Self-locking type drill chuck

A drill chuck and self-locking technology, applied in the field of self-locking drill chucks, can solve the problems of complex process, weakened anti-loosening, and the processing technology of the connection relationship between the nut and the nut sleeve is not disclosed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

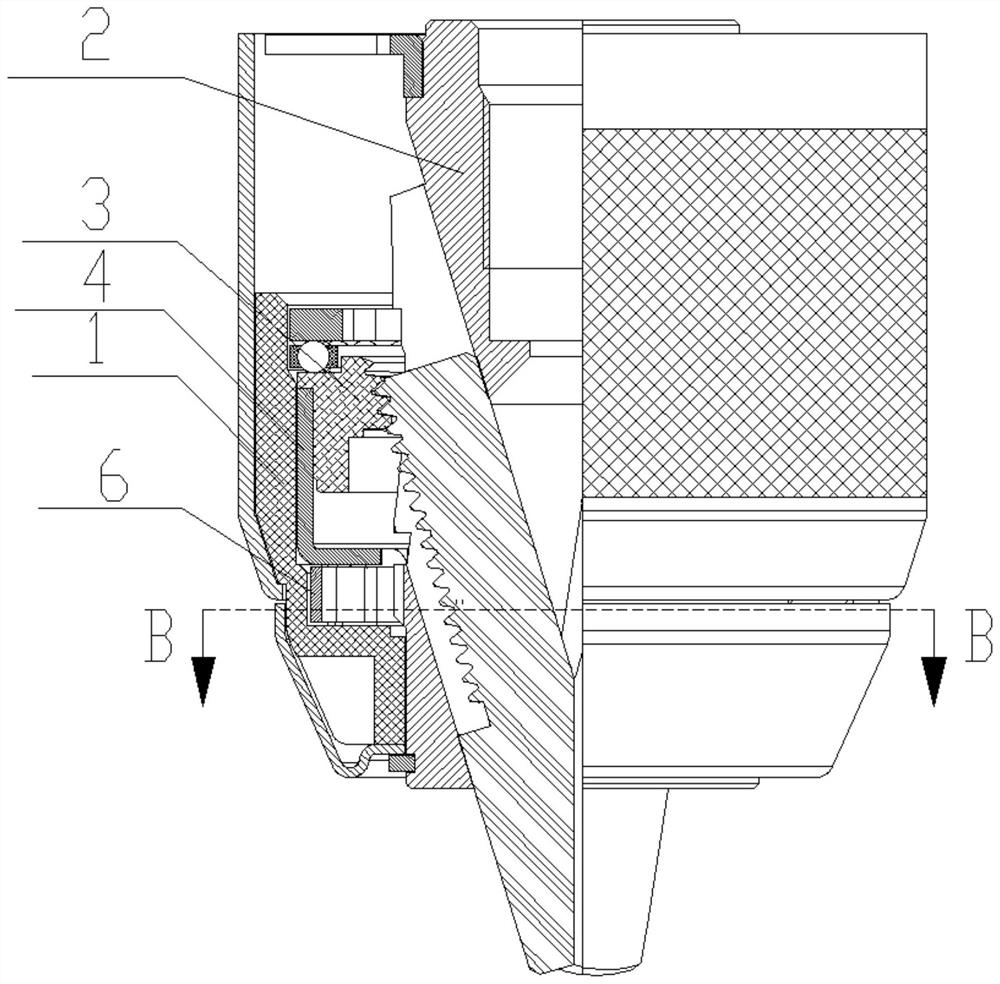

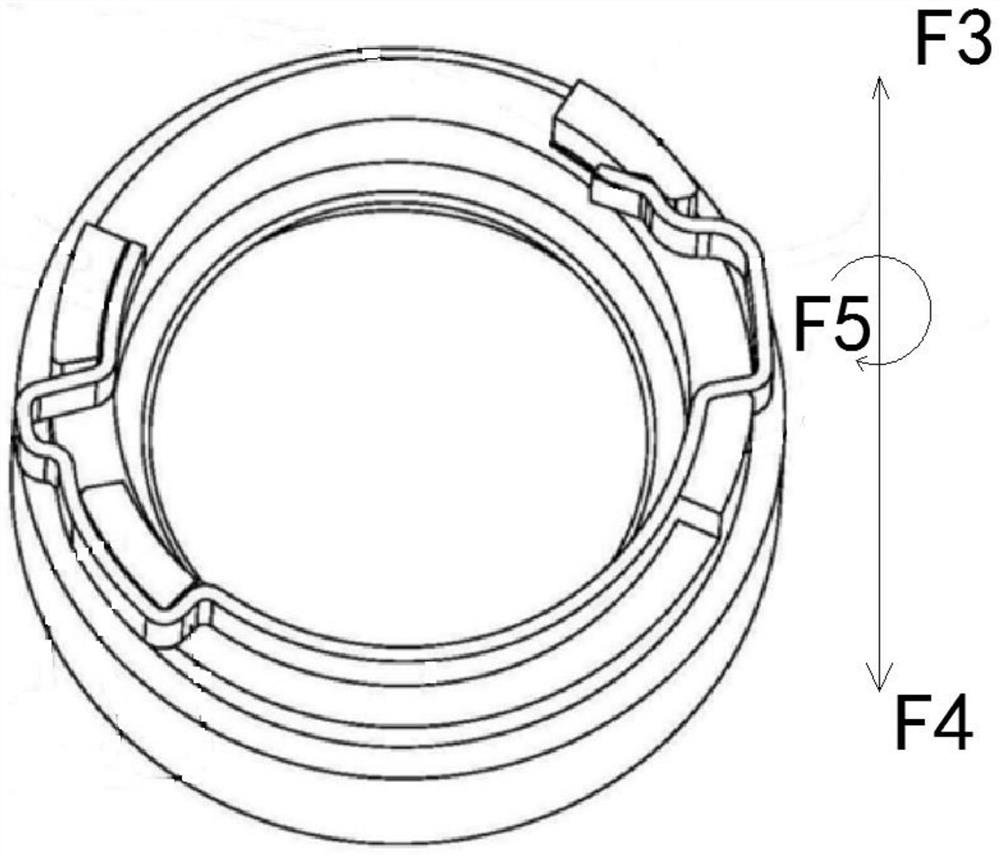

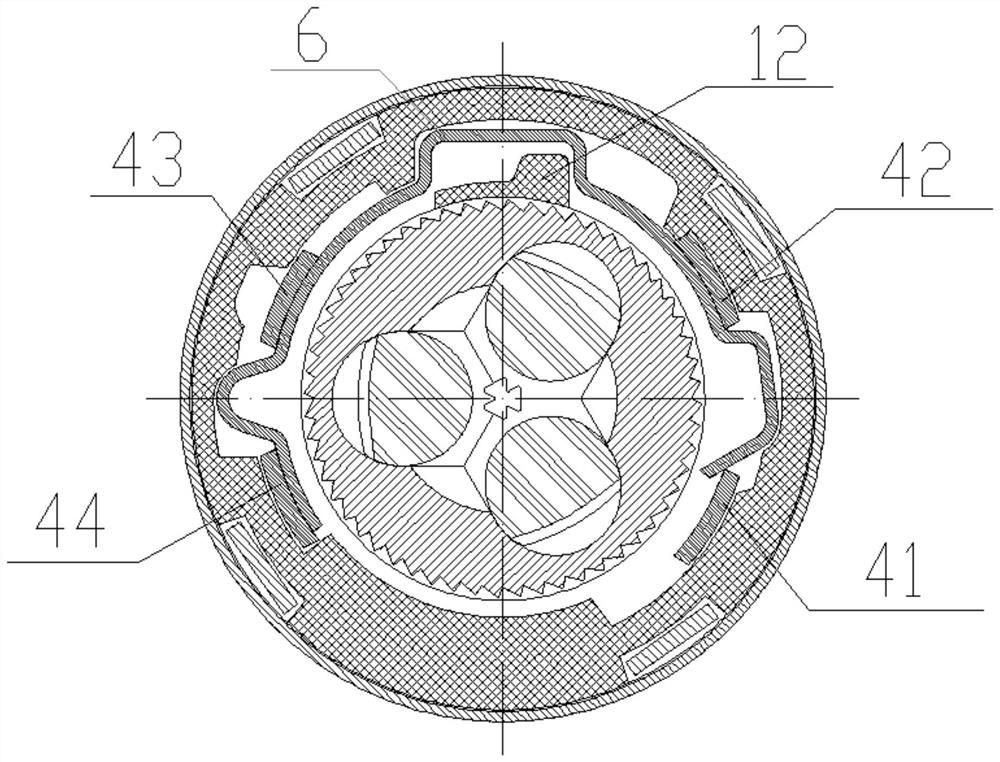

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 Shown: a self-locking drill chuck, including a rotating sleeve 1, a drill body 2, a nut 3, and a self-locking structure. The self-locking structure includes teeth 5 and shrapnel 6. The teeth 5 are on the drill body 2. The shrapnel 6 is located on the periphery of the tooth 5 and rotates synchronously with the nut 3. The first end (one end) of the shrapnel 6 is used as a lock end 61 matched with the tooth 5, and a pin is arranged near the second end 65 (the other end). The positioning protrusion 62, the rotating sleeve 1 has a cam structure that controls the locking end 61 of the elastic piece 6, and the rotating sleeve 1 also has a first part that is connected to the elastic piece 6 in the self-locking state and connected to the elastic piece in the non-self-locking state. 6 connected to the second part, the elastic piece 6 is provided with a lock end protrusion 63 that cooperates with the c...

Embodiment 2

[0047] In the above-mentioned embodiment, the rotating sleeve 1 and the housing 101 are separated, and can rotate together through clamping. Of course, as figure 1 , Figure 8 with Figure 9 As shown: the rotating sleeve 1, the shell 101 and the decorative cap 102 can also be integrally formed.

Embodiment 3

[0049] In the above embodiment, the positioning protrusion and the locking end protrusion are respectively limited between the first key and the second key, between the third key and the fourth key, of course, as figure 2 with Figure 12 Shown: the shrapnel can be inserted between the first key and the second key or between the third key and the fourth key.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com