Automatic opening mechanism for automobile engine tile cover

An automobile engine and expansion technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the weight of moving parts, increasing equipment cost, and increasing energy consumption of equipment, so as to achieve simplified control, reduced load, The effect of simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

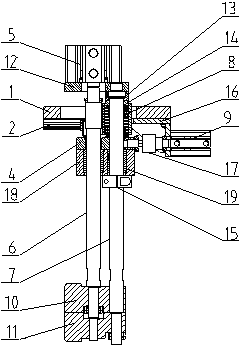

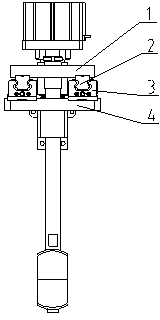

[0031] The expansion cylinder 5 is fixedly installed on the expansion cylinder seat 12, and the expansion pressure rod 7 and the expansion cylinder base 12 are locked and fixed together by the pressure rod locking block 13. The connection and fixation strength of the expanding pressure rod 7 is improved.

Embodiment 2

[0033] A down-going protective cover 14 is clamped between the return spring 8 of the expanding pressure rod 7 and the unscrewing slide table 1, and the top of the down-going protective cover 14 is retracted into a boss shape. The bottom is equipped with an upward limit block 15. The design of this place limits the longitudinal movement range of the expansion pressure rod 7, and is responsible for locating the original position and the expansion state of the expansion mechanism, which improves the reliability during operation.

Embodiment 3

[0035] The translation cylinder 9 is fixedly connected with the unscrewing slide table 1 through a translation cylinder base 16 , and a floating joint 17 is installed at the end of its piston rod, and the floating joint 17 is connected in the horizontal slide plate 4 . The design at this place can effectively improve the service life of the translation cylinder during operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com