Driving chain structure of wind generating set and wind driven generator comprising same

A technology for wind power generators and wind power generators, which is applied in the drive chain structure and wind power generator fields, and can solve the problem of increasing size, increasing the alternating gravity moment and fatigue alternating load of fan impellers, increasing manufacturing and transportation costs, etc. problem, achieve the effect of reducing bending moment, reducing fatigue alternating load and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

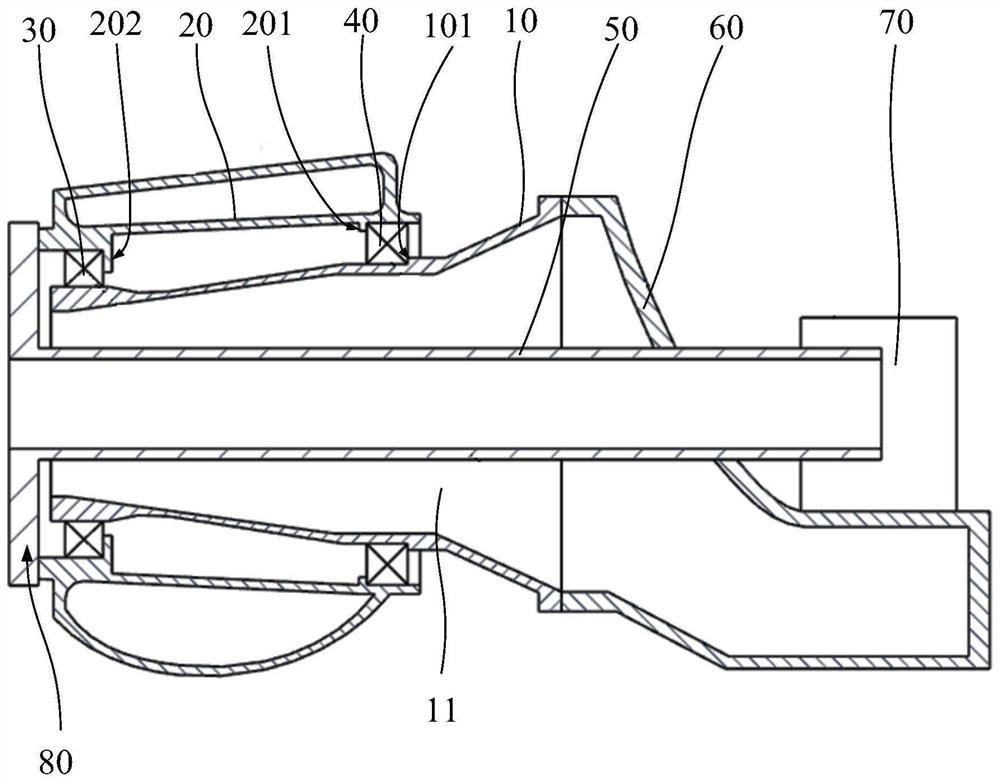

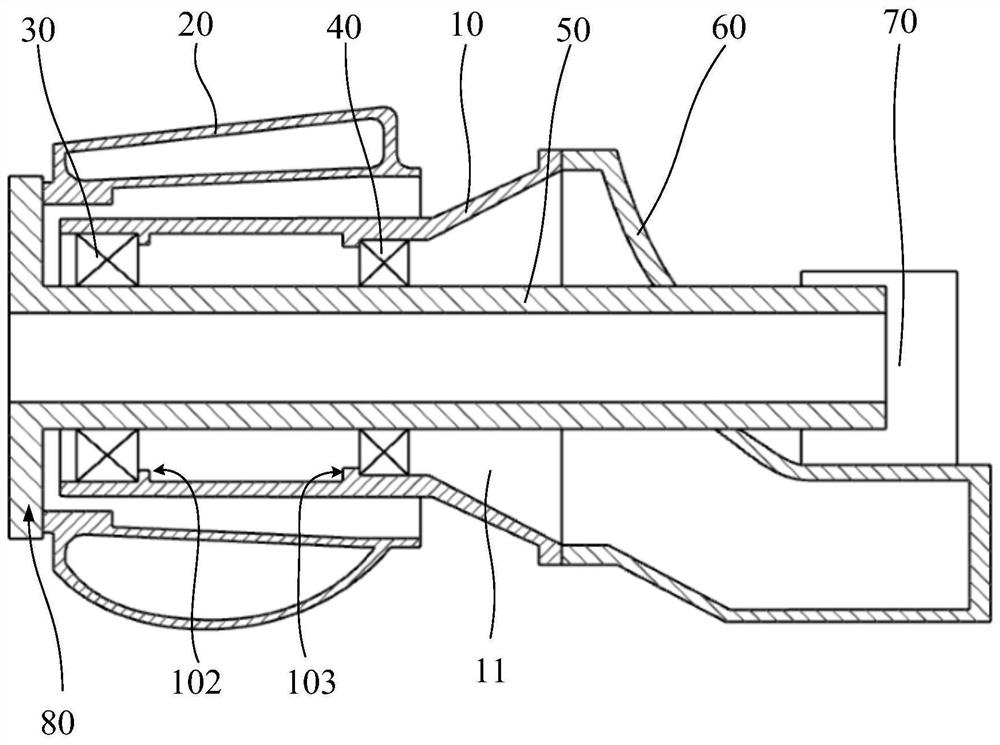

[0071] Such as image 3 As shown, the other structures of this embodiment and Embodiment 1 are substantially the same, the main difference is that: the inner ring portion of the front bearing 30 and the inner ring portion of the rear bearing 40 are both sleeved on the rotating shaft 50, and the outer ring portion of the front bearing 30 Both the outer ring portion of the portion and the rear bearing 40 are connected to the inner wall surface of the through hole 11 .

[0072] With the above structure, not only the bending moment of the fan impeller borne by the bearing is reduced, but also the alternating gravity moment of the fan impeller is shared by the bearing and the fixed shaft 10, and part of the alternating gravity moment of the fan impeller is shared by the fixed shaft 10, which can also reduce The size of the bearing reduces the production, transportation and installation costs of the bearing.

[0073] Such as image 3 As shown, in this embodiment, the inner wall su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com