Drawing gripper for weaving looms with improved performance for the transport of double weft yarns

A technology for connecting weft swords and rapier heads, which is applied in the field of weft connecting rapier heads, and can solve problems such as uneven weaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

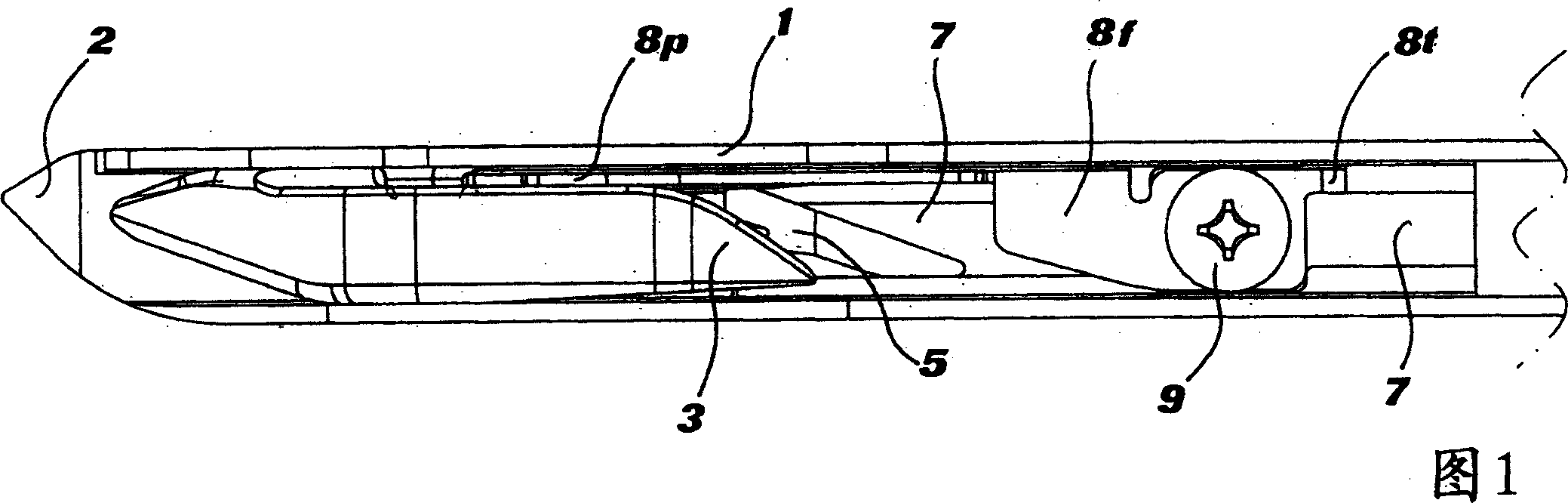

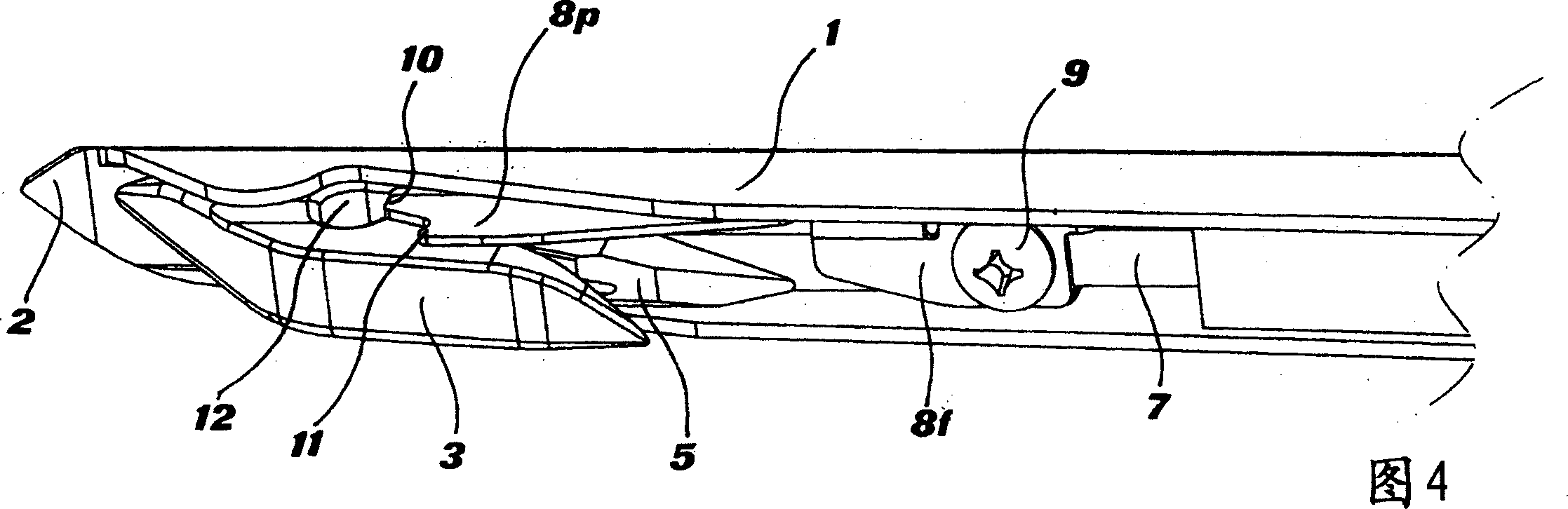

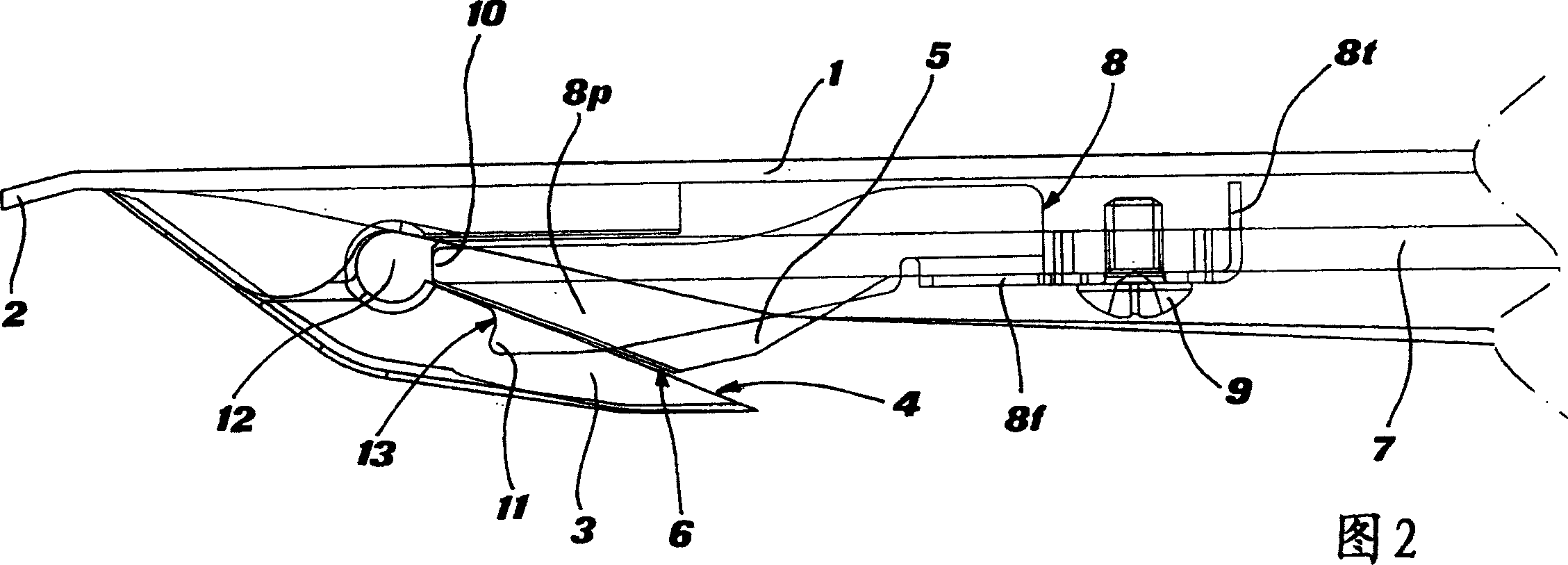

[0014] The weft-joining rapier head according to the invention comprises, in a manner known to those skilled in the art, a rapier head body 1 terminating in a tip 2 at the front. Immediately behind the rapier head tip 2, a hook member 3 is integrally connected to the rapier head body 1, the hook member 3 having a planar gripping surface 4 facing the inside of the rapier head. In the embodiment shown, the surface 4 lies on a plane which is substantially vertical and which is suitably inclined relative to the longitudinal axis of the rapier head, for example at an angle of inclination between 15° and 30°.

[0015] In known types of weft receiving rapier heads, the inner surface 4 of the hook 3 is one of two elements of the weft thread clamping device, the other comprising a movable clamping surface 6 equipped with facing the hook 3 and The wedge 5 rests on the opposite face on the body 1 of the rapier head. The wedge 5 is supported on the front end of a rod 7 movable longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com