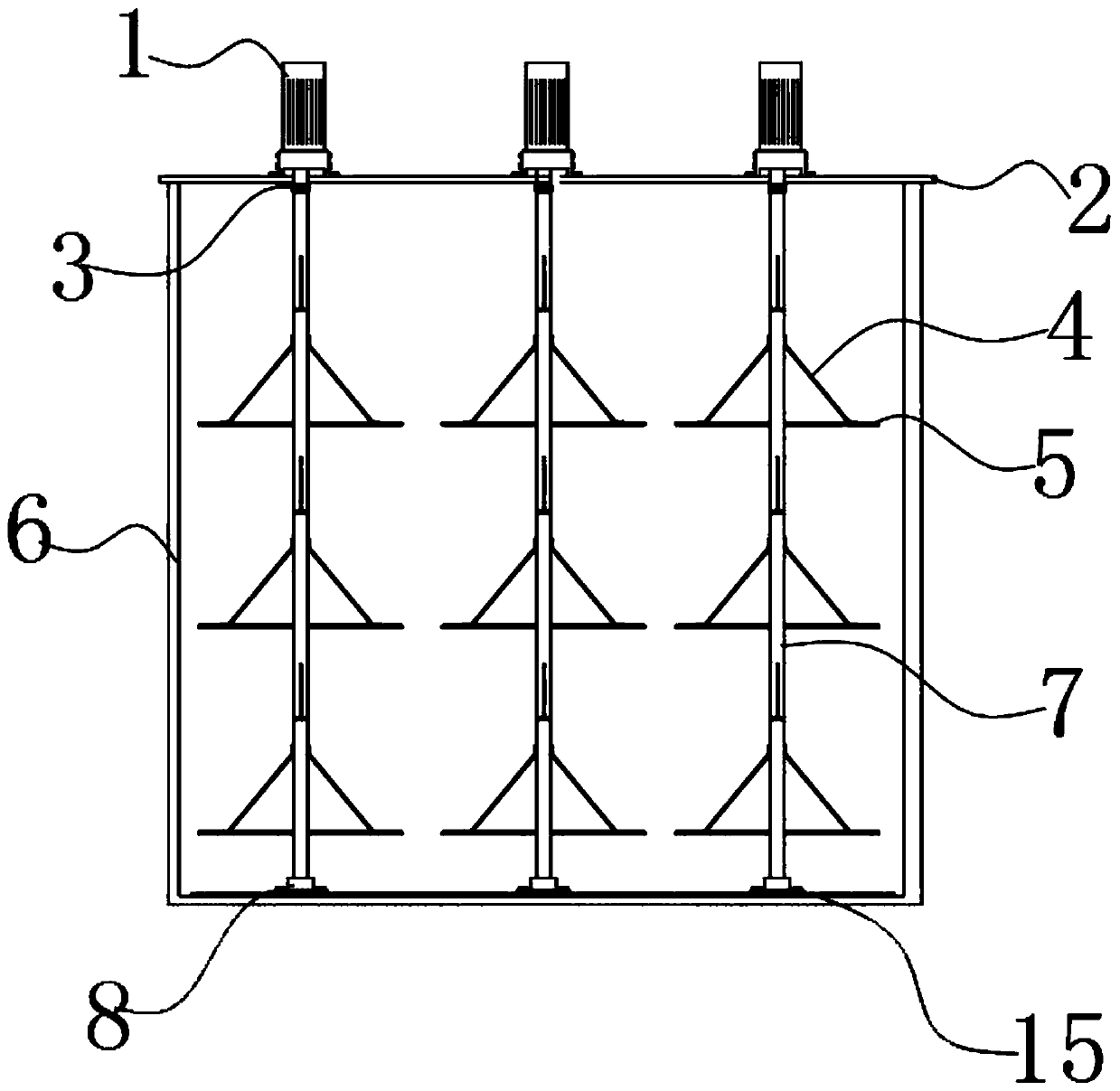

Electrical connector and electrical connector assembled component

ActiveUS9478889B2Easy to holdShort armSecuring/insulating coupling contact membersPrinted circuitsElectrical connectorElectrical and Electronics engineering

An electrical connector is to be connected to a first mating connector and a second mating connector. The electrical connector includes a plurality of terminals; and a housing for holing the terminals in a terminal arrangement direction. The housing includes an upper housing and a lower housing attached to the upper housing. The upper housing includes a plurality of upper grooves for holding the terminals. Each of the upper grooves has an upper narrow width portion having a width smaller than other part of the upper groove. The lower housing includes a plurality of lower grooves for holing the terminal. Each of the lower grooves has a lower narrow width portion having a width smaller than other part of the lower groove.

Owner:HIROSE ELECTRIC GROUP

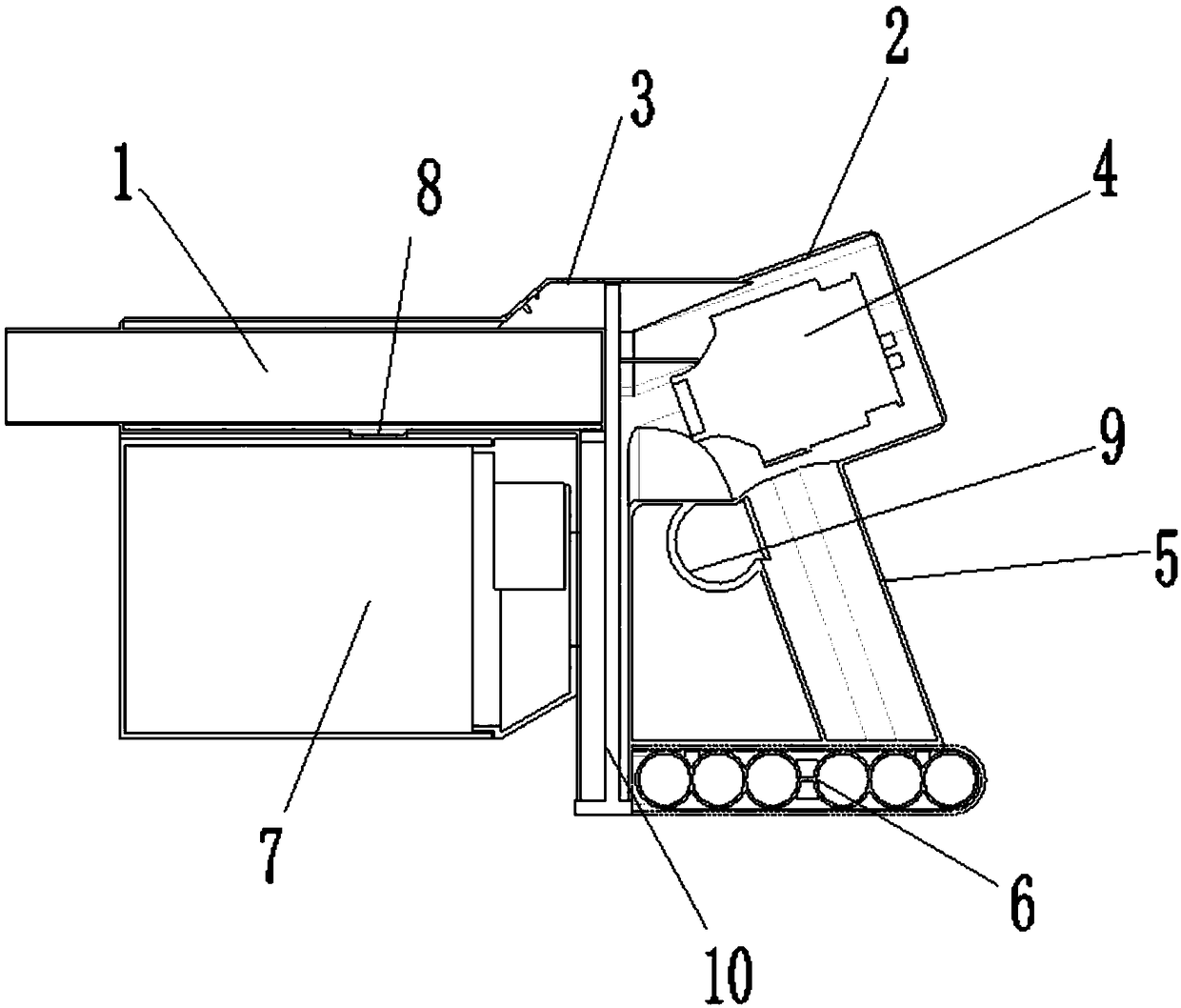

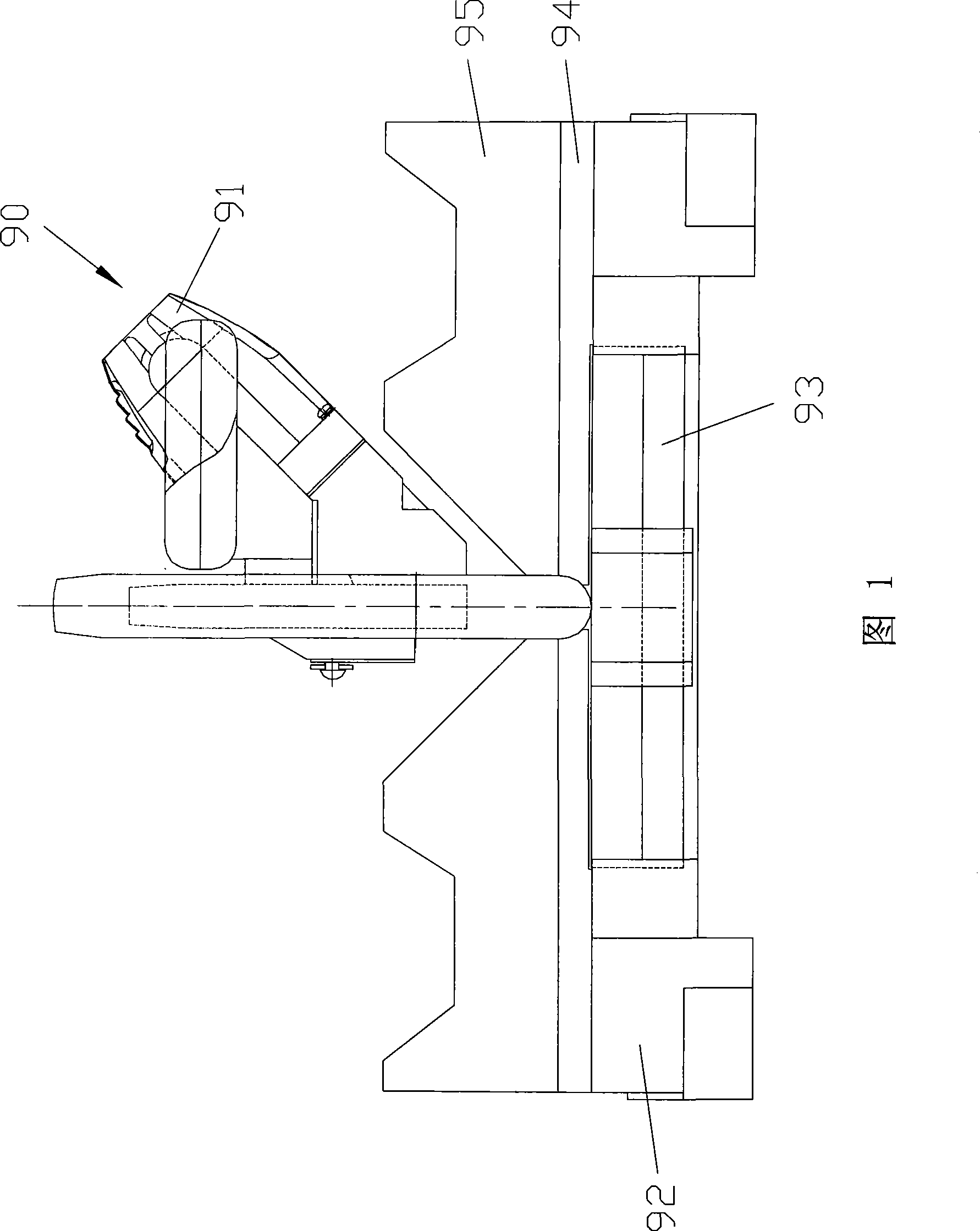

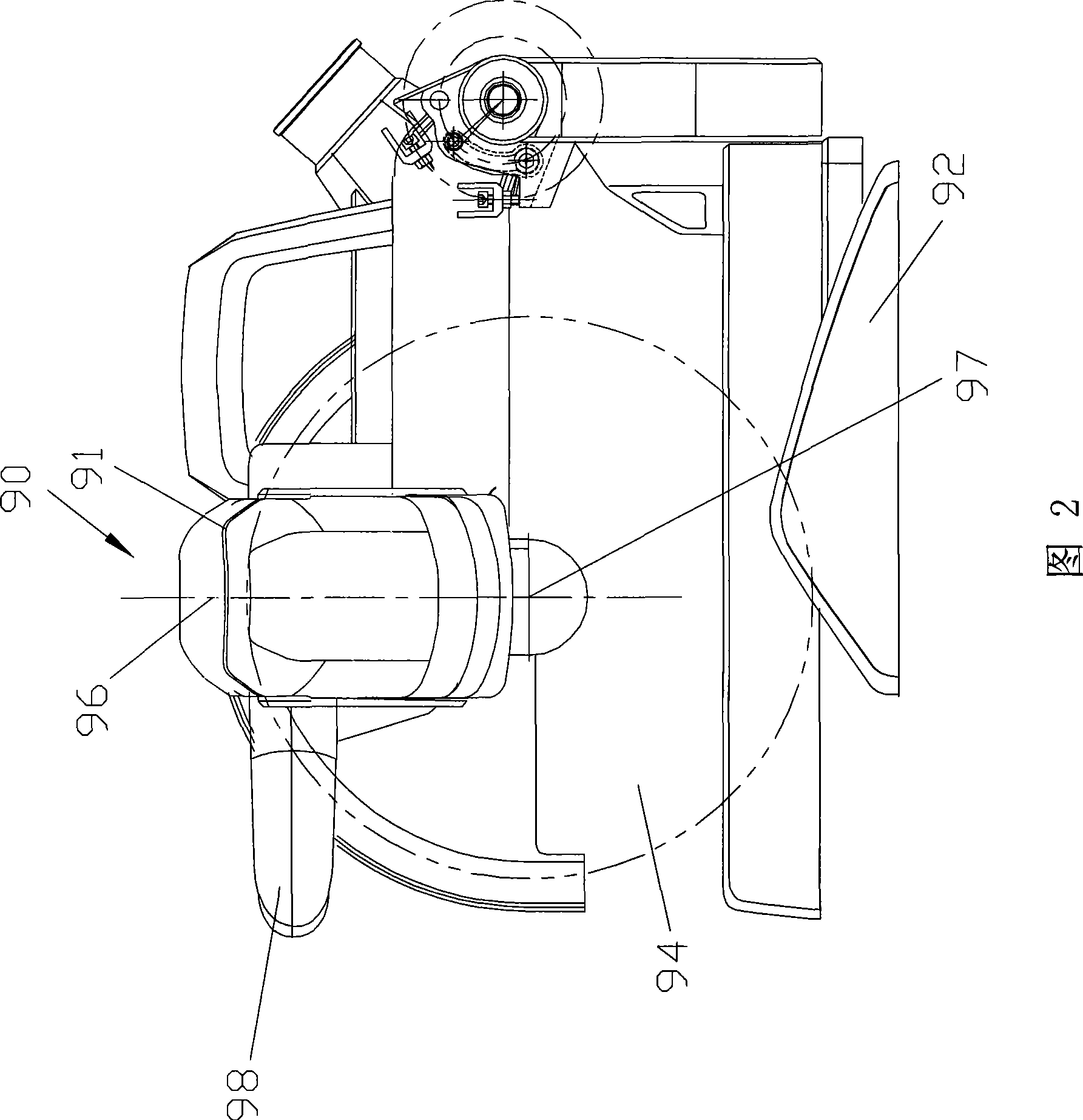

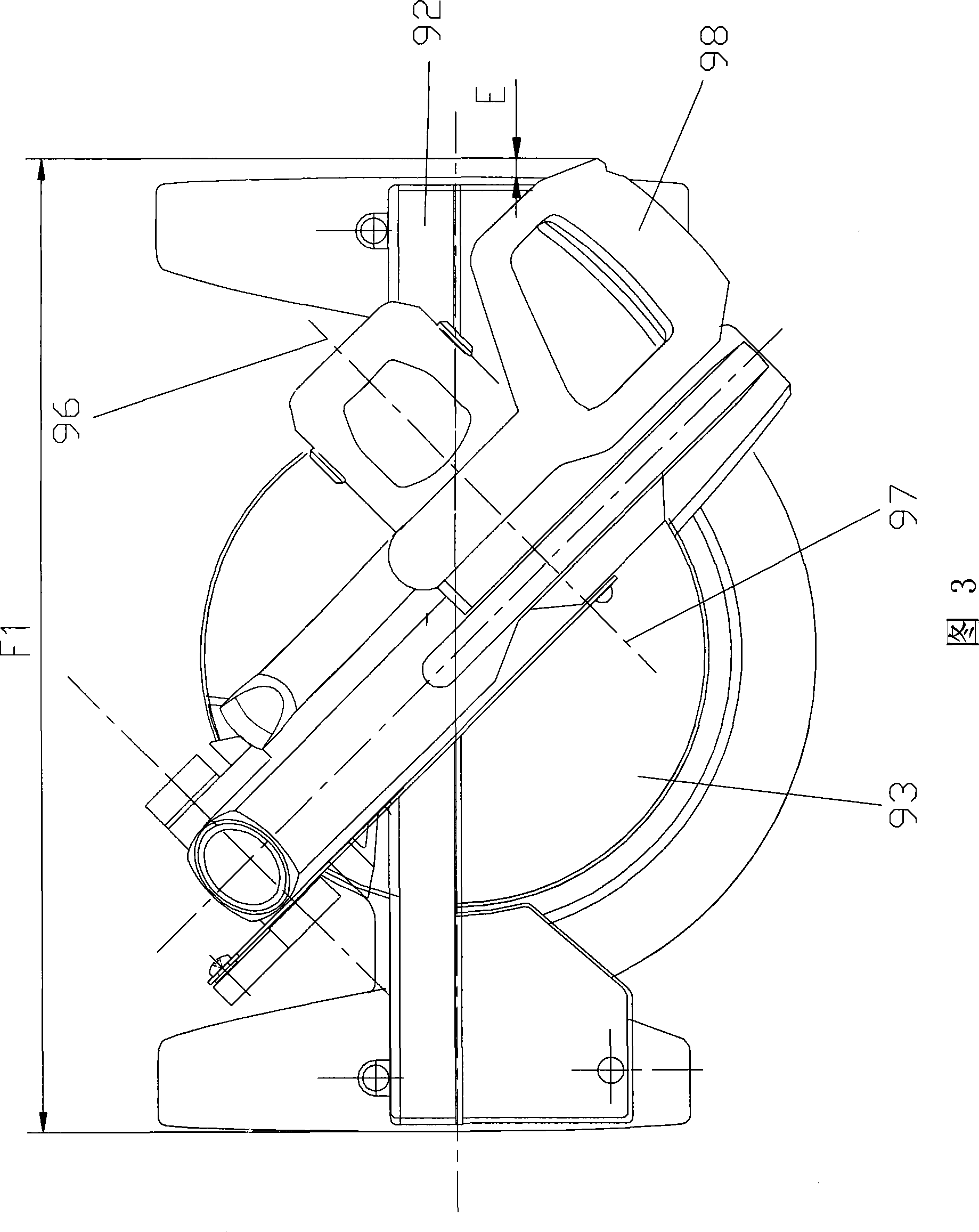

Bias cutter

InactiveCN101450398AReduced packaging volumeShorten the vertical distanceMetal sawing devicesGear wheelElectric machinery

The invention provides an oblique cutting machine, which comprises a base, a support arm in match connection with the base, as well as a sawing mechanism in movable match connection with the support arm. The sawing mechanism comprises a round saw blade, a motor and a transmission mechanism; the motor is obliquely arranged on one side of the round saw blade and is in match connection with a motor output shaft; and the round saw blade is in match connection with a saw-blade shaft, wherein the motor output shaft is obliquely arranged backwards relative to the saw-blade shaft. Therefore, the motor is also arranged relatively behind the oblique cutting machine, so as to reduce packaging volume and cost, shift the gravity center of the sawing mechanism, shorten force arm and increase the life span of a torsional spring of the sawing mechanism. In addition, as a hypoid gear is utilized as the transmission mechanism, the oblique cutting machine can reduce noise during cutting operation and is smooth in transmission, so as to improve cutting precision.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

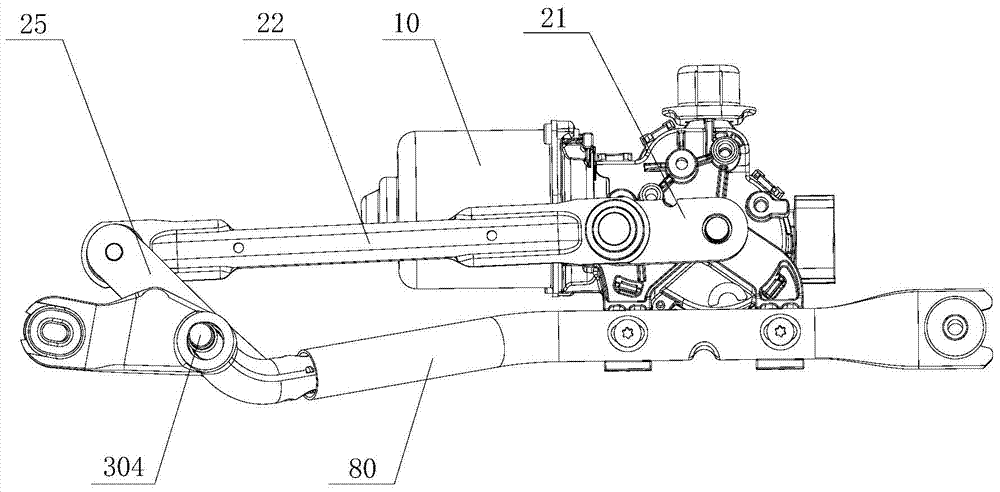

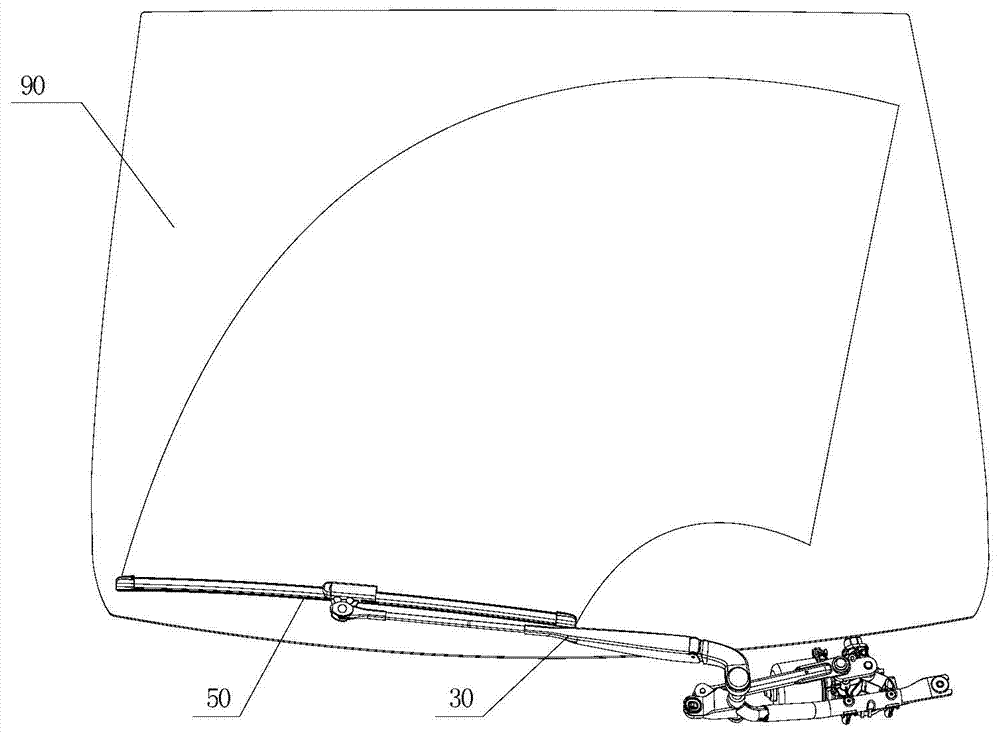

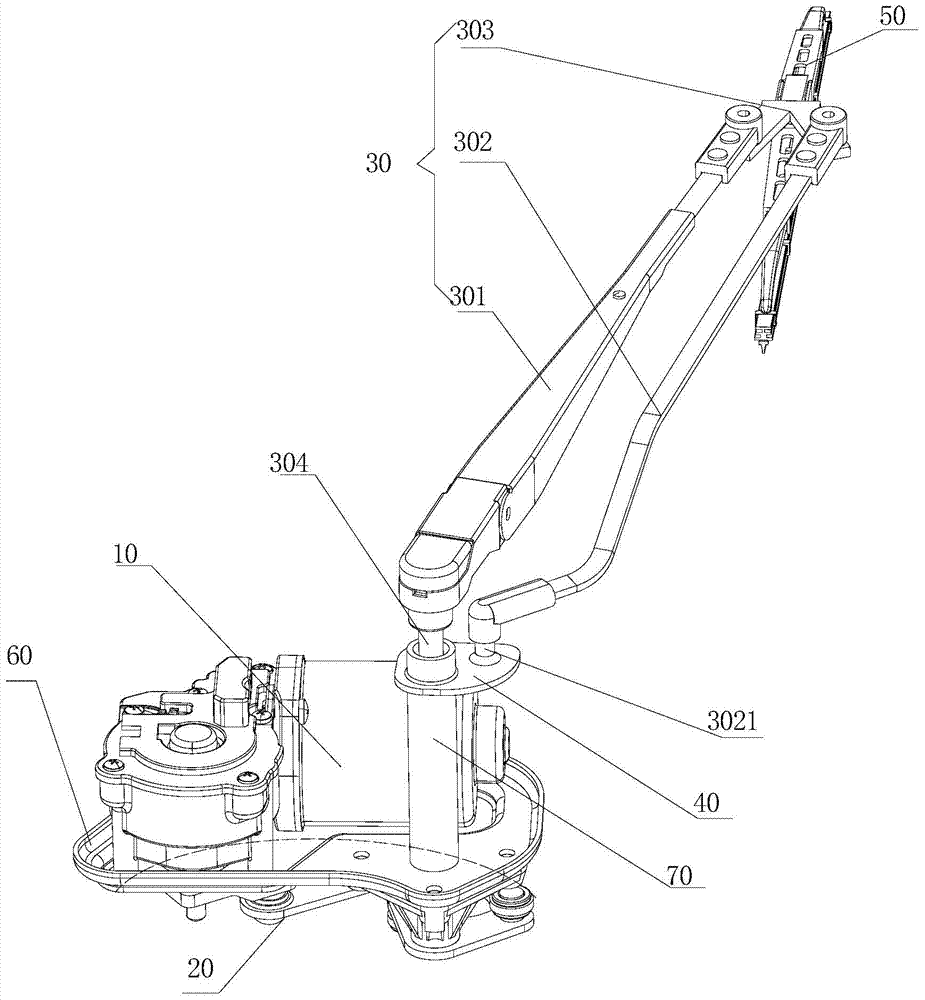

Windscreen wiper and vehicle

InactiveCN104842945AReduced installation space and movement spaceFlexible layoutVehicle cleaningElectric machineryWindscreen wiper

The invention discloses a windscreen wiper and a vehicle. The windscreen wiper comprises a motor (10), a connecting rod mechanism (20) and a wiping arm (30), wherein the connecting rod mechanism (20) is connected between the motor (10) and the wiping arm (30) for transferring the power of the motor (10) to the wiping arm (30). The windscreen wiper is characterized in that the connecting rod mechanism (20) is a multi-rod mechanism. The vehicle comprises the windscreen wiper. In the windscreen wiper disclosed by the invention, as the connecting rod mechanism (20) is the multi-rod mechanism, compared with a traditional four-rod mechanism, the multi-rod mechanism has more connecting rods, and the torque required to be transferred by each connecting rod is reduced under the condition of definite load. Therefore, force arms of all the connecting rods can be shortened, that is, the lengths of all the connecting rods can be shortened, so that the mounting space and the moving space of the connecting rod mechanism (20) can be reduced, and the windscreen wiper is convenient to arrange.

Owner:BEIQI FOTON MOTOR CO LTD

Direct drive type wind turbine generator system

InactiveCN102769374AReduce weightReduce volumeMachines/enginesWind motor combinationsNacelleHigh temperature superconducting

The invention relates to a direct drive type wind turbine generator system, comprising a frame, a main shaft, a hub and a power generator, wherein a rotor magnetic exciting coil of the power generator adopts a superconducting magnetic exciting coil. Since the direct drive type wind turbine generator system adopts a direct drive type structure, a high temperature superconducting power generator, and a main shaft layout form with double bearings, the weight and the size of a motor and the weight of a cabin can be decreased greatly, the loads on a tower frame of the system and a foundation can be reduced, and the bending moments of the main shaft and the bearings can be decreased; and therefore, the economy and the reliability of system operation are improved.

Owner:GUODIAN UNITED POWER TECH

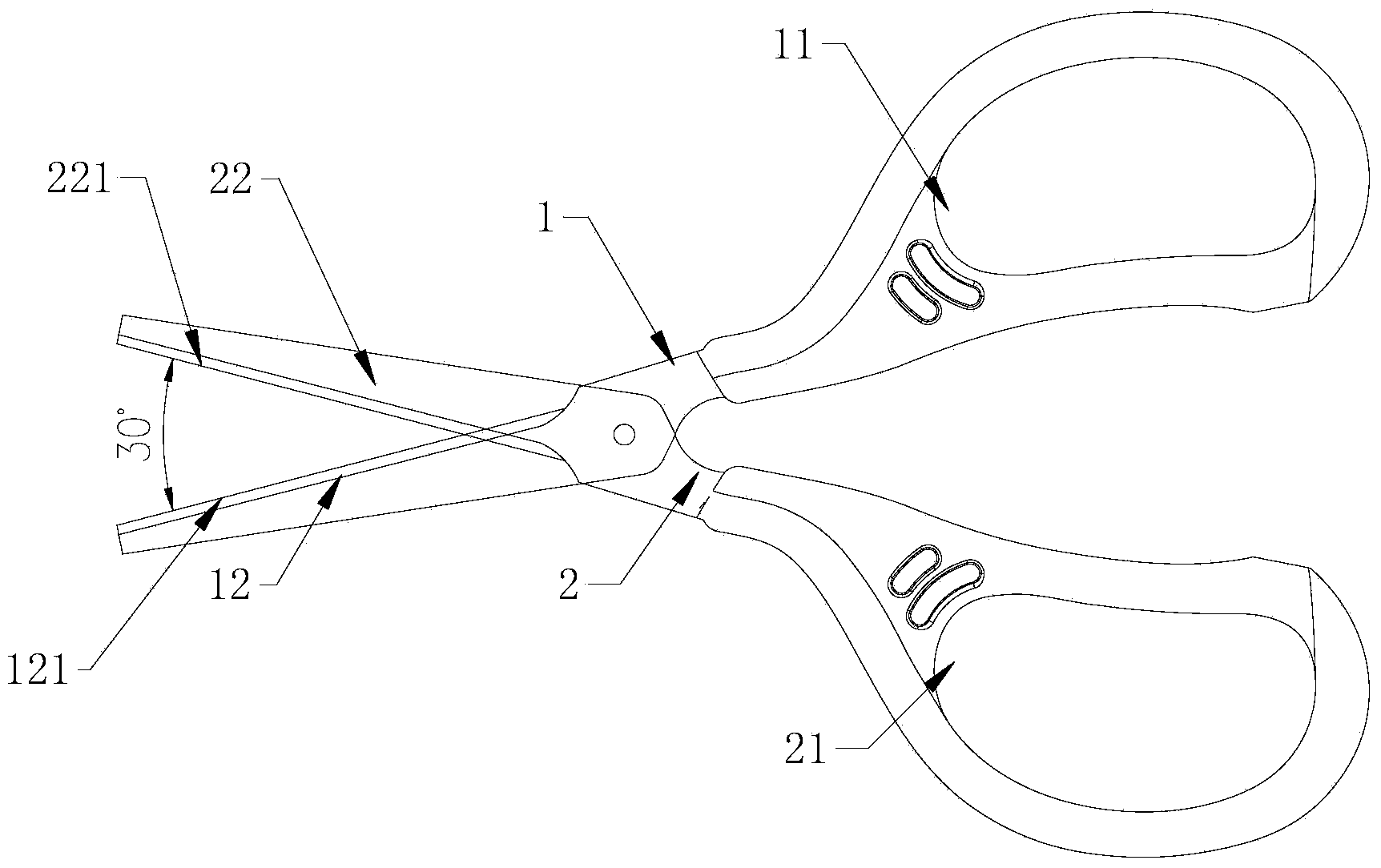

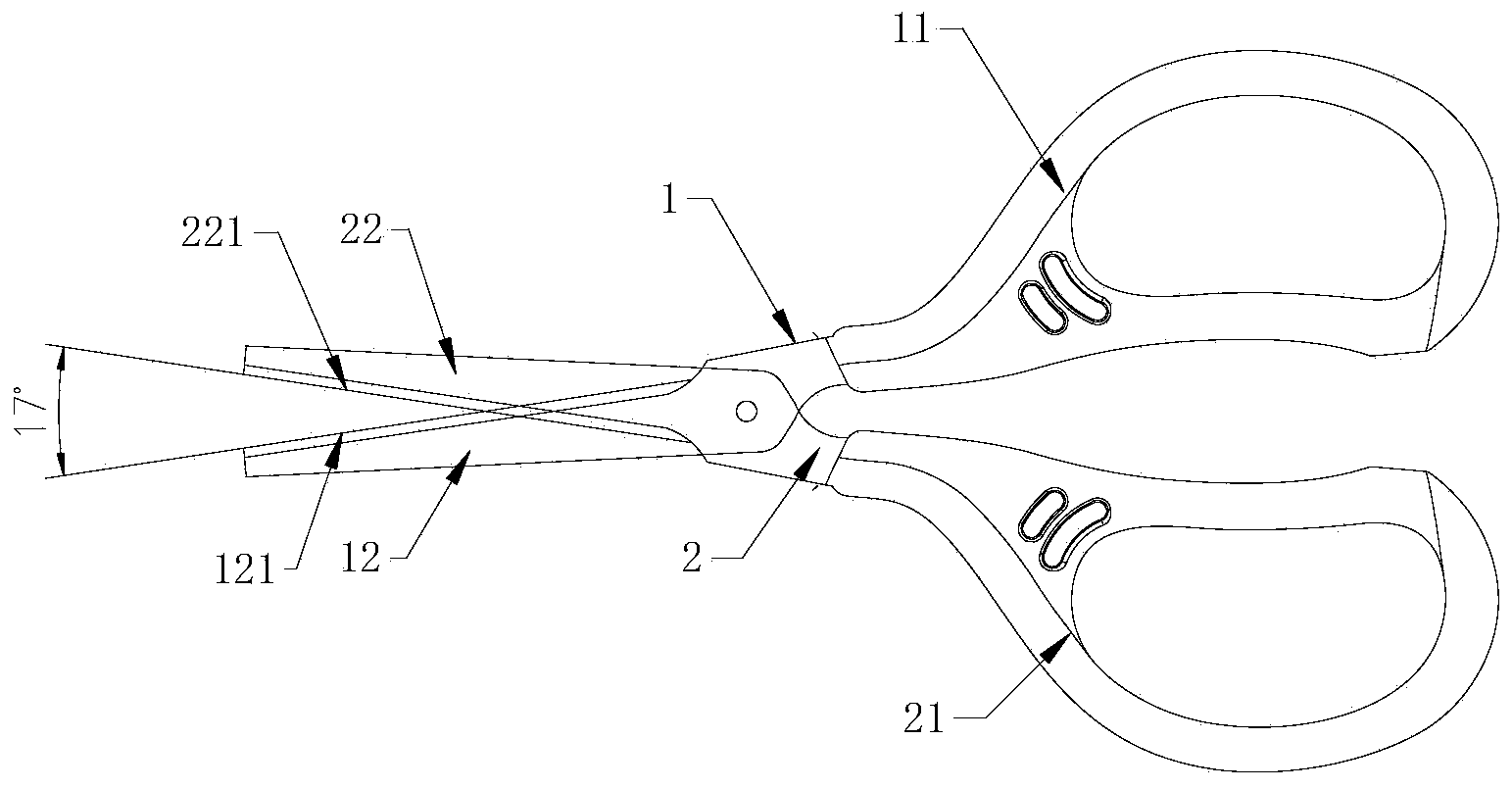

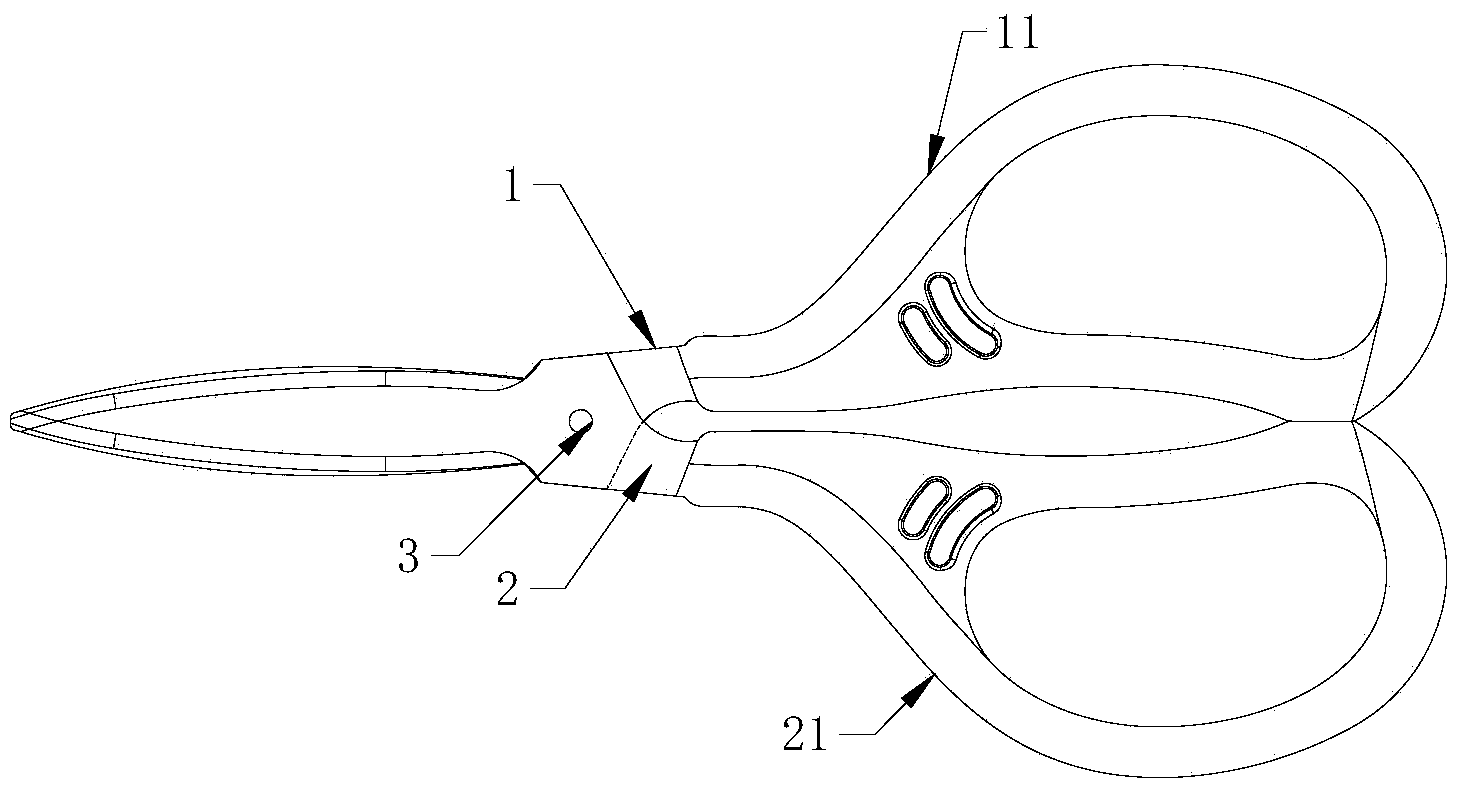

Scissors

InactiveCN103522309AReduce angleShort armMetal working apparatusMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a pair of scissors which is simple in structure and saves labor. The scissors comprise a first half body and a second half body which are matched mutually and hinged in the middle portions. The tail of the first half body and the tail of the second half body are provided with a first grab handle and a second grab handle respectively, and the head of the first half body and the head of the second half body are provided with a first scissor head and a second scissor head respectively. A first cutting edge is arranged on the side, close to the second scissor head, of the first scissor head, a second cutting edge is arranged on the side, close to the first scissor head, of the second scissor head, the outline of the first cutting edge and the outline of the second cutting edge are arc and arranged symmetrically, and included angles between tangent lines of all crosspoints of the first cutting edge and the second cutting edge are the same.

Owner:张家港市信佳塑料五金制品有限公司

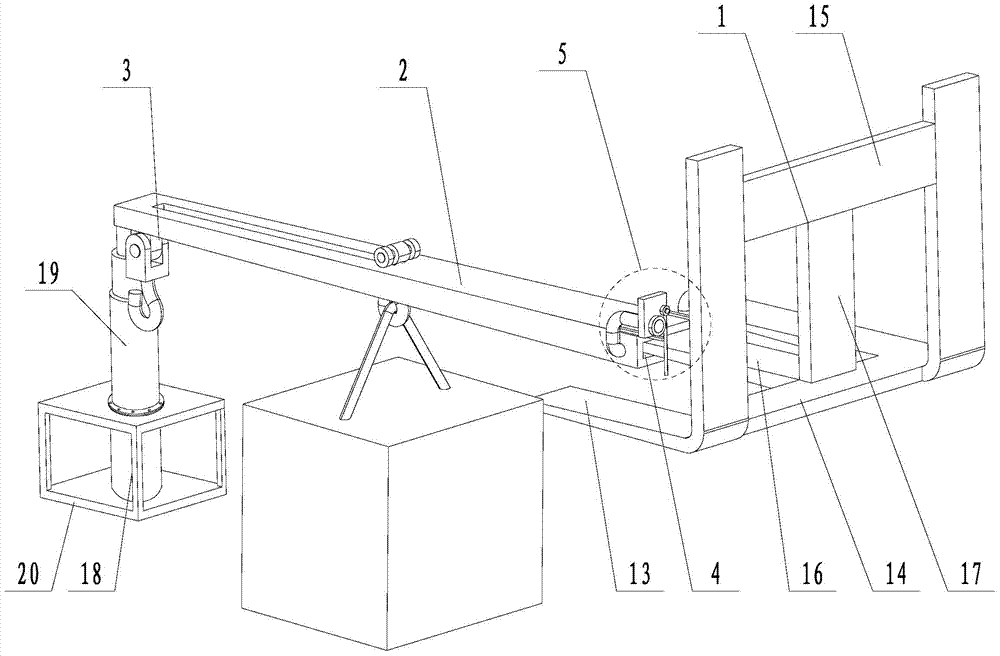

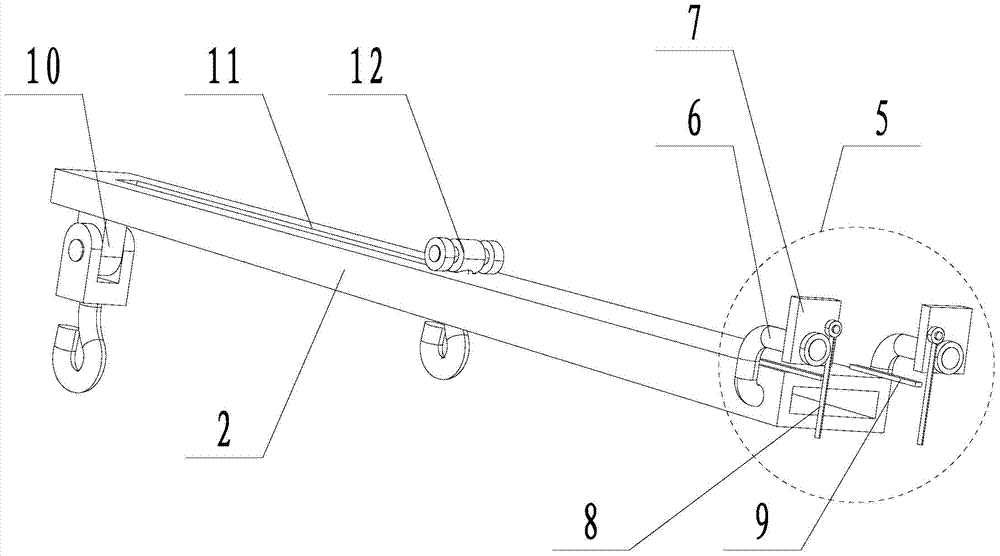

Forklift hoisting tool and hoisting method thereof

The invention discloses a forklift hoisting tool and a hoisting method thereof and aims at solving the problems that hoisting equipment of external hoisting companies is required to be dispatched and used for assistance, not only are high service expenses required to be paid, but also the maintenance of equipment is delayed and economic losses are caused to enterprises when faulted equipment in workshops are required to be hoisted and moved for maintenance. The forklift hoisting tool comprises a forklift frame and a hoisting arm, wherein a hoisting hook is arranged on the hoisting arm, an insertion hole is formed in one end of the hoisting arm, the forklift frame is inserted into the insertion hole, an insertion limiting mechanism is fixedly connected at a position of the end at which the insertion hole is arranged on the hoisting arm, the insertion limiting mechanism comprises two limiting bars, two limiting plates and supporting bars which are connected onto the limiting plates, the two limiting bars are respectively arranged on the two sides of the insertion hole, the two limiting plates for limiting the forklift frame are respectively and movably connected onto the end parts of the two limiting bars, the connecting positions of the limiting bars and the limiting plates are arranged at turning angle positions below the outer sides of the limiting plates and are deviated from the gravity centers of the limiting plates, and the two supporting bars for supporting the limiting plates are movably connected onto edge positions on the inner sides of the two limiting plates.

Owner:NINGBO SHANGZHONGXIA AUTOMATIC TRANSMISSION

Automatic opening mechanism for automobile engine tile cover

The invention discloses an automatic opening mechanism for an automobile engine tile cover. The automatic opening mechanism comprises an unscrewing sliding table. Sliding blocks are symmetrically arranged on two sides of the bottom of the unscrewing sliding table along the length direction, guide rails matched with the sliding blocks are arranged below the sliding blocks, and the bottoms of the guide rails are fixed on a horizontal sliding plate. An opening cylinder is arranged on the upper portion of the unscrewing sliding table, the extending-out end of a piston rod of the opening cylinder is connected to an opening pull rod, an opening pressure rod parallel to the opening pull rod is fixedly installed on the side edge of the bottom of the opening cylinder, the opening pull rod and the opening pressure rod sequentially penetrate through the unscrewing sliding table and the horizontal sliding plate, a returning spring is further sleeved on an outer wall of the opening pressure rod adjacent to the unscrewing sliding table, a translation cylinder pushing the horizontal sliding plate to move along the direction of the sliding blocks is arranged outside the horizontal sliding plate positioned on the side of the opening pressure rod, and an opening top block and an opening pressure block are respectively installed at the bottom end of the opening pull rod and the bottom end of the opening pressure rod. The automatic opening mechanism is simple in structure and convenient to use, and stability and reliability of the opening process of the tile cover in assembly can be effectively guaranteed.

Owner:安徽唐古拉工业技术有限公司

Double-conductor equipment wire clamp

InactiveCN108258440AHigh strengthImprove current carrying capacitySoldered/welded conductive connectionsConnections effected by permanent deformationCarrying capacityEngineering

The invention discloses a double-conductor equipment wire clamp, which comprises a wire clamp body and a crimping pipe, wherein the crimping pipe and the wire clamp body are connected in an interpolating mode. The invention adopts the crimping pipe interpolation welding, effectively increases the welding area and improves the overall strength of a welding seam. After the welding area is increased,the overall current carrying capacity of the wire clamp is improved, and the problem of excessive temperature rise of fittings caused by insufficient current carrying area is effectively prevented. In actual operation, an external force is transmitted from conductors to the crimping pipe, a distance between a direct force-receiving portion of the crimping pipe and a welding seam fixed point is just a distance in a non-crimping region, the force arm is short, the stress state is good, the wire clamp can prevent welding snap under the action of a higher external force, and long-term operation is guaranteed; the material of the double-conductor equipment wire clamp is changed from pure aluminum in the traditional scheme to aluminum alloy, thus the tensile property and bending resistance aregreatly improved; and water leaking holes can be formed directly under accumulative water positions of the fittings and are directly processed in a fitting production factory, the working procedures on the construction site are reduced, the installation efficiency is improved, and the fittings are effectively prevented from spalling due to the accumulative water.

Owner:STATE GRID XINJIANG ELECTRIC POWER CO ECONOMIC TECH RES INST +1

Electrical connector and electrical connector assembled component

ActiveUS20140357131A1Short armEasy to holdSecuring/insulating coupling contact membersTwo-part coupling devicesEngineeringElectrical connector

An electrical connector is to be connected to a first mating connector and a second mating connector. The electrical connector includes a plurality of terminals; and a housing for holing the terminals in a terminal arrangement direction. The housing includes an upper housing and a lower housing attached to the upper housing. The upper housing includes a plurality of upper grooves for holding the terminals. Each of the upper grooves has an upper narrow width portion having a width smaller than other part of the upper groove. The lower housing includes a plurality of lower grooves for holing the terminal. Each of the lower grooves has a lower narrow width portion having a width smaller than other part of the lower groove.

Owner:HIROSE ELECTRIC GROUP

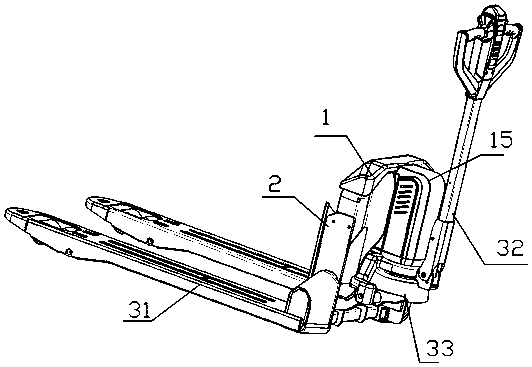

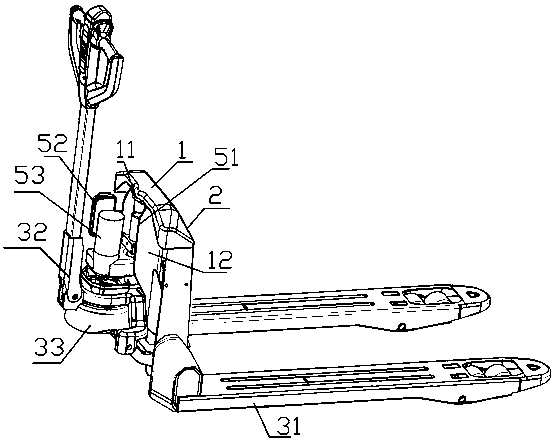

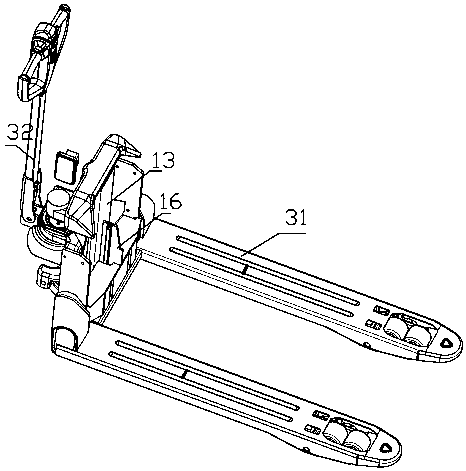

Industrial vehicle

The invention relates to the field of automatic mechanical equipment, in particular to an industrial vehicle. The invention is realized through the following technical scheme: the industrial vehicle comprises a handle, a main frame and a driving wheel assembly, and further comprises a controller, a pump station and a jacking device, wherein a stand column is mounted on the main frame and comprisesa top plate and a back plate connected with the top plate; the jacking device is abutted against the top plate; and compared with the controller and the pump station, the jacking device is closer tothe back plate. The invention aims to provide the industrial vehicle which is high in stability and lifts stably, the positional relation of various components of the vehicle is optimally designed, ashort vehicle body design is implemented, and thus, the radius of turning circle is small.

Owner:NOBLEELEVATOR INTELLIGENT EQUIP CO LTD

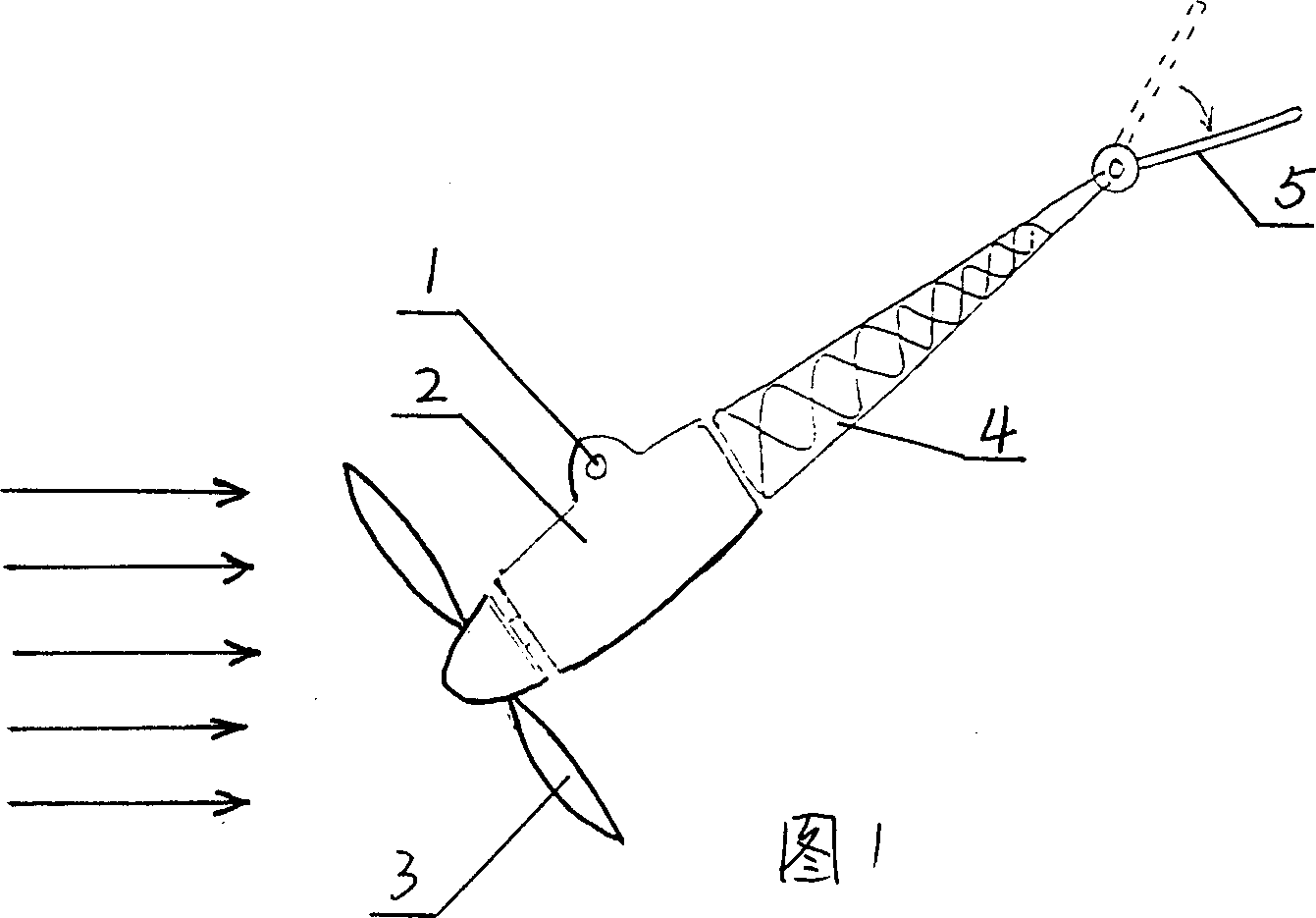

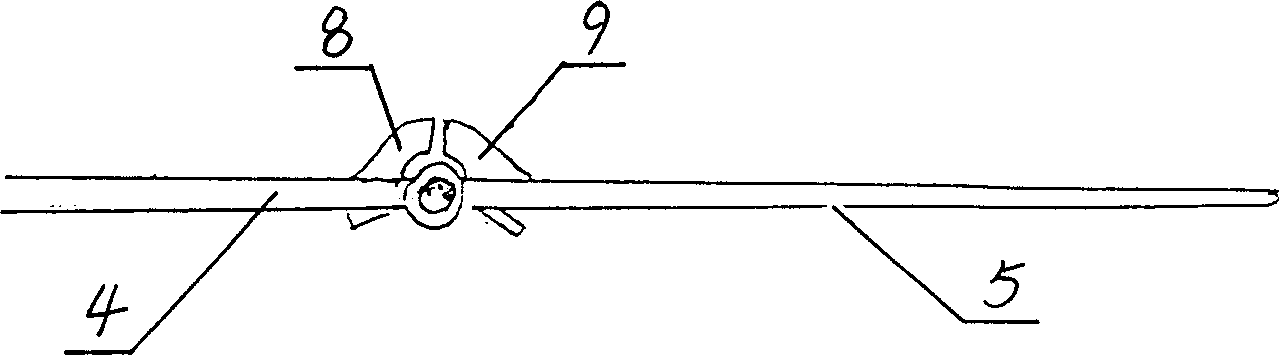

Tail plate folding type speed-regulating mechanism for wind power generator

The present invention relates to a wind-driven generator tail plate folded speed regulating mechanism. Said mechanism includes power generator machine body mounted on the vertical shaft, wind wheel mounted on the front end of the machine body of power generator, tail bar mounted on the rear end of the machine body of the power generator and tail plate mounted on the rear end of tail rod. The tailplate is wobbly connected on the rear end of tail bar, and the tail plate and tail bar are connected together by means of jointed shaft. When the wind force is strong, the tail plate can be rotated relatively to tail bar, so that the arm of force is shortened, and force moment is reduced.

Owner:韩旭生

Driving chain structure of wind generating set and wind driven generator comprising same

The invention discloses a driving chain structure of a wind generating set and a wind driven generator comprising the same. The wind generating set comprises a front frame, a fan impeller, a rotatingshaft, a fixed shaft, a front bearing and a rear bearing, the fixed shaft is arranged on one side, facing the fan impeller, of the front frame, the fixed shaft is provided with a through hole which communicates with the interior of the front frame, the rotating shaft is arranged in the through hole, the front end of the rotating shaft extends out of the through hole and is fixedly connected with ahub of the fan impeller, and the hub is arranged outside the fixed shaft in a sleeving mode and can rotate relative to the fixed shaft; and the front bearing and the rear bearing are both arranged onthe fixed shaft or the rotating shaft, and the gravity center of the fan impeller is located between the front bearing and the rear bearing. According to the driving chain structure and the wind driven generator, the gravity center of the fan impeller is located between the front bearing and the rear bearing, the arm of force from the gravity center of the fan impeller to the two bearings is shortened, the bending moment of the fan impeller borne by the bearings is reduced, the fatigue alternating load required to be borne by the bearings is further reduced, therefore, the sizes of the bearings can be reduced, and the cost of the wind generating set can be reduced.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

Moving device for large flower pots

Owner:来安县永阳知识产权运营有限公司

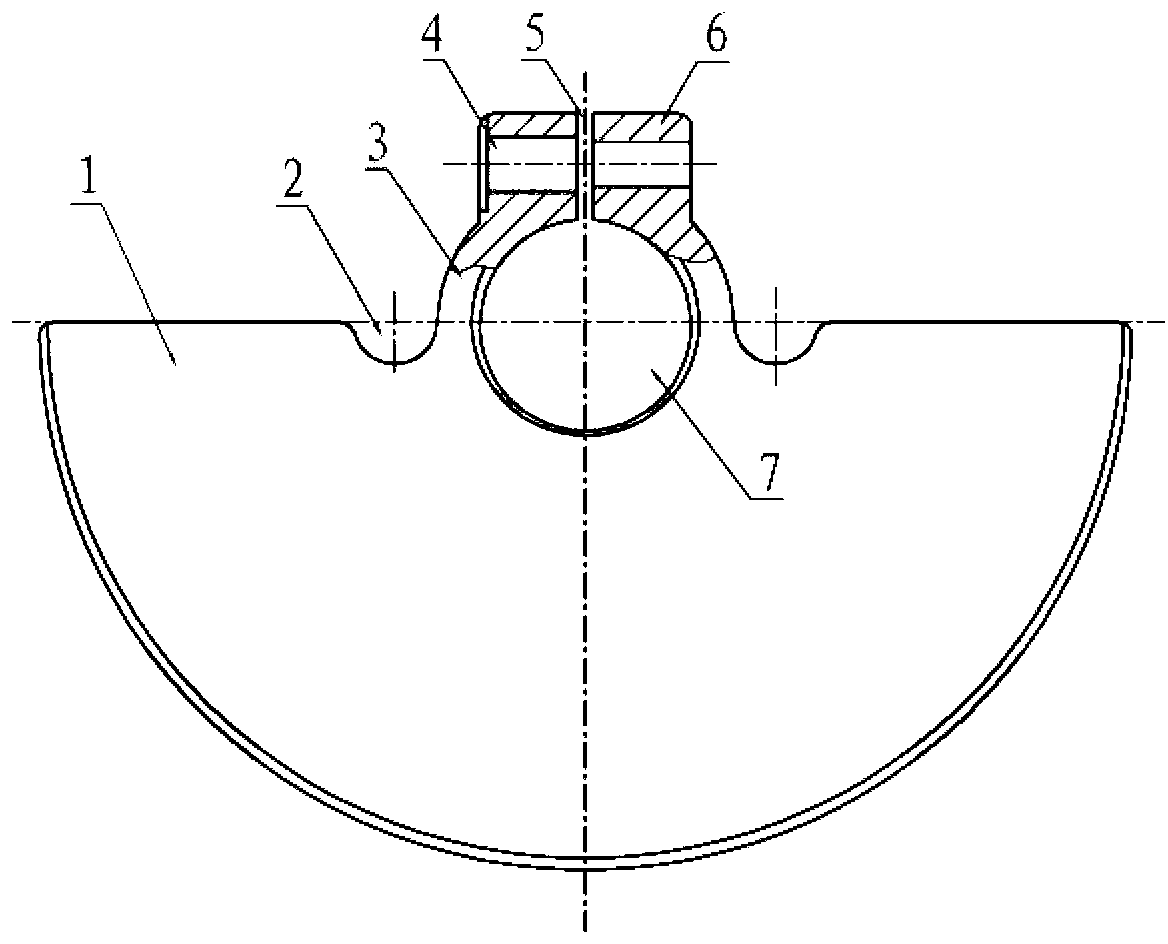

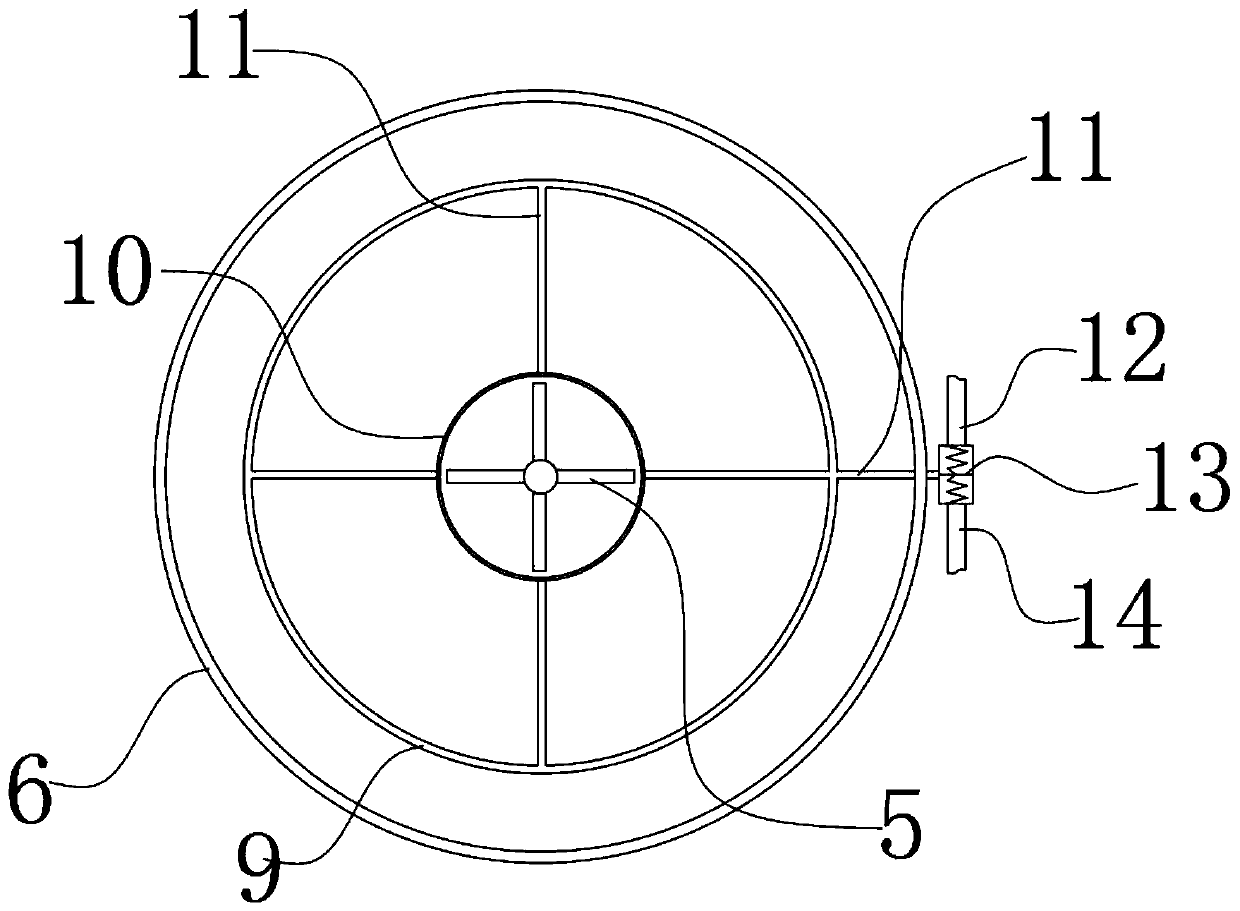

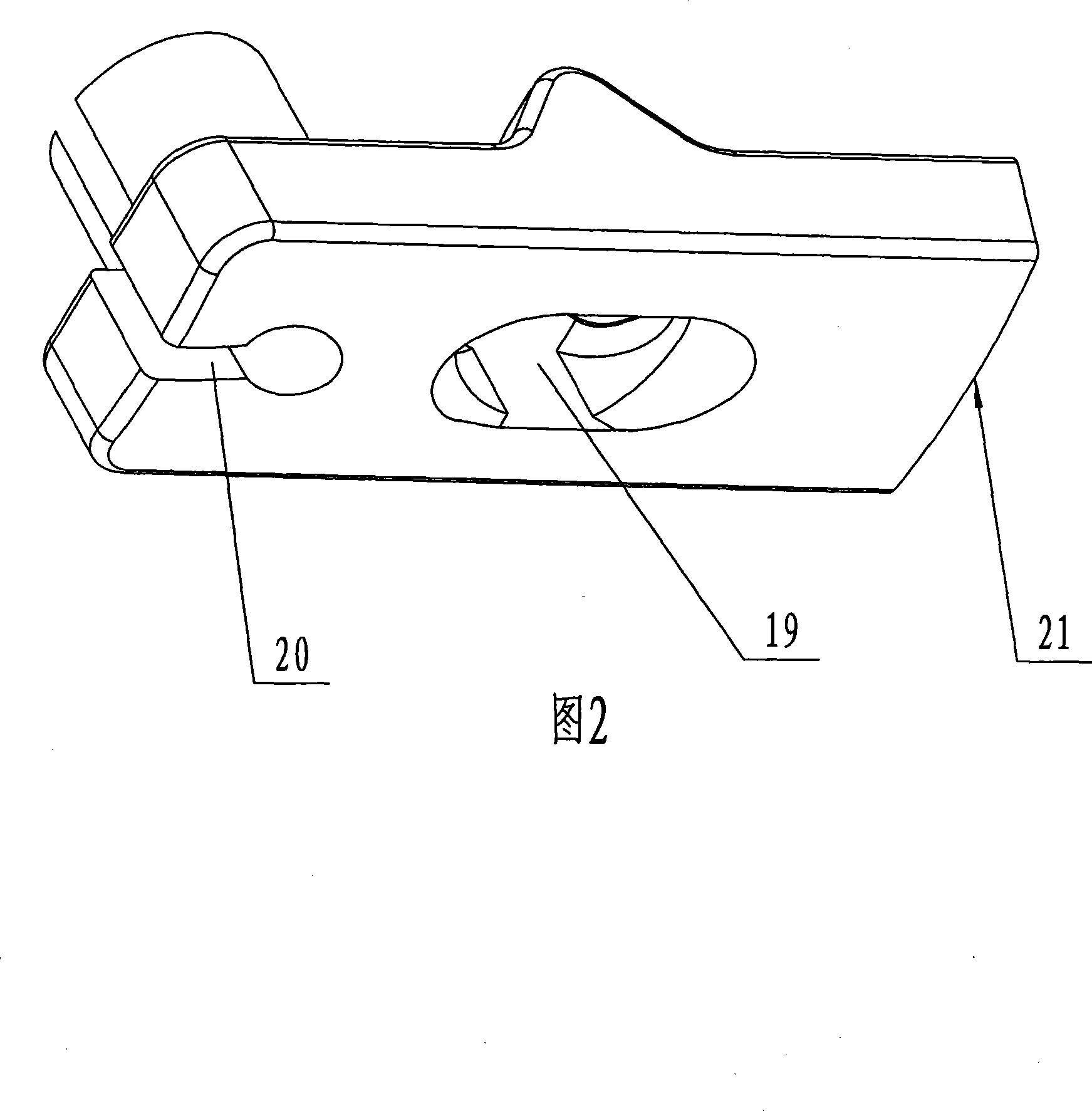

Eccentric block for vibration motor

InactiveCN103326506AClamping is not easyShort armMechanical energy handlingEngineeringMechanical engineering

The invention provides an eccentric block for a vibration motor. The eccentric block is composed of an eccentric block body (1), an eccentric block periphery (3) and a peripheral clamping device (6) which are arranged on the same plane. The eccentric block periphery (3) is arranged in the middle of the eccentric block body (1), stress grooves (2) are formed in the connection positions of the eccentric block periphery (3) and the eccentric block body (1), and a rotating shaft hole (7) is formed between the eccentric block periphery (3) and the eccentric block body (1). The peripheral clamping device (6) is arranged on the eccentric block periphery (3), and the peripheral clamping device is provided with an opening groove (5) and a fastening bolt hole (4) which is in perpendicular intersection with the opening groove.

Owner:钟祥新宇机电制造股份有限公司

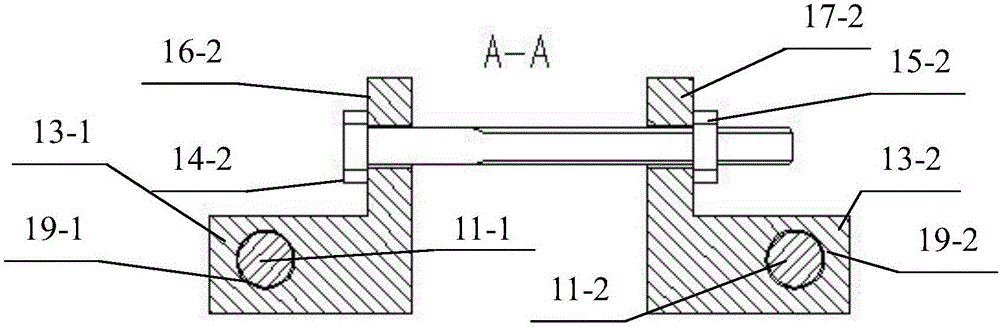

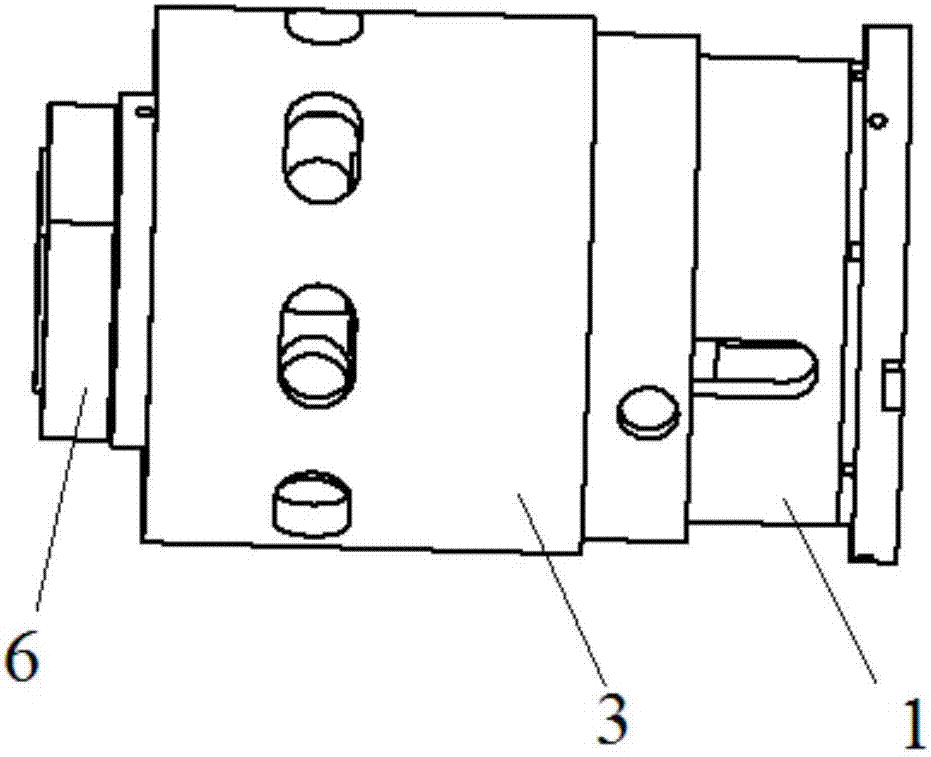

Tool holder for piping end part machining

ActiveCN107159913AReduce runoutReduced round runoutTurning machine accessoriesPositioning apparatusEngineeringMachining

The invention discloses a fixture for piping end port forming. The fixture comprises a tool bit slide seat, wherein a hobbing cutter support seat is connected in the tool bit slide seat in a manner of coaxial slide fit, a rotating cutter assembly is arranged on the end part of the hobbing cutter support seat, and mutually-matched wedge surfaces are formed on the rotating cutter assembly and the tool bit slide seat; a slide sleeve sleeves outside the tool bit slide seat in a manner of coaxial slide; a waist-shaped guide hole formed in the axial direction of the tool bit slide seat is formed in the sidewall of the tool bit slide seat; the hobbing cutter support seat and the slide sleeve realize mutual connection through a pin shaft penetrating through the waist-shaped guide hole; and a location assembly used for ensuring the coaxiality of piping machining is arranged on the end part of the slide sleeve. The tool holder disclosed by the invention is convenient to use, high in machining accuracy, stable in control on the coaxiality of pipelines during machining, and higher in location accuracy, more convenient and faster relative to traditional machinery.

Owner:山东中宝金属材料有限公司

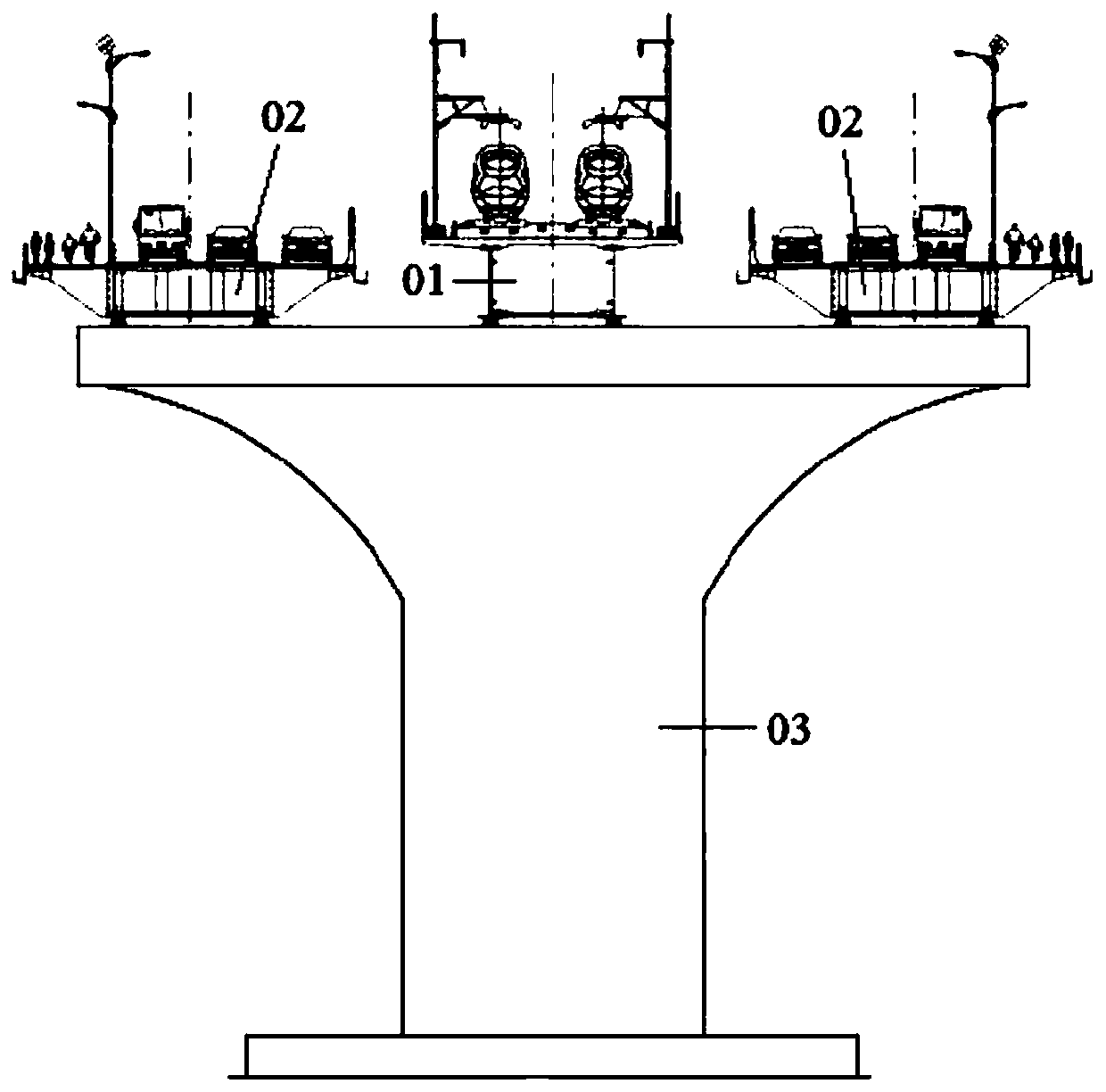

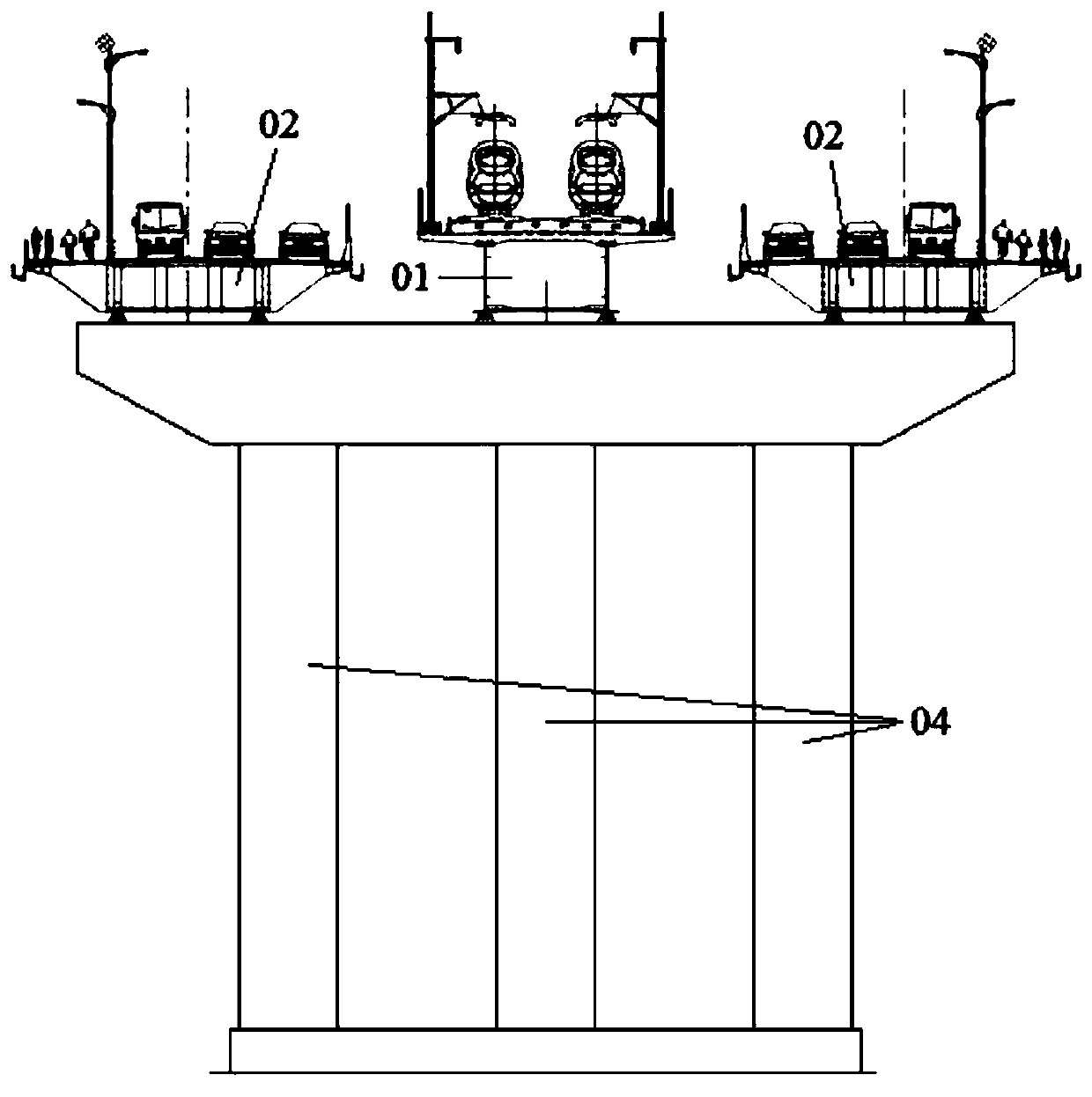

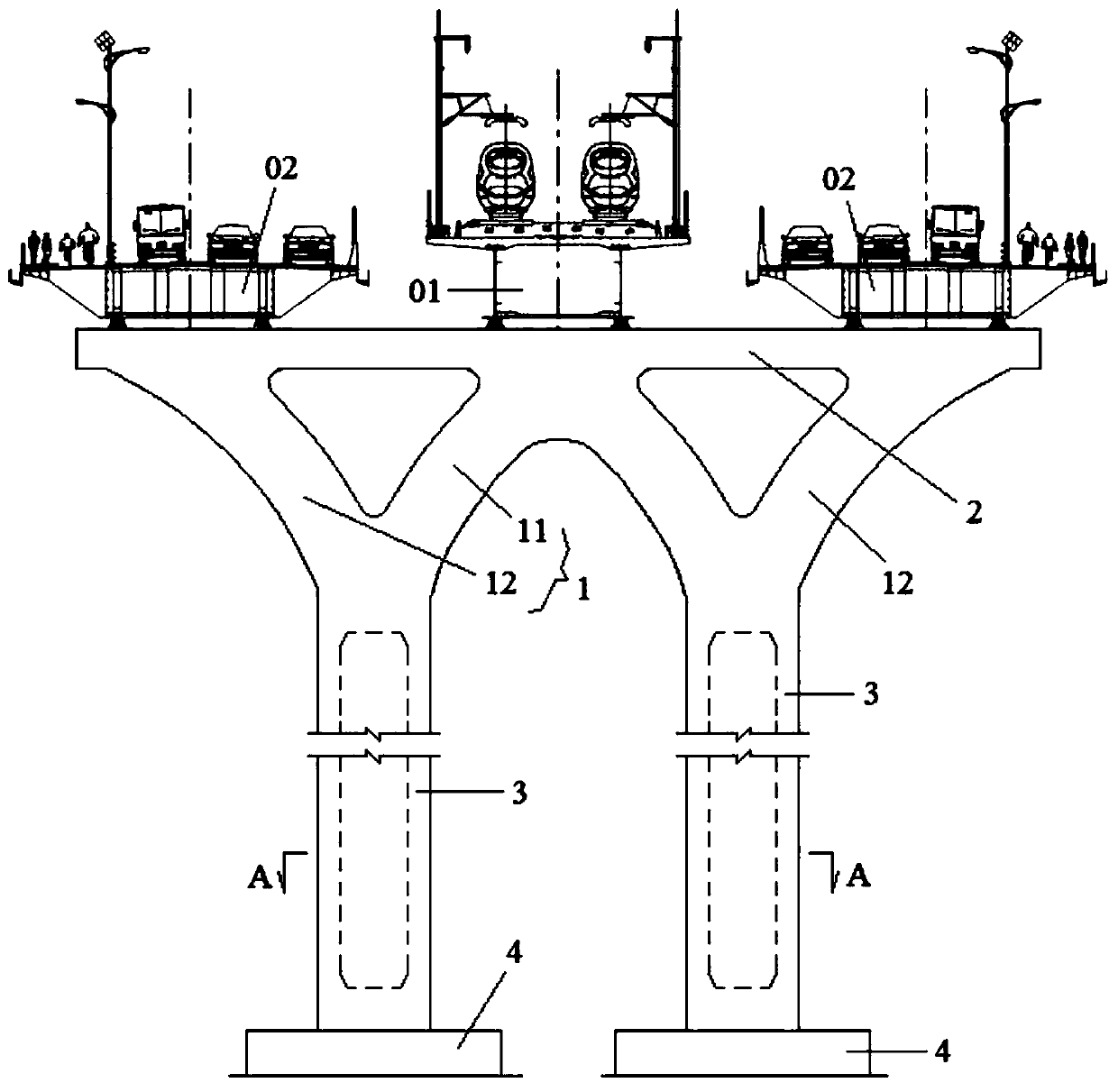

W-shaped pier

PendingCN111321660ASimple structureEasy to manufactureBridge structural detailsArchitectural engineeringPier

The invention discloses a W-shaped pier. The W-shaped pier comprises an upper pier body, a lower pier body and a bent cap; the upper pier body is W-shaped; the top of the upper pier body is connectedwith the bent cap; the bottom of the upper pier body is connected with the lower pier body; the lower pier body is a double-column pier. According to the W-shaped pier, the upper pier body on the upper portion of the W-shaped pier is W-shaped and can better adapt to arrangement of the support of a wide-body beam bridge; cantilever arms are short, so that stress is reasonable, and therefore, the defects of a traditional Y-shaped single-column pier in the wide-body beam bridge are effectively overcome, and construction is convenient; the upper pier body has a cavity, so that materials are saved;meanwhile, the lower pier body of the lower portion of the W-shaped pier is a double-column pier, and compared with a three-column pier or large-size pier body design adopted by a traditional wide-body beam bridge, such a structure can assist in saving land under the bridge and reducing construction cost. The W-shaped pier is simple in structure, convenient to manufacture and good in effect.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

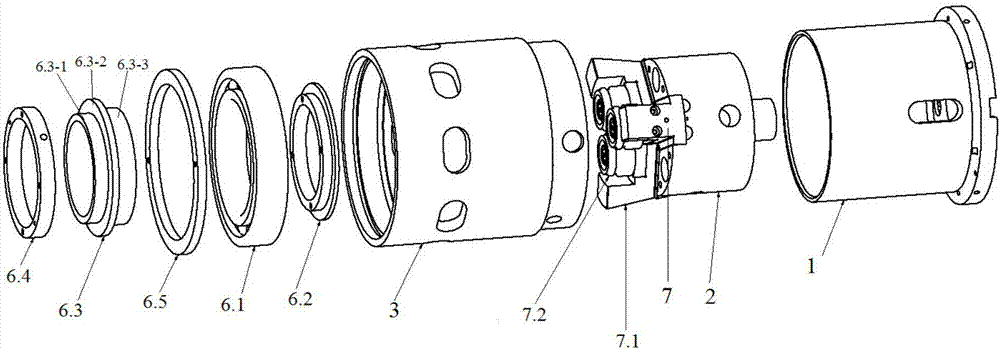

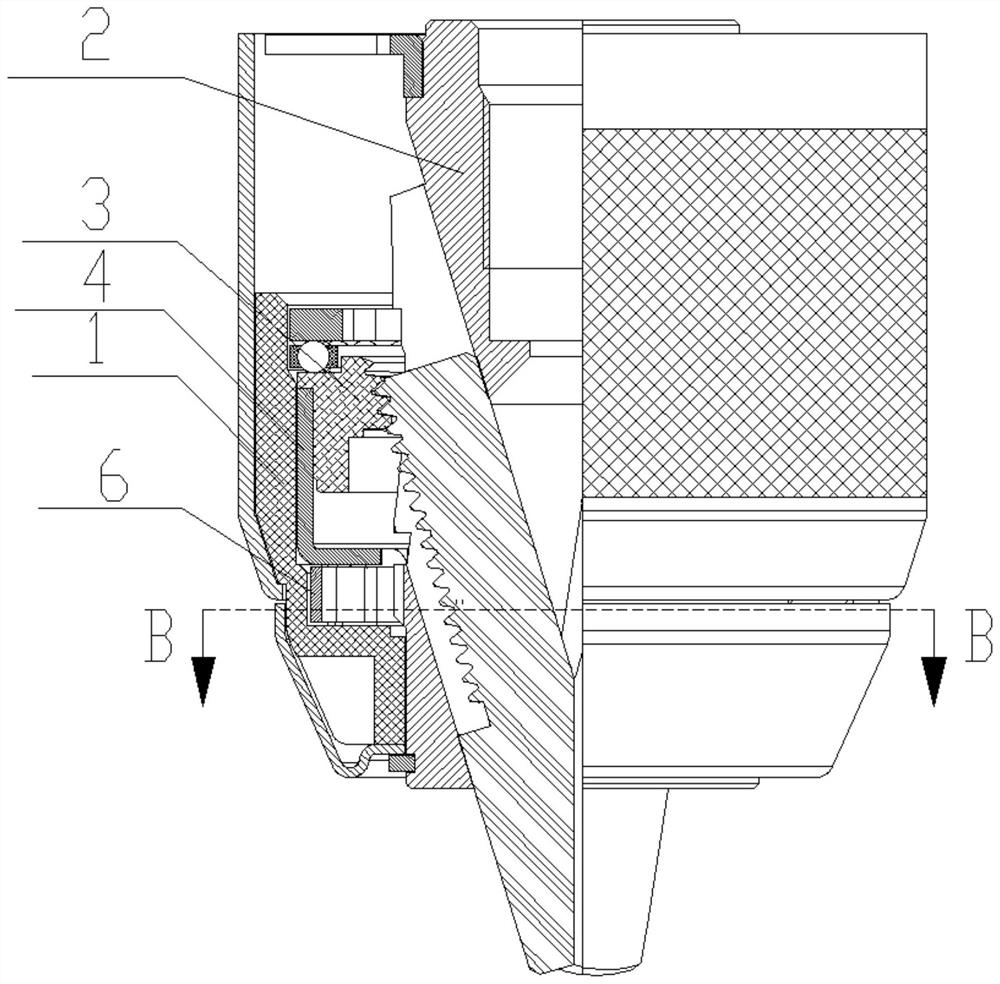

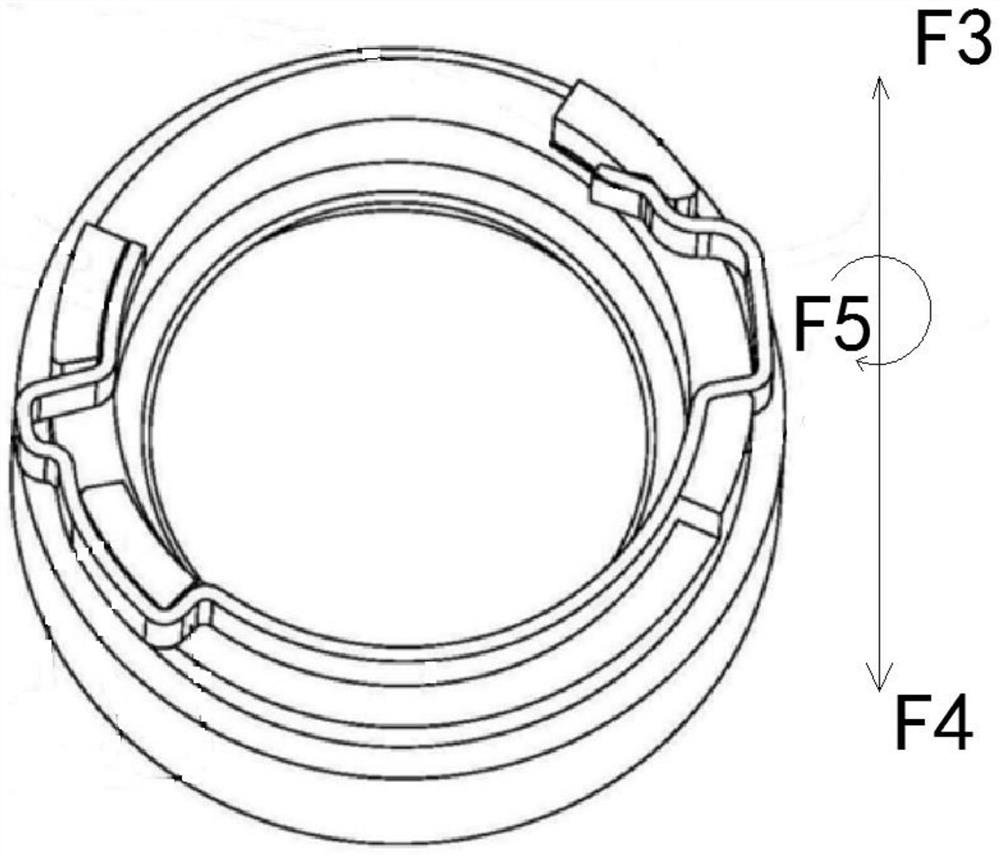

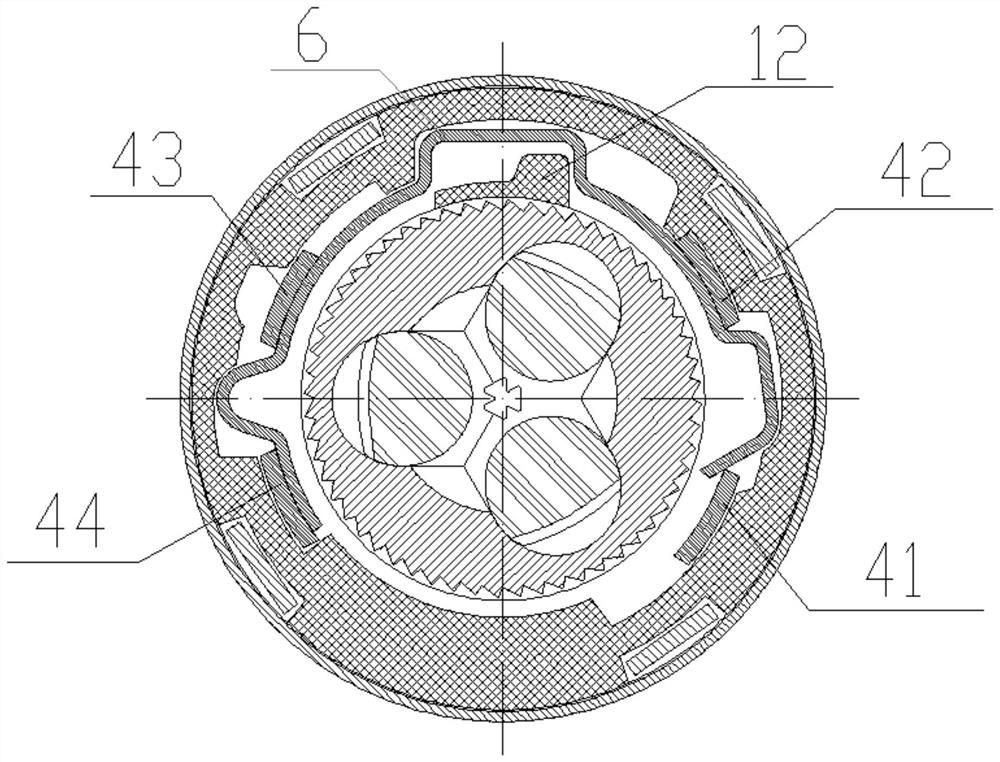

Self-locking type drill chuck

PendingCN111822758AIncrease elasticityImprove satisfactionChucksTool adaptersEngineeringInterference fit

The invention discloses a self-locking type drill chuck, belongs to the field of drill chucks, and particularly relates to a self-locking type drill chuck. A nut sleeve is in interference fit with theoutside of a nut, a plurality of keys are arranged on the nut sleeve along the circumferential direction, an elastic sheet is limited among the keys of the nut sleeve through self elasticity to be assembled on the nut, and a supporting protrusion which is arranged between a positioning protrusion and a locking end protrusion and is recessed inwards is arranged on the elastic sheet; and a rotary sleeve is provided with a hollow groove and a supporting convex key which are matched with the supporting protrusion when a non-self-locking state and a self-locking state are mutually switched, in theself-locking state, the supporting convex key abuts against the supporting protrusion of the elastic sheet, and the supporting force is generated on the elastic sheet. The self-locking type drill chuck is simple in structure and high in practicability.

Owner:ZHEJIANG CHAOLI MECHANICAL TOOLS

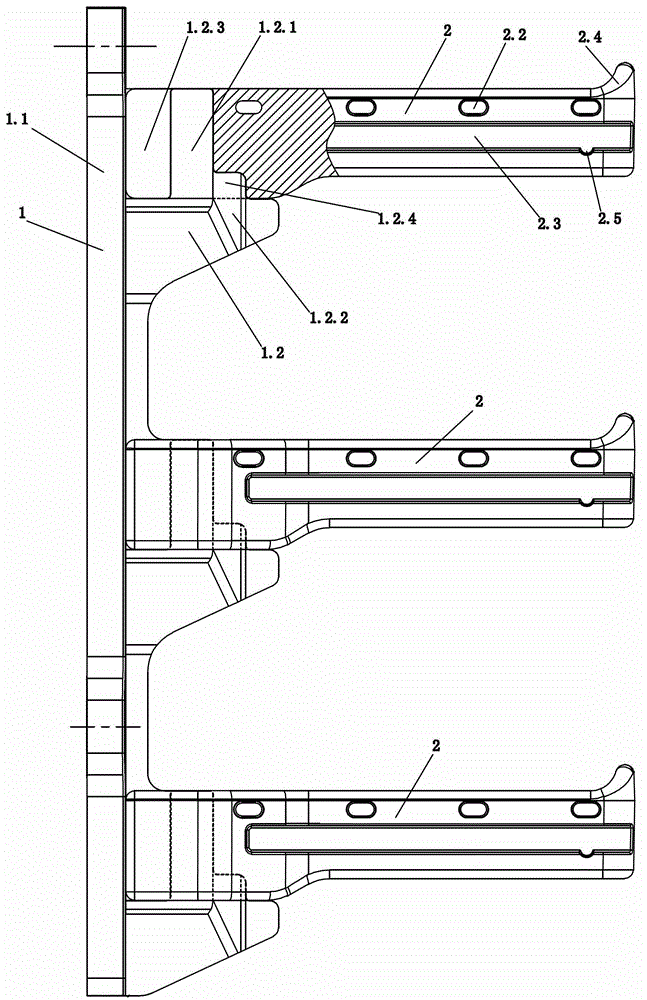

Cable rack

The invention relates to a cable rack, which comprises a stand column and a support arm respectively made of a fiber-reinforced thermosetting polymer composite material, wherein the stand column comprises a stand column body; a plurality of forward and convexly extending support arm support parts are uniformly distributed on a front surface of the stand column body; a support arm connecting column is arranged in the middle parts of upper surfaces of the support arm support parts; a connecting column reinforcing rib is arranged between the support arm connecting column and the stand column body; and correspondingly, a sleeve joint hole is arranged on a rear end of the support arm, and comprises a sleeve joint hole body adapted to the support arm connecting column and a sleeve joint hole opening arranged on a rear side of the sleeve joint hole body and adapted to the connecting column reinforcing rib. The cable rack has the advantages of simple and reasonable structure, easiness in processing and manufacturing, convenience in storage, transportation, installation and maintenance, high use reliability and safety, and long service life.

Owner:况骄庭 +1

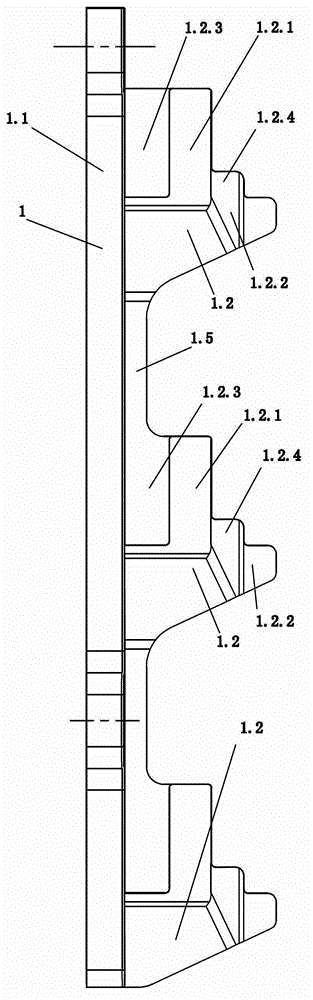

Mixing device for producing high-performance permanent magnetic ferrite material

PendingCN110270252AShort armReduce torqueRotary stirring mixersTransportation and packagingMaterials scienceElectric motor

The invention discloses a mixing device for producing a high-performance permanent magnetic ferrite material, and relates to the technical field of magnetic material production equipment. The mixing device for producing the high-performance permanent magnetic ferrite material comprises a mixing cylinder which is built of a mixture of cement and pebbles, a supporting rack is set up on the top of the mixing cylinder, multiple motors are installed on the top of the supporting rack, and an independent shaft lever is connected with the bottom of each motor. According to the mixing device for producing the high-performance permanent magnetic ferrite material, multiple stirring claws are arranged in the mixing cylinder, each stirring claw is driven by one corresponding independent motor, thus when the stirring claws conduct stirring, force arms are short, torque is low, when the stirring claws conduct stirring in the mixing cylinder, resistance of a material to the stirring claws is low, and in order to prevent the situation that in a stirring process, the material precipitates on the bottom of the mixing cylinder, coils used for spraying water or gas to the bottom of the mixing cylinder are arranged on the bottom of the mixing cylinder in a coiled mode, so that precipitation of the material is avoided, and the evenness of the material stirred in the mixing cylinder is improved.

Owner:ANHUI HONGTAI ELECTROMAGNETIC

Gravitational gym shoe

InactiveCN102771947AShort armReduce the burden onUpperBootlegsClassical mechanicsStructural engineering

Owner:李诺吉

Pruning machine

ActiveCN101226415AShorten the lengthLess bendingCuttersCutting implementsThermal deformationEngineering

The invention discloses a pruning machine, wherein a steel wire shaft (7), an upright rod (12), a switch top block (13), a main button (2), a lifting plate (8) and an inching switch (6) are arranged at the left of a motor component (5), a draw plate (10) and a sub button (4) are arranged at the right of the motor component (5), two ends of the steel wire shaft (7) are respectively connected with the right end of the main button (2) and the left end of the lifting plate (8), a rigid metal rod (9) is connected between the right end of the lifting plate (8) and the upper end of the draw plate (10), the lower ends of the draw plate (10) and the sub button (3) are hinged with a shell (11), the lifting plate (8) is sliding sheathed on the upright rod (12) sheathed by the switch top block (13), and the inching switch (6) is above the switch top block (13). The invention has the advantages that the invention can turn on and off motor with small force and can prevent thermal deformation of driving mediums caused by the heat radiation of motor.

Owner:NINGBO ENERGY POWER TOOLS

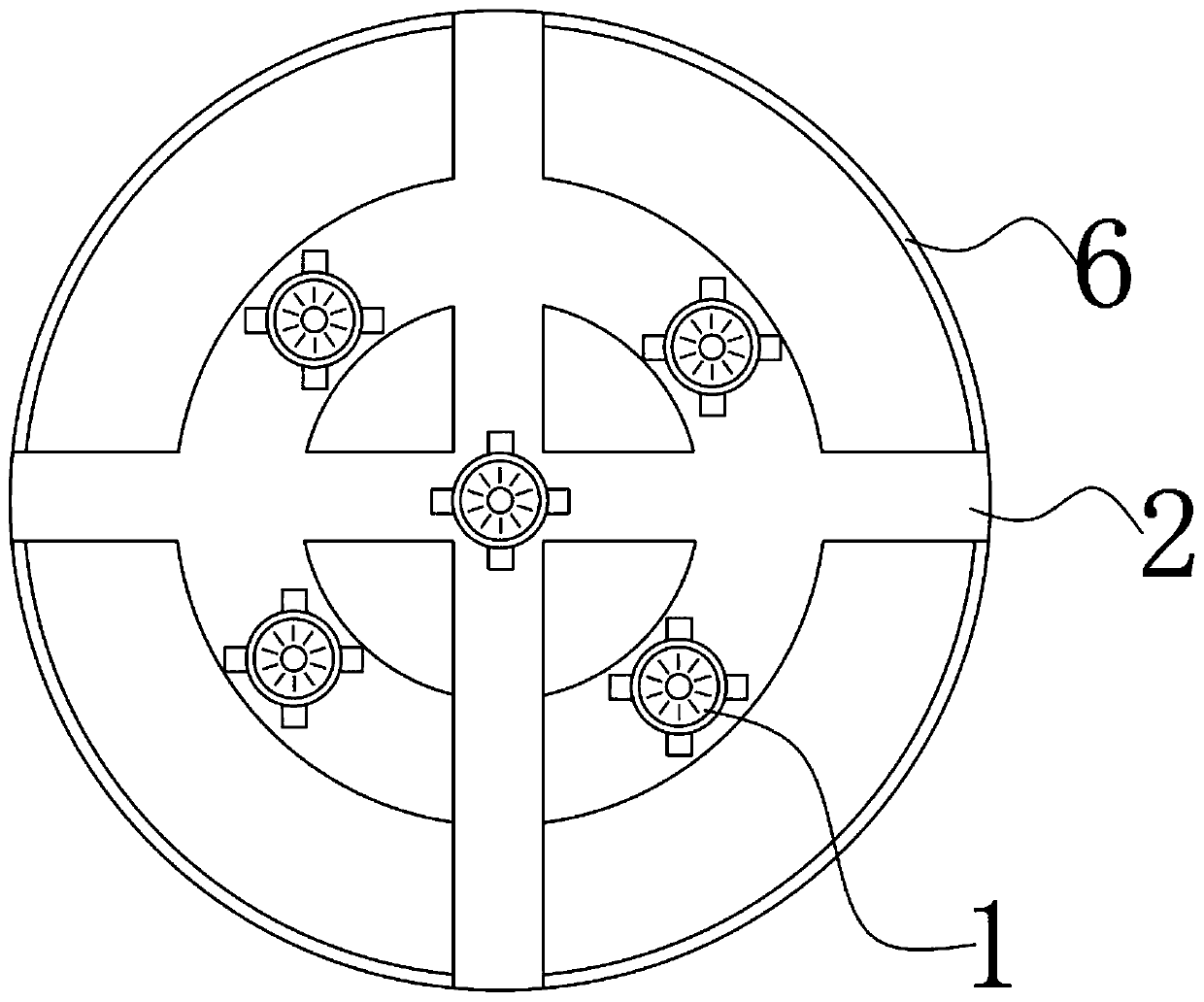

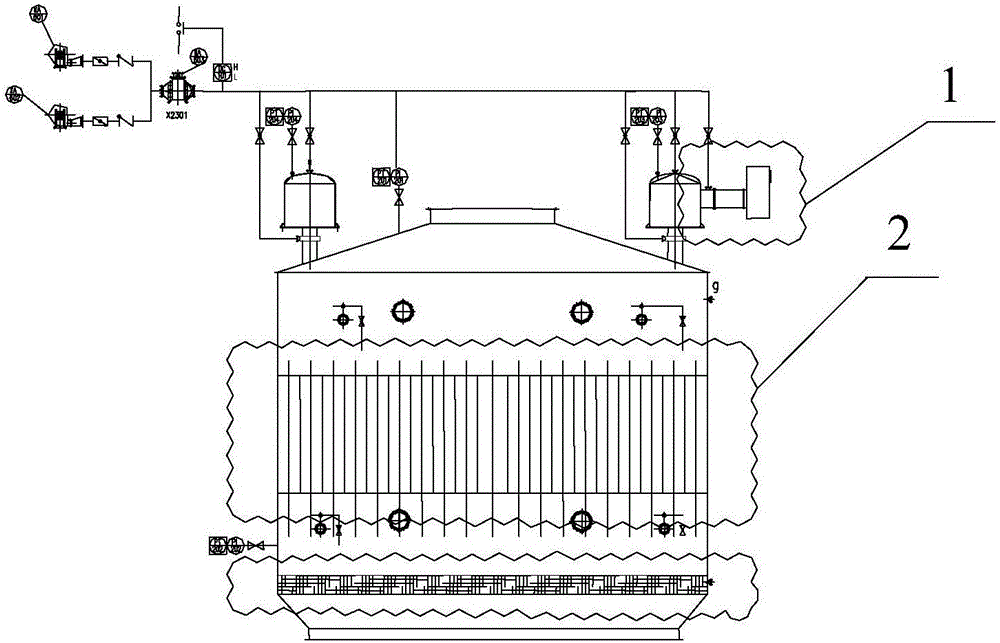

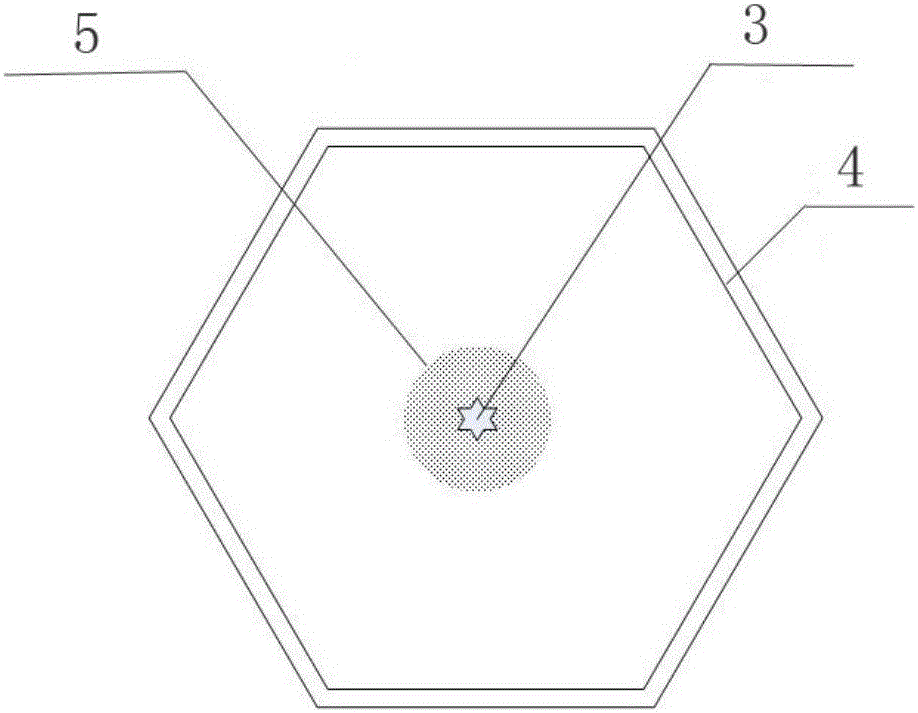

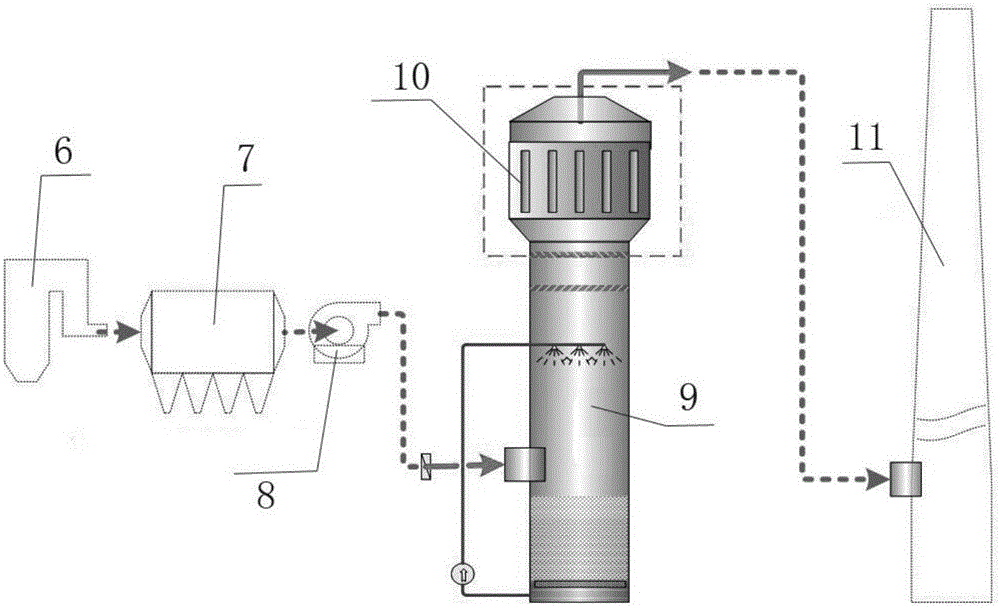

Novel efficient wet type electrical precipitator based on pulse power supply

ActiveCN105944837AEmission reductionReduce turbidityExternal electric electrostatic seperatorElectric supply techniquesParticulatesGlass fiber

The invention provides a novel efficient wet type electrical precipitator based on a pulse power supply. The wet type electrical precipitator comprises an orthohexagonal cellular conductive glass fiber reinforced plastics anode tube, a titanium electrode discharge wire and a high voltage pulse power supply device, wherein the output end of the high voltage pulse power supply device is connected to the titanium electrode discharge wire, the high voltage pulse power supply is input to the titanium electrode discharge wire, the high voltage pulse power supply is a high voltage power supply integrated by a base voltage overlapped pulse voltage, and the titanium electrode discharge wire is positioned in the center of the anode tube. By applying the overlapped voltage and the titanium electrode discharge wire to the wet type electrical precipitator, the dust removal efficiency is improved as a result of a reasonable structural design of the titanium electrode discharge wire and the anode tube. The wet type electrical precipitator can reduce particulate matter emission by over 95%, can reduce over 90% of SO3 emission and can remarkably reduce the turbidity of visible smoke emitted by a wet chimney, and has perspectiveness of mercury removal. The technical problem that smoke particulates are emitted by reaching the standard or are emitted in an ultralow manner is effectively solved, so that the investment cost is lowered, and the land is saved.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

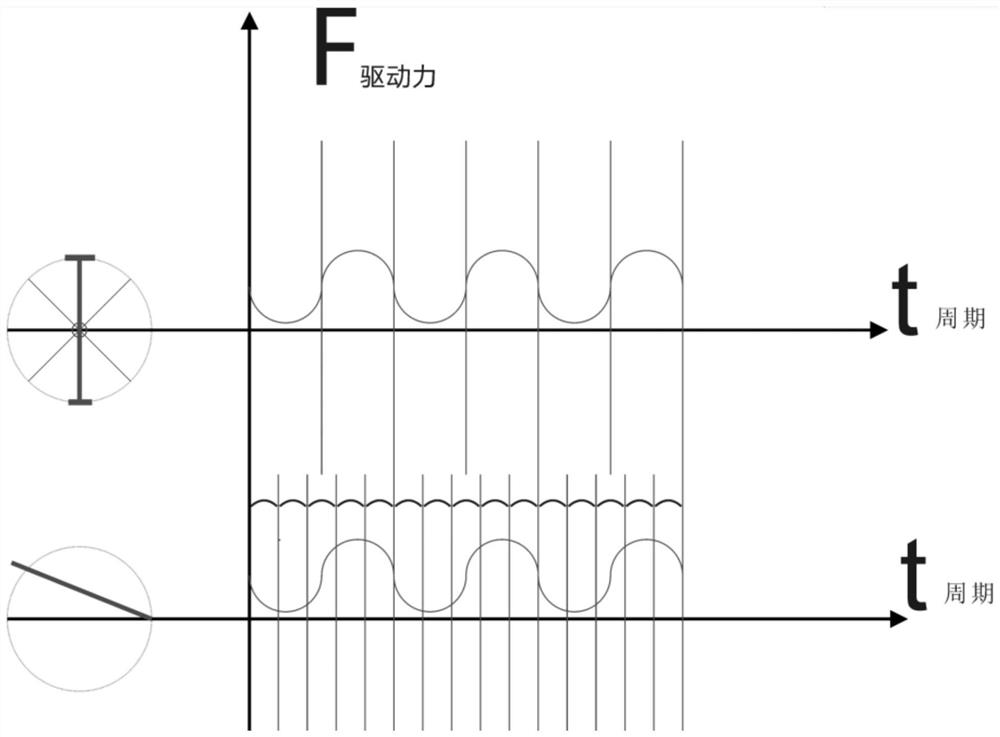

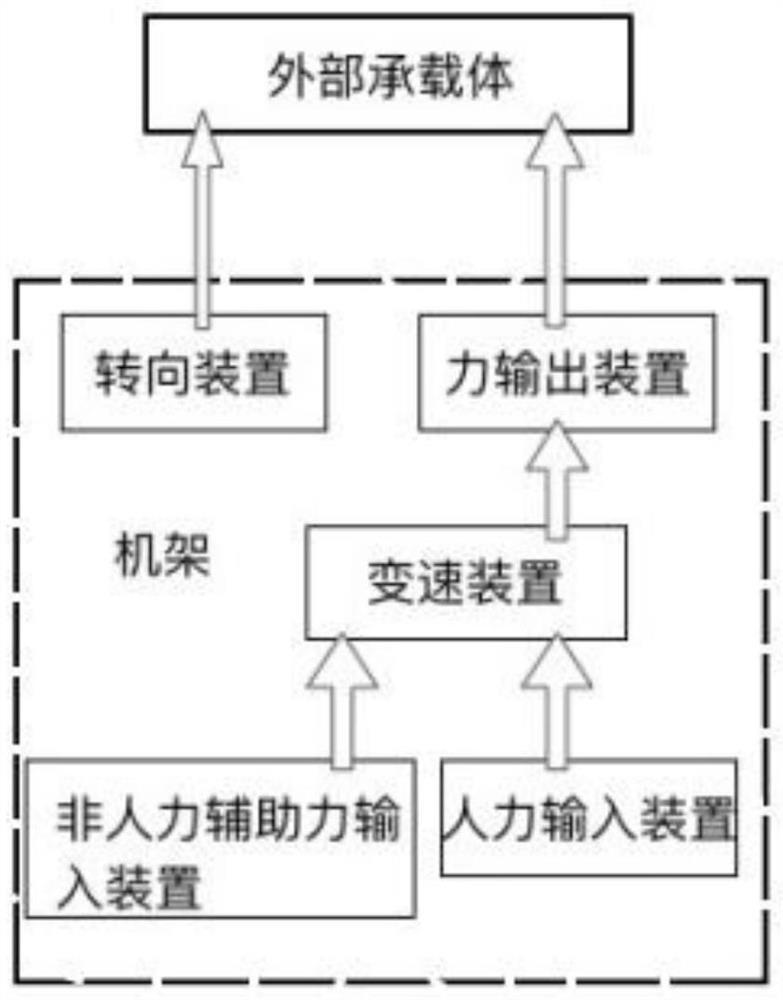

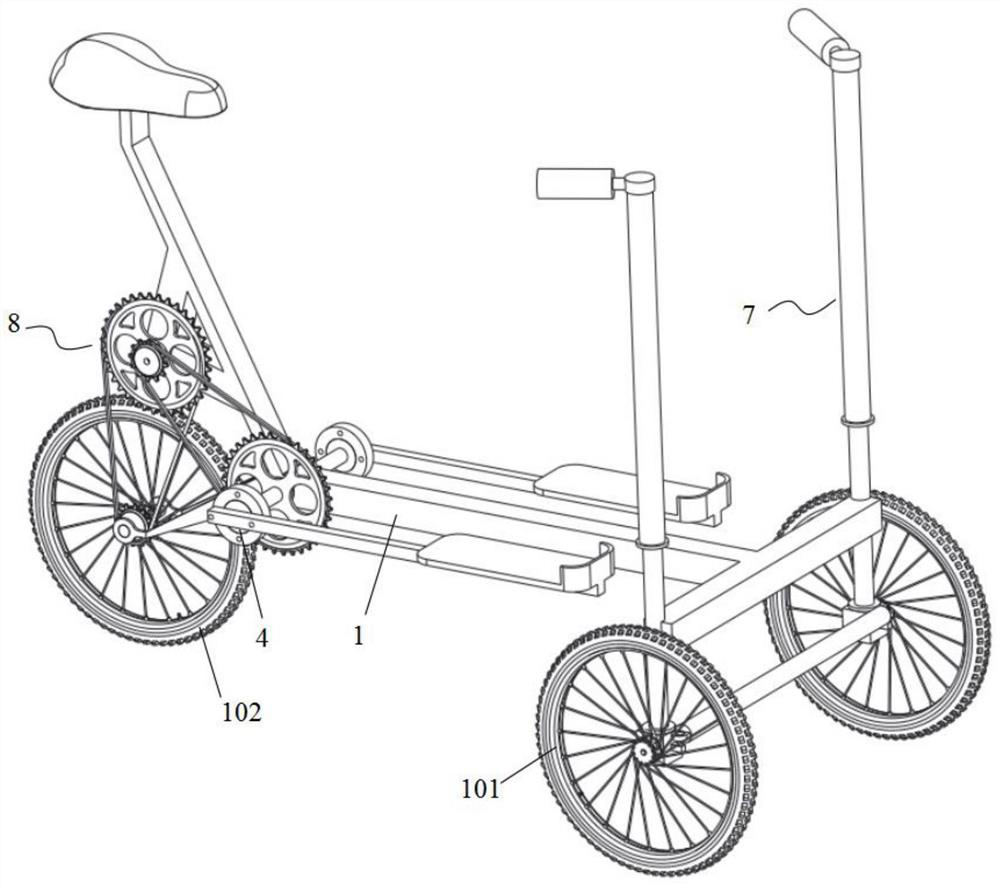

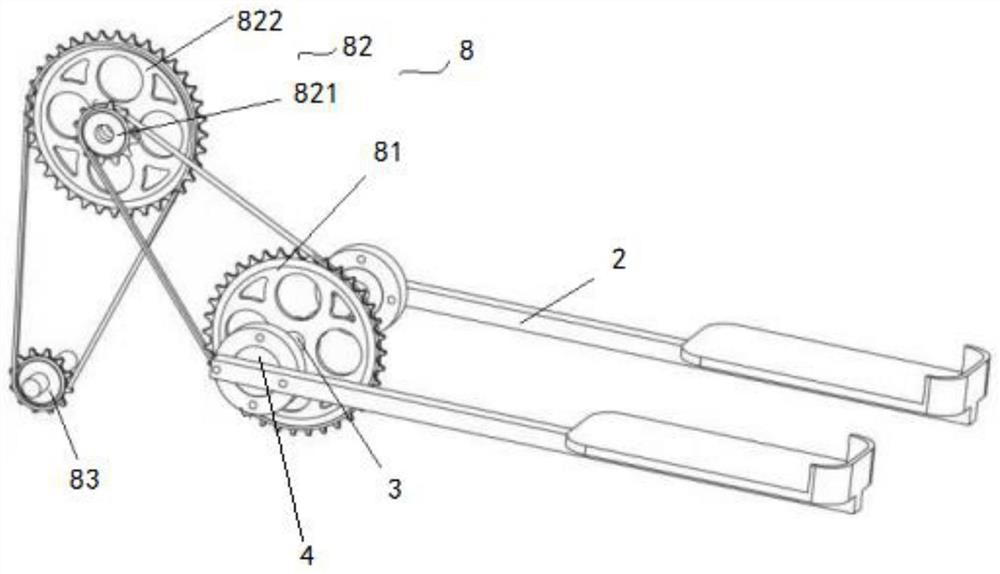

Pedal bicycle

The invention provides a pedal bicycle which is characterized by comprising a frame, and a manual variable speed driving device, a steering device, a front wheel and a rear wheel which are mounted on the frame, the manual variable speed driving device comprises a rack, a force application handle, a main power shaft, a one-way overrunning clutch, a reset device and a variable speed gear set, one end of the force application handle is fixed to the input end of the one-way overrunning clutch, and the output end of the one-way overrunning clutch is fixed to the main power shaft; the force application handle rotates around the main power shaft in a reciprocating mode to sweep a sector face to move and do work, the driving force arm corresponding to the force application handle directly drives the input end of the one-way overrunning clutch to rotate forwards and backwards, and therefore the output end of the one-way overrunning clutch is intermittently driven to rotate in a one-way mode. The variable speed gear set is an angular speed increasing gear set and comprises an input end gear, a middle change gear set and a terminal gear which are in transmission connection in sequence. The power output efficiency is high, the structure is compact, no idle stroke exists in transmission, and safety and comfort are achieved.

Owner:西安双驱自正智能科技有限公司

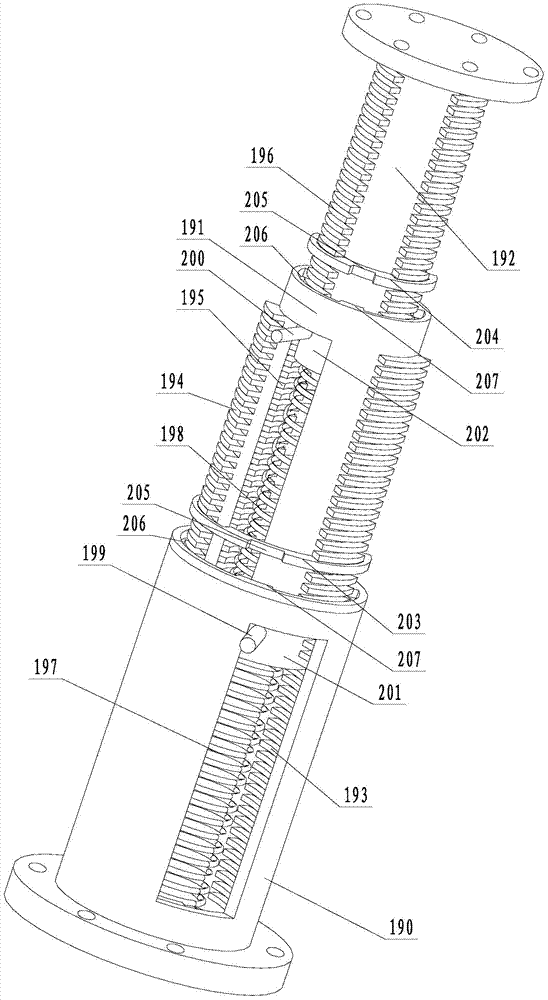

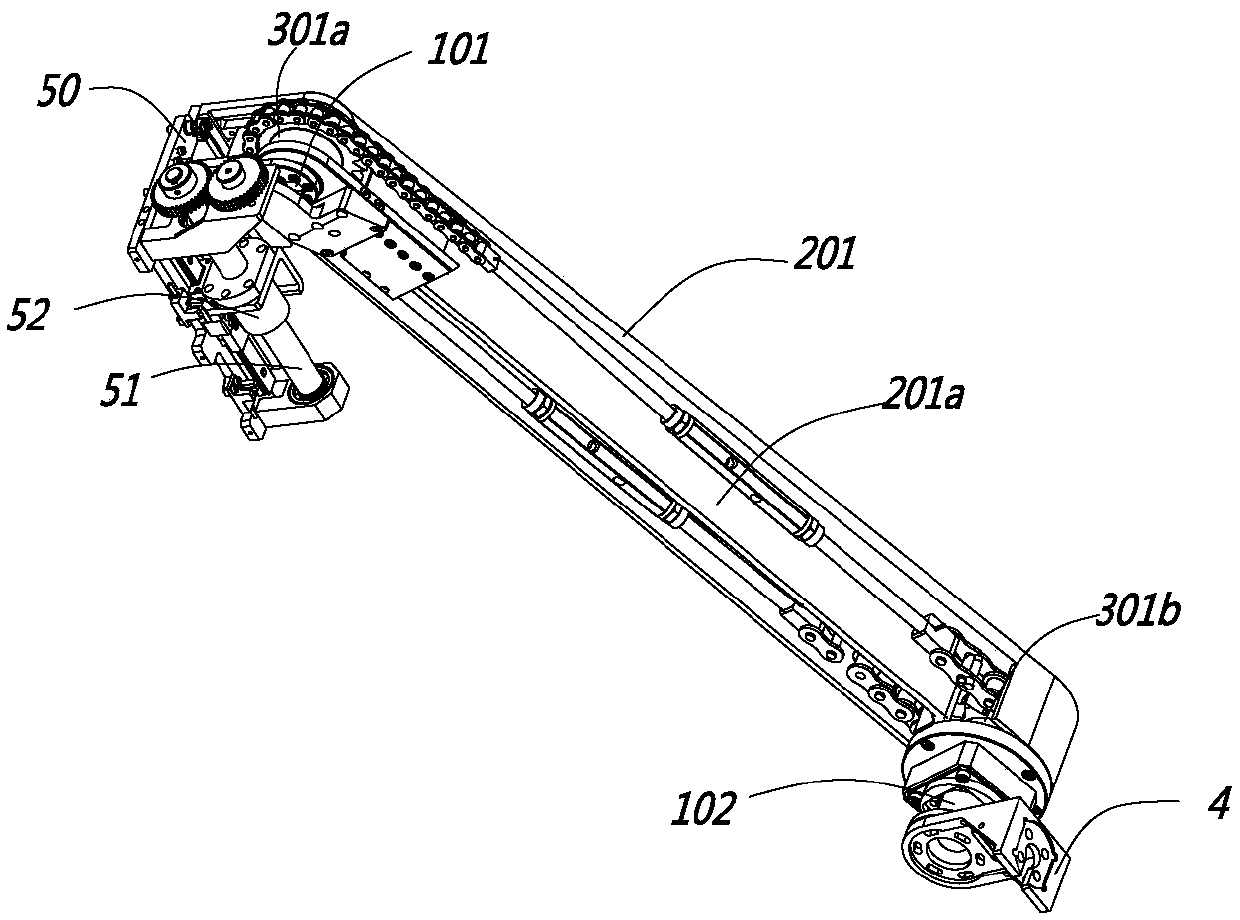

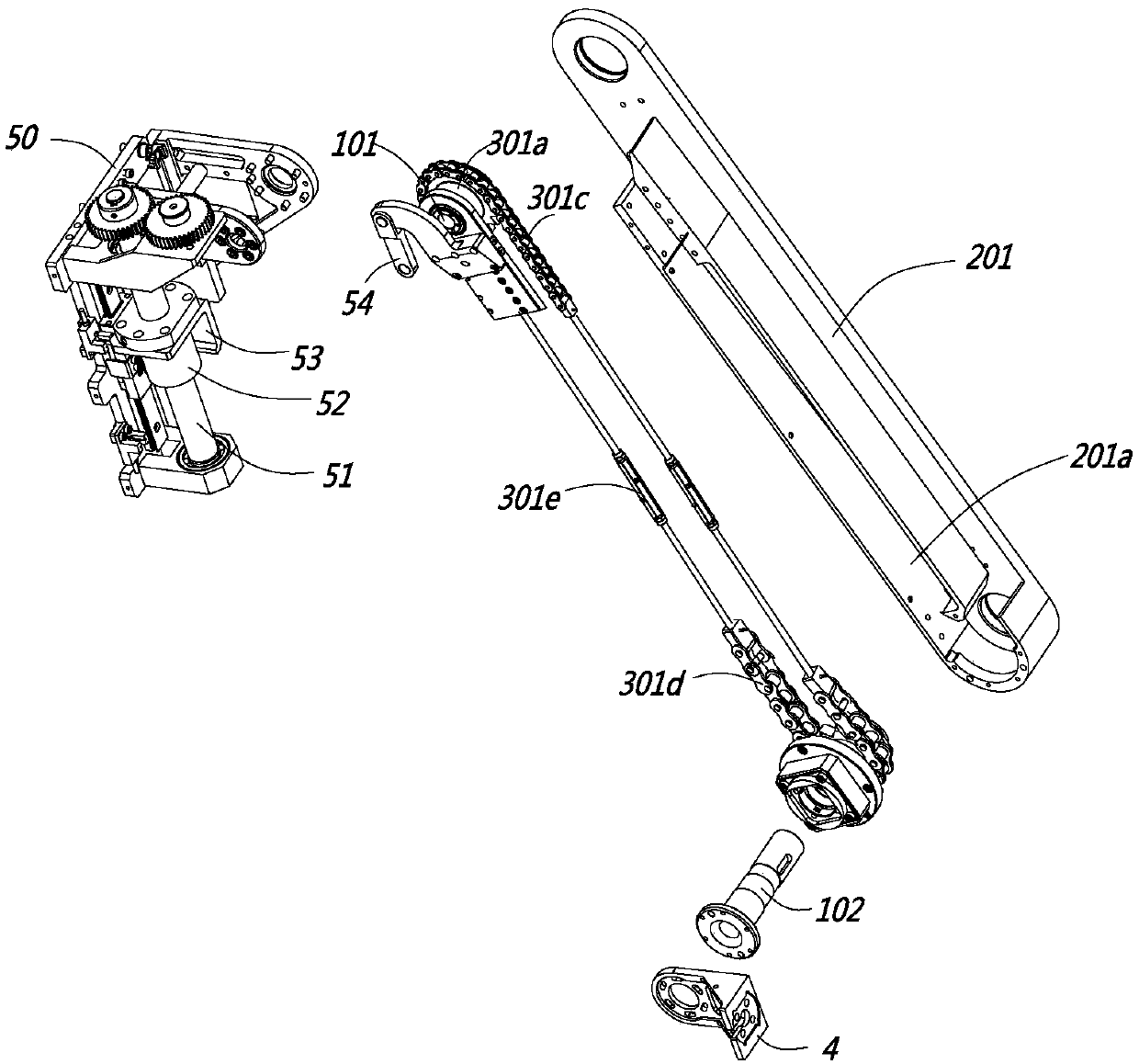

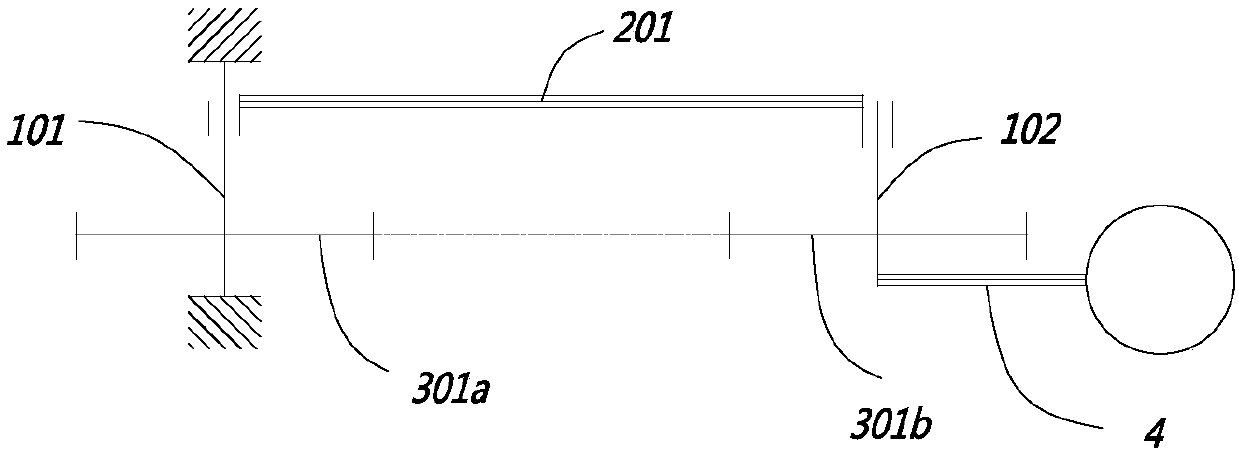

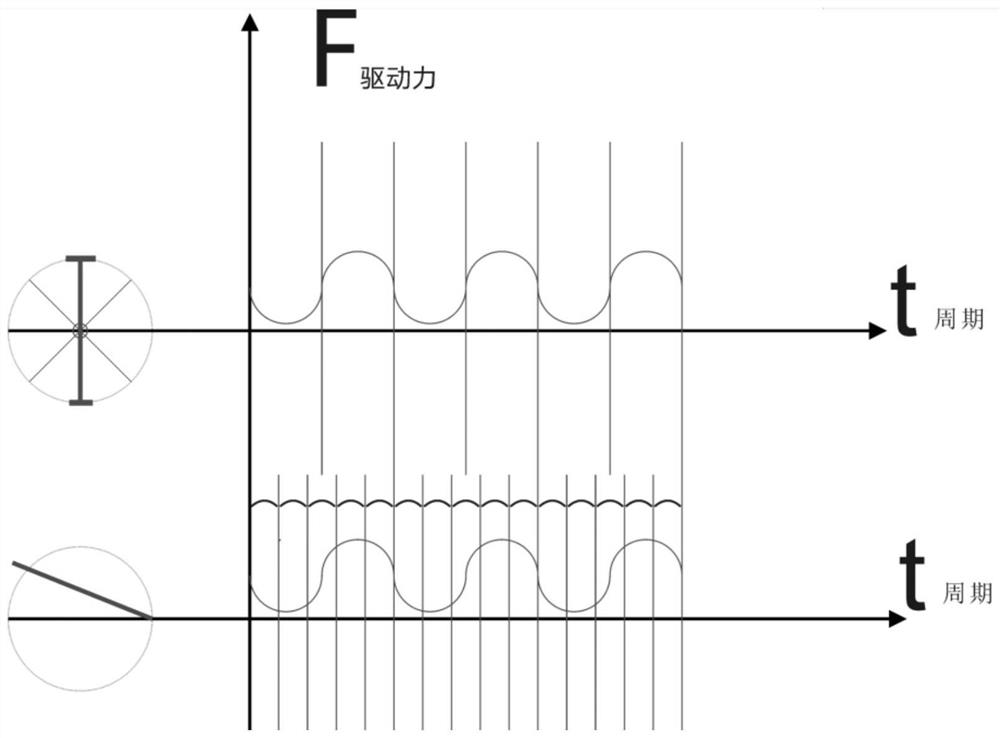

Large-stroke telescopic mechanism

The invention discloses a large-stroke telescopic mechanism, and belongs to the field of mechanical telescopic equipment. The large-stroke telescopic mechanism comprises a first rotating shaft, a second rotating shaft and a first transmission arm, the two ends of the first transmission arm are rotationally connected with the first rotating shaft and the second rotating shaft correspondingly, the first transmission arm is rotated around the first rotating shaft under the effect of a driver, the first rotating shaft and the second rotating shaft are in transmission connection through a first transmission mechanism, the first transmission mechanism includes a front transmission wheel and a rear transmission wheel which are mutually driven, the front transmission wheel is fixedly connected with the first rotating shaft, the rear transmission wheel is fixedly connected with the second rotating shaft, and the second rotating shaft is used for being connected with a terminal arm. The large-stroke telescopic mechanism has the advantages of making the expansion and contraction more stable and the telescopic stroke longer.

Owner:ZHEJIANG GUOZI ROBOT TECH

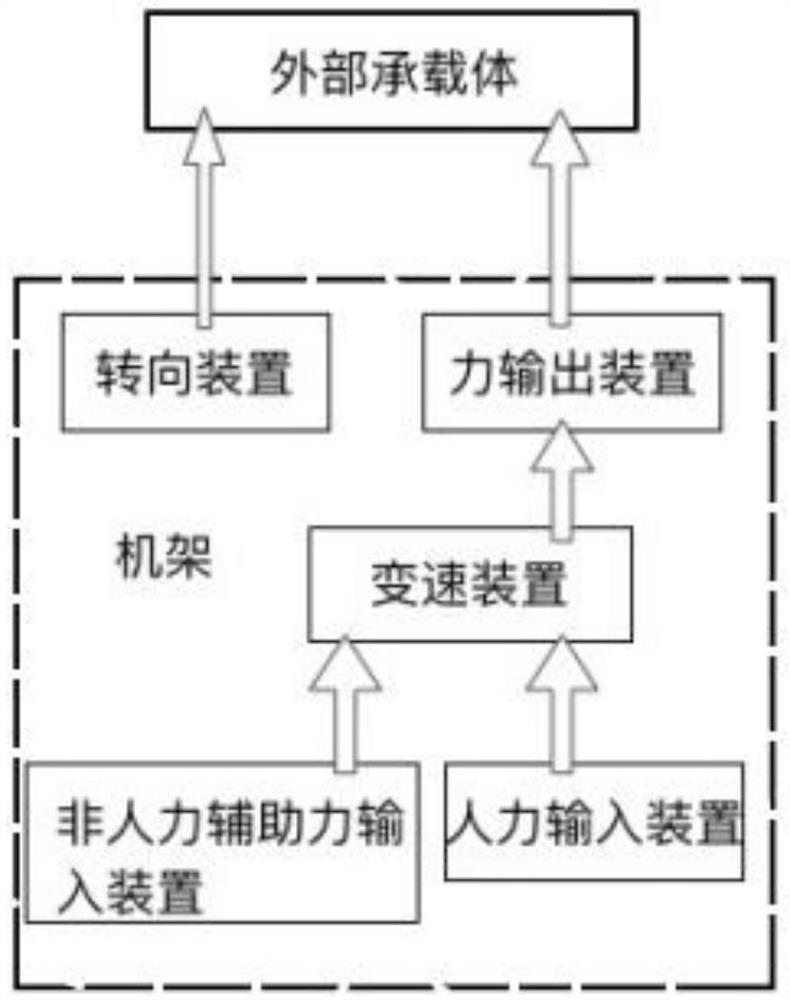

Manual variable-speed driving device, man-powered bicycle, man-powered aircraft and man-powered ship

PendingCN114044079AImprove output efficiencyShort armWheel based transmissionChain/belt transmissionFlight vehicleGear wheel

The invention provides a manual variable-speed driving device which comprises a rack, a force application handle, a main power shaft, a one-way overrunning clutch, a reset device and a variable-speed gear set. One end of the force application handle is connected with the input end of the one-way overrunning clutch, and the output end of the one-way overrunning clutch is connected to the main power shaft; the force application handle rotates around the main power shaft in a reciprocating mode to sweep a sector face to move and do work, a driving force arm corresponding to the force application handle directly drives the input end of the one-way overrunning clutch to rotate forwards and backwards, so that the output end of the one-way overrunning clutch is intermittently driven to rotate in a one-way mode. The variable-speed gear set is an angular speed increasing gear set and comprises an input end gear, a middle change gear set and a terminal gear; the output end of the one-way overrunning clutch is fixedly connected with the input end gear through a main power shaft. The invention further provides a man-powered bicycle, a man-powered aircraft and a man-powered ship. The power output efficiency is high, the structure is compact, the arm of force is long, and safety and reliability are achieved.

Owner:XIAN DUAL-DRIVE & SELF-CORRECTING INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com