Air clamper in use for principal axis of lathe

A pneumatic clamping and lathe spindle technology, which is applied to positioning devices, clamping, turning equipment, etc., to achieve significant energy saving and consumption reduction, multiple clamping stages, and fast clamping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

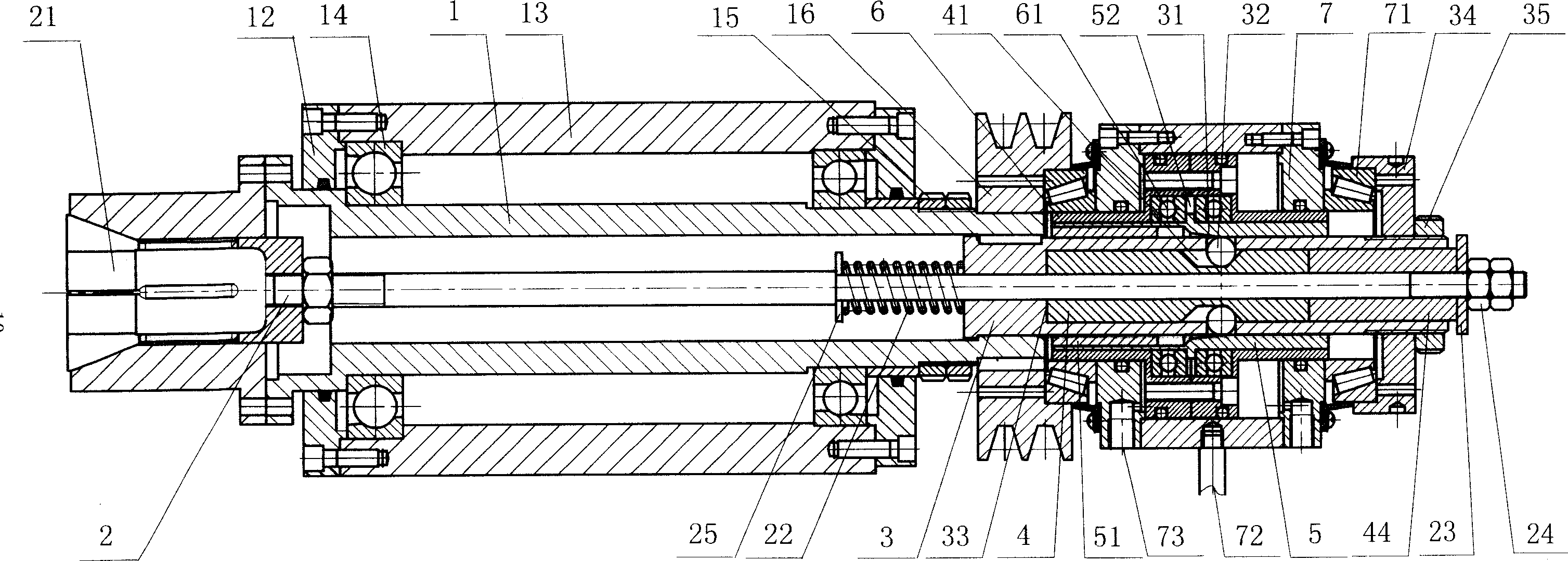

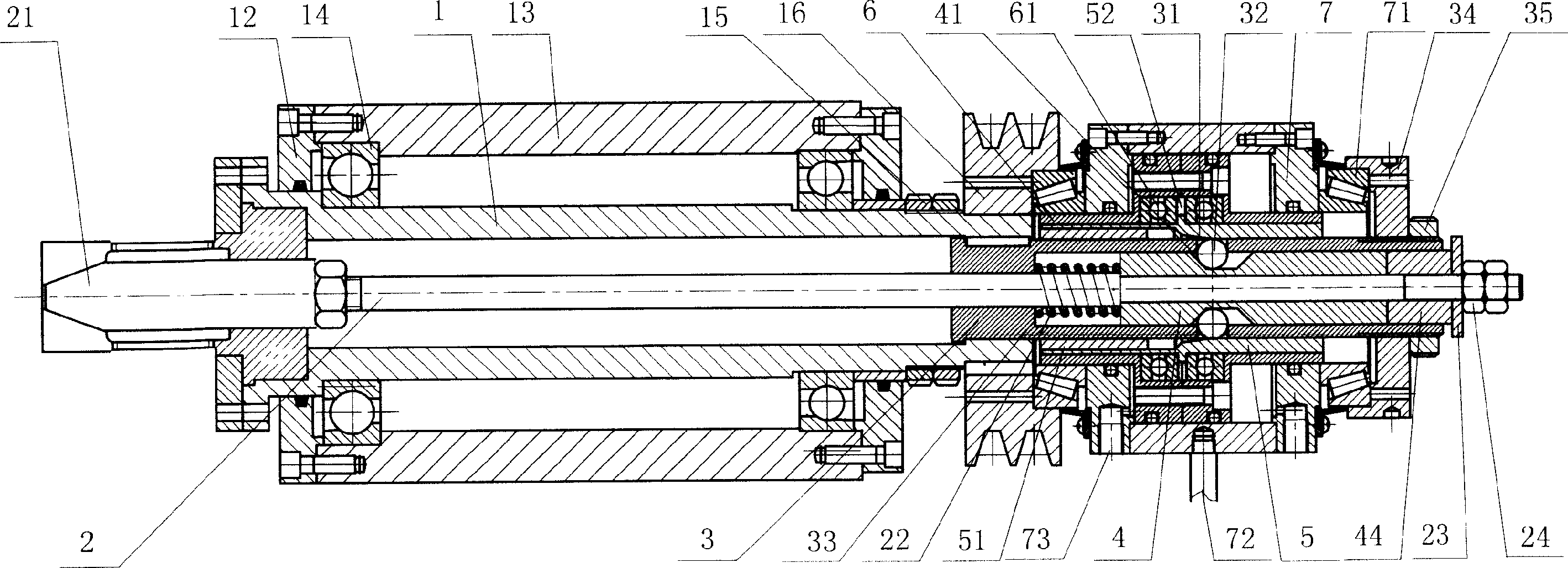

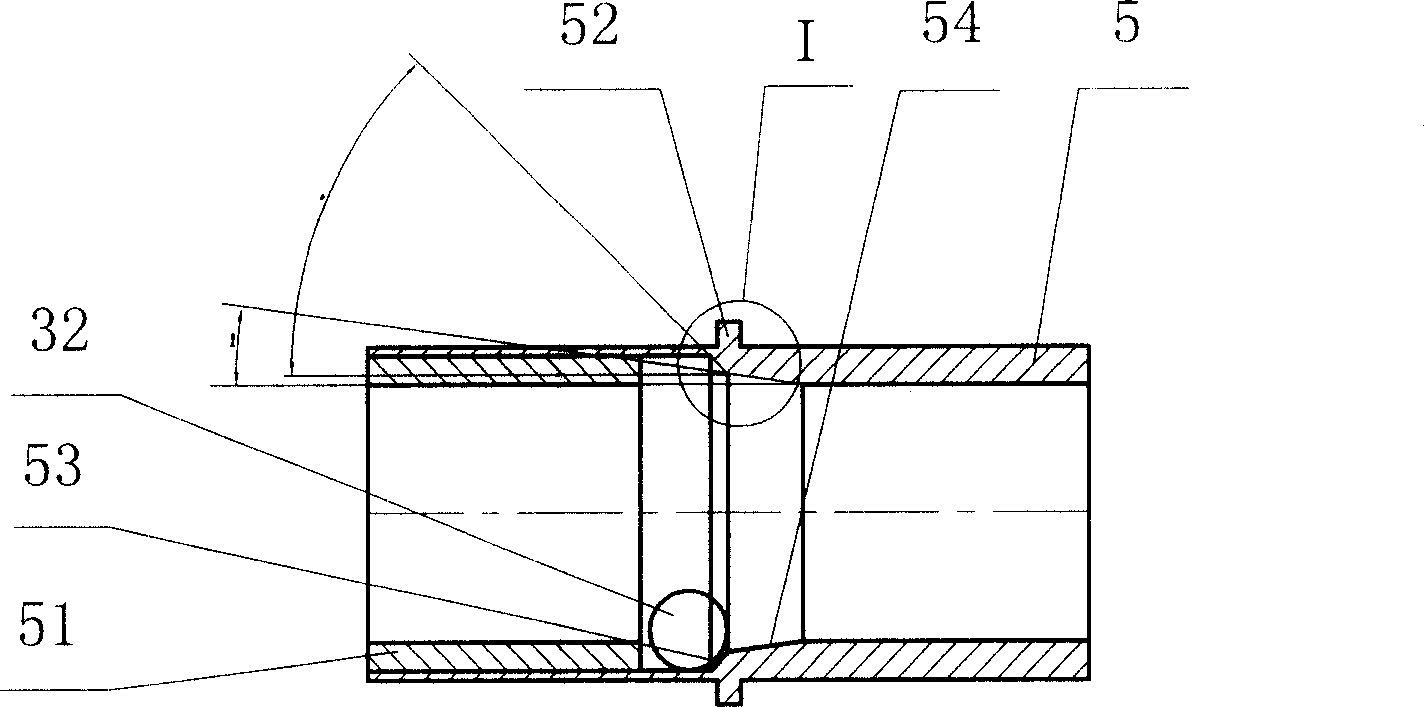

[0025] A pneumatic clamping device for the spindle of a lathe shown in the accompanying drawing, the spindle 1 passes through the front and rear end covers 12 on it and the axle seat bearing 14 arranged on the inner wall of the front and rear ends of the spindle seat 13 and passes through the tail of the spindle 1 The locking nut 15 on the top is fixedly connected with the main shaft seat 13 as a whole. The center of the main shaft 1 is provided with a pull rod 2, the front end of the pull rod 2 is provided with a clip spring 21, and the rear portion of the pull rod 2 is provided with a loosening mechanism, which includes a steel ball sleeve 3 arranged on the inner wall pull rod 2 at the tail of the main shaft 1. The steel ball 32 in the radial through hole 31 of the steel ball sleeve 3, the pull rod sleeve 4 adapted to the steel ball sleeve 3, the steel ball ring groove 41 located in the middle of the pull rod sleeve 4, and the long and short ends 42, 43 of the pull rod sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com