Cable rack

A cable support and support technology, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problem of poor connection reliability between the support arm and the column, the support arm body is prone to breakage and damage, and the force structure is not strong. Reasonable and other issues, to achieve the effect of good reliability and safety, convenient storage, transportation, installation and maintenance, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

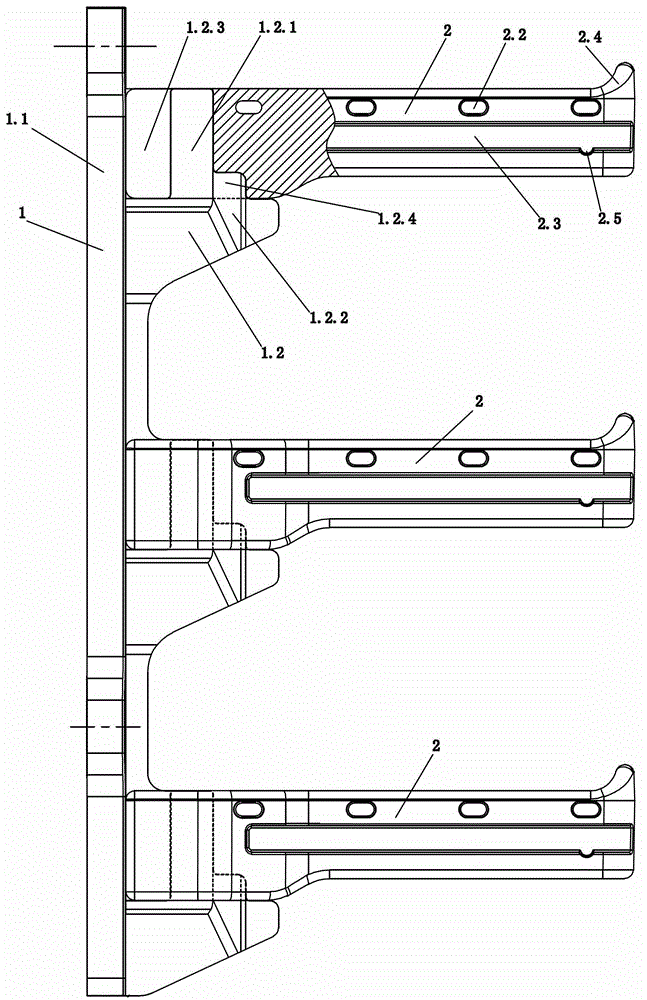

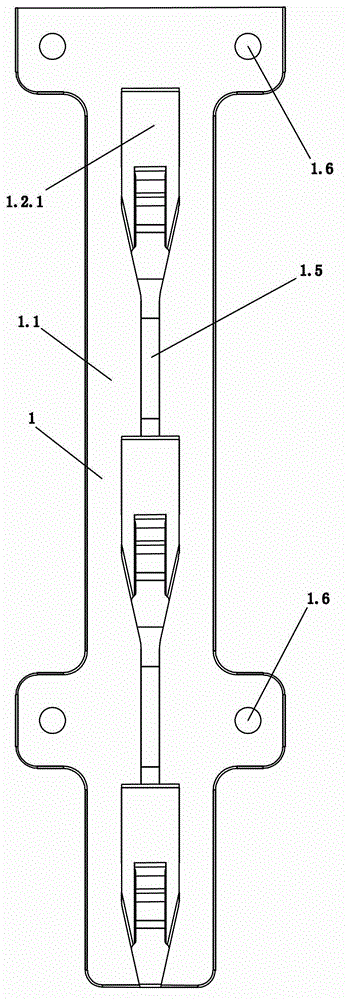

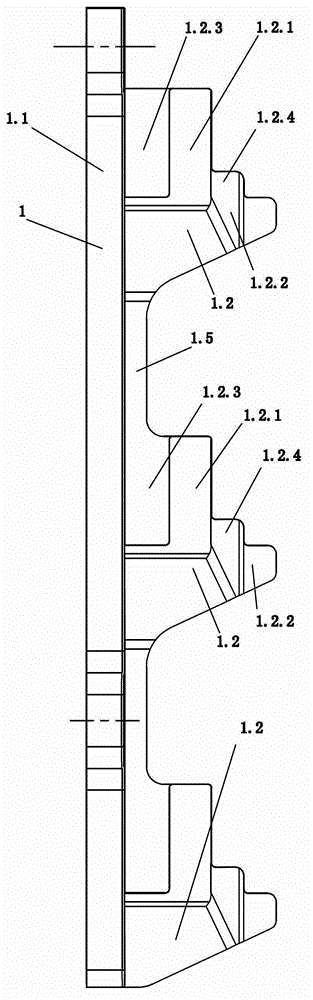

[0024] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. figure 1 In the figure, the front of the stand is on the left and the back of the stand is on the right.

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the present invention includes a column 1 and a support arm 2 both made of fiber-reinforced thermosetting polymer composite materials; There are a number of bracket arm support parts 1.2 protruding forward evenly on the front surface of the bracket arm support part 1.2. The middle part of the upper surface of the bracket arm support part 1.2 is provided with a bracket arm connecting column 1.2. There is a connecting column reinforcing rib 1.2.3; correspondingly, the rear end of the support arm 2 is provided with a socket hole, and the socket hole includes a socket hole main body 2.1 adapted to the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com