Lathe clamp and lathe

A lathe jig and jig technology, applied in the direction of clamping, clamping device, manufacturing tool, etc., can solve the problems of inconvenient clamping, insufficient clamping, easy to loose, etc., and achieve convenient clamping, convenient processing and manufacturing, and processing. high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

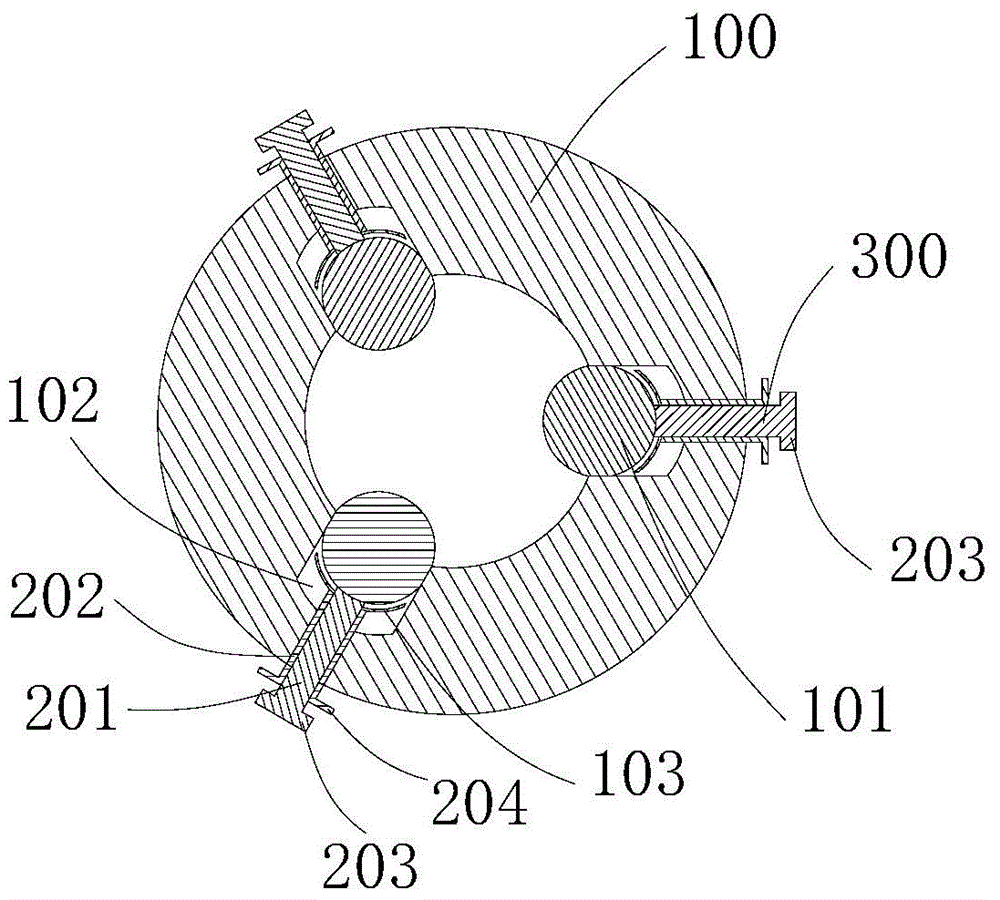

[0034] In the machining production process, fixtures are often used for processing operations. Sometimes the materials to be processed are not regular, so different fixtures are required to adapt to the operation, especially for bar-type workpieces. Due to the irregularity of the workpiece, It is inconvenient to use the traditional fixture for clamping, and after a long processing time, there will be looseness between the workpiece and the fixture, it is difficult to ensure the firmness, and it is not easy to process

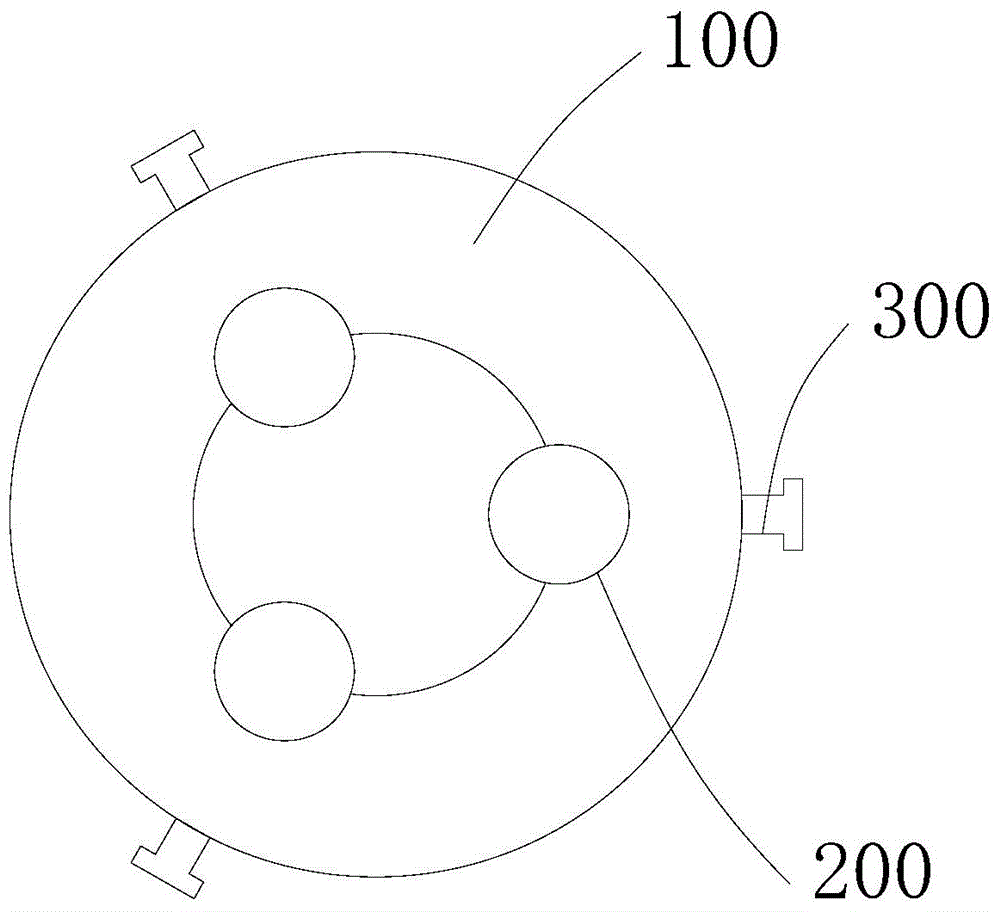

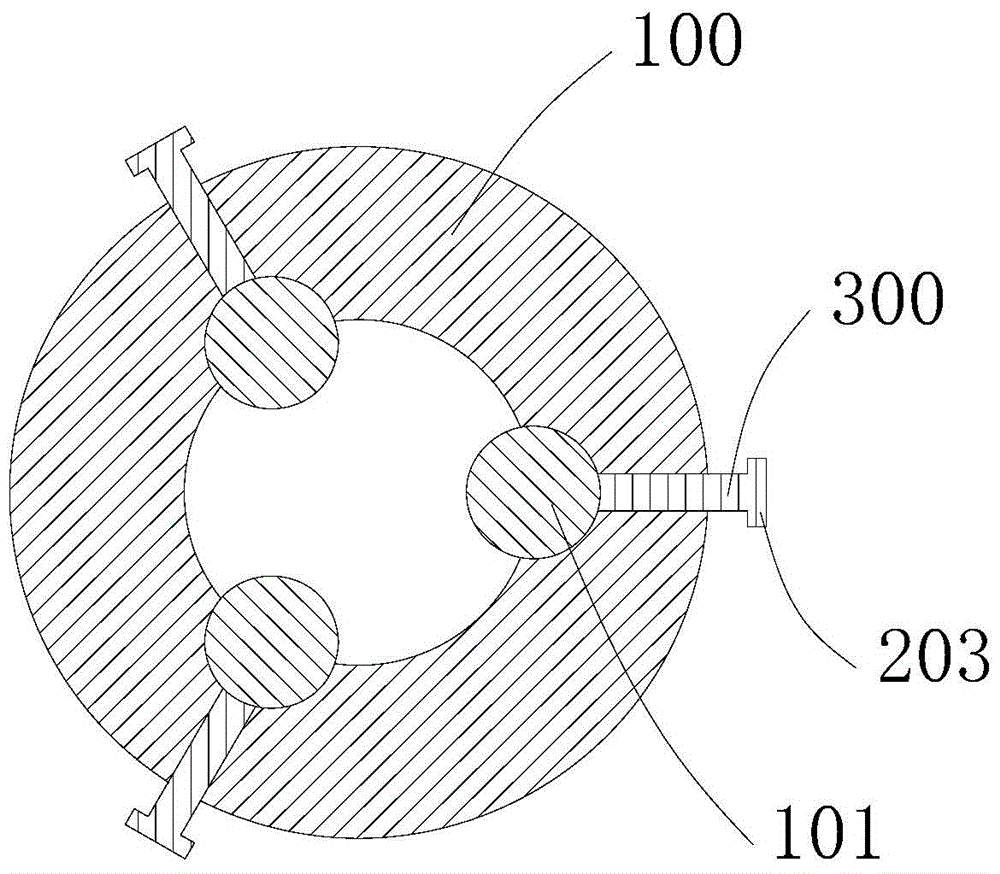

[0035] In view of this, the designer of the present invention has designed a lathe clamp and a lathe, the lathe clamp includes a clamp body and a clamp housing, the clamp body is installed on the clamp housing, and the clamp body includes a cylindrical The chuck, the cylindrical chuck is controlled by bolts, that is, when the workpiece is placed in the space surrounded by a plurality of cylindrical chucks, by screwing the bolts, the plurality of cylindrical chuck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com