Tensile fixture of round bar tensile sample

A technique for tensile specimens and fixtures, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of fixtures with high noise, high power consumption, and inability to install extensometers, and achieve the effect of safe clamping and convenient replacement of fixtures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

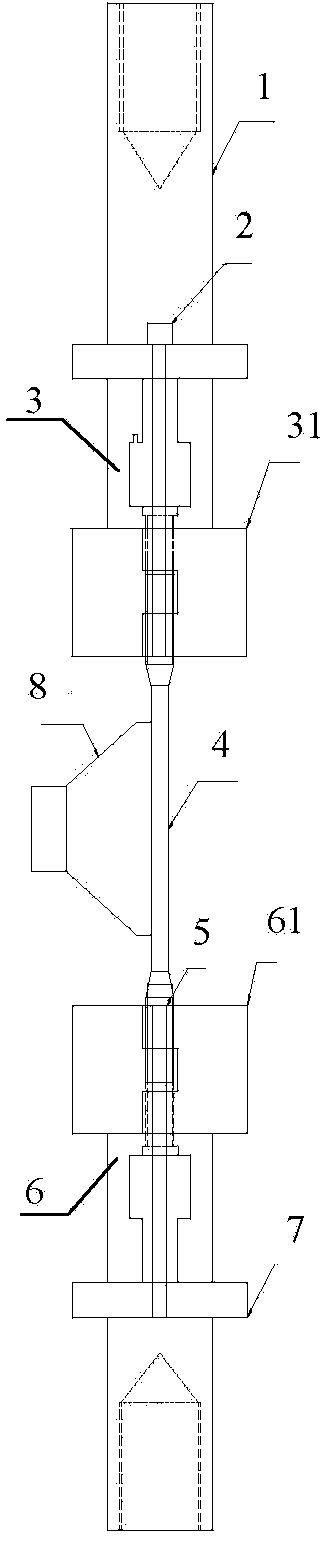

[0018] based on the following Figure 1 to Figure 7 , specifically explain the preferred embodiment of the present invention.

[0019] Such as figure 1 As shown, the present invention provides a tensile fixture for a round bar tensile sample, the fixture includes an upper connector 1 and a lower connector 7 connected to the testing machine respectively, and the fixture also includes an upper clamp 3 connected to the upper connector 1 , the upper clamp 3 has an upper clamp 31, the upper clamp 31 has an internal thread, the clamp also includes a lower clamp 6 connected to the lower connector 7, the lower clamp 6 includes a lower clamp 61, and the lower clamp 61 has an internal thread , the fixture also includes an upper pin 2 arranged in the upper chuck 31 and a lower pin 5 arranged in the lower chuck 61 .

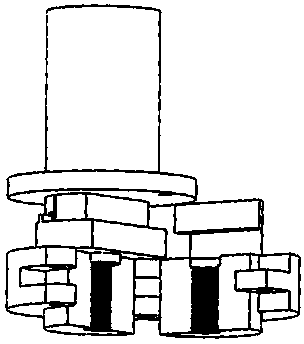

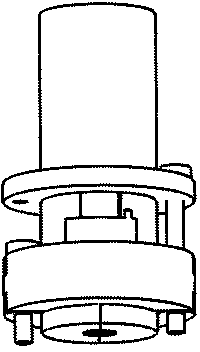

[0020] Such as figure 2 As shown, it is a schematic diagram of the open state of the upper clamp 3, such as image 3 As shown, it is a schematic diagram of the closed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com