Vacuum clamp

A technology of vacuum clamps and fixtures, used in manufacturing tools, workpiece clamping devices, etc., can solve the problems of gas leakage, unstable clamping, silicon wafer fragments, etc., and achieve the effect of safe clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

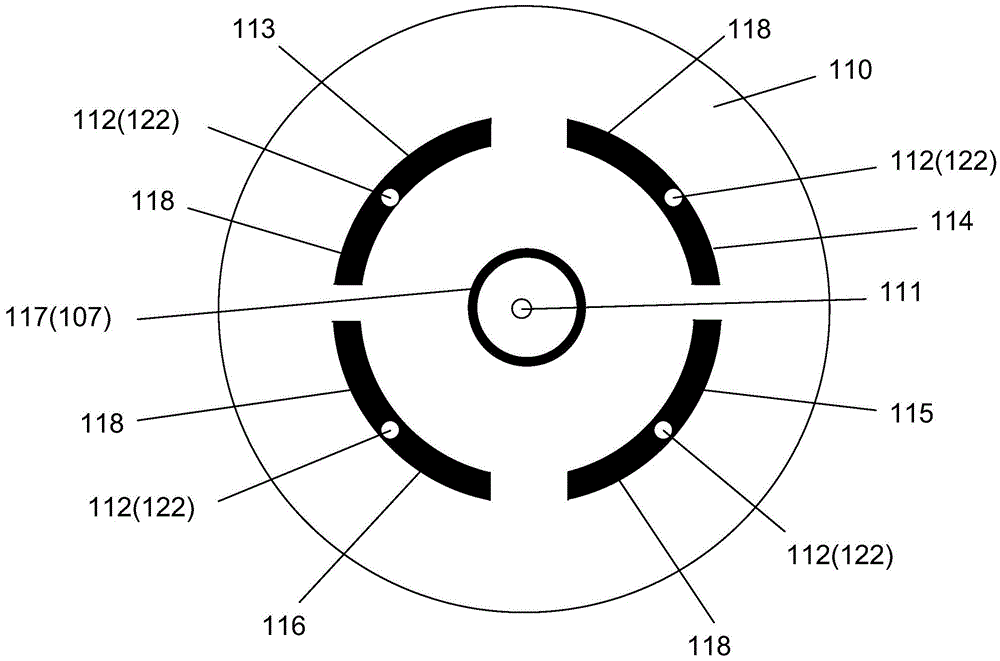

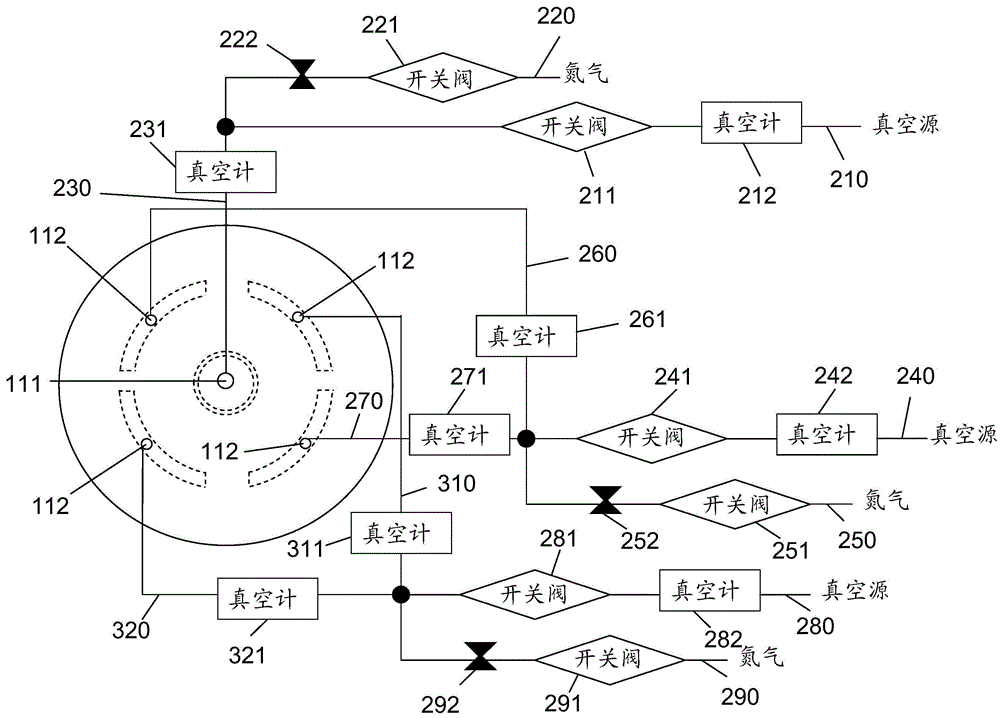

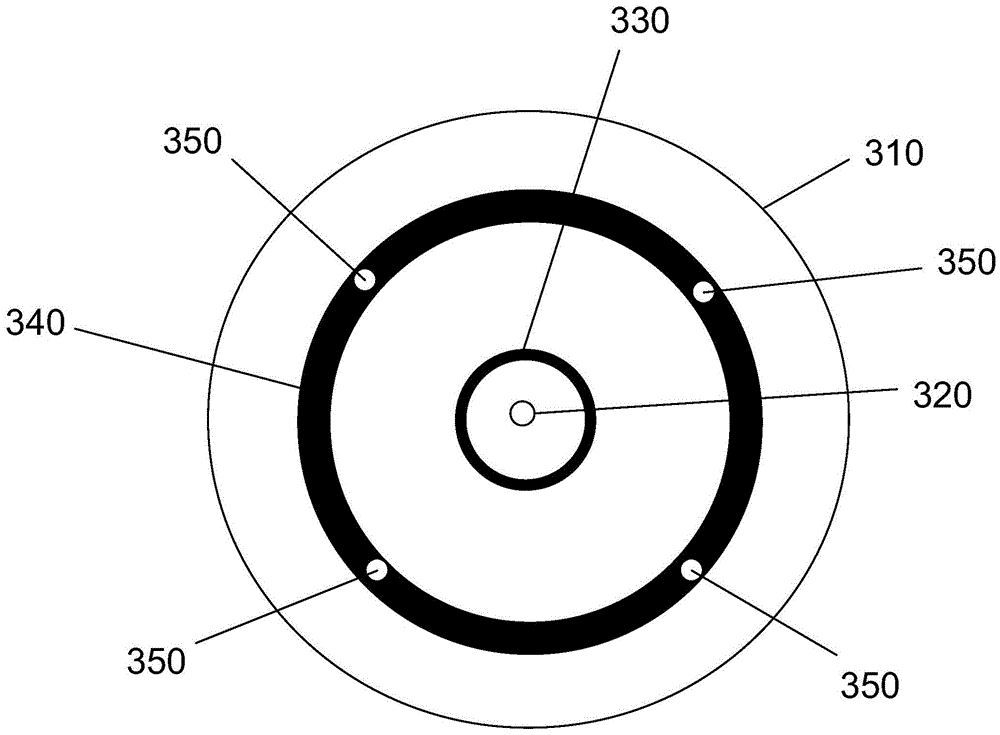

[0014] refer to figure 1 , reveals a bottom view of the vacuum fixture of the present invention. A vacuum fixture according to a representative embodiment of the present invention includes a fixture body 110. The fixture body 110 has a front surface and a back surface opposite to the front surface. The front surface of the fixture body 110 is arranged opposite to the silicon wafer. The groove 107 , the inner groove 107 is an annular groove, and the inner groove 107 is arranged adjacent to the center of the clamp body 110 . A vacuum channel 111 is opened on the fixture body 110 surrounded by the inner groove 107 , and the vacuum channel 111 runs through the front and back of the fixture body 110 . The front of the fixture body 110 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com