Industrial vehicle

An industrial vehicle and main frame technology, applied in the field of automated machinery and equipment, can solve the problems of increasing product cost and assembly time, increasing the complexity of the body, and large body length and space, so as to improve the overall aesthetics and facilitate installation and removal Save labor and improve structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

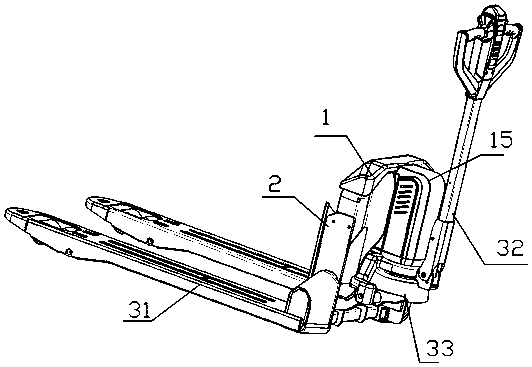

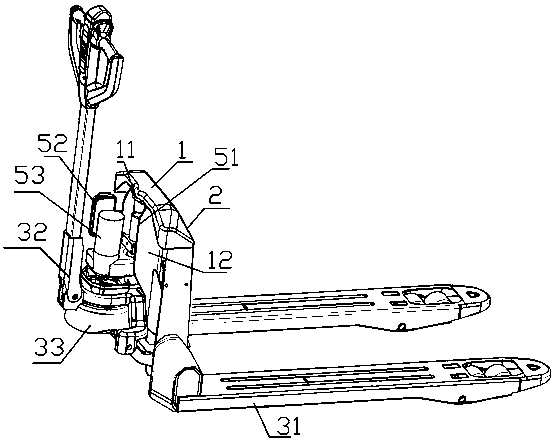

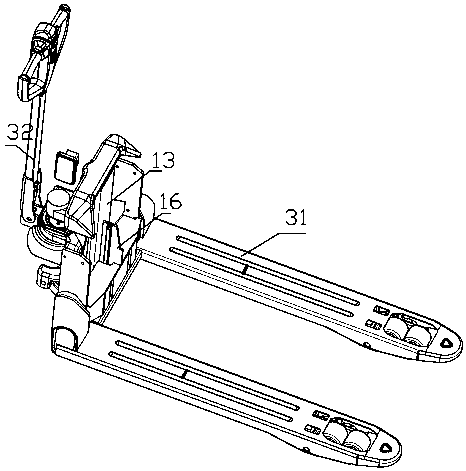

[0040] Example 1, such as figure 1 with figure 2 As shown, an industrial vehicle can be different types of vehicles such as forklifts, stackers, and sorting vehicles. The technical solution takes forklifts as an example. Including the main frame 2, the entire vehicle can be roughly divided into two assembly units, wherein, assembly A includes a handle 32 and a drive wheel assembly 33, and unlike the prior art, the handle 32 is directly connected to the drive wheel assembly 33, rather than through the pump station bracket or the main frame for connection.

[0041] The other, assembly B, includes the main frame 2 to which the uprights 1 are attached. Jacking device 51, battery box body 4, pumping station 53 and controller 52 are all in the part of this assembly B. Specifically, the jacking device 51 may use components such as oil cylinders, and the pump station 53 is used to supply oil to the jacking device. Both the pumping station 53 and the controller 52 can be fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com