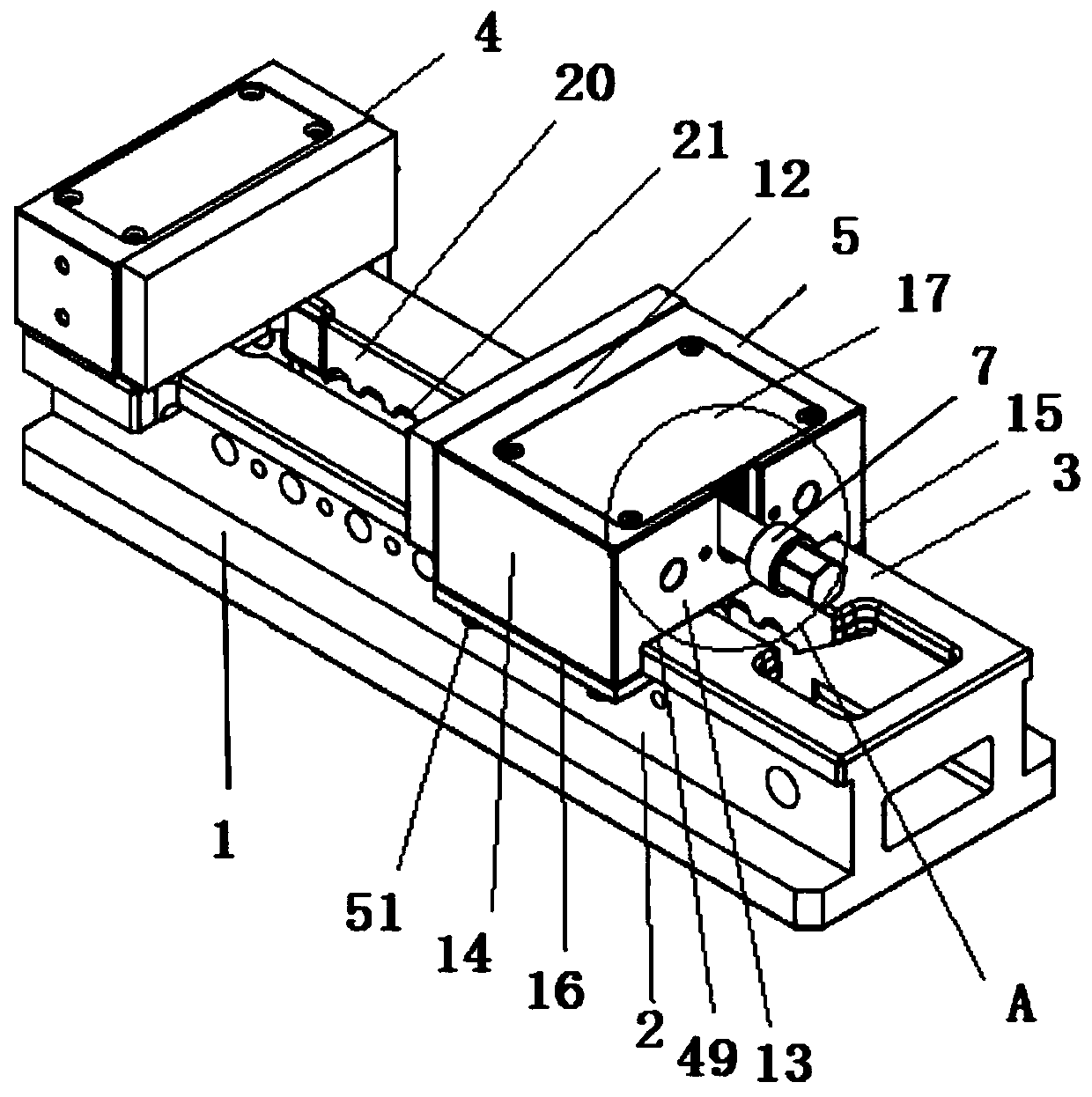

Quick clamping flat tongs

A kind of flat-nose pliers, fast technology, applied in the direction of clamping, supporting, positioning device, etc., can solve the problem of false clamping of workpiece, damage to workpiece and knife, take up large space, etc., to ensure smooth movement, improve processing accuracy, guarantee The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

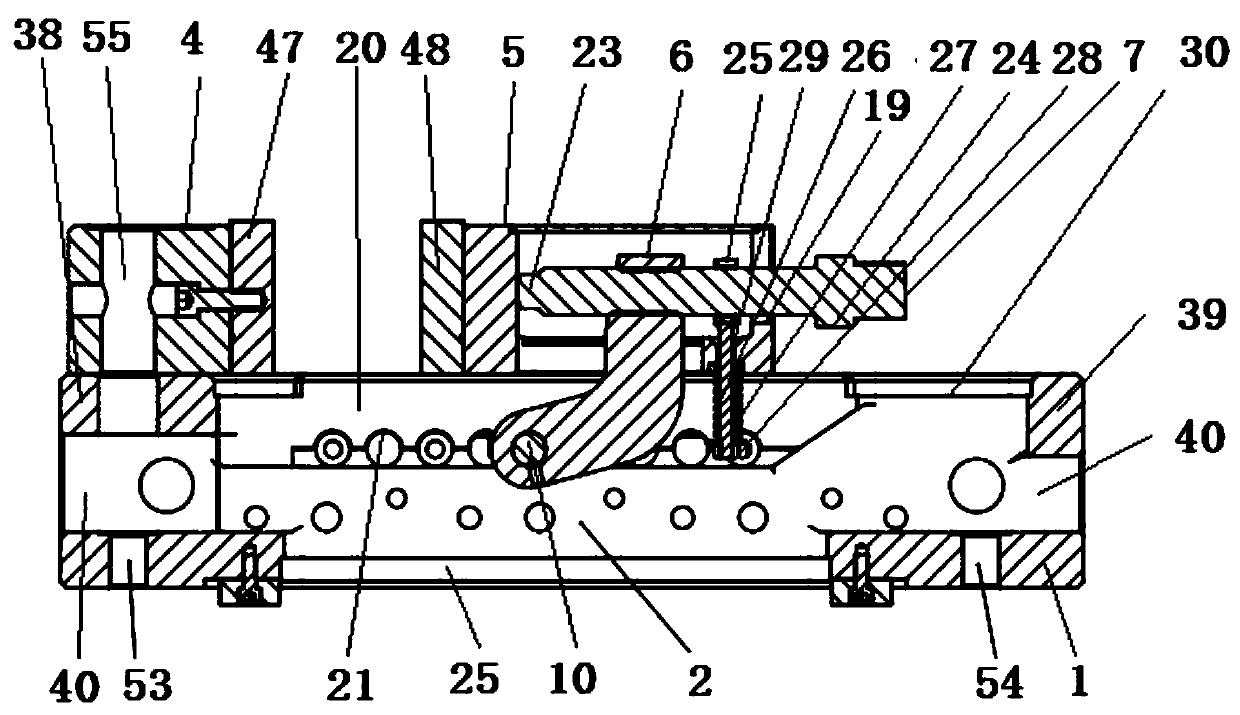

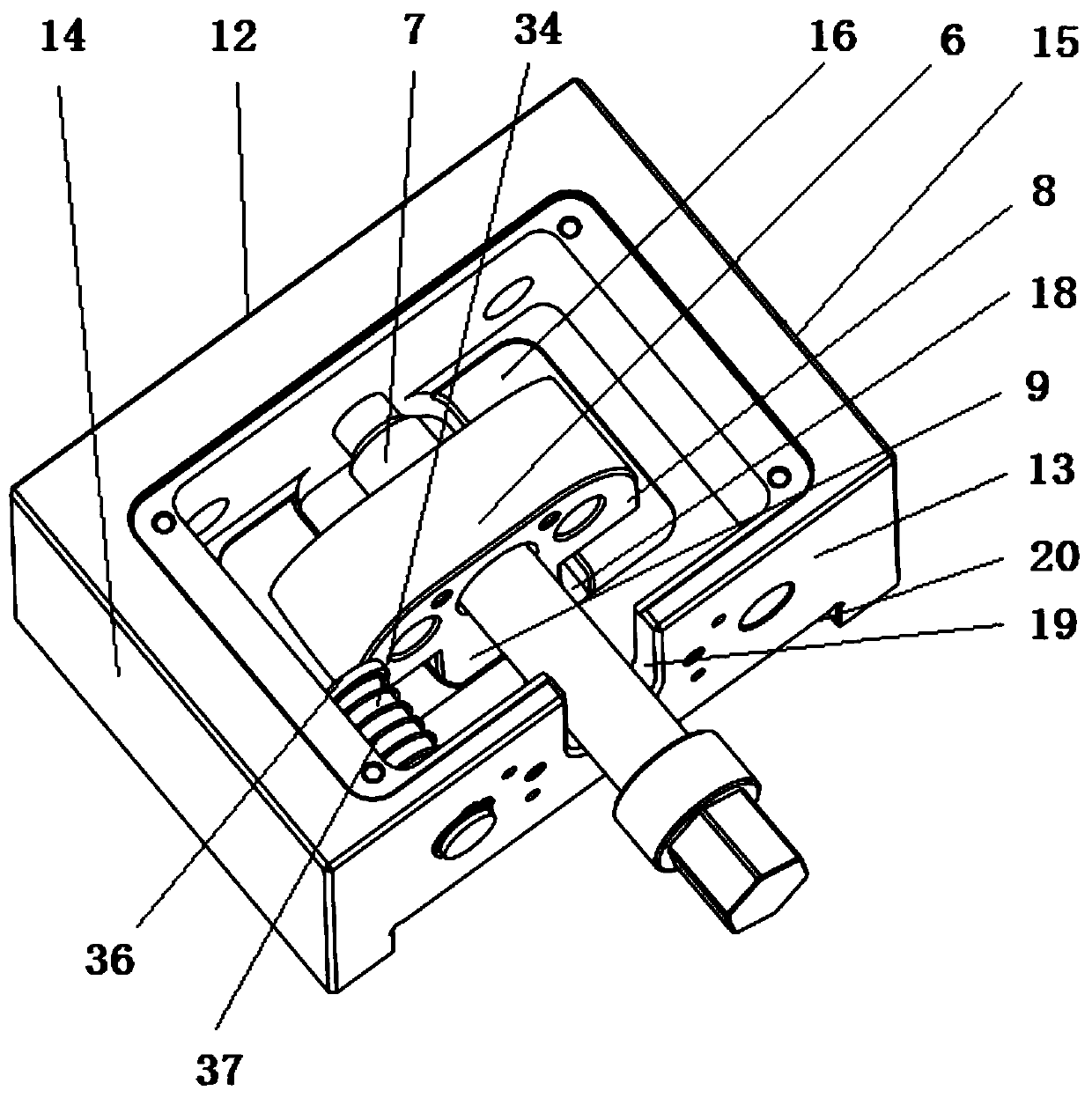

Embodiment 1

[0082] Embodiment 1: In the process of clamping square workpieces in the present invention, when workpieces of different specifications need to be clamped and the distance between the movable jaw and the fixed jaw needs to be adjusted at a large distance, the operator holds the handle section at one end of the clamping screw , lift the clamping screw, so that the clamping screw drives the hook pin to leave the slot, and then push the movable jaw, the movable jaw quickly moves to the side of the workpiece along the slide rail, and pushes the workpiece through the clamping surface of the movable jaw Lean against the clamping surface of the fixed jaw, then press down and release the clamping screw, the clamping nut rotates smoothly with the arc surface of the bottom surface of the support arm in contact with the horizontal bottom surface, so that the clamping screw is reset on the screw Under the action of the device, it returns to the movable channel of the screw. At the same tim...

Embodiment 2

[0083] Embodiment 2: When using the flat-nose pliers to clamp the workpiece upright on the machine tool, the front end of the fixed jaw of the flat-nose pliers can be used as the positioning reference plane and quickly positioned by the spacer, and then the base is fixed on the vertical surface of the workbench. When clamping the workpiece, the operator holds the handle section at one end of the clamping screw, and lifts the clamping screw outward, so that the clamping screw drives the hook pin to leave the slot, and then under the action of gravity of the movable jaw, along the The slide rail quickly moves to the side of the workpiece, so that the movable jaw pushes the workpiece against the clamping surface of the fixed jaw and the movable jaw, and then pushes the clamping screw into the movable channel of the screw, and the hook pin is on the tension spring Under the action of the screw, it tightly leans against the card slot. At the same time, the clamping screw is reset to...

Embodiment 3

[0084] Embodiment 3: When the workpiece is clamped on the machine tool side by using the vise pliers, the support column can be fixed on the side wall of the slide rail through the connecting screw according to the need, and the outer end surface of the fixed support column and the side of the base are in the On the same positioning reference plane, if it is necessary to increase the adsorption area between the vise and the magnetic template of the workbench during side installation, the support column can be changed into a support pad and fixed on the side wall of the slide rail to ensure that the vise can stand sideways safely and stably. The surface is used as a positioning and ready to be adsorbed on the magnetic template; then, use a tool to penetrate the hole through the tool to screw the screw into the front to hide the through hole and then connect it with the vertical surface of the worktable, and then use the screw to screw in and hide the through hole It is fixedly t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com