A full degree of freedom restraint fixture for impact fatigue testing machine

An impact fatigue and testing machine technology, applied in impact testing, strength characteristics, testing of machine/structural components, etc. Small footprint, easy disassembly, and reliable sample clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

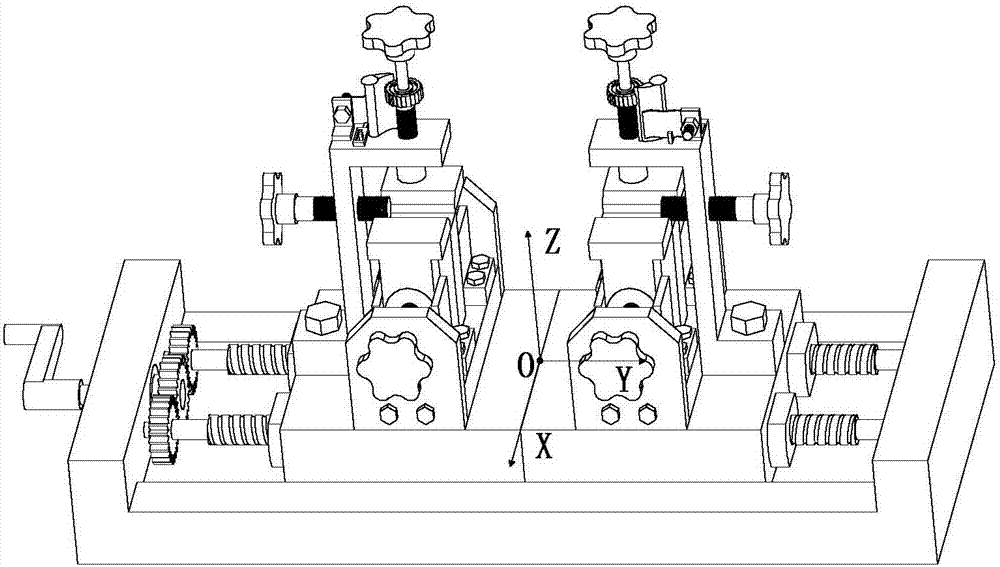

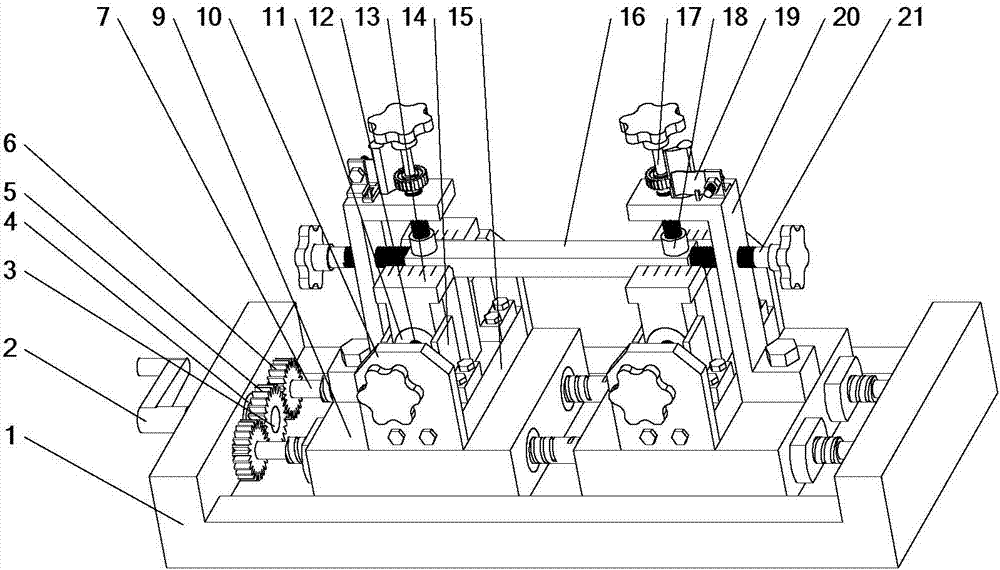

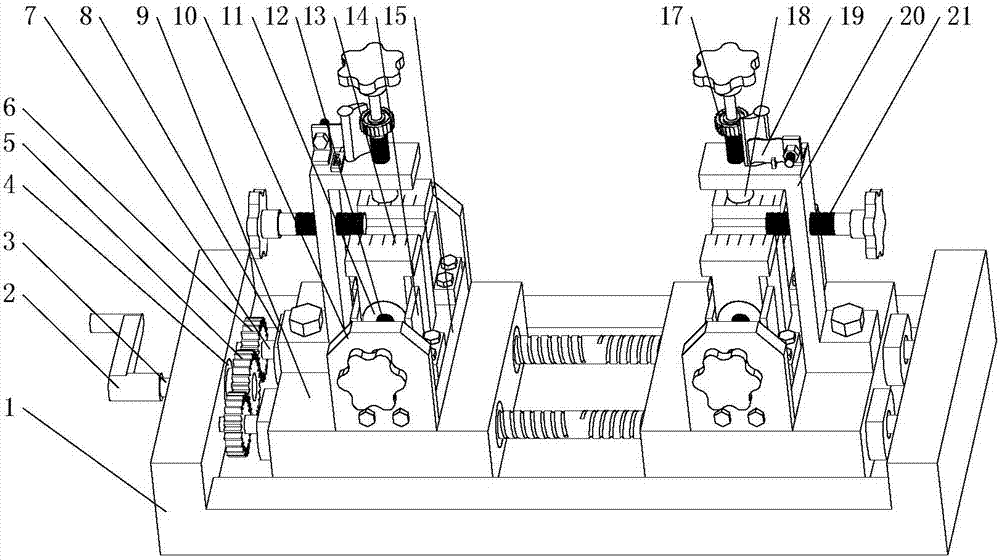

[0025] Such as figure 1 , 2 As shown in and 3, a full-degree-of-freedom restraint fixture for an impact fatigue testing machine is composed of a distance adjustment mechanism, an X-direction clamping mechanism, a Y-direction clamping mechanism, a Z-direction clamping mechanism, and a Z-direction clamping self-locking mechanism 19 composition. The distance adjustment mechanism is used to adjust the distance between the two sample support seats to adapt to samples of different lengths; the X-direction clamping mechanism, Y-direction clamping mechanism and Z-direction clamping mechanism are used to clamp the sample, and all the samples are restrained freely. Degree; Z-direction clamping self-locking mechanism is used to prevent the Z-direction clamping mechanism from loosening in the impact direction.

[0026] Such as Figure 4 and 5 As shown, the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com