Novel efficient wet type electrical precipitator based on pulse power supply

A technology of wet electrostatic precipitator and high-voltage pulse power supply, which is applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problem that the peak value of electrostatic precipitator cannot meet the dust removal requirements, and achieve the purpose of suppressing back corona and increasing driving force. The effect of increasing speed and preventing back corona

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

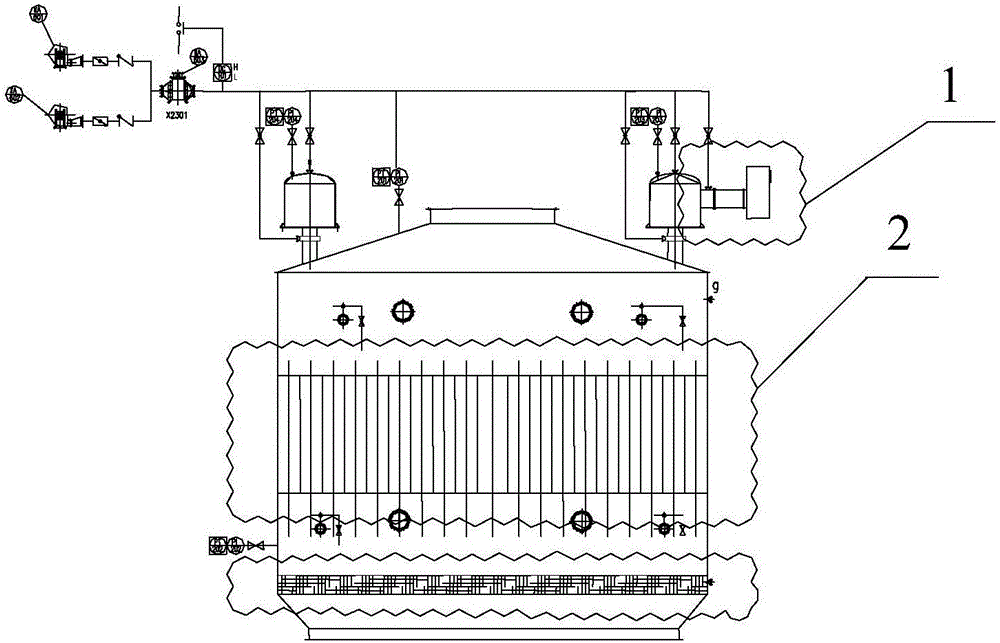

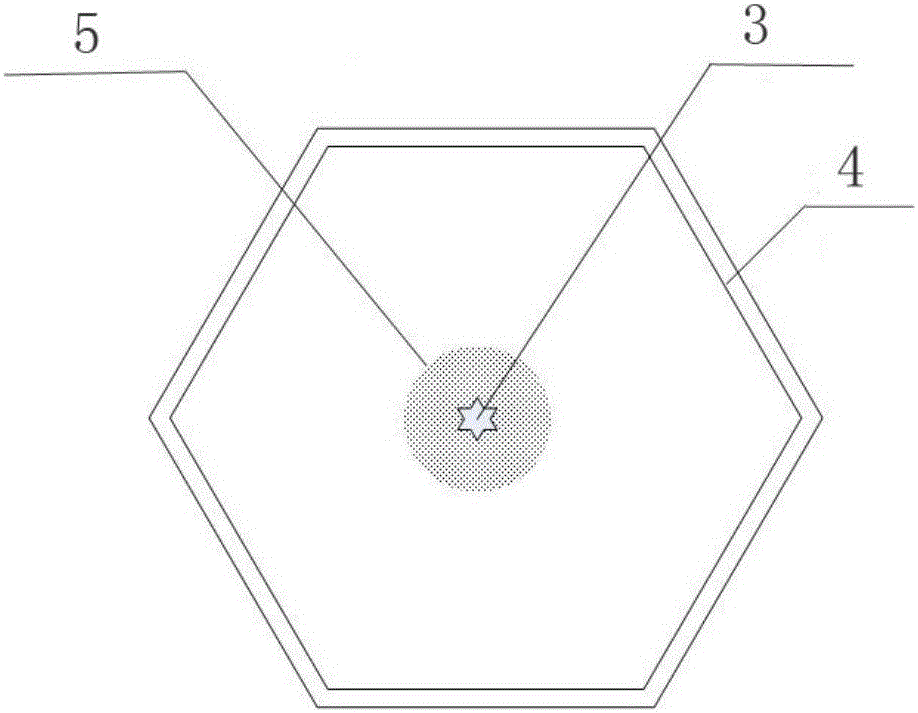

[0039] A new type of high-efficiency wet electrostatic precipitator based on pulse power supply. The wet electrostatic precipitator includes a regular hexagonal honeycomb conductive glass fiber reinforced plastic anode tube 4, a titanium electrode discharge wire 3 and a high-voltage pulse power supply device 1. The output terminal of the high-voltage pulse power supply device Connect the titanium electrode discharge line, input the high-voltage pulse power supply to the titanium electrode discharge line, the high-voltage pulse power supply is a high-voltage power supply integrated with the base voltage superimposed pulse voltage, and the titanium electrode discharge line is located in the center of the anode tube. The high-voltage pulse power supply generates corona discharge through titanium discharge wires.

[0040] The high-voltage pulse power supply is a high-voltage power supply integrated with base voltage superimposed pulse voltage, and the high-voltage pulse power suppl...

Embodiment 2

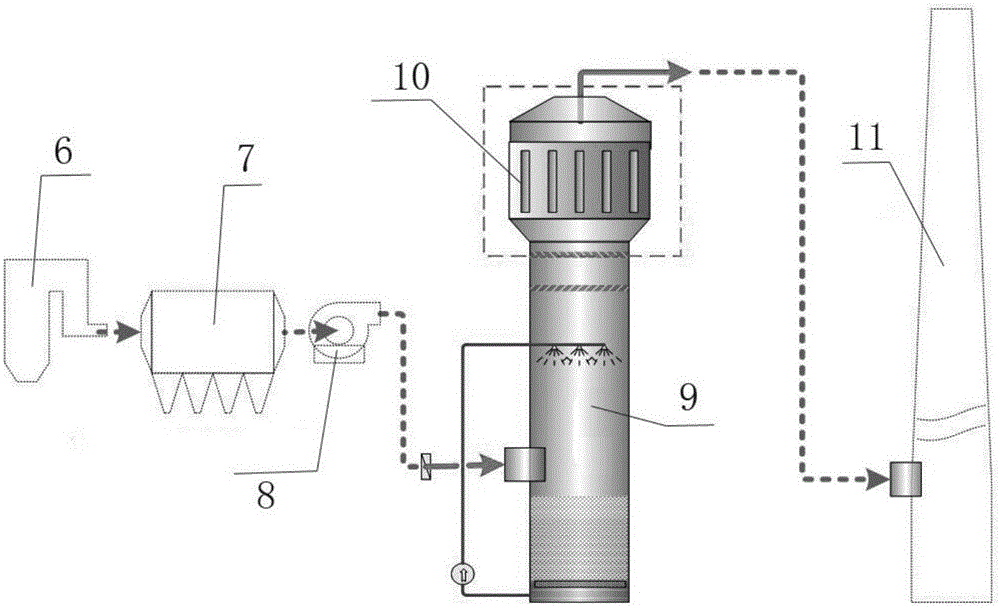

[0060] In the Power Division of Sinopec Baling Petrochemical Branch, the #1 boiler (220t / h) was implemented to carry out flue gas desulfurization treatment transformation. The transformation method and dust removal effect after transformation are shown in Table 1:

[0061] Table 1

[0062] Transformation method

[0063] From Example 1 and Example 2, it can be known that the superimposed voltage and the titanium electrode wire are applied to the wet electrostatic precipitator, the reasonable structural design of the titanium electrode discharge wire and the anode tube improves the dust removal efficiency, and the wet electrostatic precipitator can Reduce particulate matter emissions by more than 95%, and can reduce SO by more than 90% 3 Emissions can significantly reduce the turbidity of visible flue gas emitted by wet chimneys, which is forward-looking for mercury removal; effectively solve the technical problem of flue gas particulate matter reaching the standard or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com