Fixture for detecting errors of transmission wave surface of large-sized neodymium glass plate

An error detection and neodymium glass technology is applied in the field of clamping devices for error detection of large-size neodymium glass sheets transmitted wavefront, and achieves the effects of convenient angle adjustment, safe clamping, and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

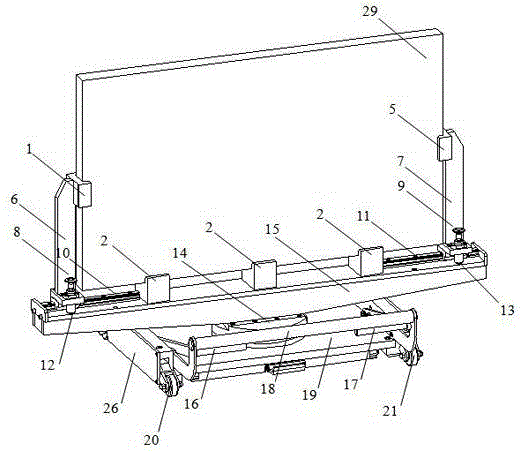

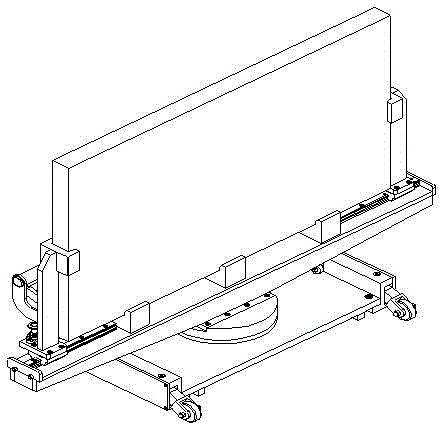

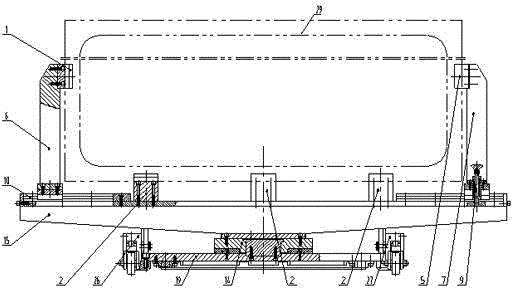

[0029]A large-size neodymium glass plate transmission wavefront error detection fixture includes a base 19, a base turntable 14 is arranged on the top surface of the base 19, and the base turntable 14 can rotate freely on the base 19. The connection mode between the base 19 and the base turntable 14 is: the base 19 and the connection pins above the base 19 are fixedly connected by screws, the base turntable 14 is sleeved on the connection pins and positioned by the shoulders of the connection pins, and the base turntable 14 The aperture is slightly larger than the diameter of the connecting pin, so the base rotating disk 14 can rotate freely around the axis of the connecting pin. In addition, a thrust bearing can also be set between the base rotating disk 14 and the base 19, and the distance between the two can be moved by the thrust bearing. The surface contact is changed to rolling contact, which effectively reduces the friction between the base turntable 14 and the base 19 ,...

Embodiment 2

[0032] On the basis of Embodiment 1, a number of left limit holes 12 are provided on the support frame 15 near the end of the I-shaped left slide rail 10, and some left limit holes 12 are located on the same side of the I-shaped left slide rail 10. The limiting holes 12 are arranged along the length direction of the I-shaped left slide rail 10 . One end near the right slide rail 11 of the I-type on the bracing frame 15 is provided with some right limit holes 13, and some right limit holes 13 are positioned at the same side of the I-type right slide rail 11, and some right limit holes 13 are along the right side of the I-type. The lengthwise direction of the slide rails 11 is arranged. Left support arm 6 bottom is connected with left screw rod 8, and the outer diameter of left screw rod 8 is compatible with the inner diameter of left limit hole 12, when needing to move left support arm 6, lift left screw rod 8 to make left screw rod 8 stop from the left Break away from the hol...

Embodiment 3

[0035] On the basis of the first or second embodiment, the two sides of the base 19 are also provided with traveling mechanisms. This walking mechanism comprises left lifting roller cover 26, right lifting roller cover 27, left lifting roller 20, right lifting roller 21, handle 18, left lever 16 and right lever 17. The left lifting roller cover 26 is fixedly connected to the left side of the base 19, and the right lifting roller cover 27 is fixedly connected to the right side of the base 19. The central position of left lifting roller cover 26 and right lifting roller cover 27 all offers the rectangular through hole that is used to place lifting roller, makes left lifting roller cover 26 and right lifting roller cover 27 form " back " font structure. The left lifting roller 20 is placed in the rectangular through hole of the left lifting roller cover 26, the left lifting roller 20 can move up and down along the height direction of the left lifting roller cover 26, and the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com