Multifunctional mortise and tenon machine and implementing method thereof

A mortise and tenon machine, a multi-functional technology, applied in the direction of making tongues or tongues and grooves, can solve the problems of inability to guarantee the accuracy of finished products, inconvenient workpiece clamping, affecting the effect of processing, etc., to save time, simple structure, prolong the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

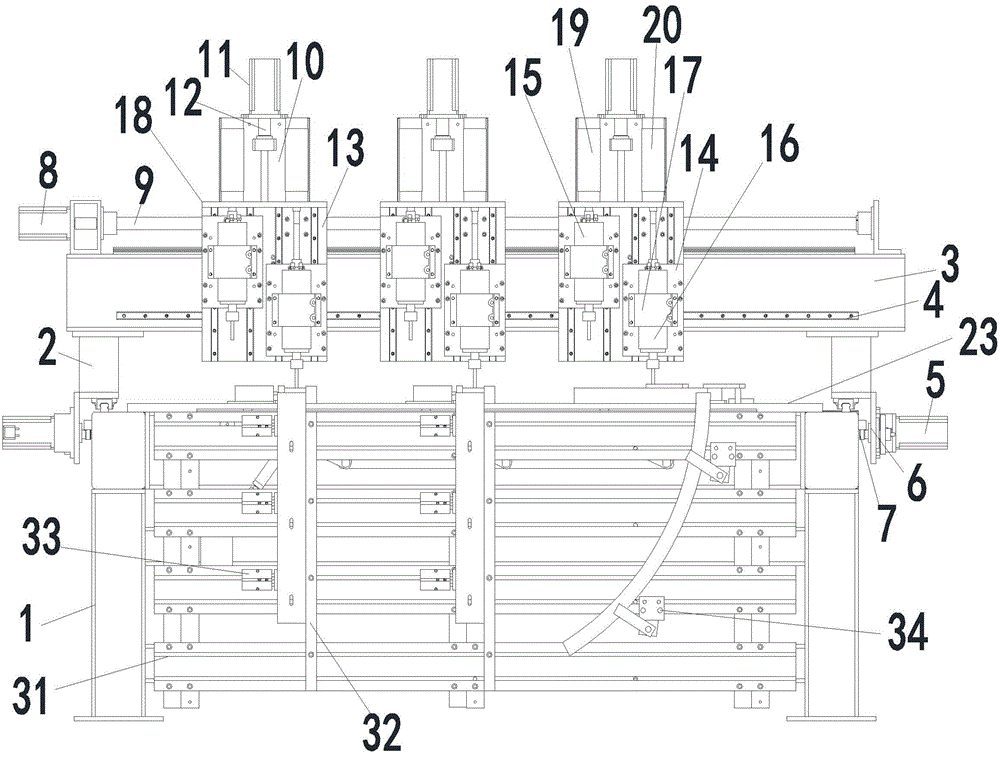

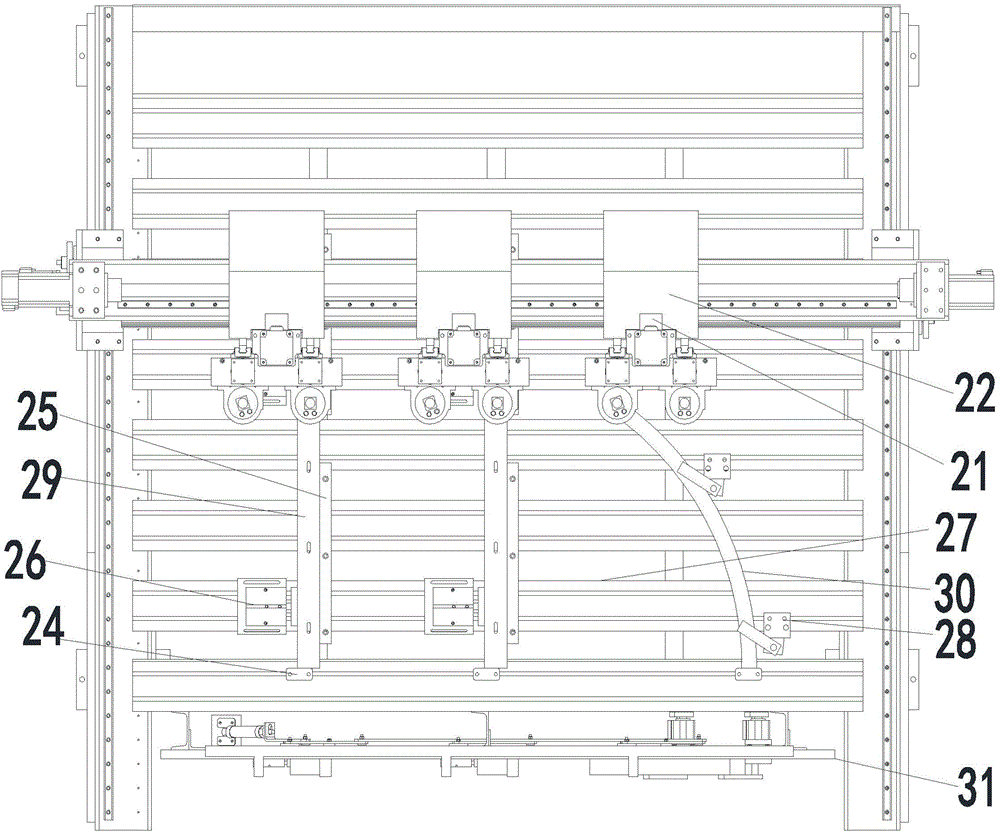

[0040] Such as Figure 1~2 As shown, a machine head suitable for mortise and tenon machines includes a frame 1, the left and right ends of the frame 1 are provided with front and rear moving devices, the front and rear moving devices are connected with the bottom end of the beam support 2, and the top of the beam support 2 is provided with The left and right moving device, the beam support 2 is provided with a beam 3, the beam 3 is provided with a left and right guide rail 4, a number of interchangeable knife sets are arranged on the left and right guide rail 4, a horizontal table 23 is arranged under the exchangeable knife set, and the horizontal table 23 ends Some horizontal positioning plates 24 are arranged on the upper part, and some horizontal workpiece backers 25 and horizontal compression cylinders 26 are longitudinally arranged on the horizontal table top 23 .

[0041] The front and rear moving device in the present embodiment includes front and rear motors 5, and fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com