Double-conductor equipment wire clamp

A technology of equipment wire clips and double wires, which is applied in the direction of conductive connection, multi-conductor connectors, electrical components, etc., can solve the problems of unfavorable power grid operation, affecting the service life of fittings, and magnifying weld stress, so as to prevent water accumulation in fittings Cracking, preventing excessive temperature rise of fittings, and good stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

[0020] A wire clip for double-conductor equipment includes a wire clip body and a crimping pipe, and the crimping pipe and the wire clip body are connected in an inserting manner.

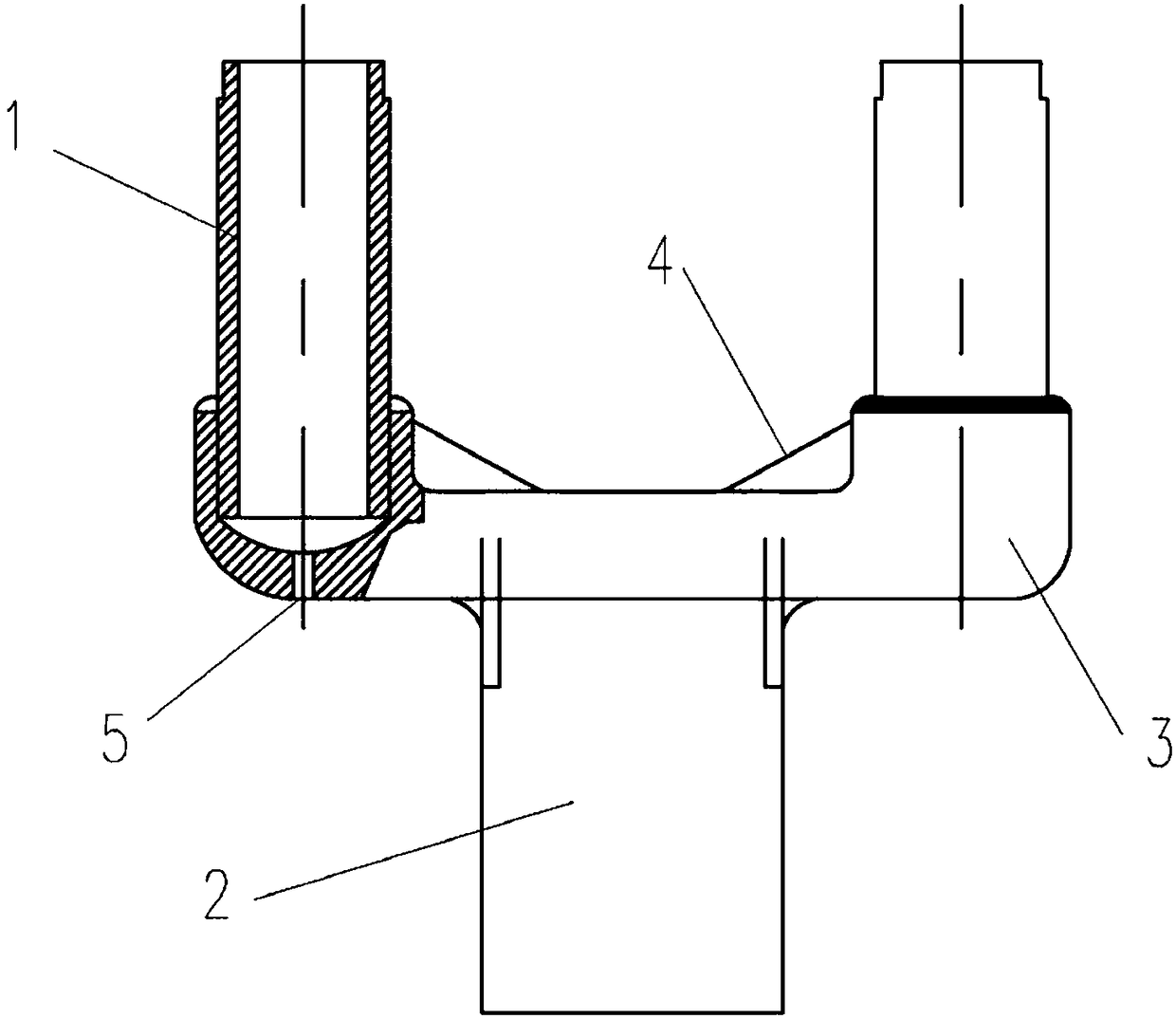

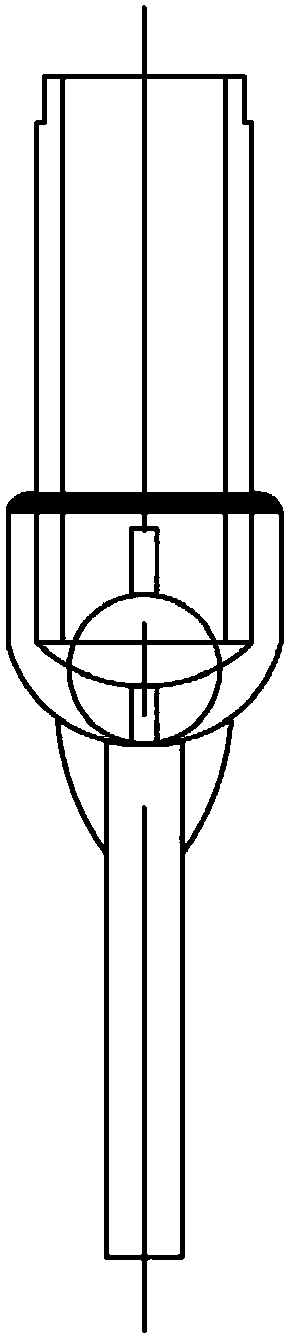

[0021] Such as figure 1 , 2 As shown, a double-conductor equipment clamp includes a clamp body and a crimping tube 1. The equipment clamp body adopts a casting process and is made of aluminum alloy, and its tensile and bending properties are greatly improved; the crimping tube 1 and The clamp body adopts interpolation connection. In this embodiment, the crimping tube 1 and the clamp body adopt interpolation welding. The clamp body includes a terminal board 2 and a "U"-shaped part 3. The " Both ends of the U"-shaped piece 3 are respectively provided with a hollow cylinder for inserting the crimping tube 1, the structure of the inner hollow part of the hollow cylinder is a combina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com