Fixture for turning thin aluminum valve plate

A technology for processing thin plates and aluminum valve plates, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. It can solve the problems of difficult control, valve plates exceeding the error range, product bending deformation, etc., to achieve compact design, reduce Overhang length, the effect of increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

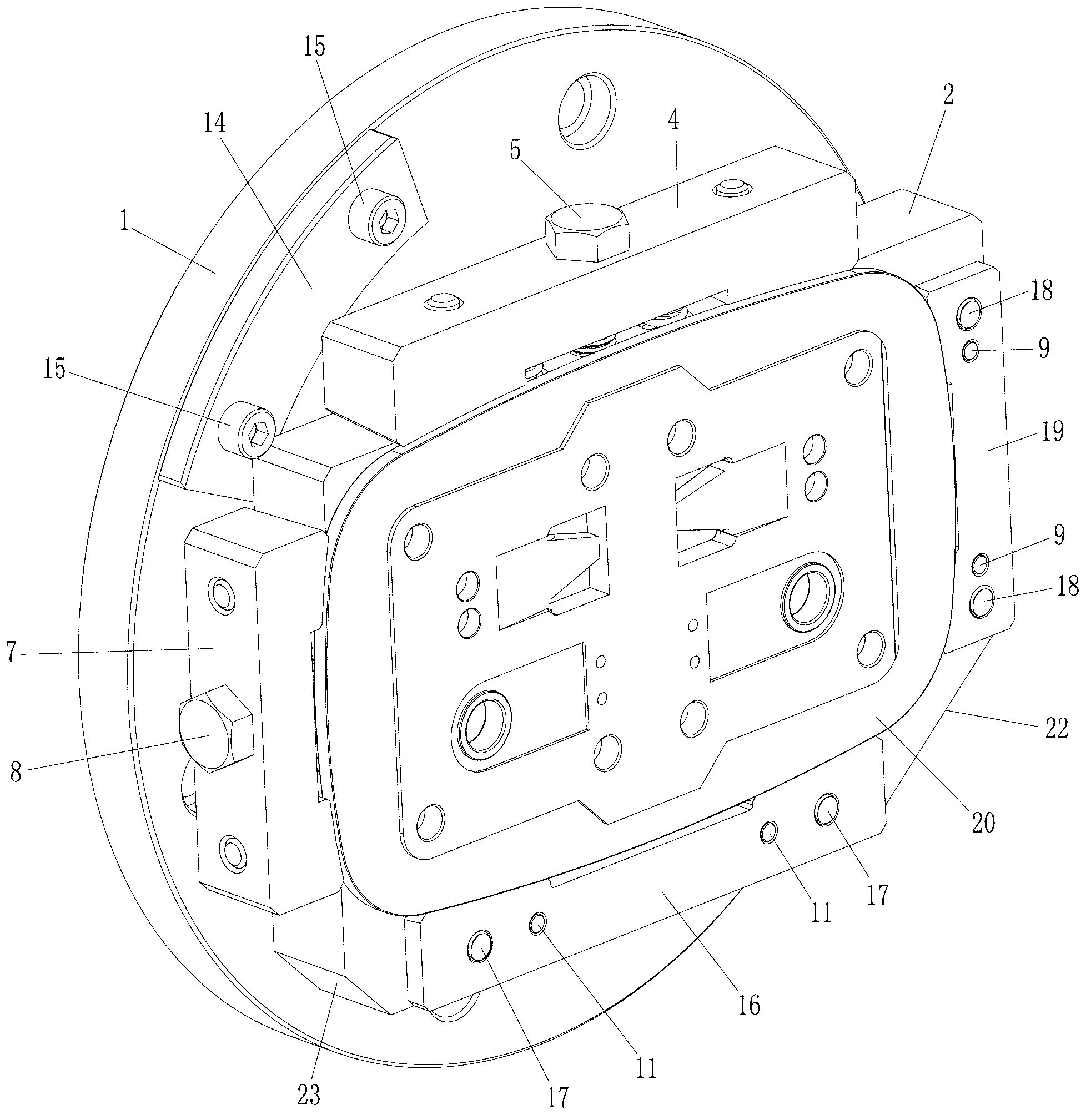

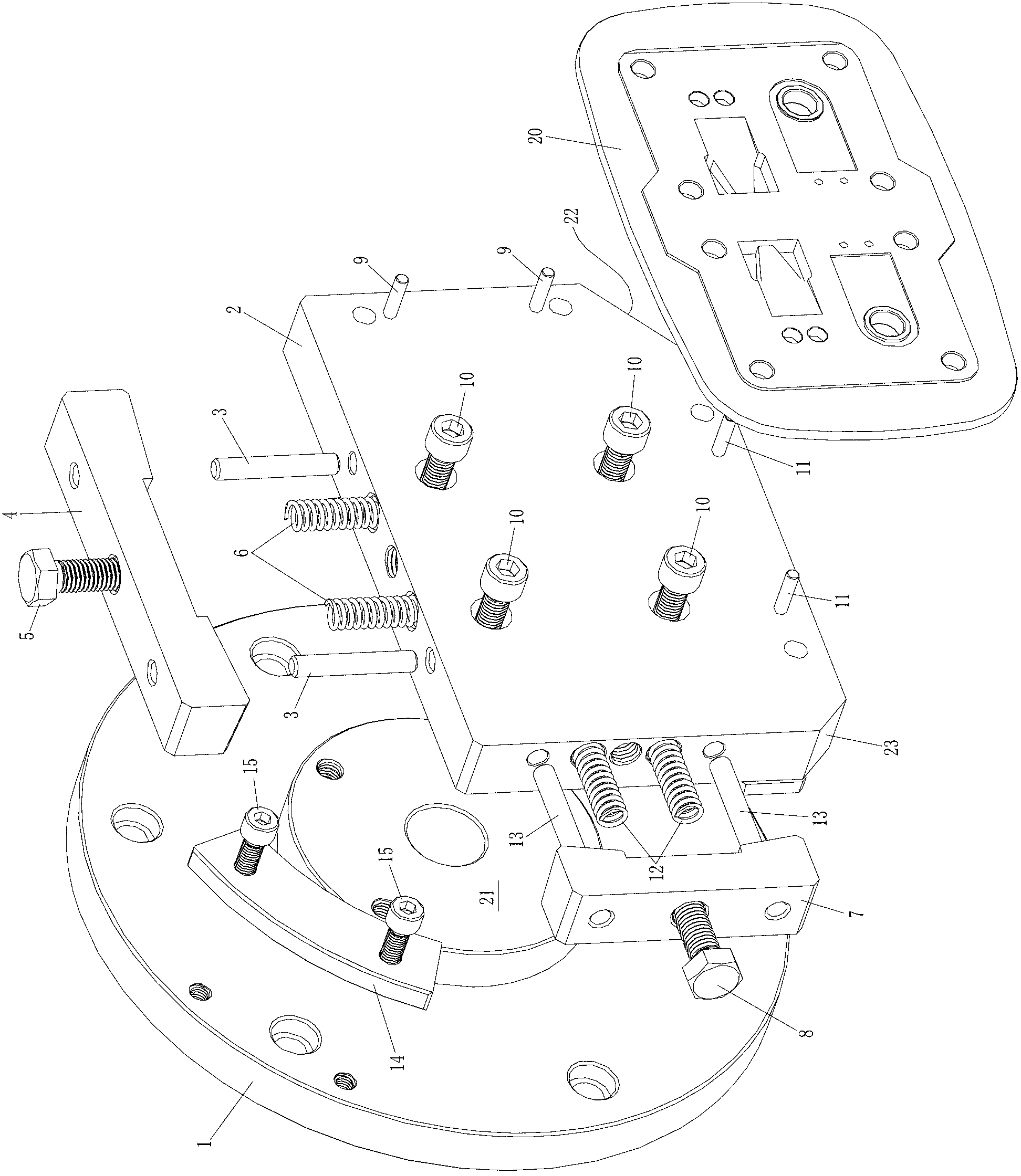

[0014] Example: see figure 1 and figure 2 , the present invention is connected to the main shaft of the CNC lathe via the flange chassis 1, the flange chassis 1 is universally matched with the three-jaw chuck flange of the CNC lathe, the material is HT200, and the positioning seam tire 21 of the flange chassis 1 is passed through four M10 inner hexagonal main board fixing screws 10 are connected and fixed with the rectangular valve plate positioning main board 2. The positioning plane of the valve plate positioning main board 2 is perpendicular to the center line of the lathe spindle. The positioning plane of the valve plate positioning main board 2 is flattened by turning with a turning tool, and it is not necessary to level the positioning plane in the future to ensure the perpendicularity of the positioning plane and the spindle of the CNC lathe. The valve plate positioning main board 2 deviates from the center of the flange chassis 1 downwards and to the right. The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com