Flexible vector tactile and slip composite sensor

A composite sensor and flexible technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve the problems of inability to detect slippage, the sensor has no anti-skid function, etc., to achieve the effect of safe clamping, simple electrode layer structure, and satisfying use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

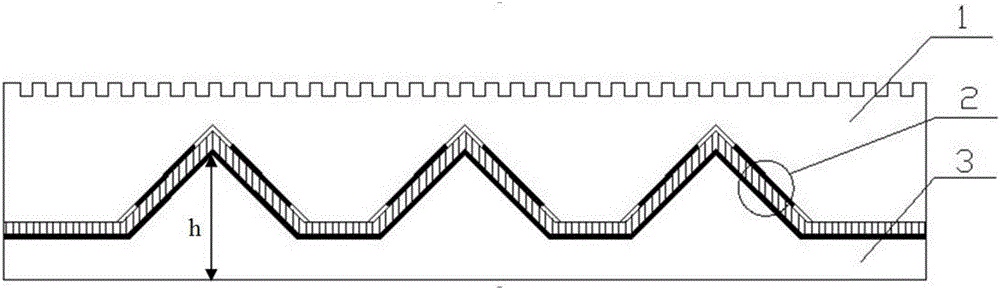

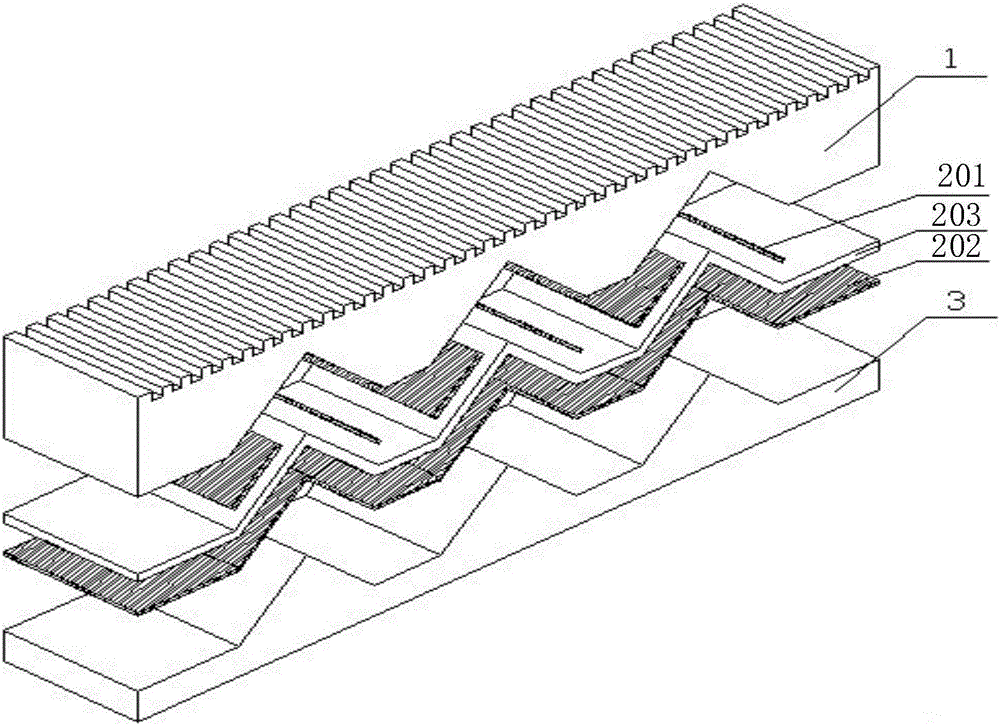

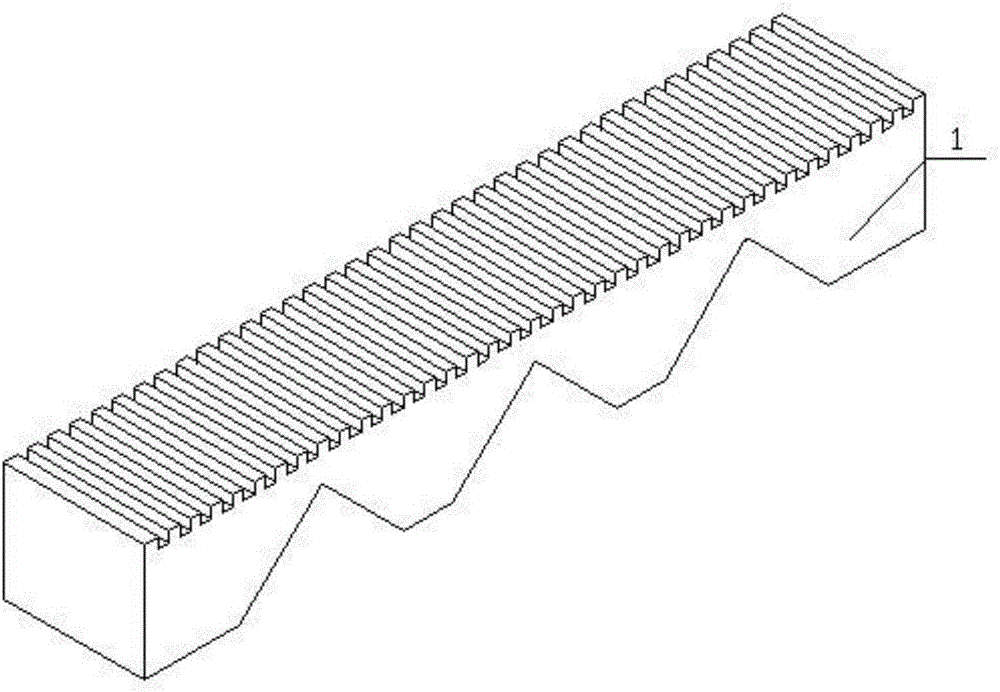

[0025] The invention provides a flexible vector touch-slip composite sensor, the sensor is a cuboid structure as a whole, the surface has an array of microstructures at equal intervals, which are used to contact and conduct surface normal pressure or friction; the middle layer has multiple pairs of forces The sensitive unit provides differential output signals; the bottom surface is bonded to the surface of the robot hand or instrument. The paired force-sensitive units are respectively located on both sides of the symmetrical protrusion structure. Specifically, such as figure 1 and figure 2 As shown, the sensor includes: an upper flexible substrate 1, a force-sensitive structural layer 2 and a lower flexible substrate 3, and the force-sensitive structural layer 2 includes an upper electrode layer 201, a bottom electrode layer 202 and an upper elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com