Thin-wall blind hole part honing clamp

A blind hole and parts technology, applied in the field of honing fixtures for thin-walled blind hole parts, can solve the problems of labor and time-consuming, slow clamping and low work efficiency for clamping workpieces, and achieves safe and reliable clamping and fast clamping. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

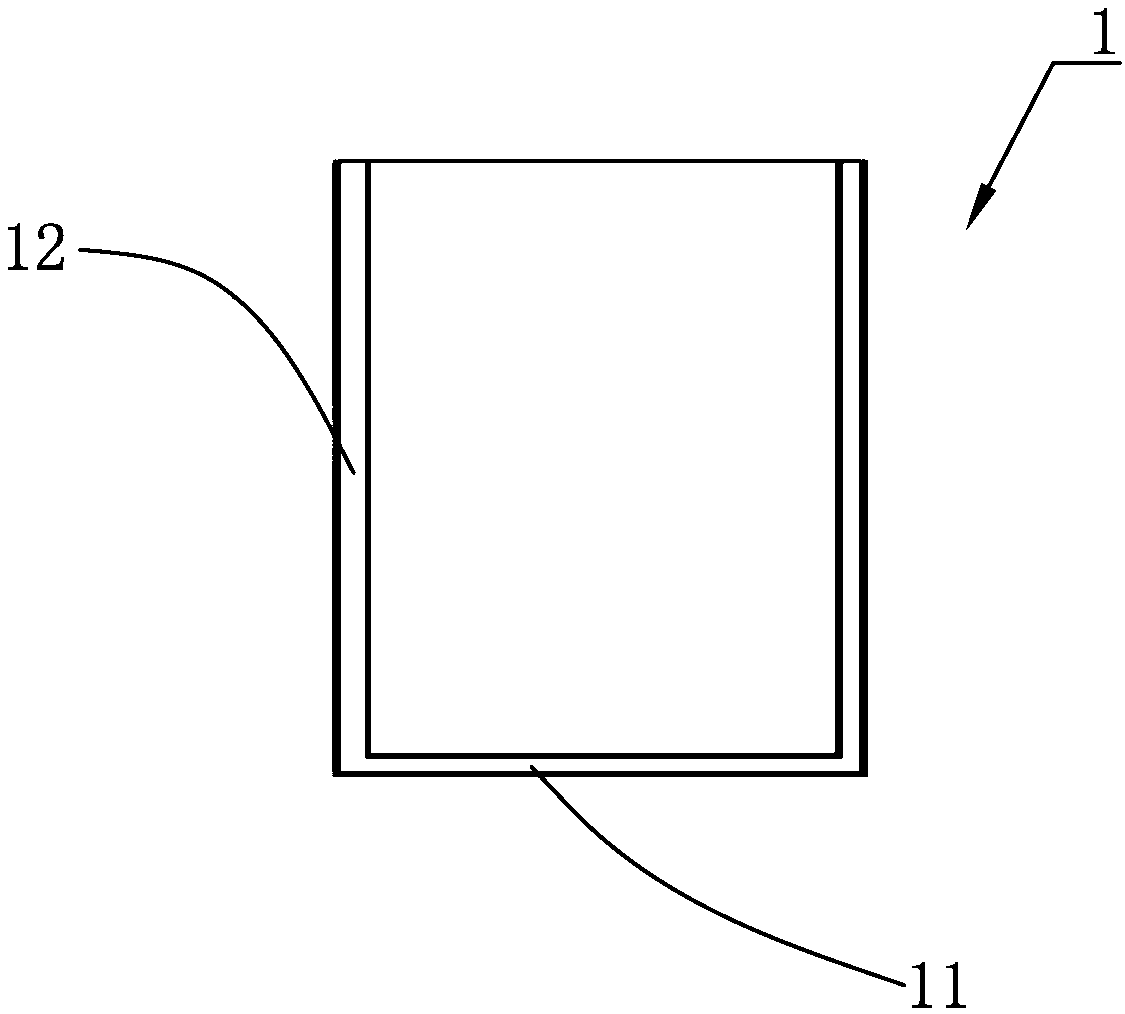

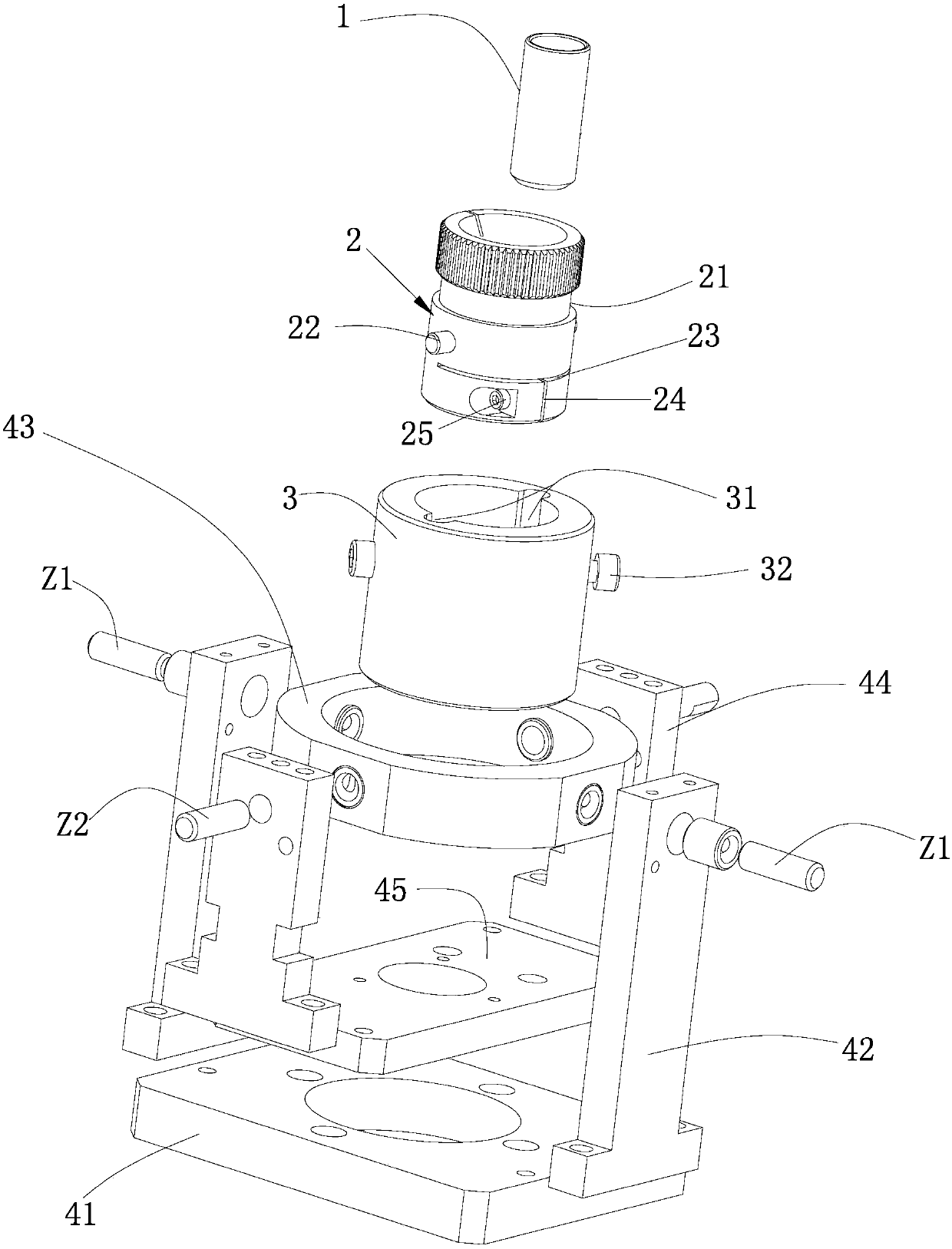

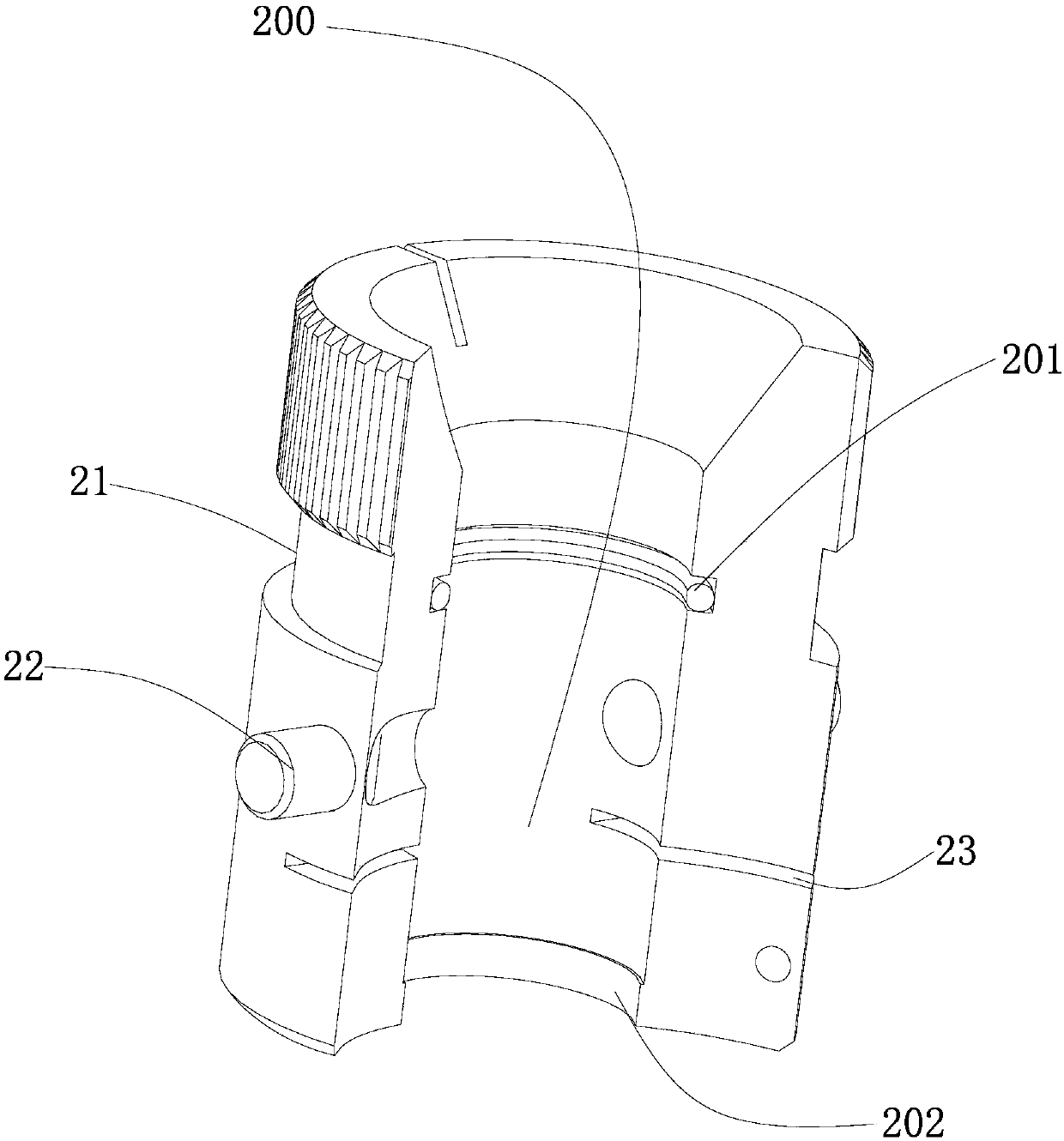

[0022] like figure 1 As shown, a honing fixture for a thin-walled blind hole part 1 is used for clamping a thin-walled blind hole part 1. The thin-walled blind hole part 1 has a compacted part 11 and a hollow part 12 (the compacted part refers to the bottom part Where there is a little thickness, the hollow part refers to the place where the inner hole of the thin-walled blind hole part passes through, that is, the hollow part is above the compacted part. The hollow part should not be too tight when clamping, otherwise the part will be deformed and damaged. The compacted part can be apply a slightly larger included angle force), the honing fixture includes a support frame, a fixture body arranged on the support frame, the fixture body is connected to the support frame, and the fixture body includes an accommodation space 200 for accom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com