Mixing device for producing high-performance permanent magnetic ferrite material

A permanent magnet ferrite and mixing device technology, which is applied to mixers with rotating stirring devices, mixers, transportation and packaging, etc., can solve problems such as large motor loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

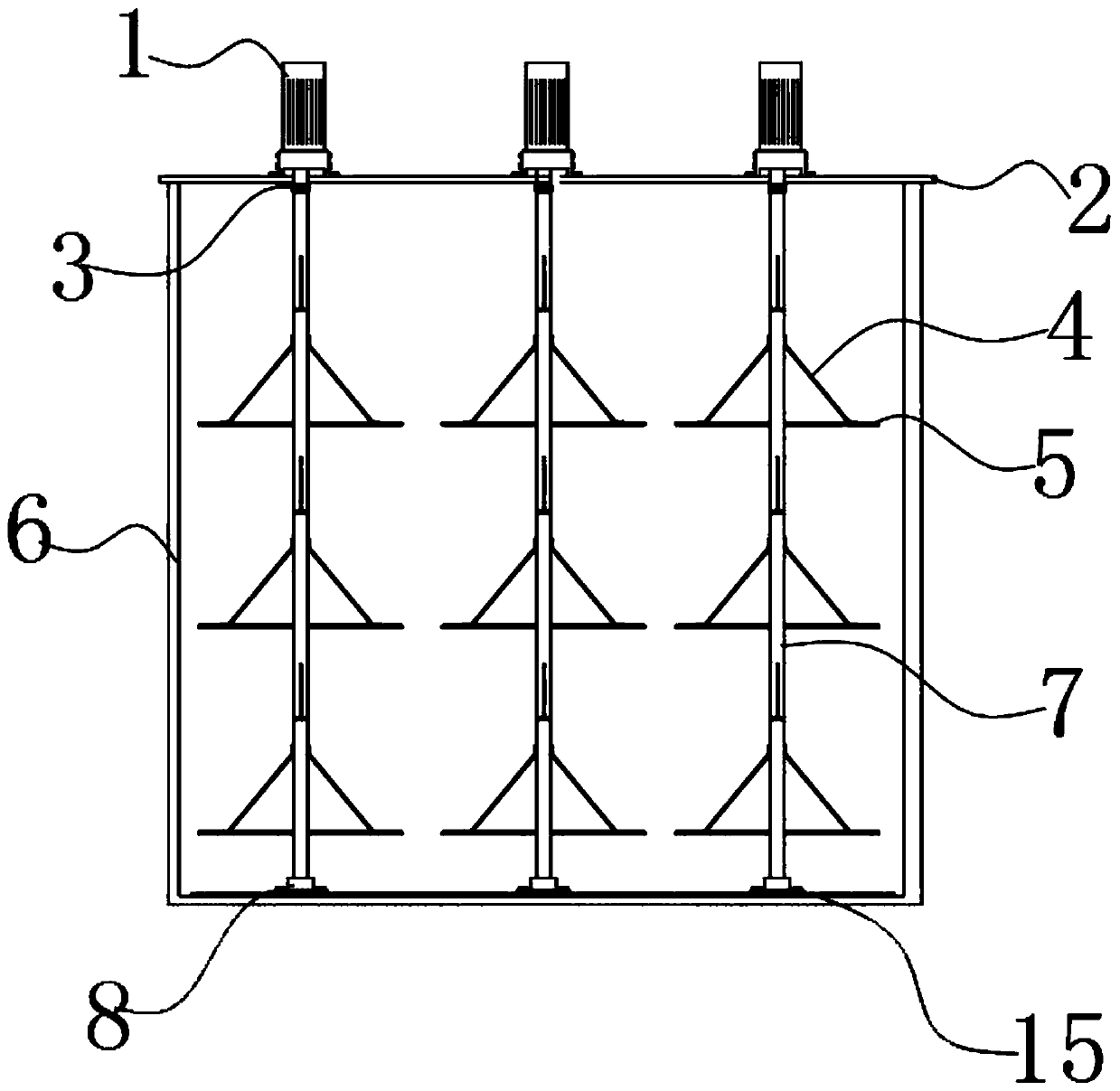

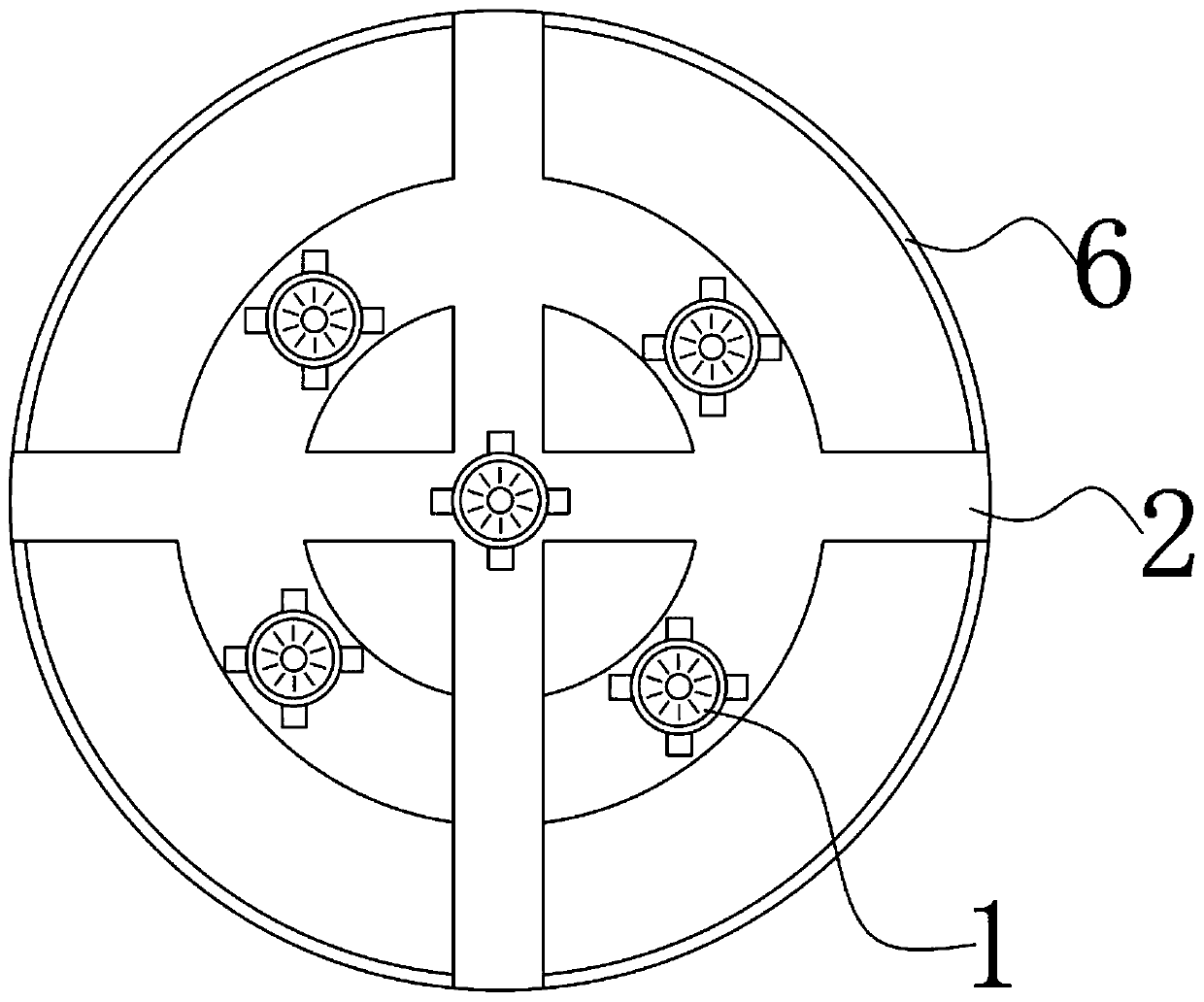

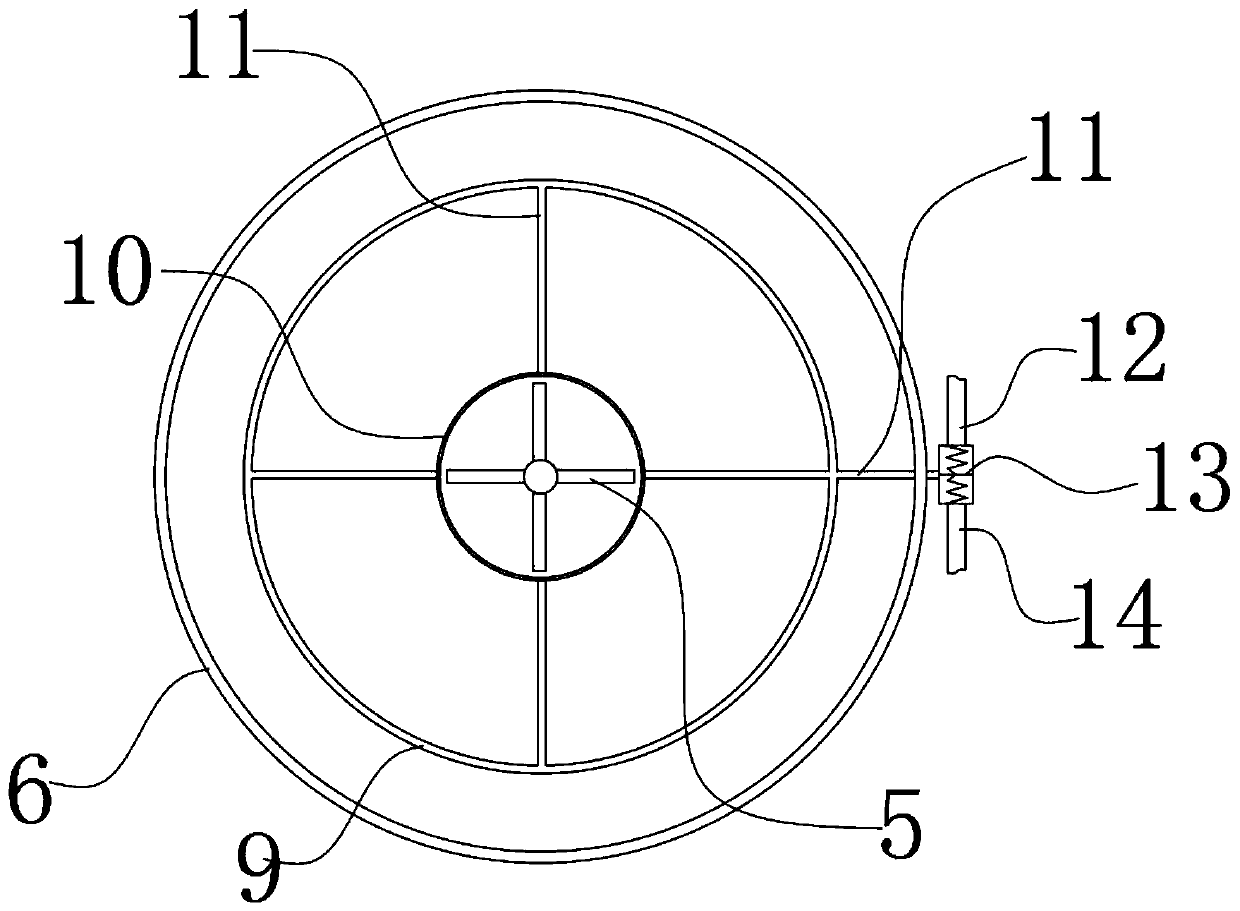

[0021] see Figure 1-4 , is a schematic diagram of the overall structure in one embodiment; it includes a mixing cylinder 6 made of cement and stones, a support frame 2 is built on the top of the mixing cylinder 6, and a motor 1 is installed on the top of the support frame 2, and the motor 1 has a total There are multiple, each motor 1 is connected to an independent shaft 7 at the bottom, the outer wall of each shaft 7 is provided with a stirring claw 5, and the bottom end of each shaft 7 is fixed on the base 8, There are a plurality of bases 8, and the bases 8 are evenly distributed on the bottom of the mixing cylinder 6, so that each stirring claw is driven by an independent motor, so that when the stirring claws start stirring, the force arm is shorter and the torque is smaller. When the stirring claws are stirred in the mixing barrel, the resistance of the material to the stirring claws is small. The bottom plate of the mixing barrel 6 has a pipe 15 to avoid material sedim...

Embodiment 2

[0024] see Figure 1-4 , is a schematic diagram of the overall structure in one embodiment; it includes a mixing cylinder 6 made of cement and stones, a support frame 2 is built on the top of the mixing cylinder 6, and a motor 1 is installed on the top of the support frame 2, and the motor 1 has a total There are multiple, each motor 1 is connected to an independent shaft 7 at the bottom, the outer wall of each shaft 7 is provided with a stirring claw 5, and the bottom end of each shaft 7 is fixed on the base 8, There are a plurality of bases 8, and the bases 8 are evenly distributed on the bottom of the mixing cylinder 6, so that each stirring claw is driven by an independent motor, so that when the stirring claws start stirring, the force arm is shorter and the torque is smaller. When the stirring claws are stirred in the mixing barrel, the resistance of the material to the stirring claws is small. The bottom plate of the mixing barrel 6 has a pipe 15 to avoid material sedim...

Embodiment 3

[0029] see Figure 1-4 , is a schematic diagram of the overall structure in one embodiment; it includes a mixing cylinder 6 made of cement and stones, a support frame 2 is built on the top of the mixing cylinder 6, and a motor 1 is installed on the top of the support frame 2, and the motor 1 has a total There are multiple, each motor 1 is connected to an independent shaft 7 at the bottom, the outer wall of each shaft 7 is provided with a stirring claw 5, and the bottom end of each shaft 7 is fixed on the base 8, There are a plurality of bases 8, and the bases 8 are evenly distributed on the bottom of the mixing cylinder 6, so that each stirring claw is driven by an independent motor, so that when the stirring claws start stirring, the force arm is shorter and the torque is smaller. When the stirring claws are stirred in the mixing barrel, the resistance of the material to the stirring claws is small. The bottom plate of the mixing barrel 6 has a pipe 15 to avoid material sedim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com