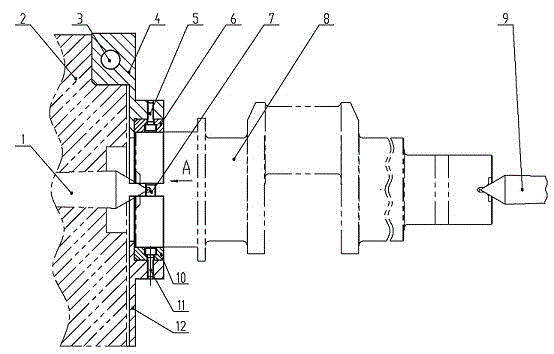

Driver plate for clamping crank shaft

A crankshaft and machine tool spindle technology, applied in the field of shaft parts clamping devices, can solve the problems of poor safety and reliability, small clamping range, unable to meet the needs of crankshaft processing, etc., and achieve reasonable structure, safe and reliable clamping, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

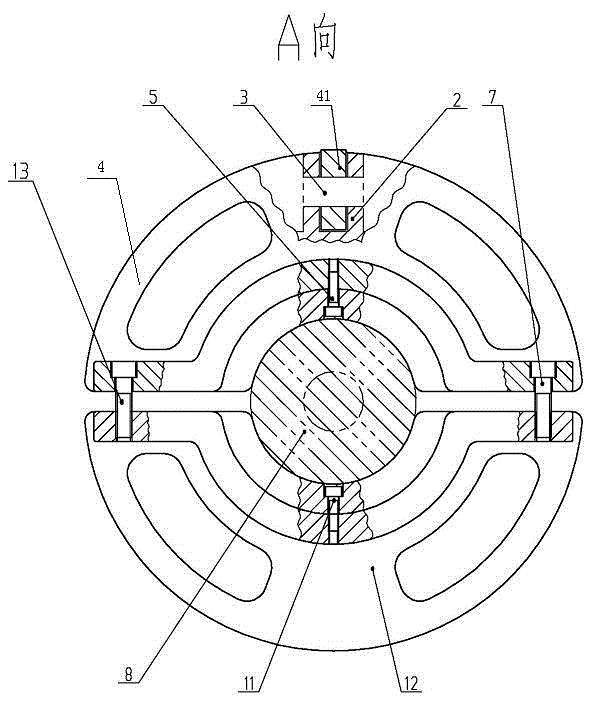

[0011] from figure 1 with figure 2 It can be seen that a crankshaft clamping dial includes a machine tool spindle 2 with a top 1 in the center, an upper shoe seat 4, a lower shoe seat 12, an upper slip 6 and a lower slip 10. A lug 41 is provided, and a pin hole is provided on the lug 41. A lug groove and a pin hole are provided on the outer edge of the end surface of the machine tool spindle 2. The upper tile seat 4 and the lower tile seat 12 are centered on the top 1 of the machine tool spindle. , installed symmetrically up and down on the end face of the machine tool spindle 2, the upper shoe lug 41 is correspondingly installed in the lug groove of the machine tool spindle, and the pin 3 passes through the pin hole on the lug 41 and the pin holes on both sides of the lug groove, The upper shoe seat 4 and the machine tool spindle 1 are connected and fixed by the pin 3; the two sides of the upper shoe seat 4 and the lower shoe seat 12 are connected together by the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com