Tail plate folding type speed-regulating mechanism for wind power generator

A speed regulating mechanism and foldable technology, which is applied in wind turbines, wind turbine control, wind power generation, etc., can solve the problems of extending the lever arm and being easily damaged, and achieve the advantages of shortening the lever arm, prolonging the service life and reducing the torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

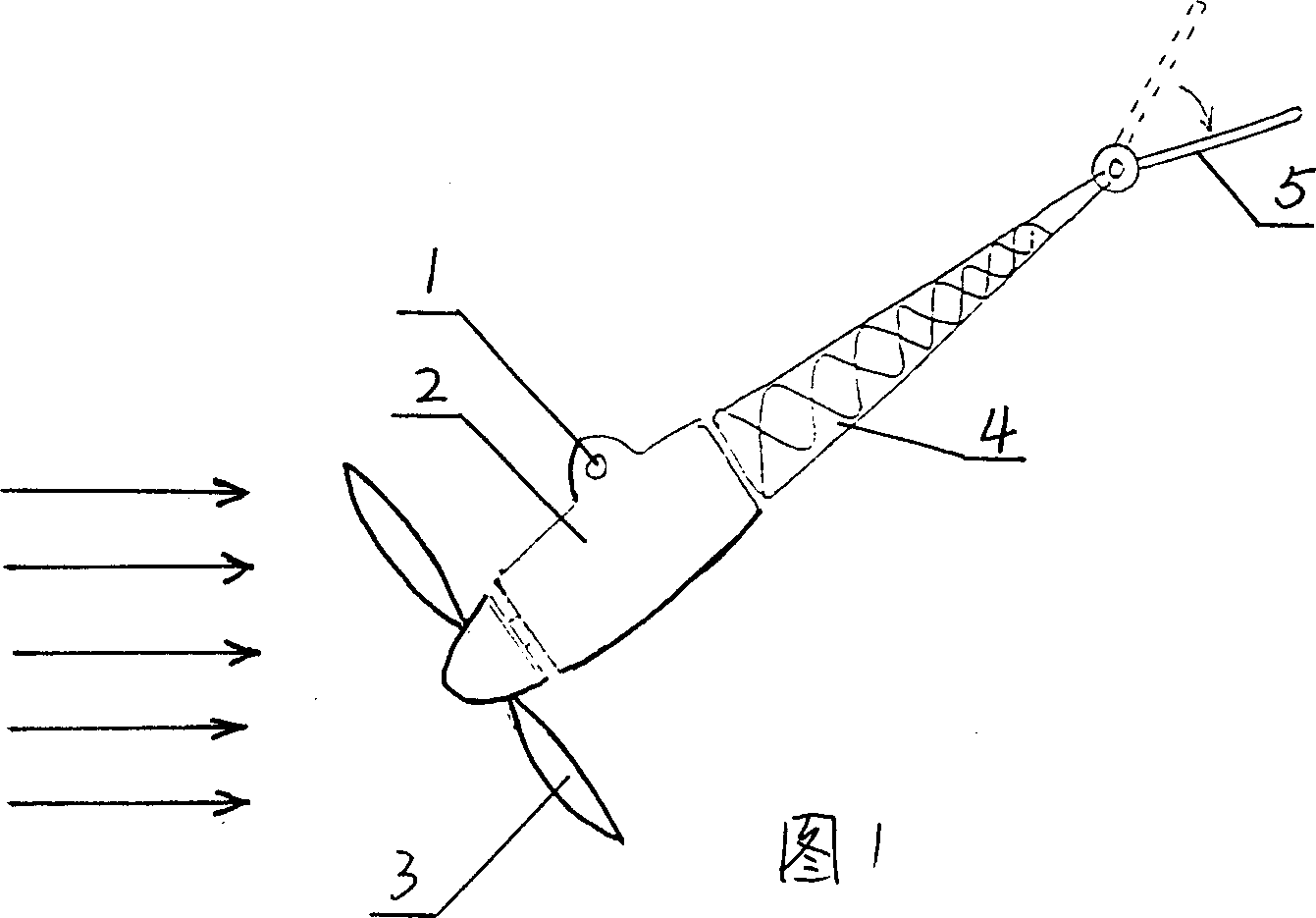

[0013] As shown in Fig. 1 , the wind power generator tail plate folding speed regulating mechanism according to the present invention includes a generator body 2 installed on the vertical shaft 1, a wind wheel 3 installed at the front end of the generator body 2, and a wind wheel 3 fixedly installed on the generator body. The tail bar 4 at the rear end of the body 2 and the tail plate 5 installed at the rear end of the tail bar 4 , the tail plate 5 is swingably connected to the rear end of the tail bar 4 .

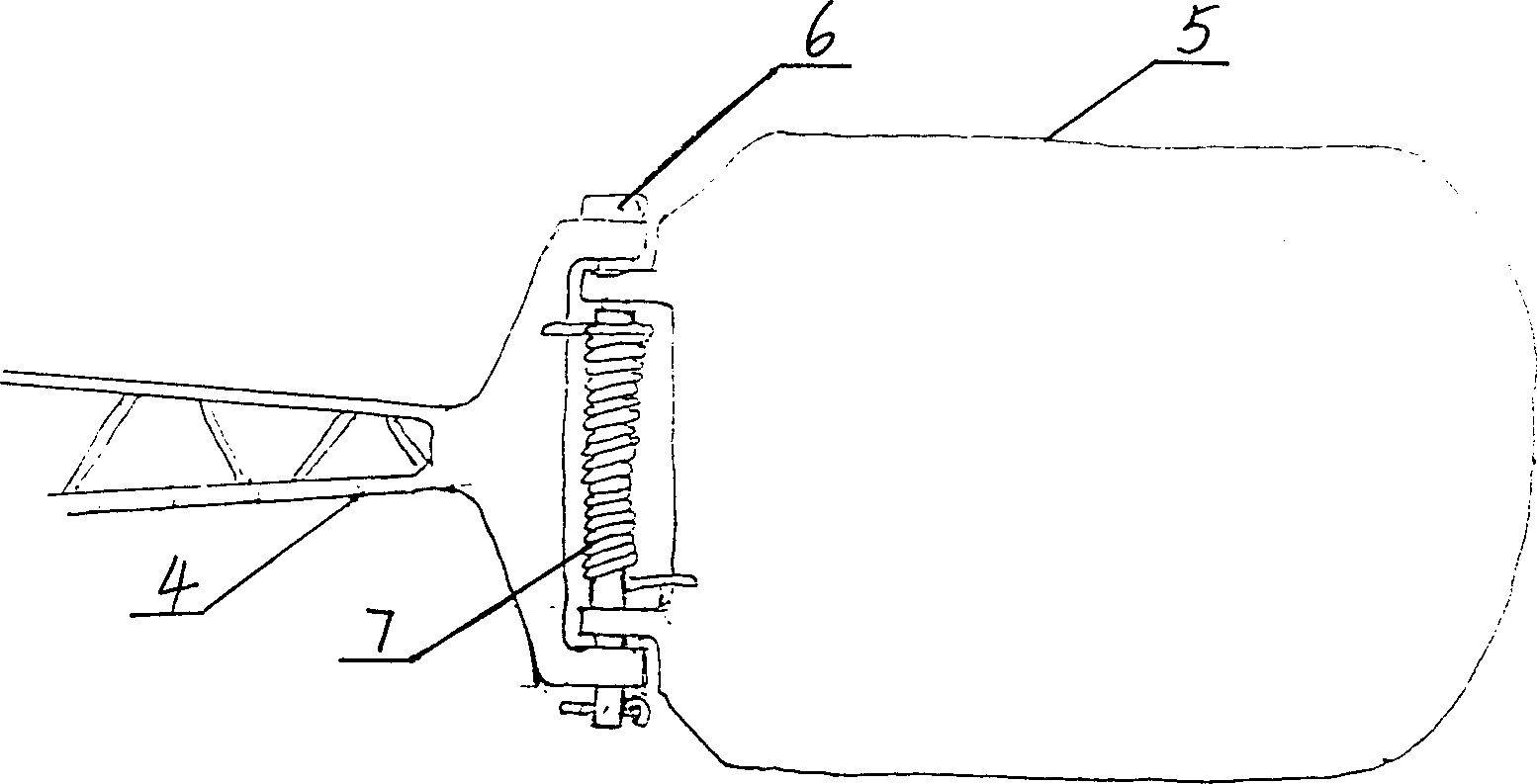

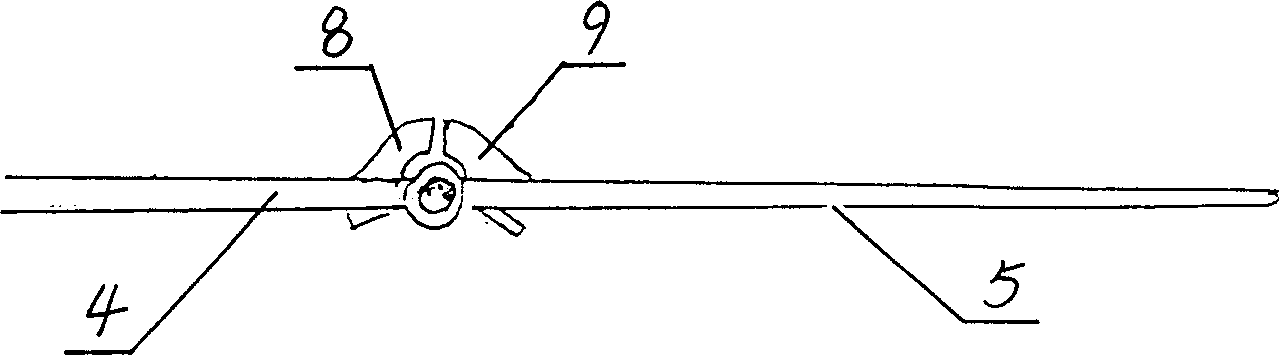

[0014] Such as figure 2 , image 3 As shown, the tail plate 5 is hinged to the rear end of the tail rod 4 through the hinge shaft 6, the hinge shaft 6 is provided with a torsion spring 7, the end of the tail rod 4 has a stop pin 8, and the corresponding position of the tail plate 5 front end has a stop pin 8. Moving block 9. When the wind was strong, the head of the generator turned to one side, and the tail plate 5 swung around the hinge shaft 6 against the power of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com