Patents

Literature

35results about How to "Stable and reliable clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric clamping jaw

InactiveCN105922254AAutomatic calculation of clamping forceStable and reliable clampingProgramme-controlled manipulatorGripping headsIndustrial engineeringSensing system

An electric clamping jaw comprises a driving part and a clamping jaw body; the clamping jaw body is mounted on the bottom of the driving part and comprises a first clamping jaw and a second clamping jaw; the first clamping jaw and the second clamping jaw are both connected with a driving mechanism, and the clamping jaw body is provided with a slippage detection sensing system and a deformation sensing system; and according to the electric clamping jaw, clamping force can be automatically calculated and adjusted.

Owner:四川东巨自动化科技有限公司

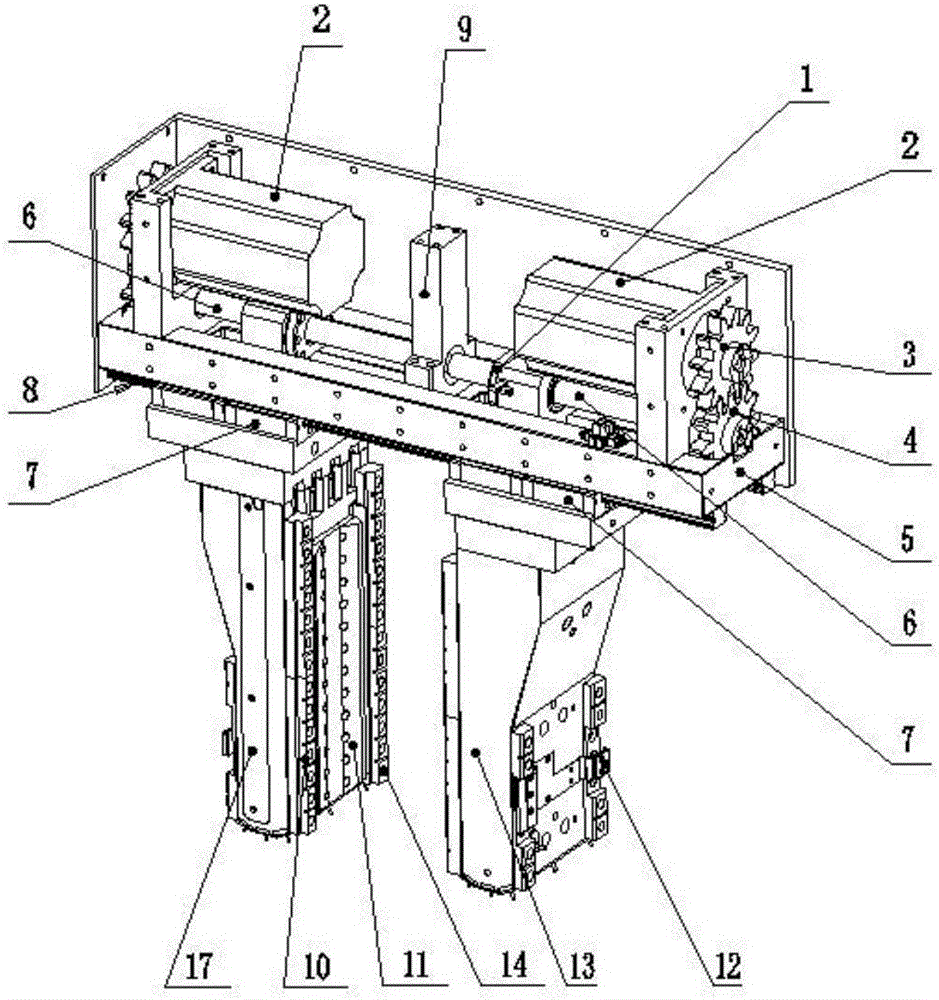

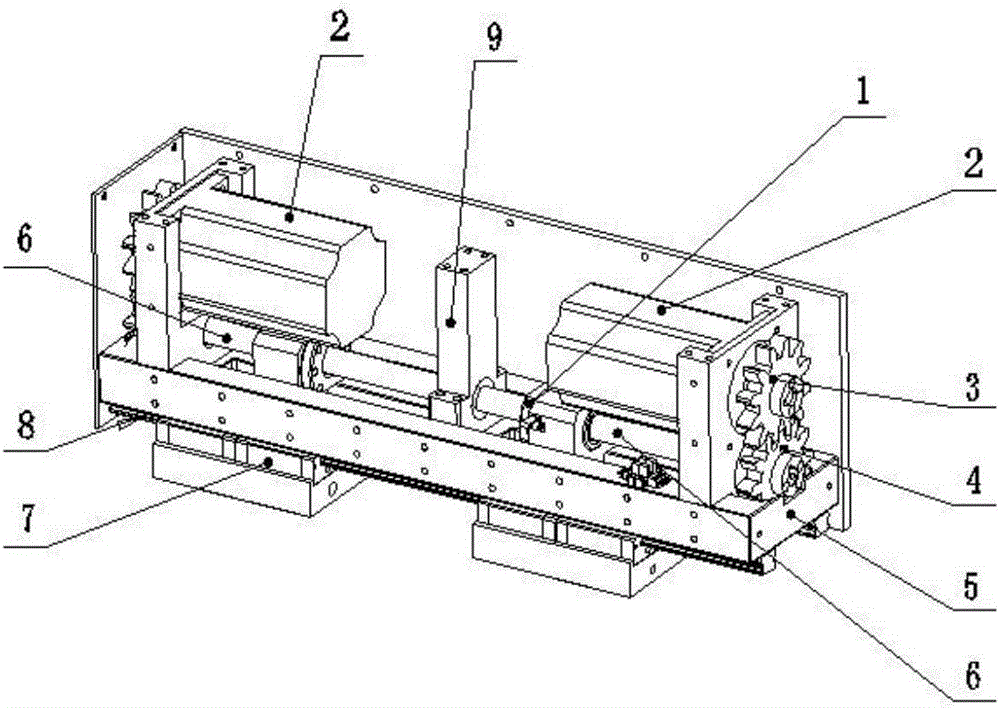

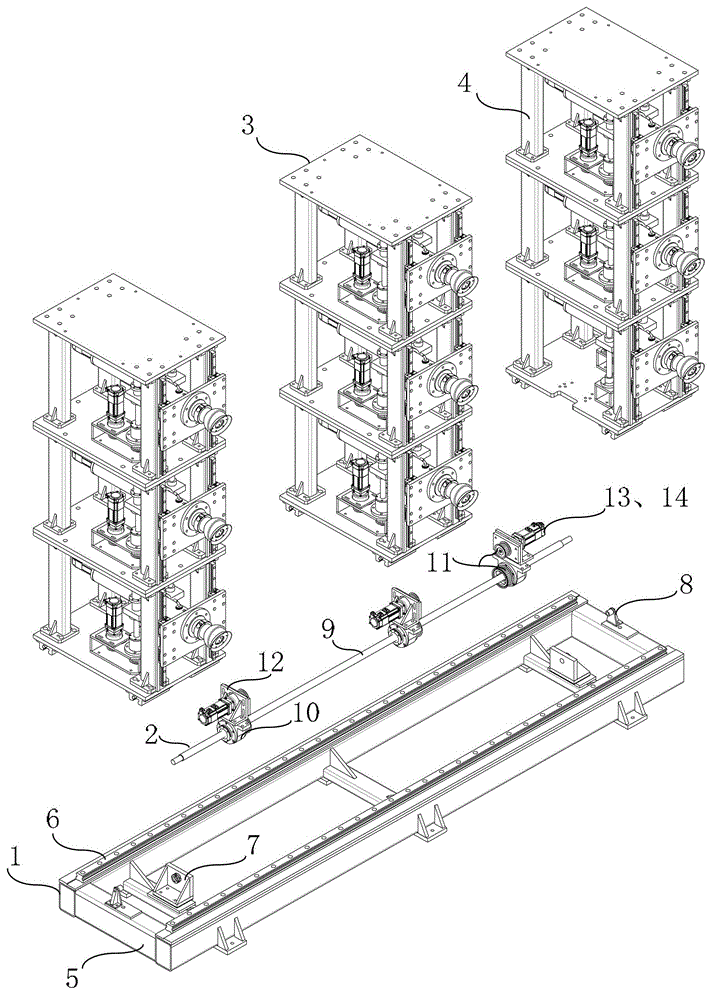

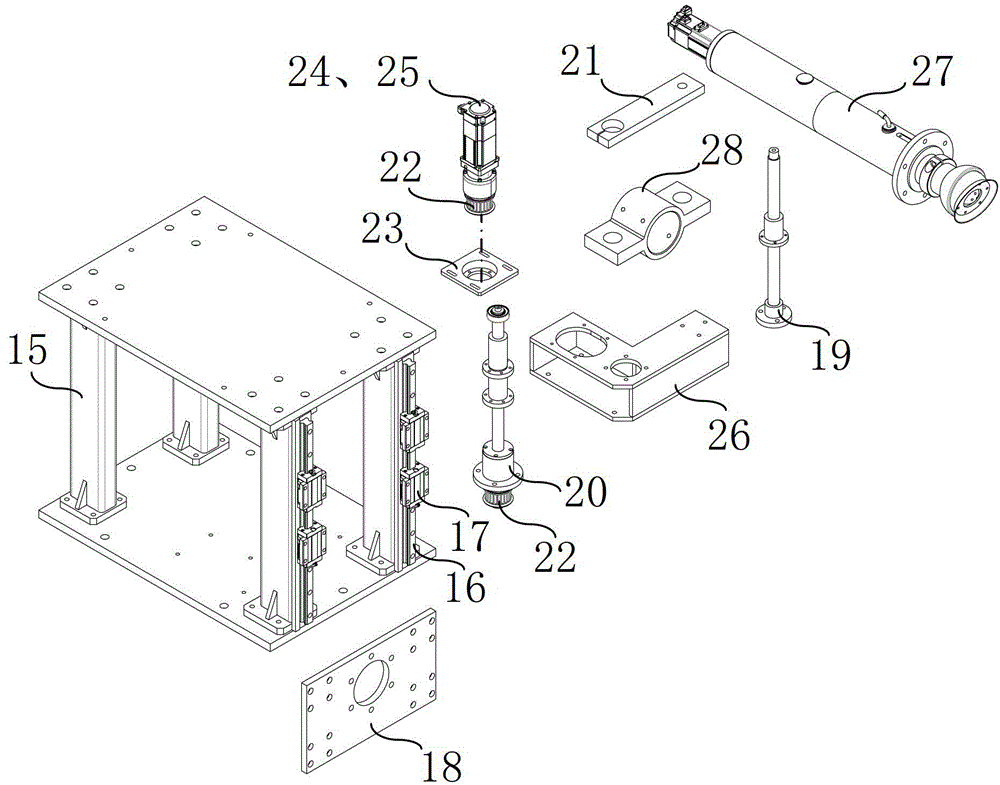

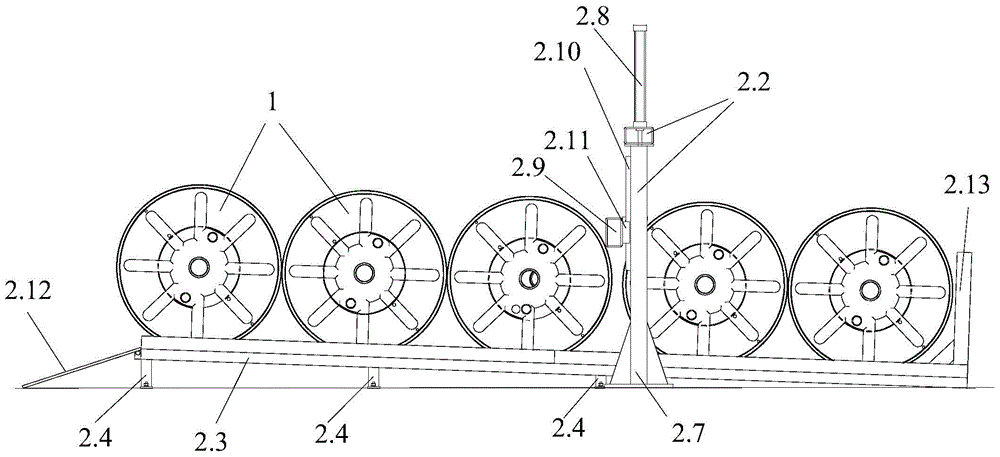

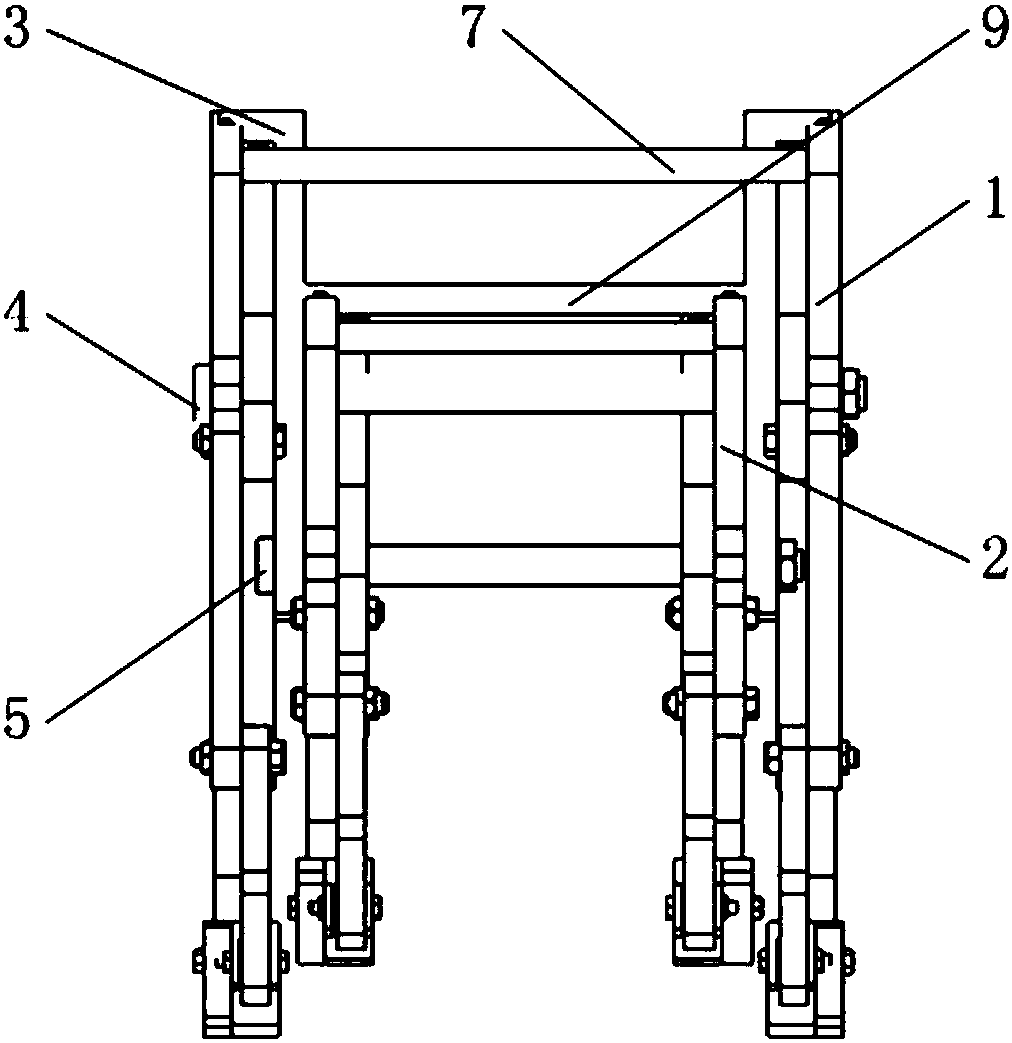

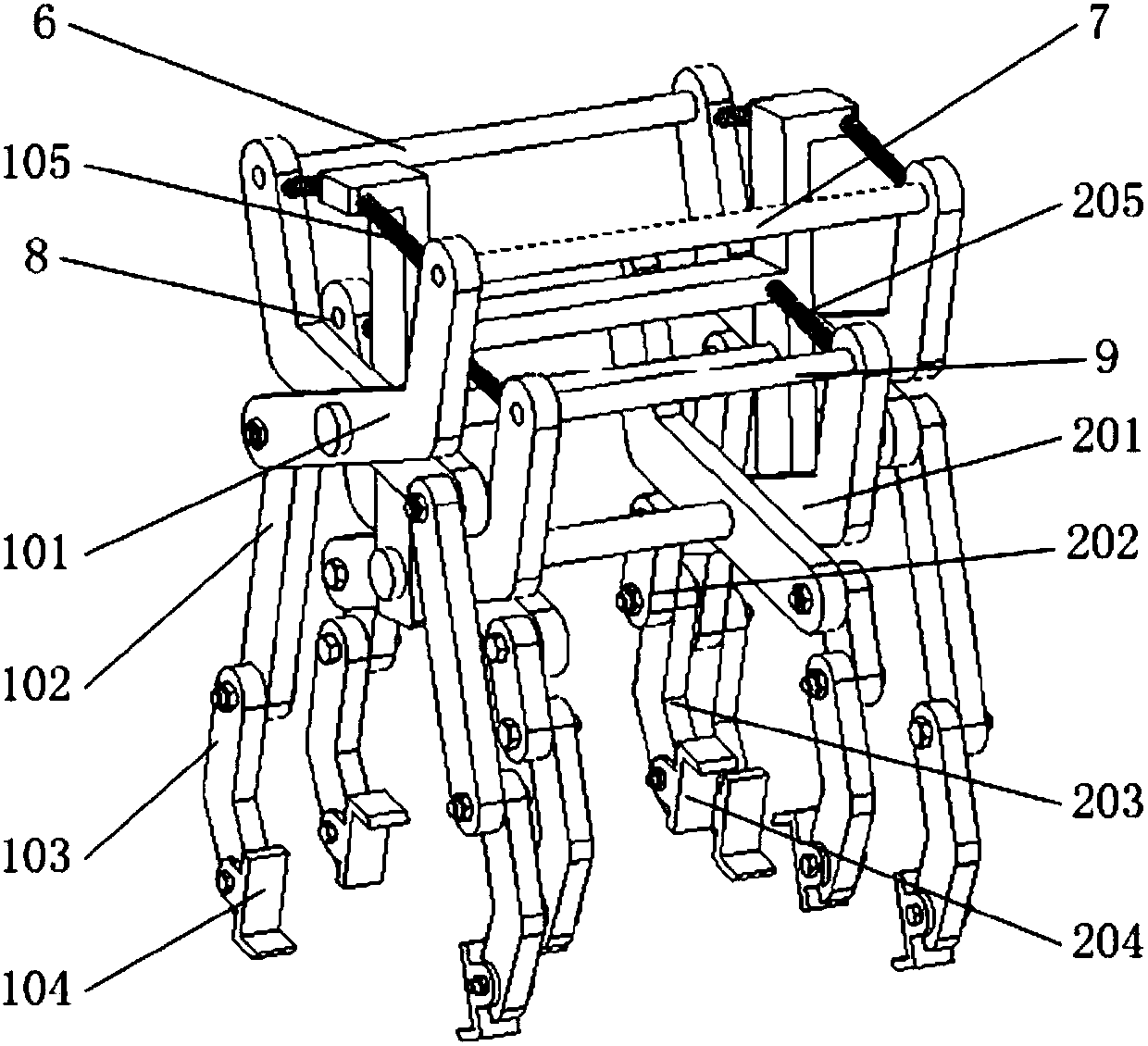

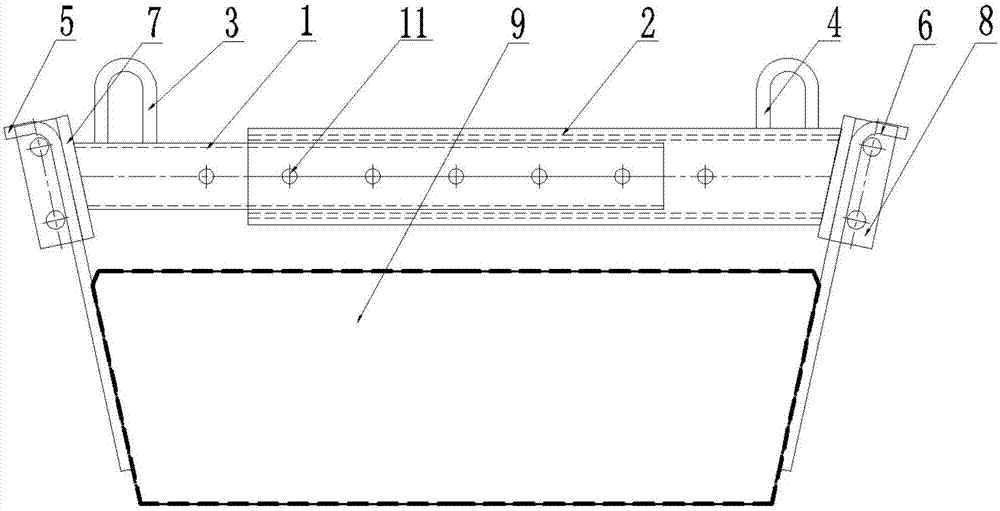

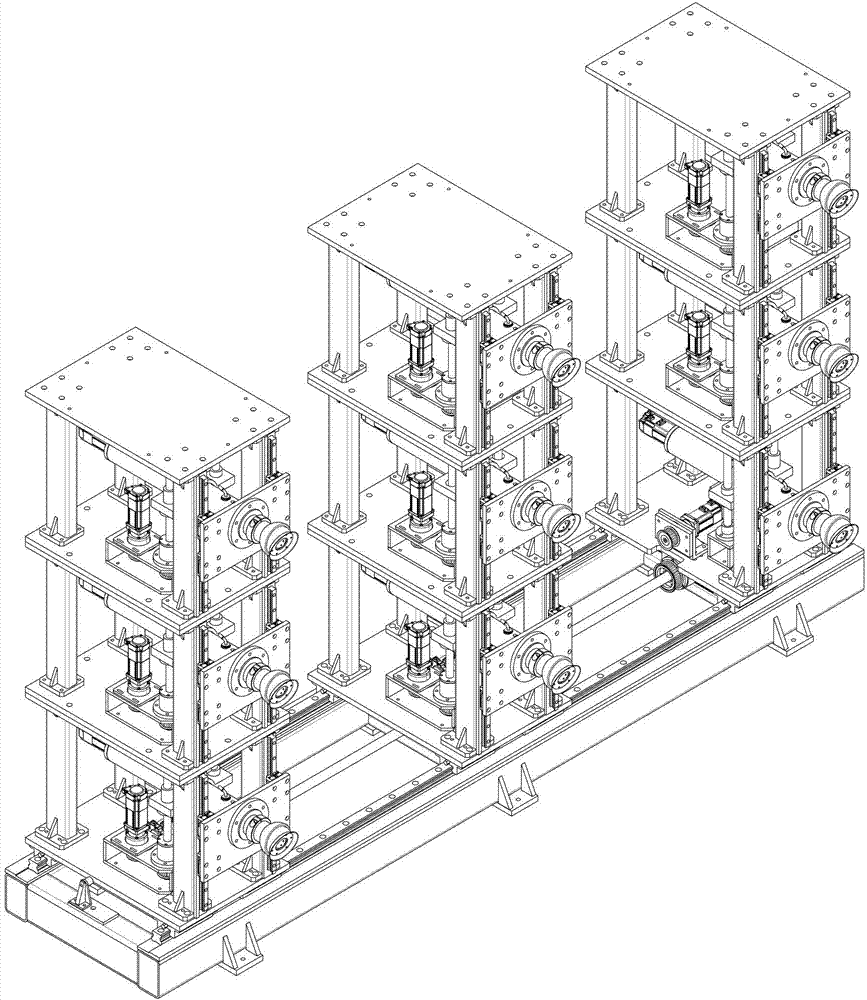

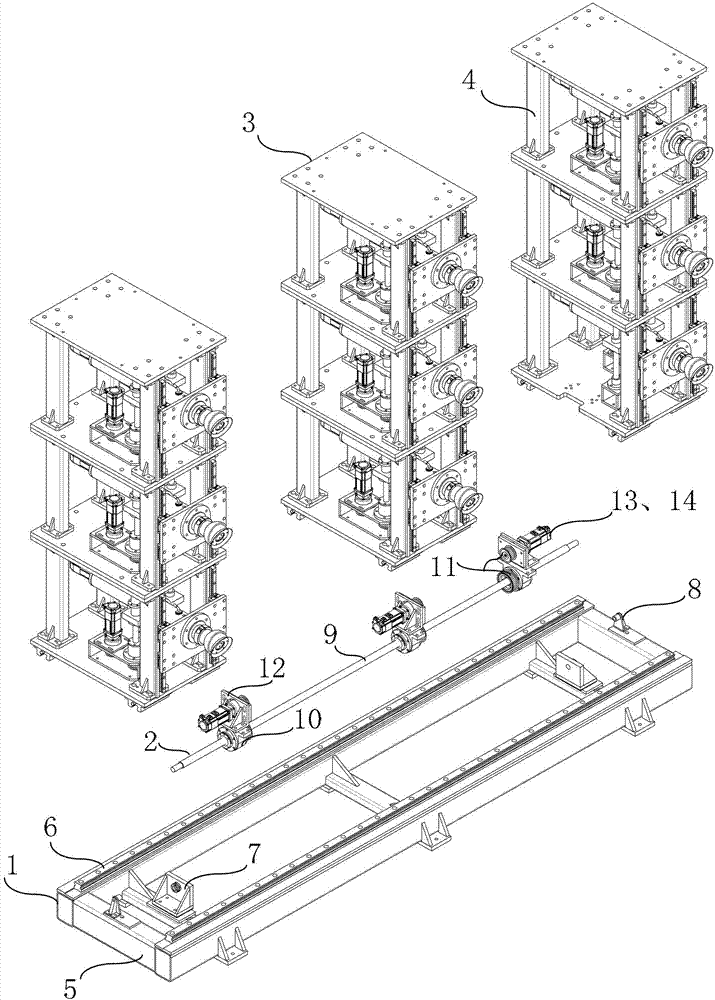

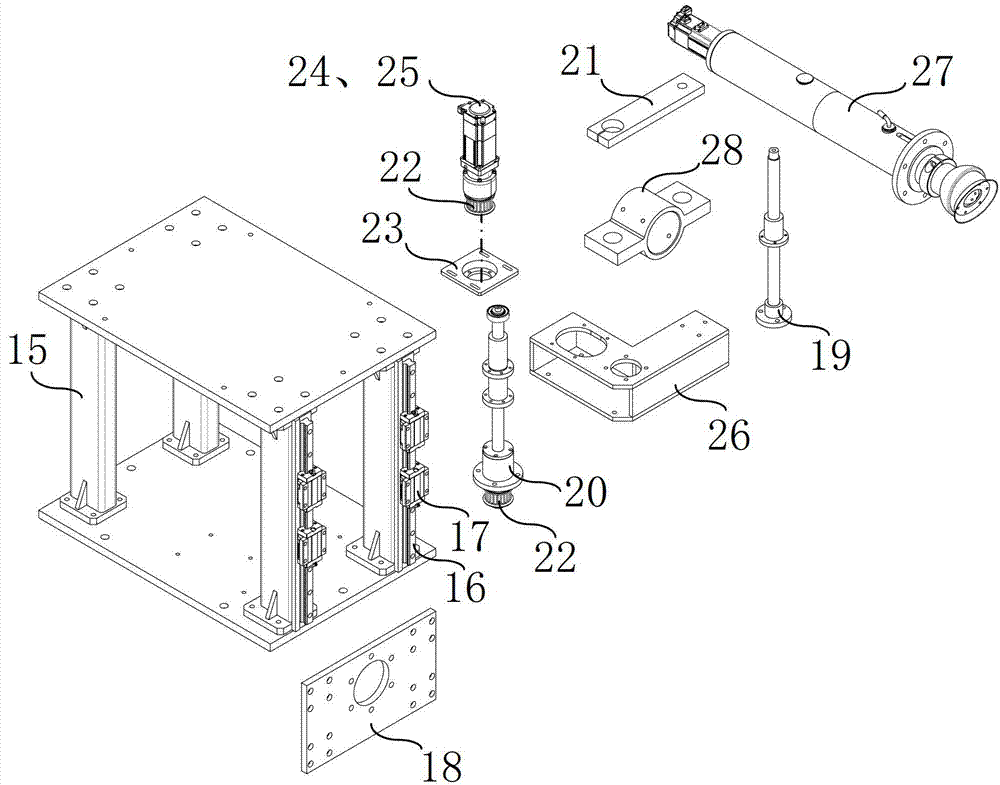

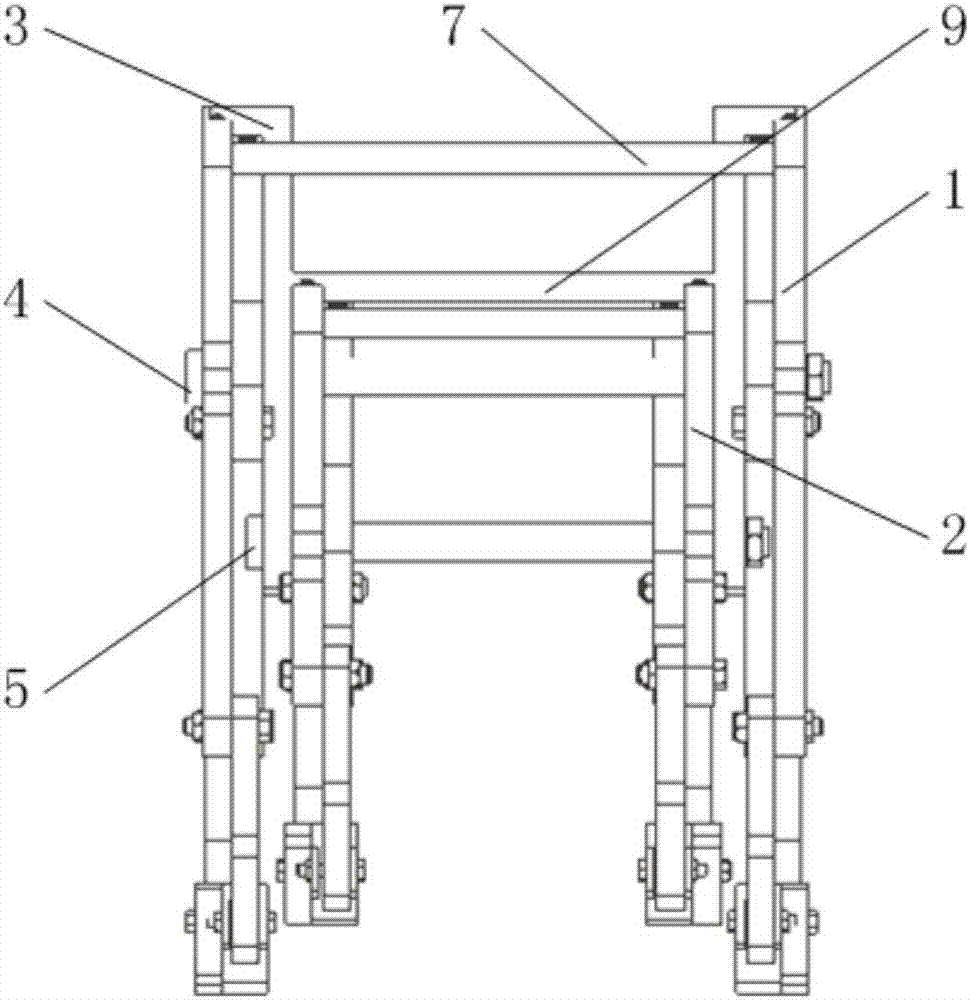

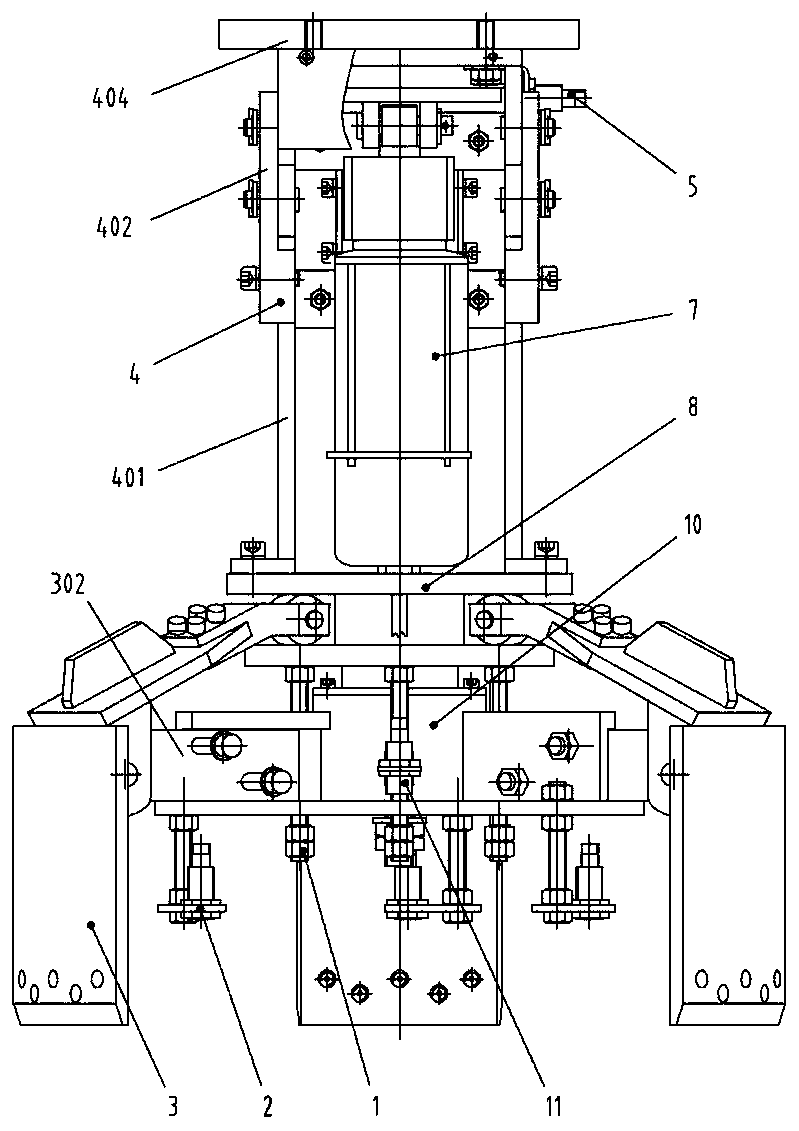

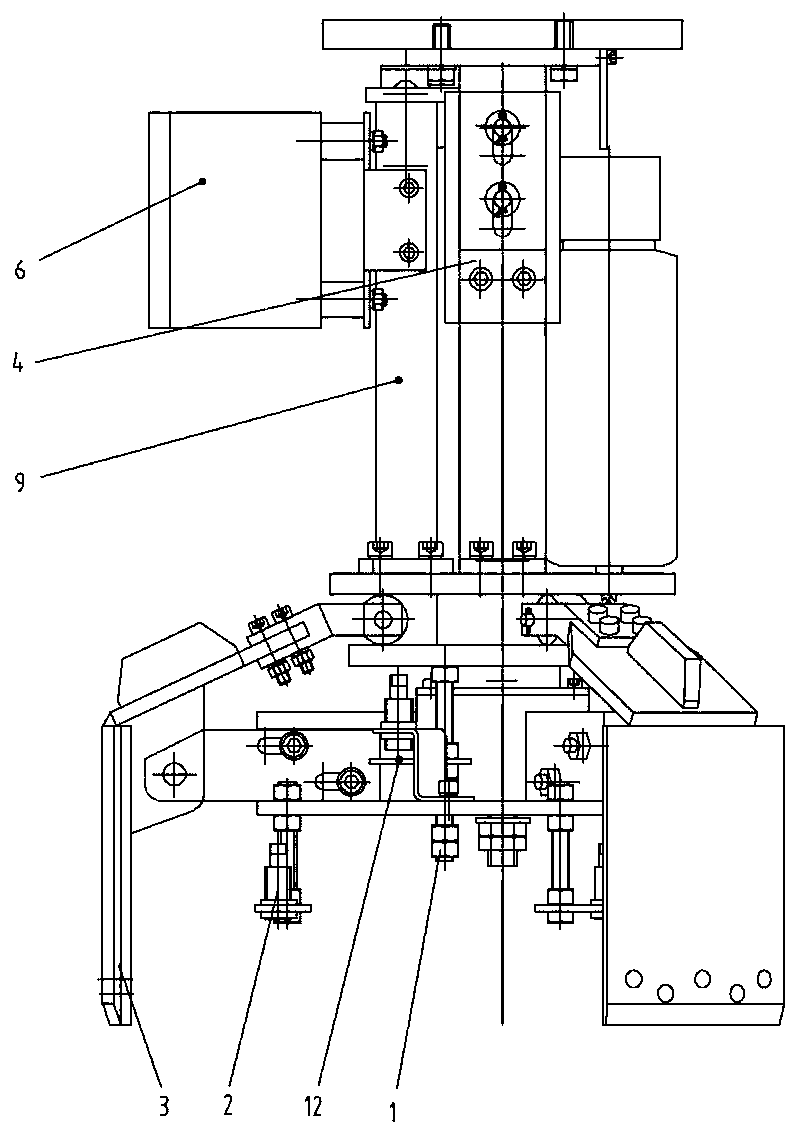

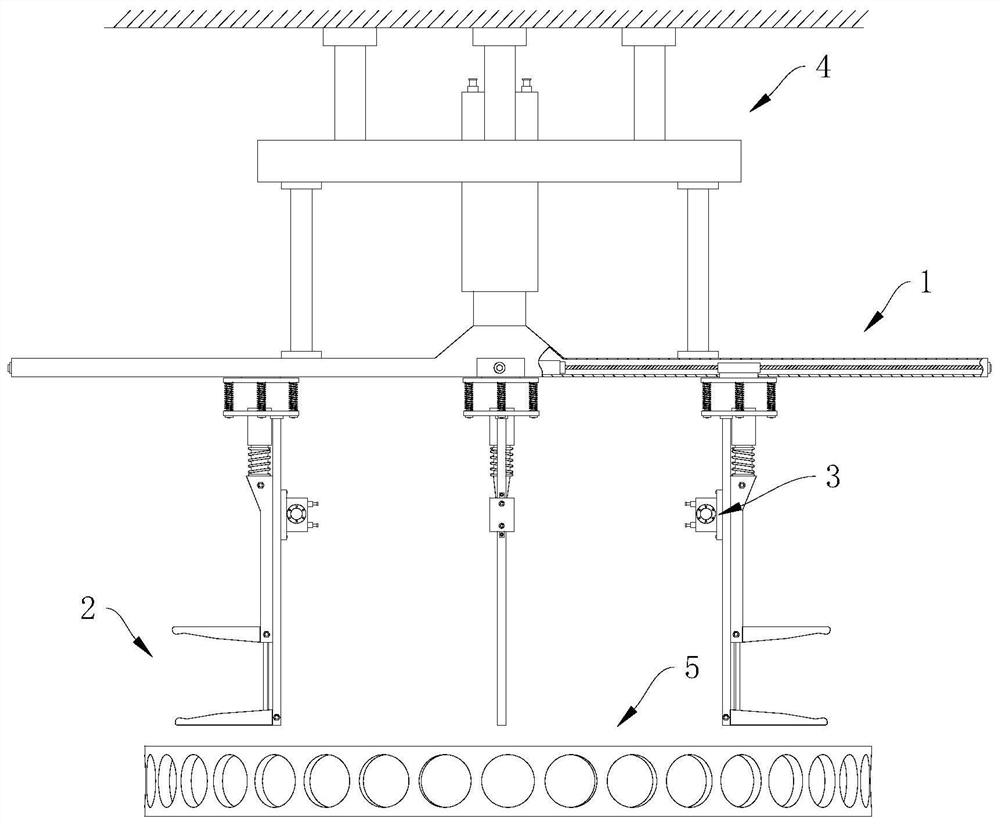

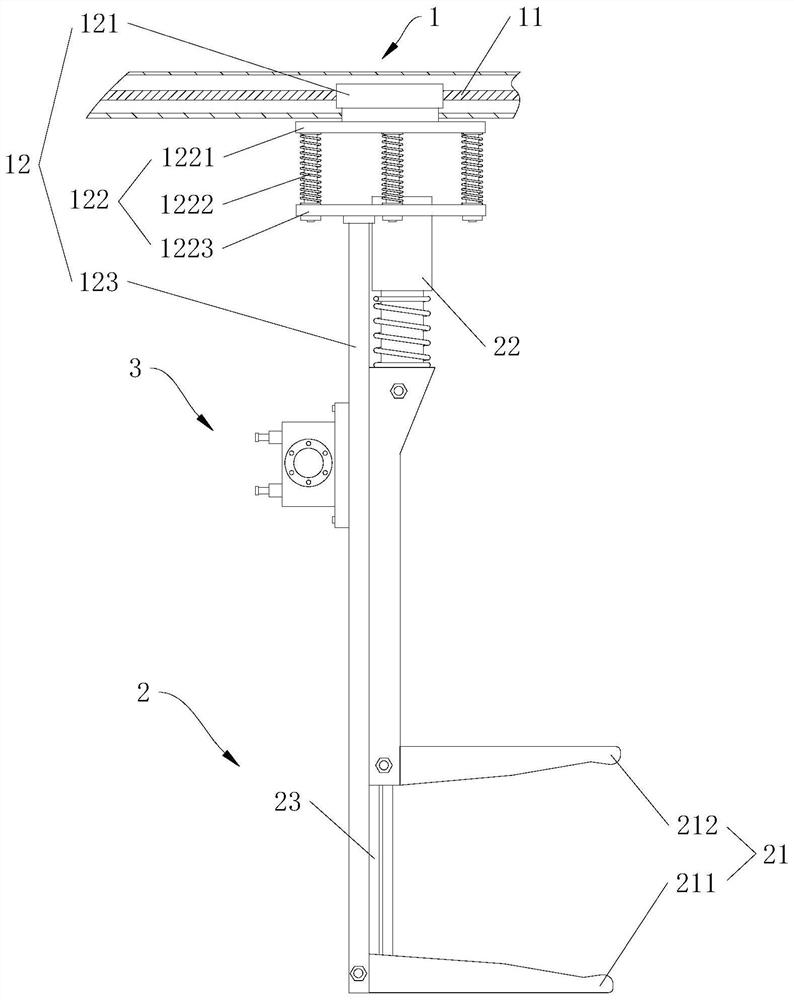

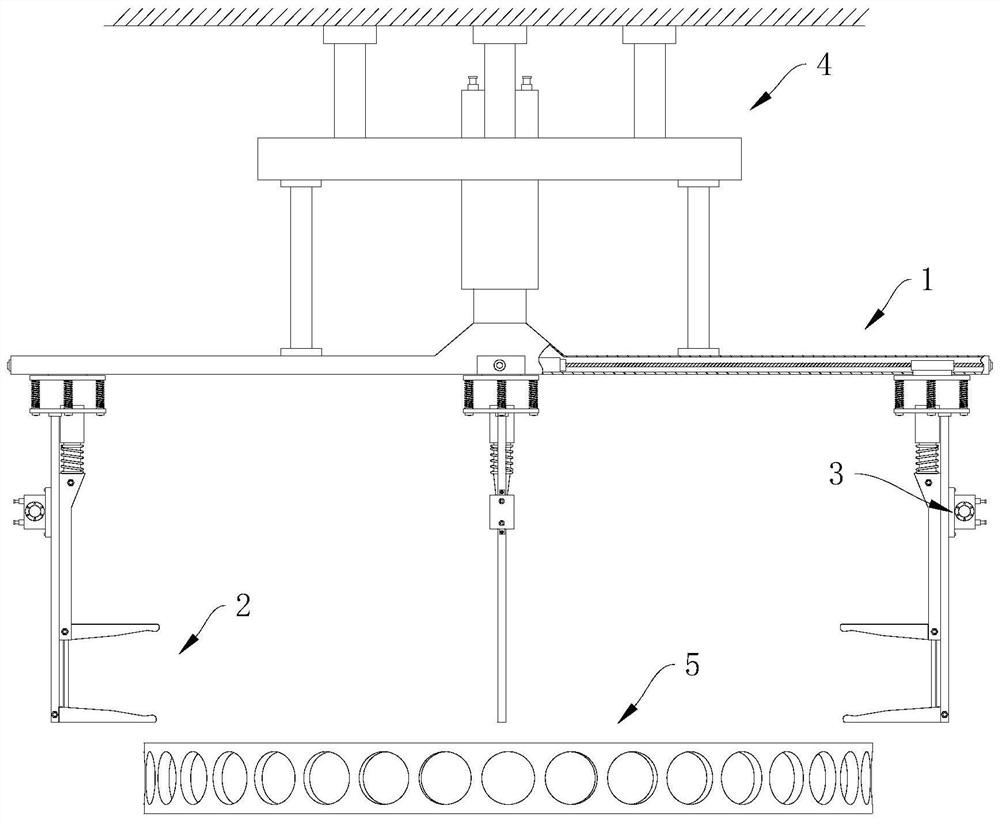

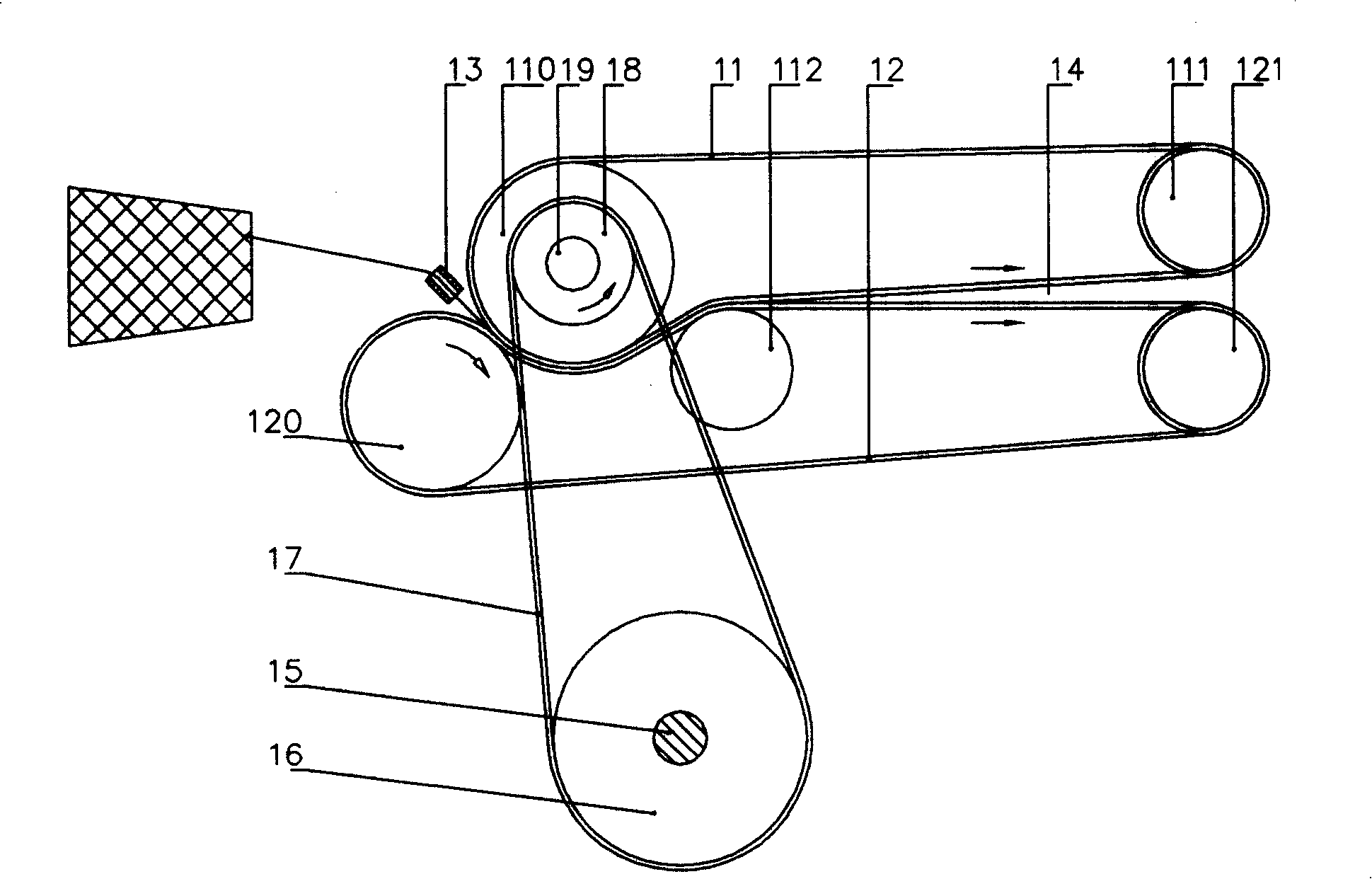

Flexible tool for assembling row-line chuck type wall board

A flexible tool for assembling a row-line chuck type wall board comprises a guide rail base, an X-direction driving unit and an upright post shape-adjusting assembly unit, wherein the guide rail base is fixedly connected to the ground; the upright post shape-adjusting assembly unit is arranged on two X-direction linear guide rails of the guide rail base and can move along the X-direction linear guide rails; and the X-direction driving unit is positioned between the bottom of the upright post shape-adjusting assembly unit and the guide rail base, is fixedly connected with the guide rail base and is connected with the bottom of the upright post shape-adjusting assembly unit. According to the flexible tool disclosed by the invention, aircraft panel assemblies are adsorbed, clamped and digitally positioned by a dot matrix vacuum chuck and stability and reliability in clamping and positioning and high positioning precision are obtained; and the digitalized positioning and drilling and riveting assembly of different wall board assemblies can be realized by reconfiguration through the dot matrix chuck of the tool. The flexible tool has higher practical value and broad application prospect in the fields of mechanical engineering / aircraft assembly.

Owner:BEIHANG UNIV

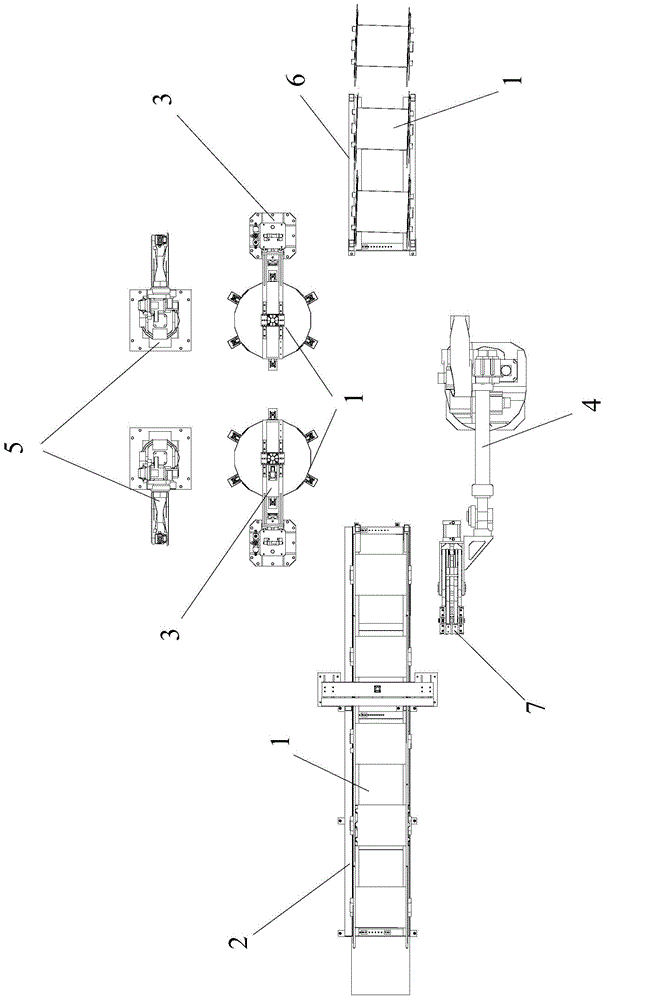

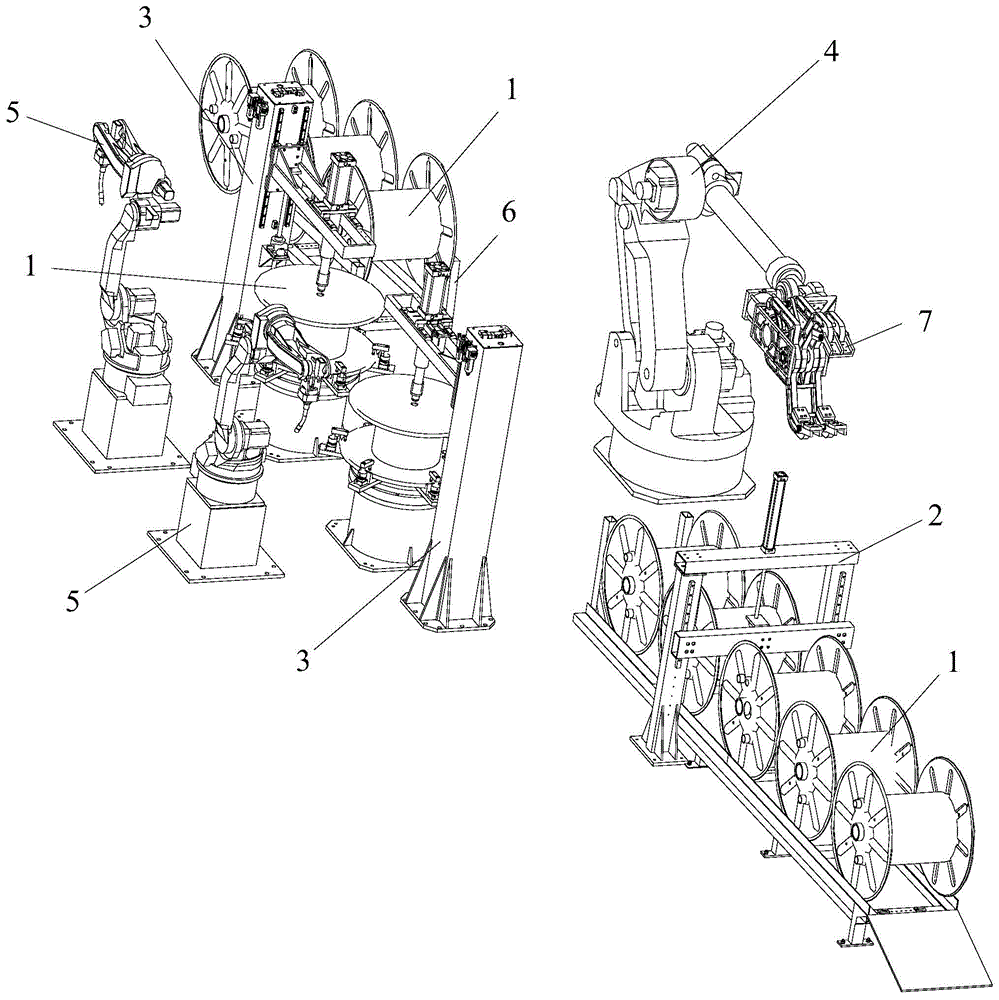

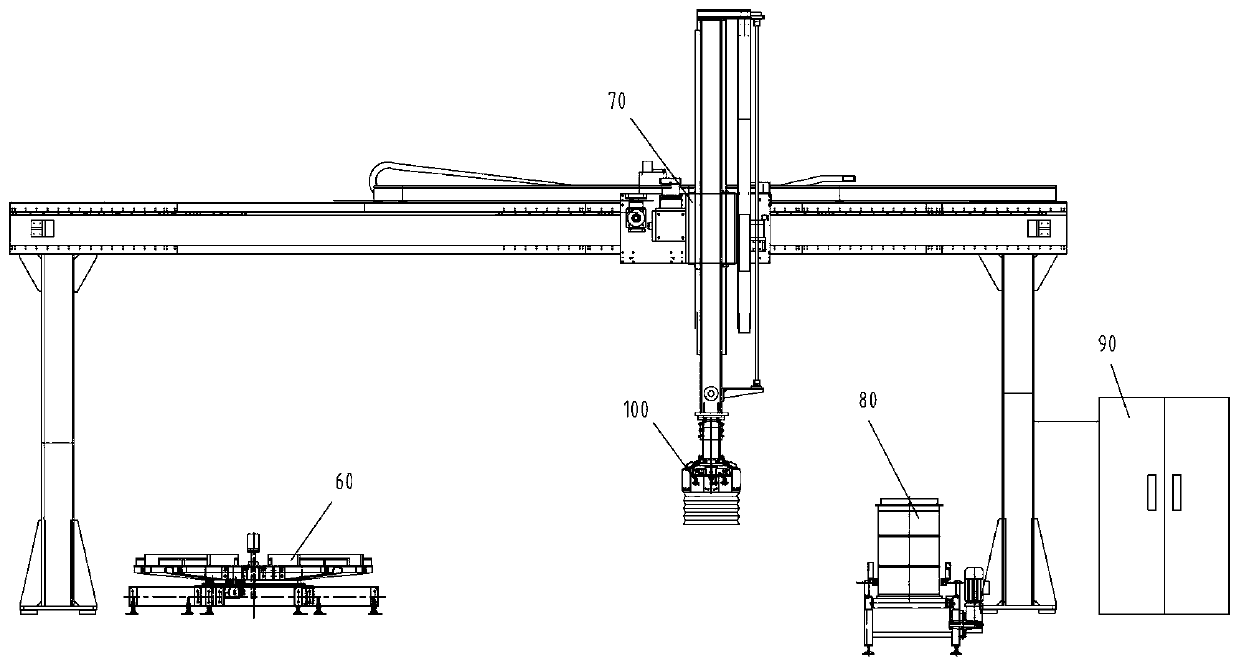

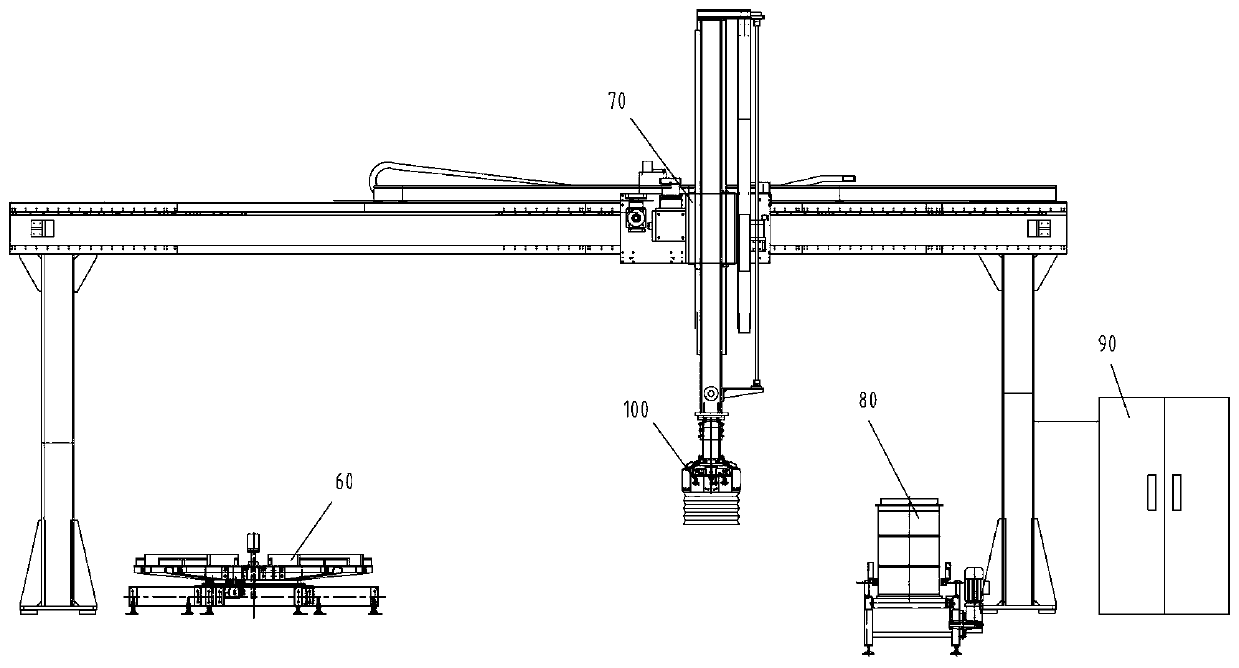

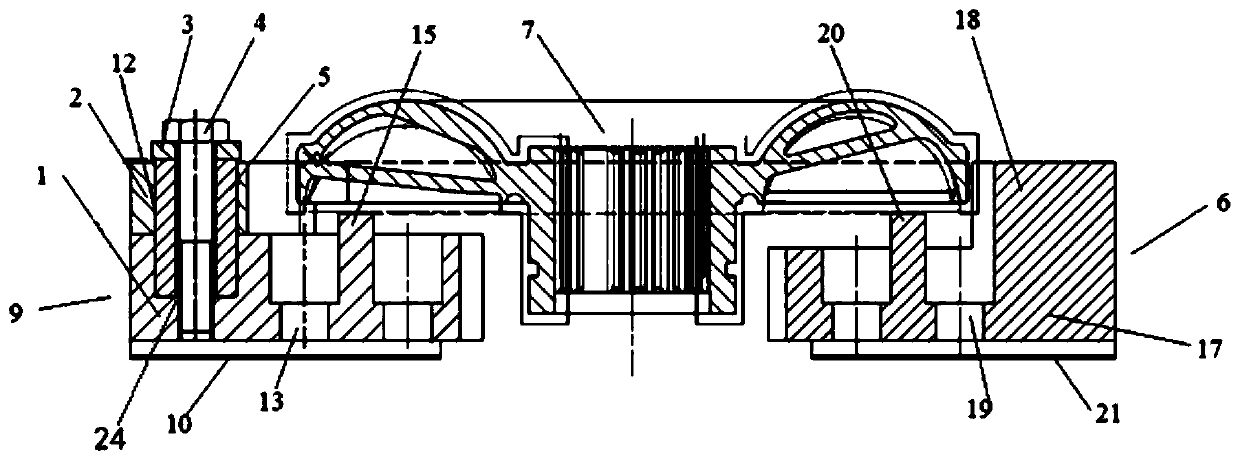

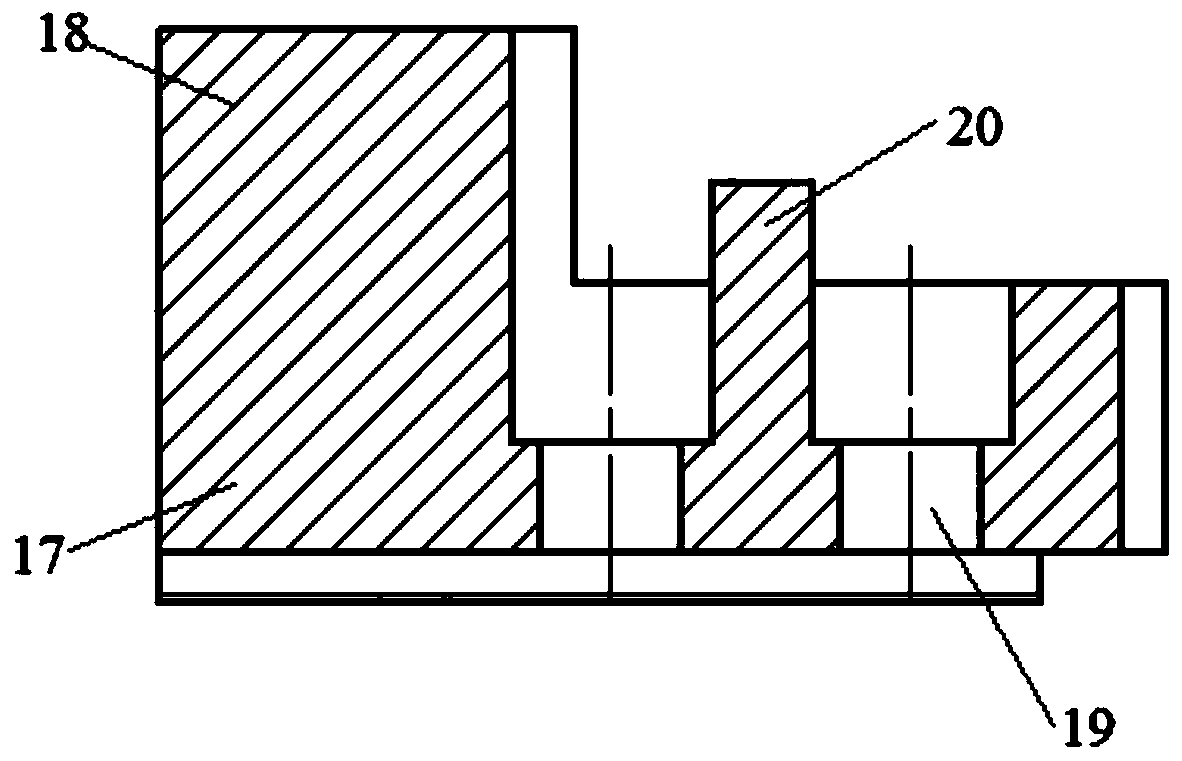

Automatic welding production line and automatic welding method for wire coils

ActiveCN104625454AHigh precisionHigh speedWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides an automatic welding production line for wire coils. The production line comprises a feeding and conveying mechanism, a pressing and positioning mechanism, a transferring manipulator, a welding manipulator, a discharging and conveying mechanism and a control mechanism in signal connection with the feeding and conveying mechanism, the pressing and positioning mechanism, the transferring manipulator and the welding manipulator. The production line is simple in structure, high in welding speed and high in welding quality stability, the phenomenon that welding of welded junctions is not uniform because of manual welding can be effectively avoided, and therefore welding efficiency, welding precision and welding quality of the wire coils can be improved. The invention further provides an automatic welding method for the wire coils. The method includes a feeding procedure, a transferring and positioning procedure, a welding procedure and a discharging procedure which are all performed in sequence, wherein in the transferring and positioning procedure, the transferring manipulator is controlled to clamp, move and overturn the wire coils, meanwhile, the pressing and positioning mechanism is used for pressing, positioning and rotating the wire coils, and the welding procedure starts. The method can be used for solving the problem that the automation degree in the current welding industry is low.

Owner:佛山市慧智智能装备有限公司

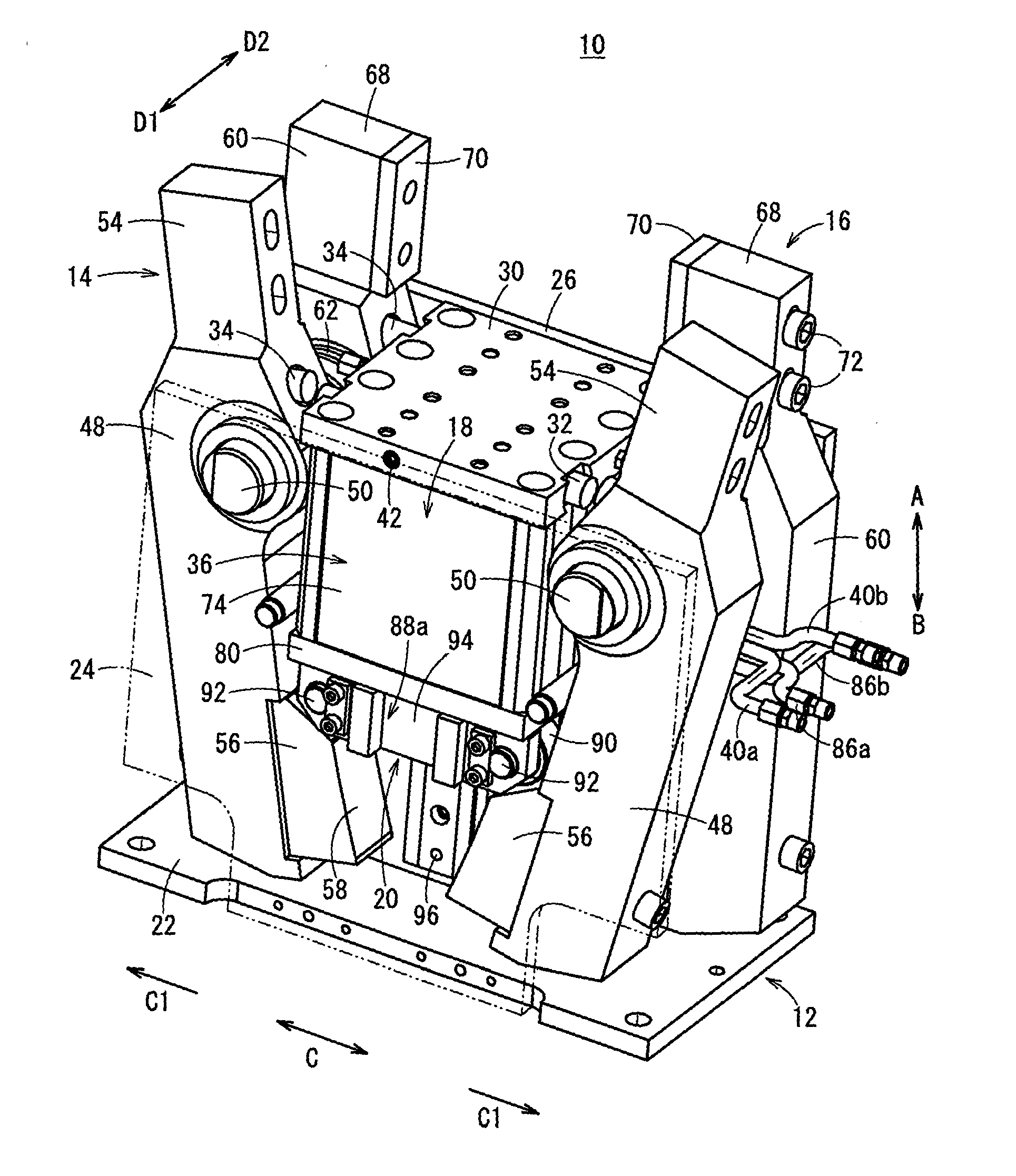

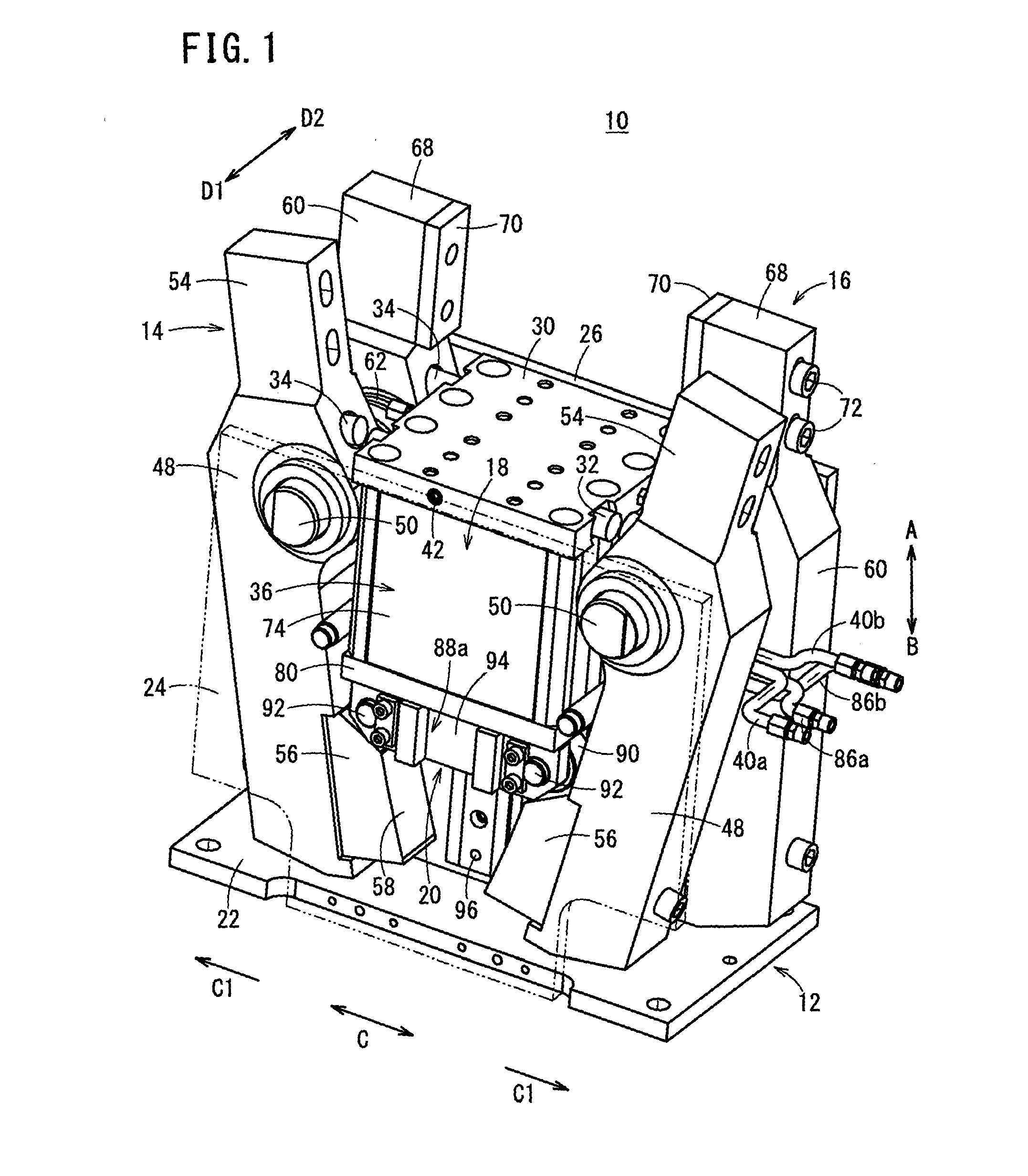

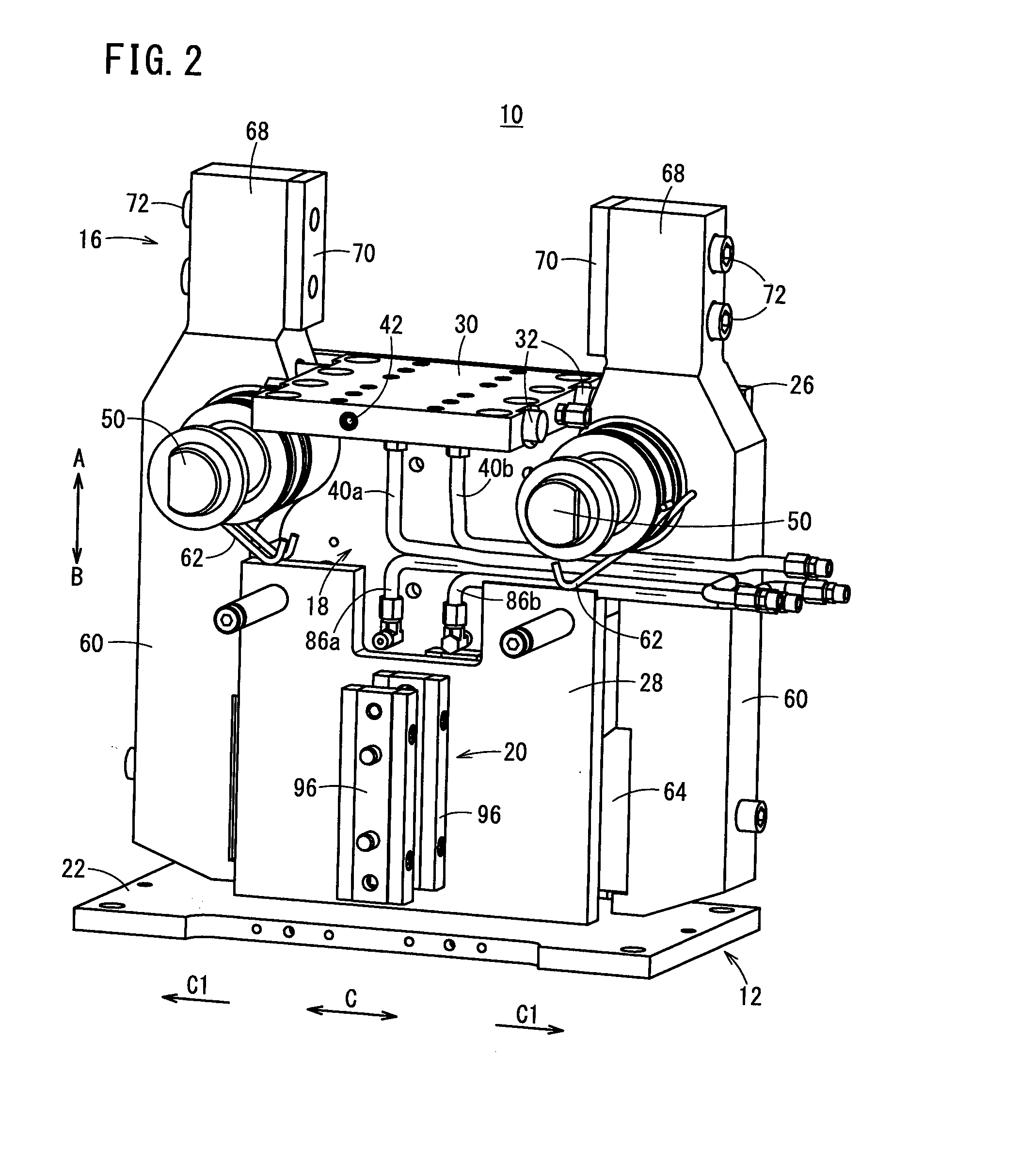

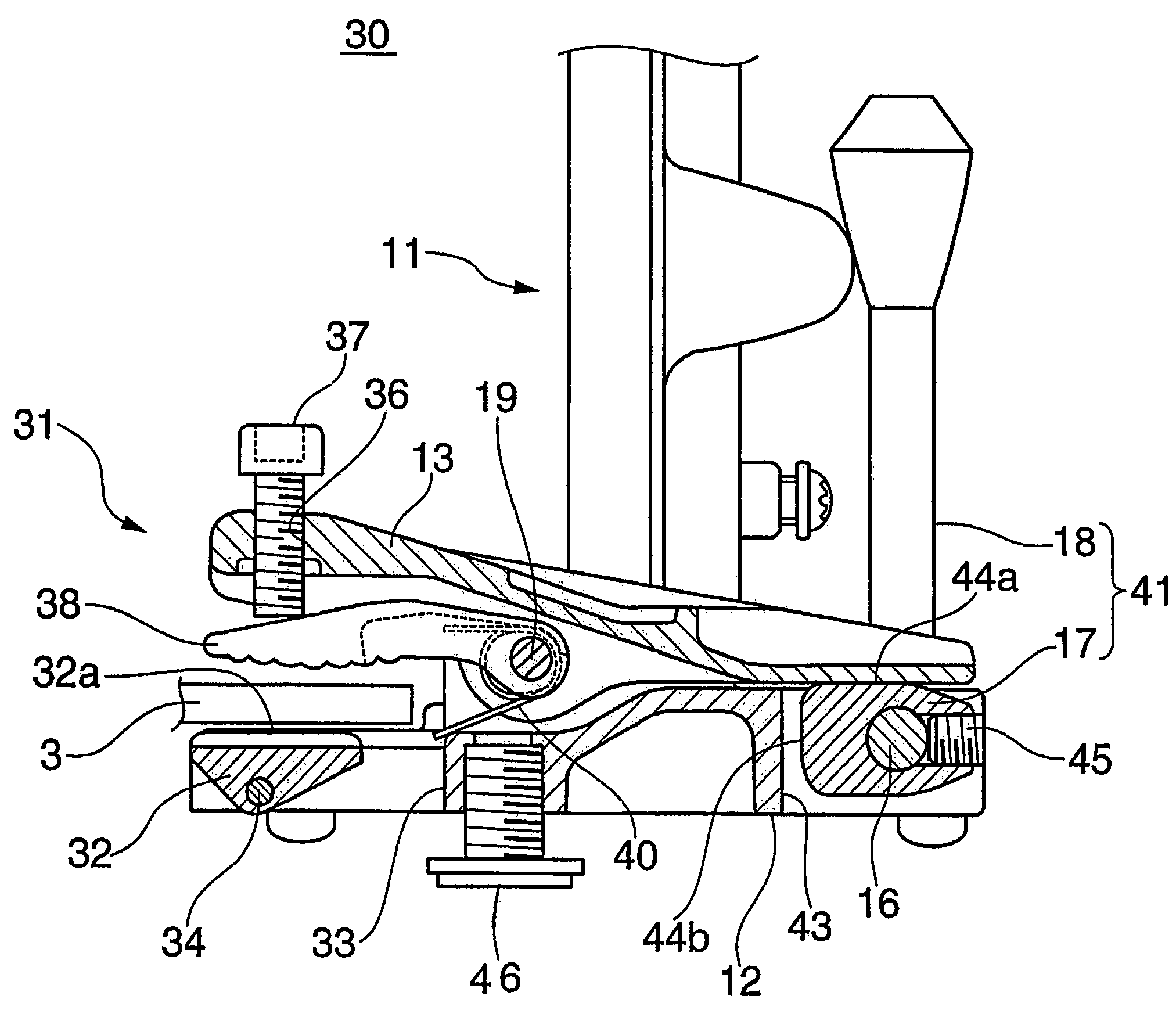

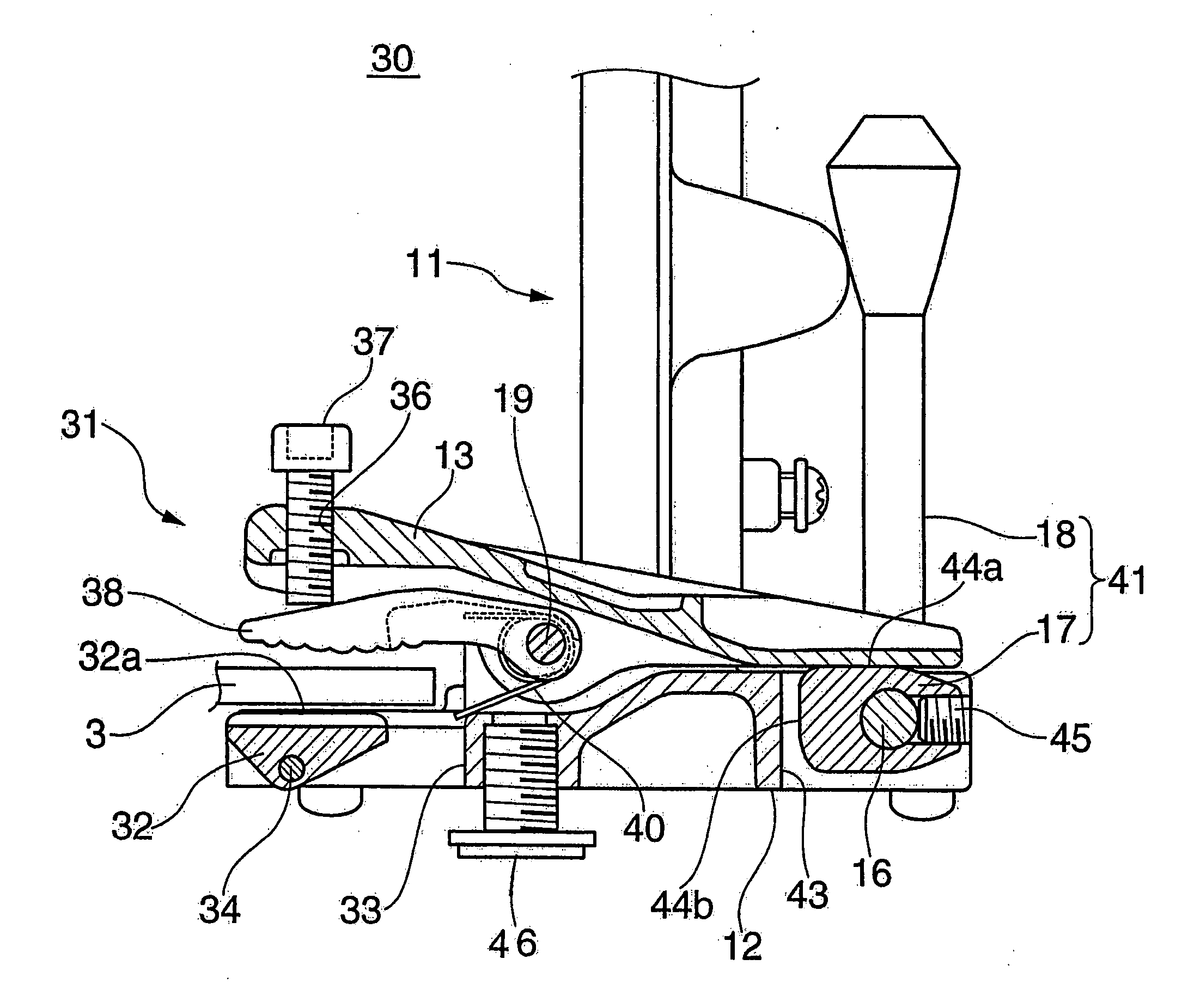

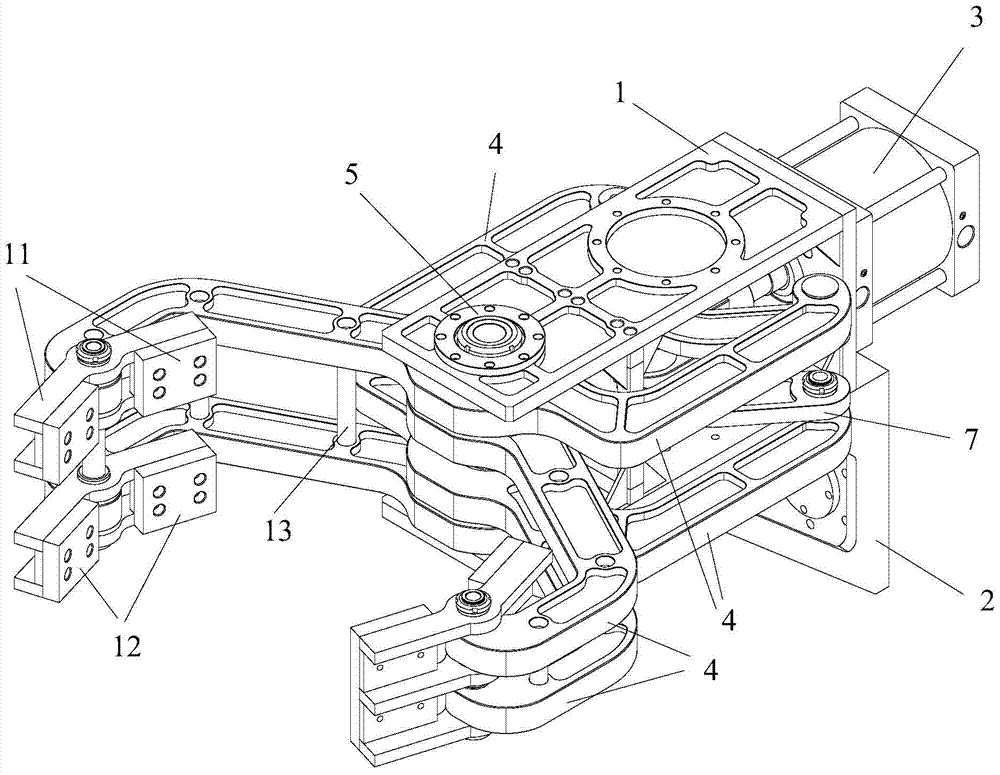

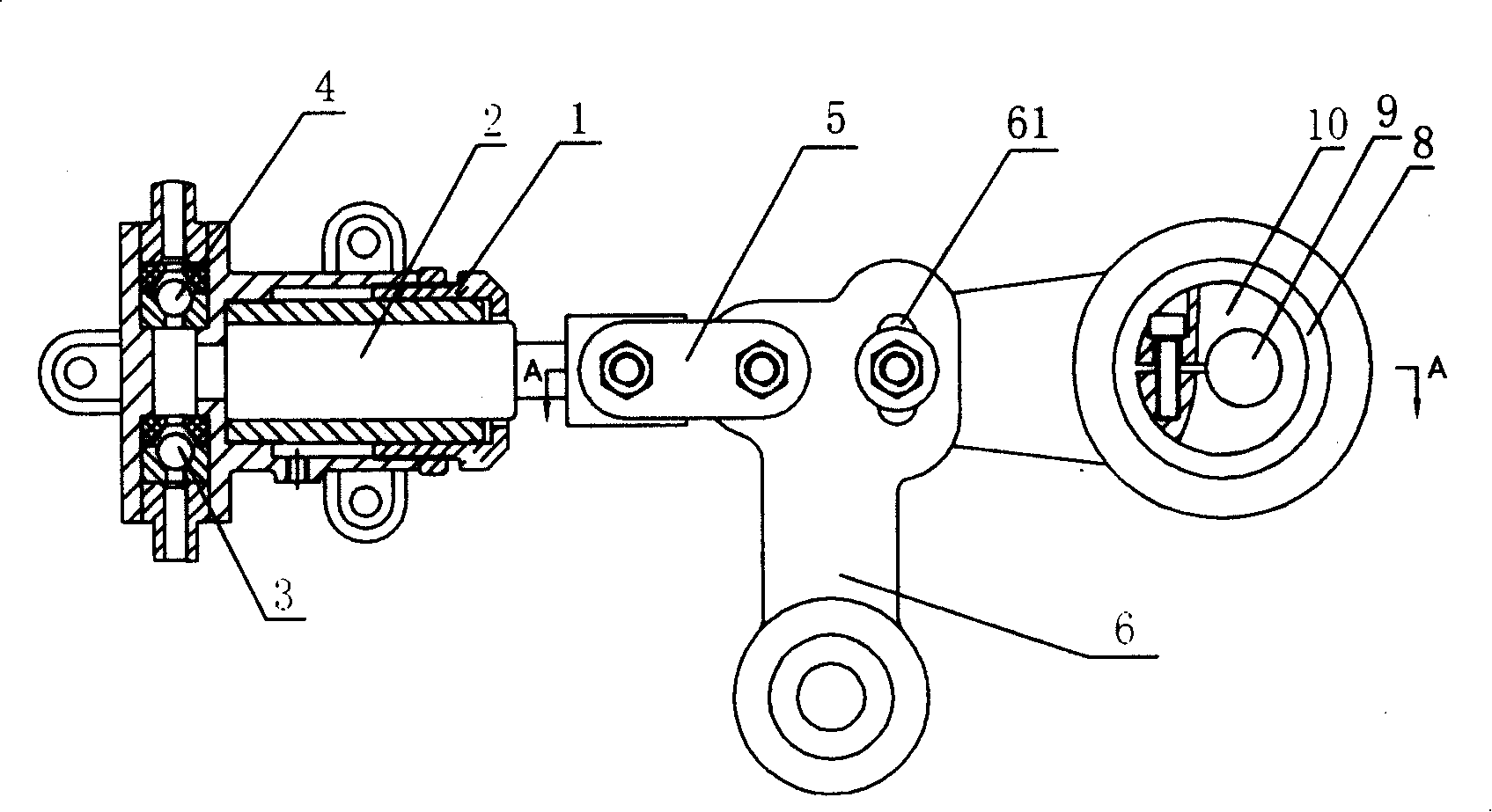

Clamp apparatus

ActiveUS20160136789A1Contribute to space savingStable and reliable clampingPositioning apparatusVicesEngineeringCam

A clamp apparatus including two pairs of first and second clamp arms, which are supported rotatably with respect to a body and are disposed mutually in parallel. First and second cam members including respective cam surfaces are provided on ends of the first and second clamp arms. The first cam members are pressed by rollers upon lowering of a block body under a driving action of a first cylinder that makes up a drive unit. The first clamp arms are rotated to assume a clamped state. The second cam members are pressed by rollers upon lowering of a block body under a driving action of a second cylinder of the drive unit, whereby the second clamp arms are rotated to assume a clamped state.

Owner:SMC CORP

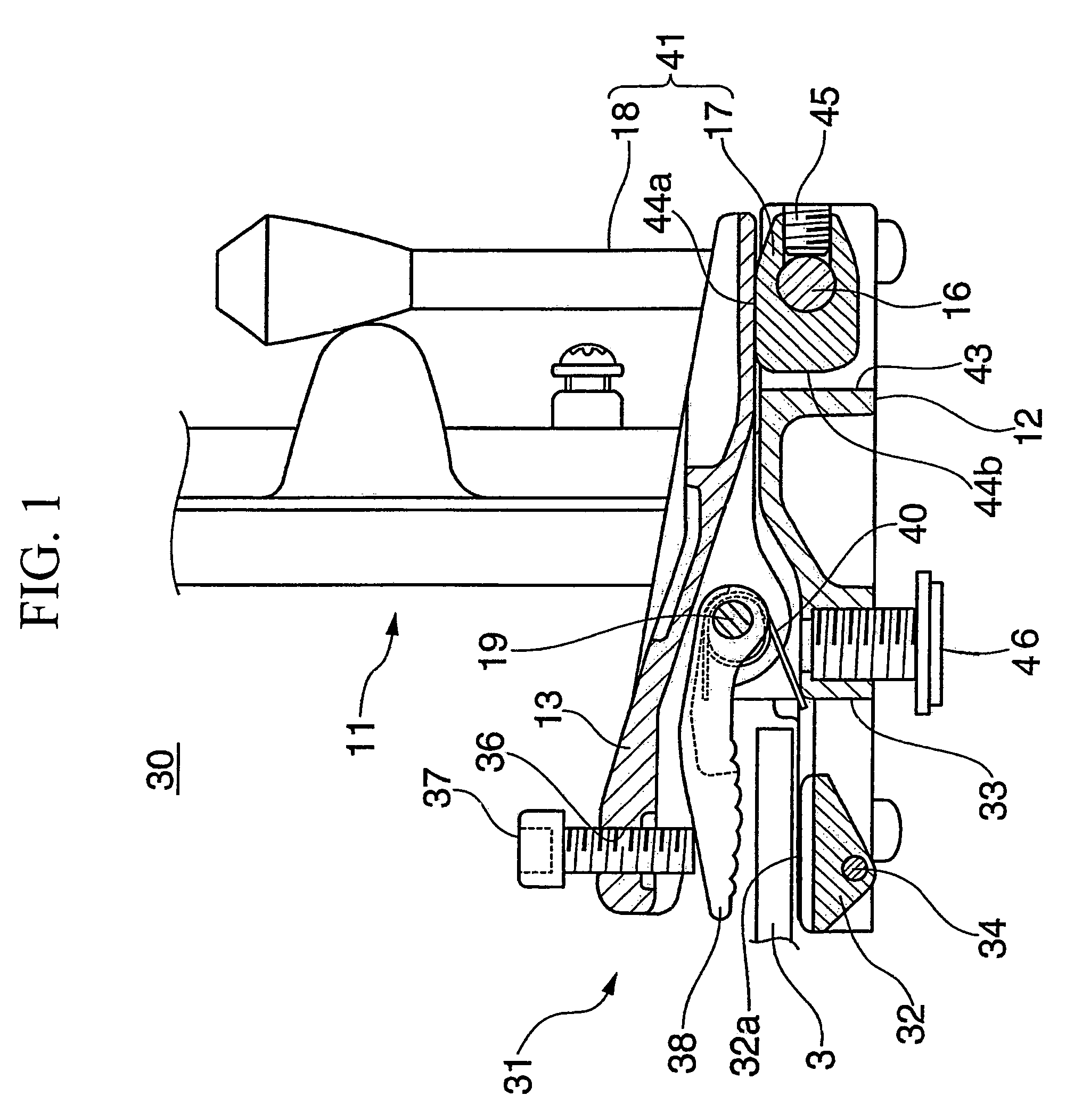

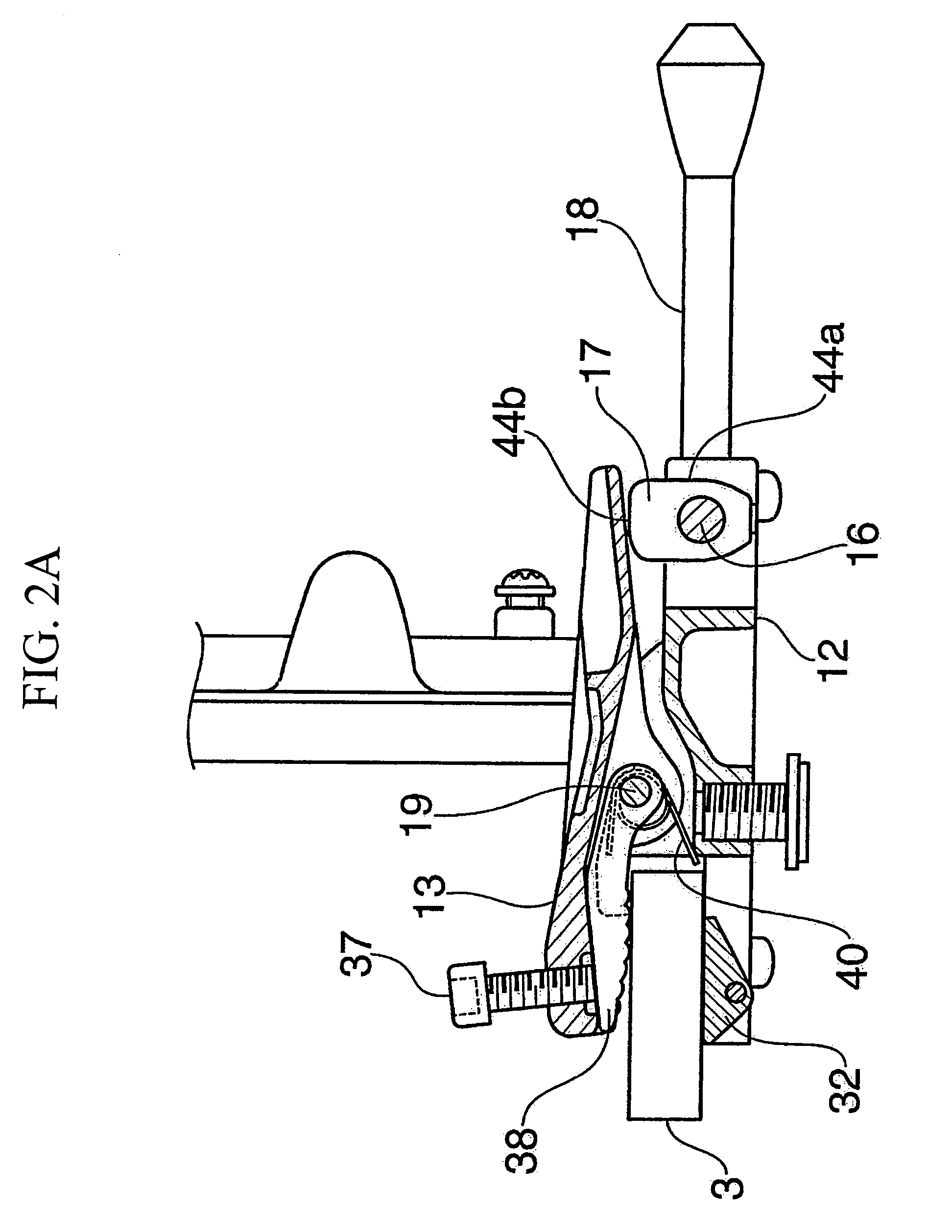

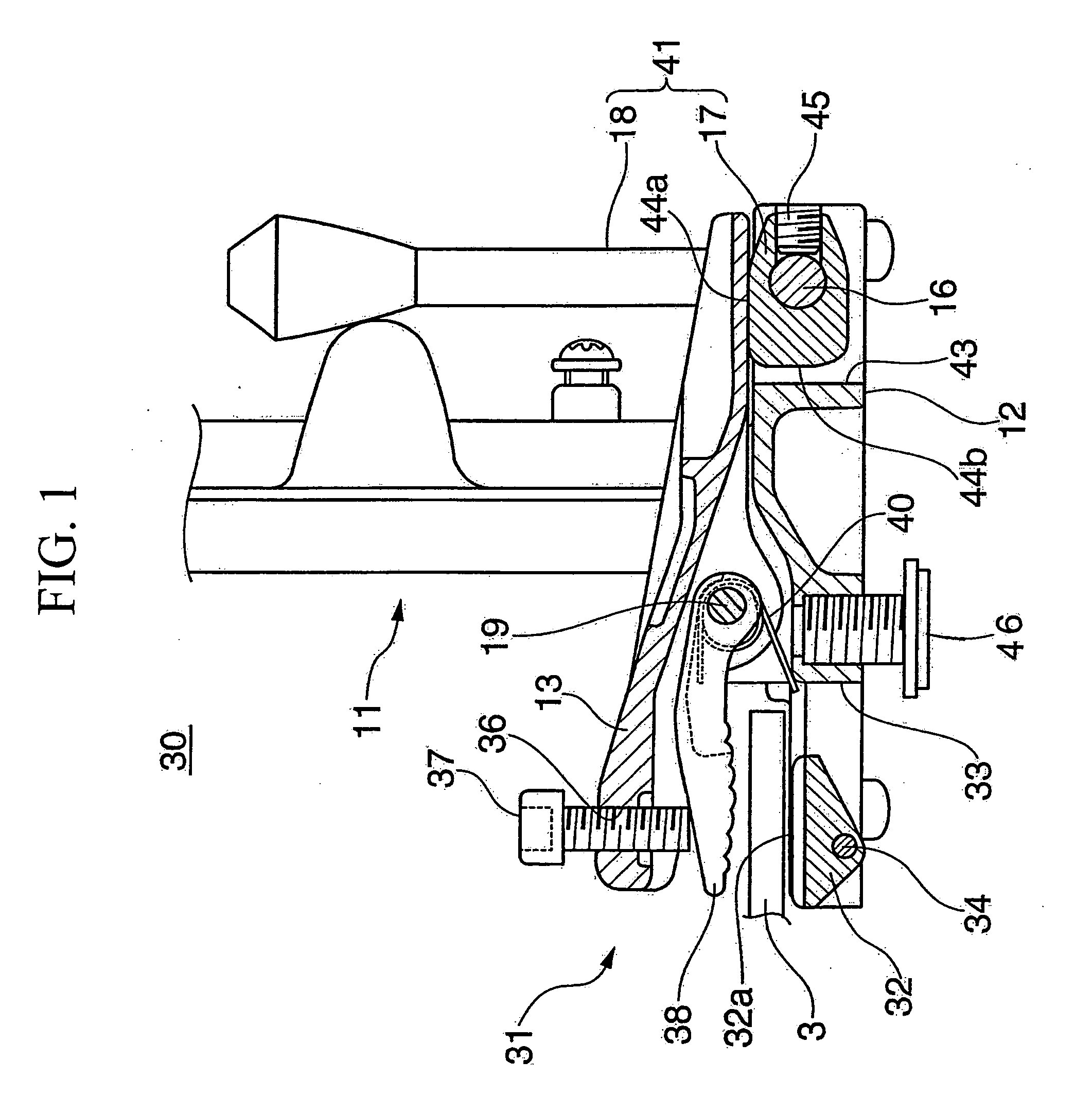

Foot pedal for drum

InactiveUS7381877B2Increased freedom of settingImprove handlingPercussion musical instrumentsFront edgeFoot boards

The present invention provides a foot pedal for a drum that can clamp a hoop regardless of a board thickness of a hoop, improves an operability, handling and moreover, appearance, and increases a freedom of a setting the angle of a foot board. A pedal frame provides a hoop pushing apparatus that clamps a drum hoop. The hoop pushing apparatus includes: a hoop clamp with rotatability; a bolt that is provided at a front edge portion of the hoop clamp, piercing the hoop clamp, and can be adjusted in height; a hoop holding and binding lever that is provided at a bottom side of the hoop clamp with rotability; and a clamp holding mechanism that rotates and holds the hoop clamp at a certain height. The hoop pushing apparatus, upon clamping, holds and binds the hoop with a hoop receiving member and the hoop holding and binding lever.

Owner:YAMAHA CORP

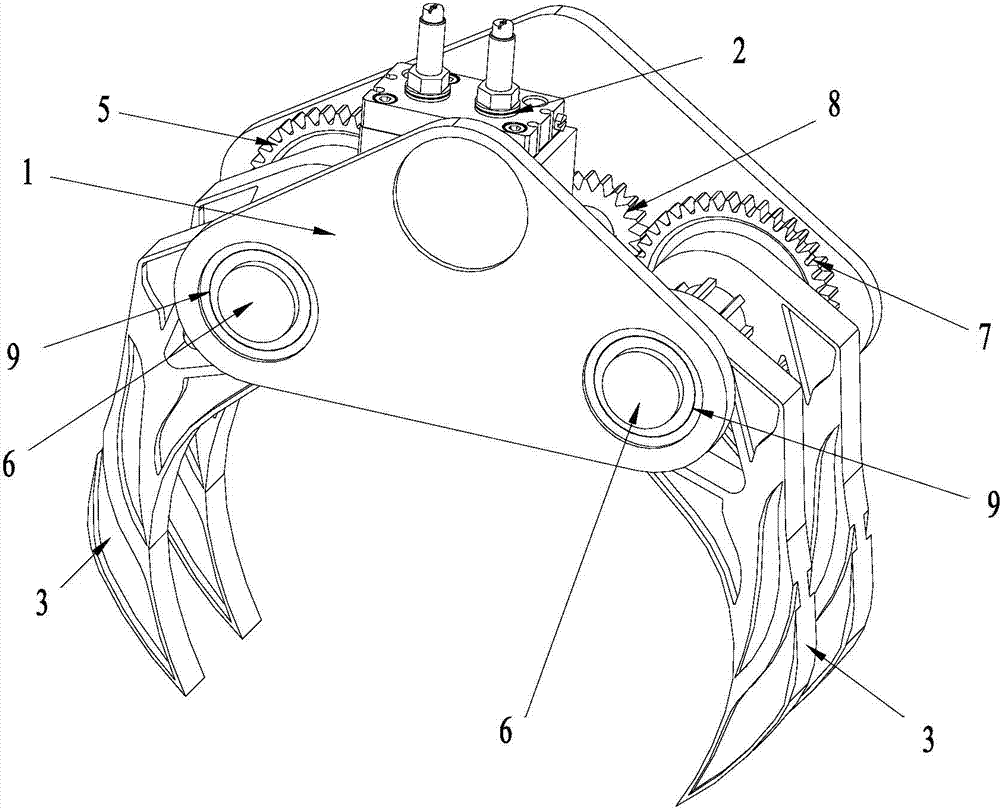

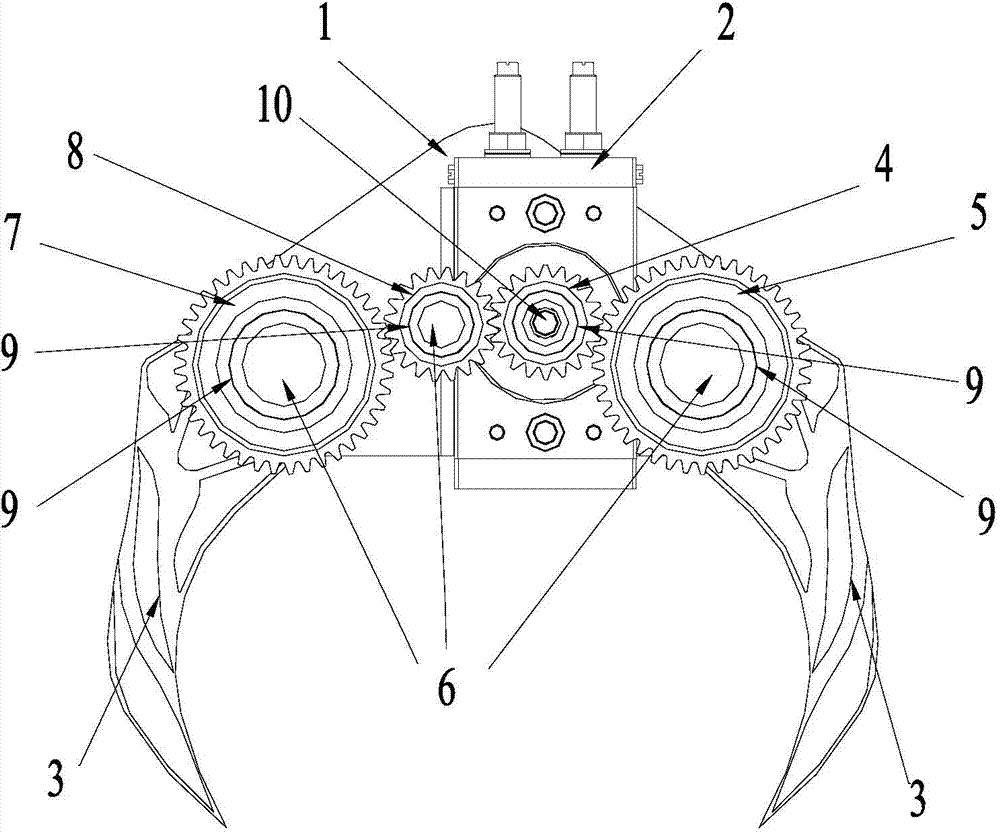

Robot gripper driven by gear

InactiveCN104772769AIncrease flexibilityImprove general performanceProgramme-controlled manipulatorGripping headsGear driveGear wheel

The invention provides a robot gripper driven by a gear. The robot gripper driven by the gear is connected with a moving section of a robot. The robot gripper comprises a bracket, a gear drive device, a driving device and at least two moving rods, wherein the bracket is connected with the moving section of the robot; the gear drive device is erected on the bracket; the driving device is connected with the gear drive device; the moving rods are connected with the gear drive device; each of the moving rods can carry out opening and closing movements. The robot gripper driven by the gear, which is provided by the invention, is simple in structure, high in universality, high in flexibility, strong in clamping force and quick in gripping speed, and the quick gripping of a workpiece and the firm clamping of the workpiece in the process that the robot moves quickly can be realized, so as to effectively solve the problem of matching the gripper with the workpiece, decrease production cost and manufacturing cost, and improve production efficiency.

Owner:广东泰格威机器人科技有限公司

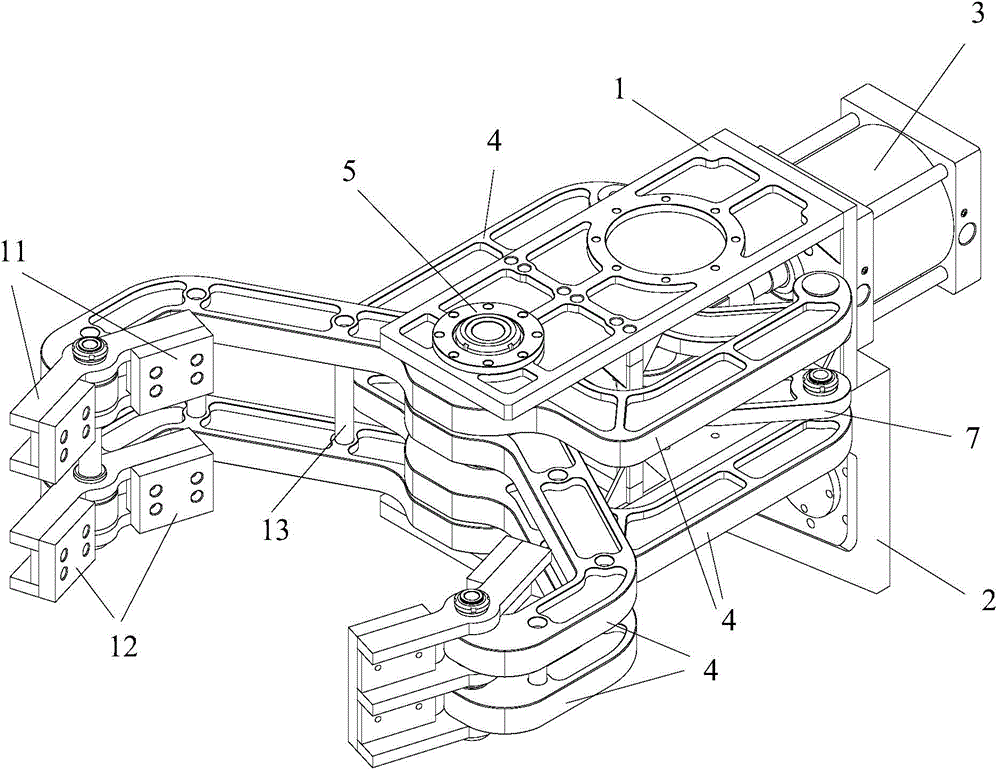

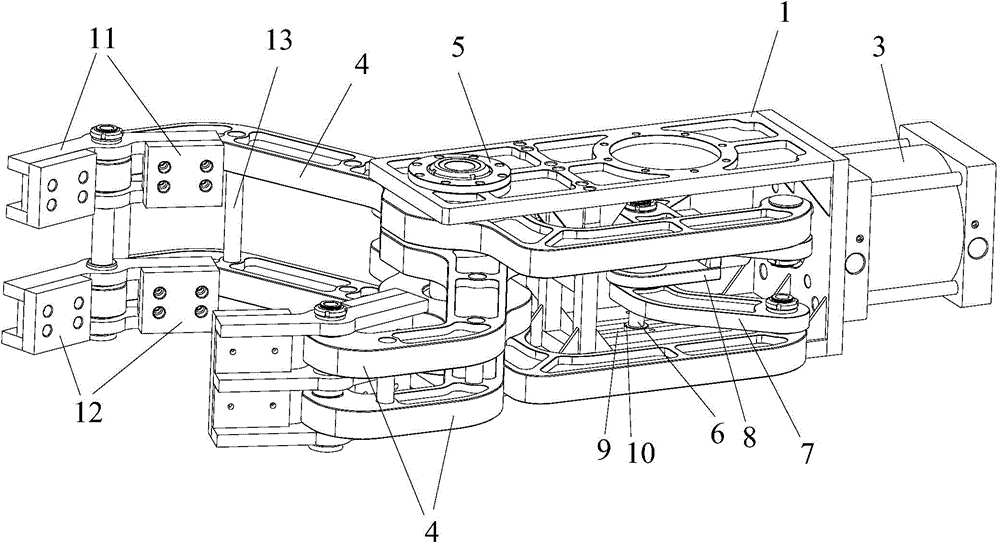

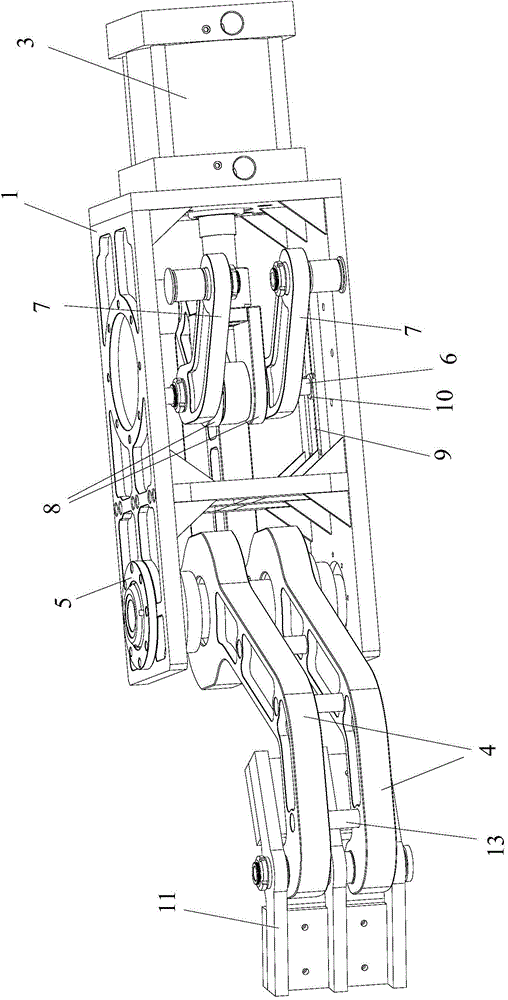

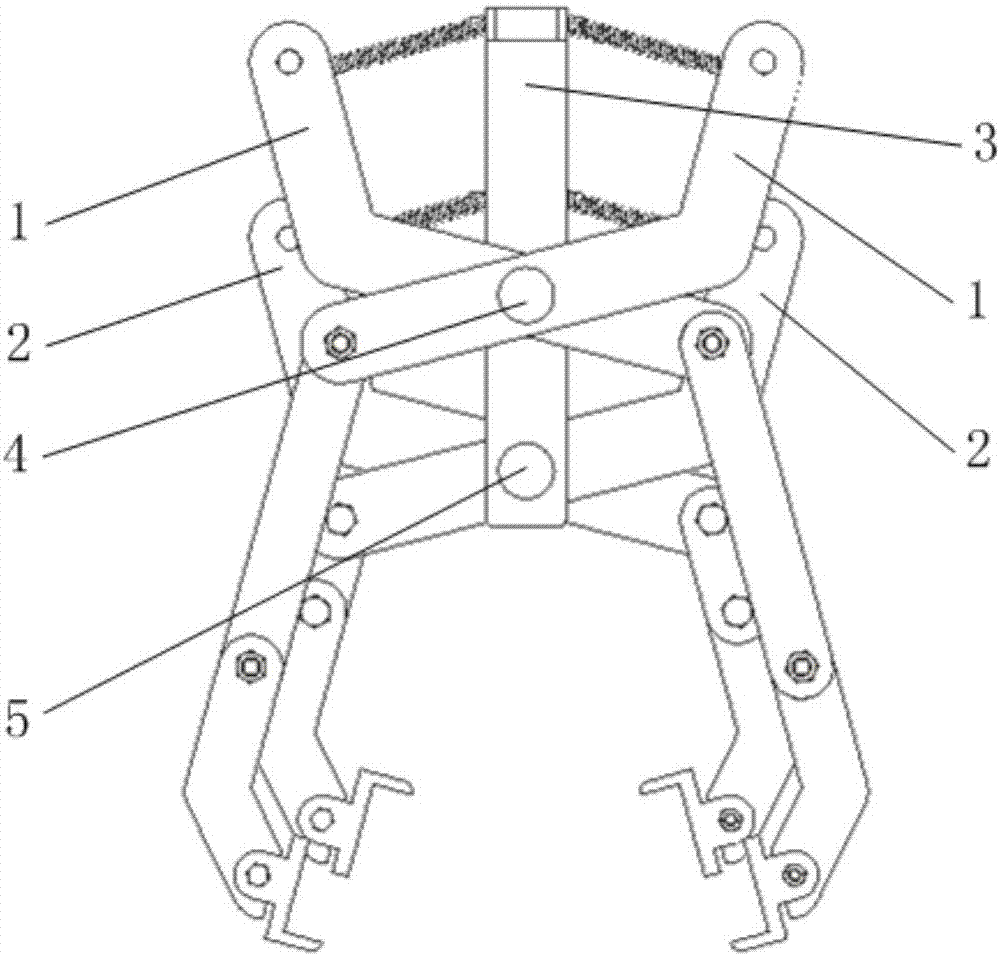

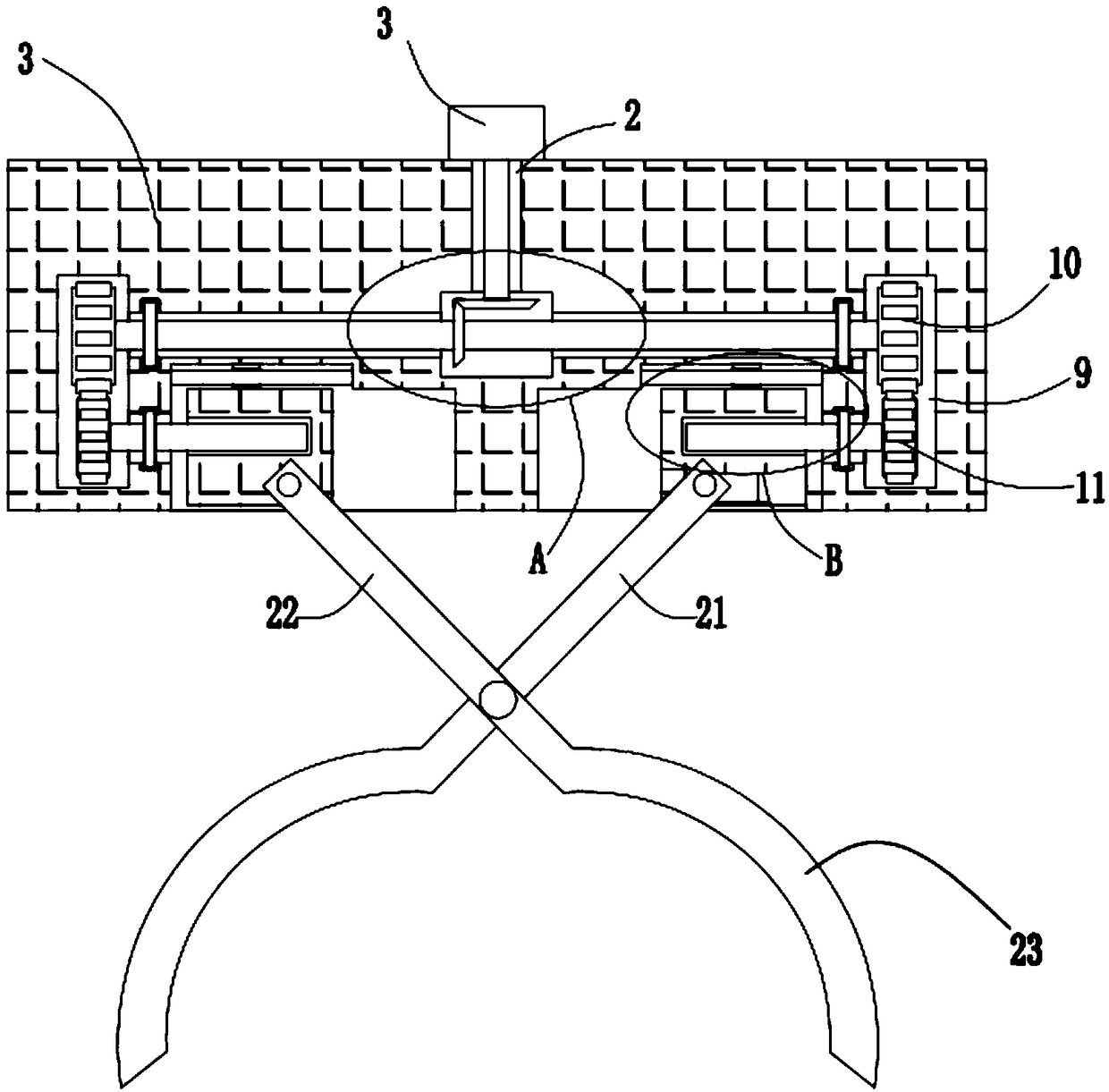

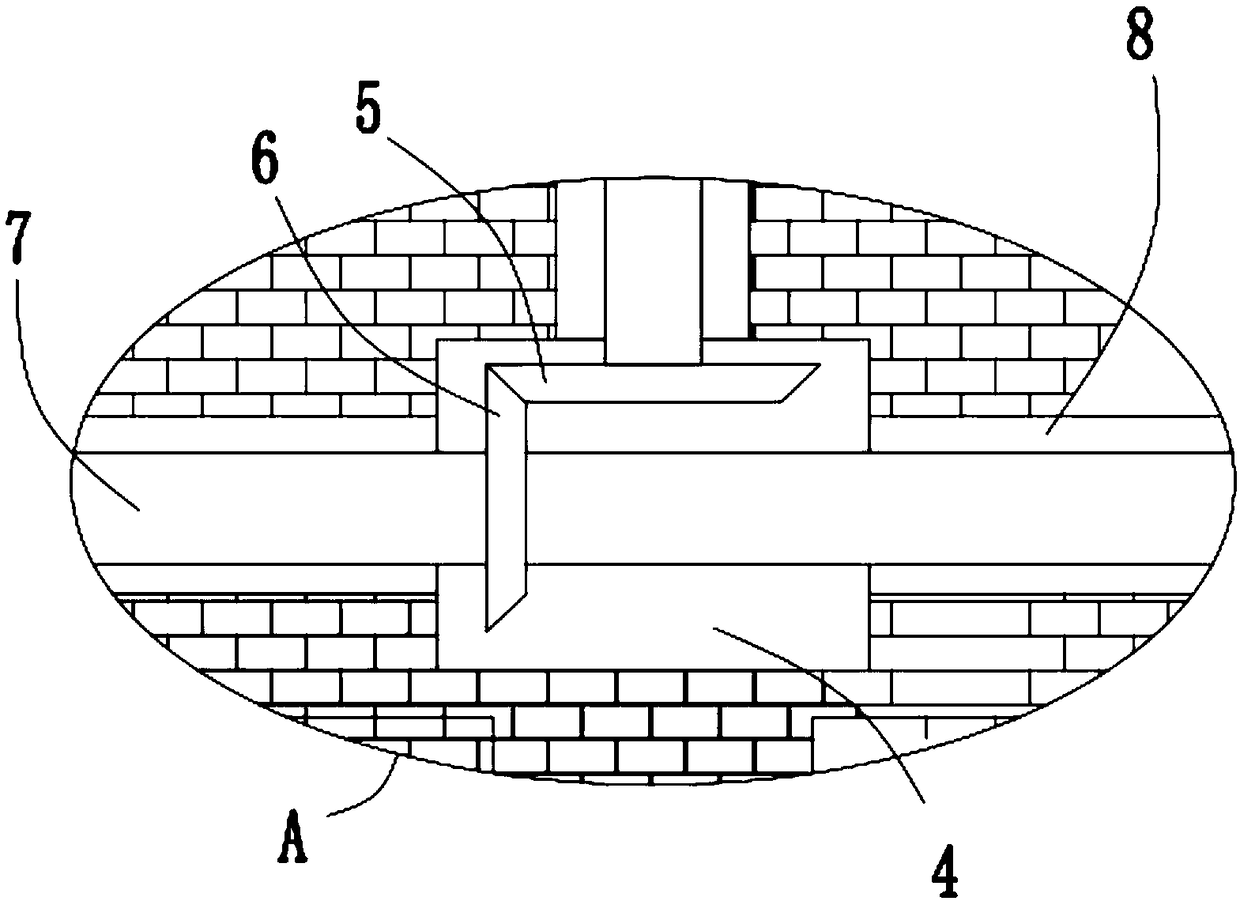

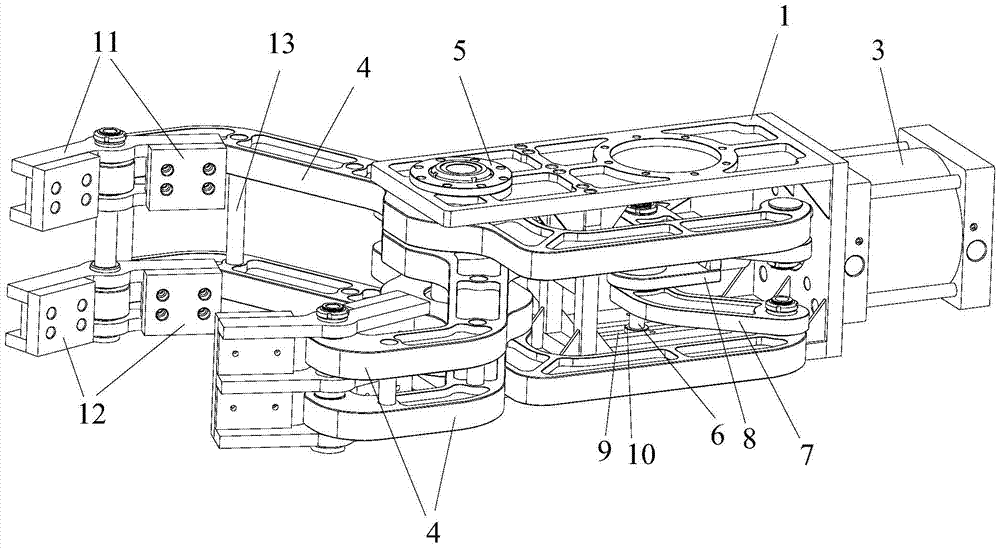

Robot clamping device

ActiveCN104589364AImprove motor flexibilityStrong clamping forceGripping headsEngineeringManipulator

The invention provides a robot clamping device, which comprises a main frame, a connecting seat, a connecting mechanism, a driving mechanism, a control mechanism and clamping arms, wherein the connecting seat is connected with the front end of a manipulator, the connecting mechanism is arranged in the main frame, the driving mechanism is used for driving the connecting mechanism to move, the connecting seat is arranged on the main frame, the two clamping arms are crossed at the two sides of the main frame, one end of each of the clamping arms is respectively hinged to the connecting mechanism, the crossing part is arranged at the main frame, and is rotationally connected with the two clamping arms, the driving mechanism is connected with the control mechanism in a signal way, and the connecting mechanism is driven to move, so as to drive the clamping arms to open and close. The robot clamping device has the advantages that the action flexibility is high, and the clamping force is large, so as to quickly grab and stably and reliably clamp a workpiece; by matching with a robot, the production efficiency and automation degree are greatly improved; the structure is simple, the operation and maintenance are easy, and the use cost is reduced.

Owner:佛山市慧智智能装备有限公司

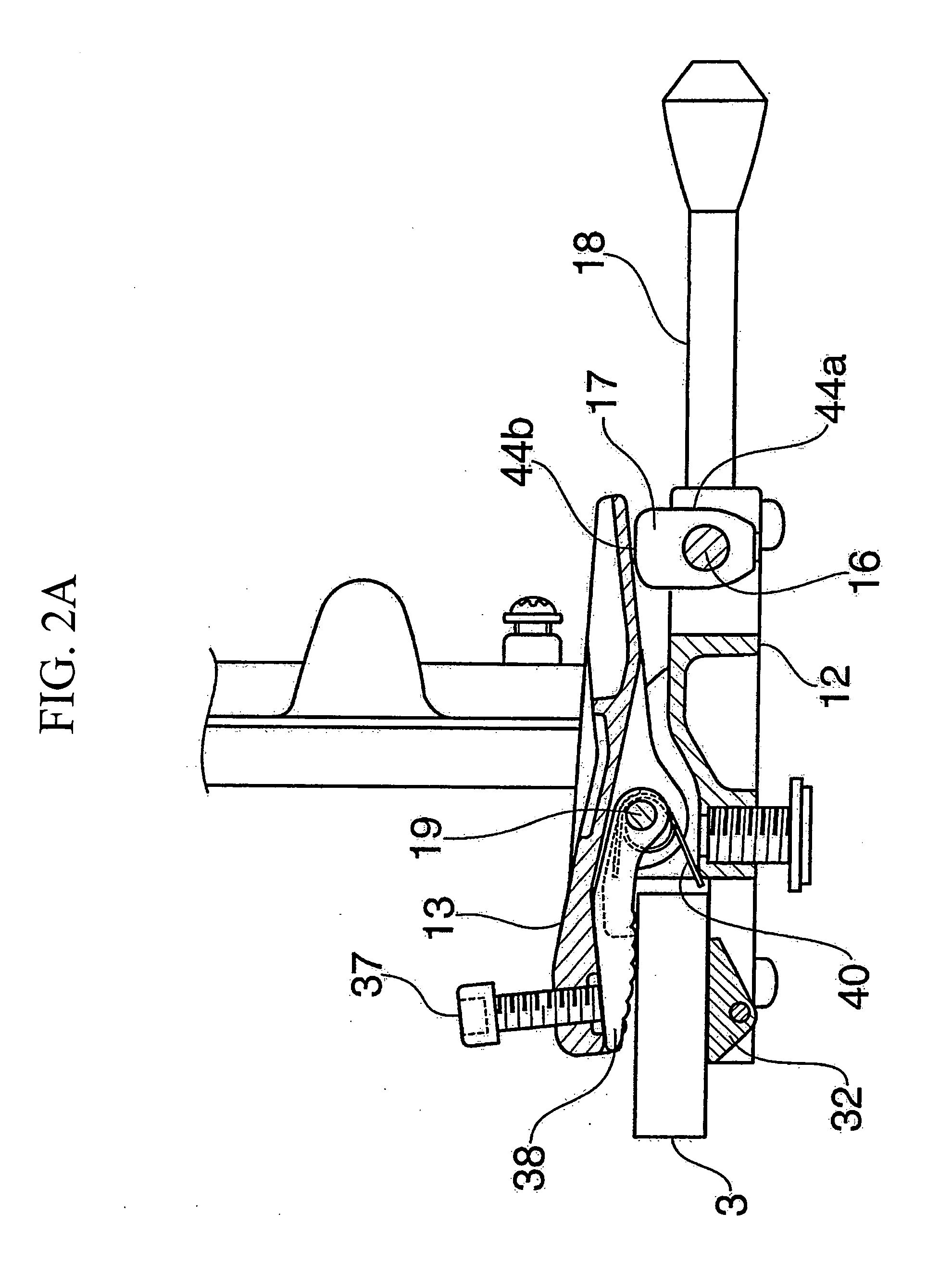

Foot pedal for drum

InactiveUS20060278060A1Increased freedom of settingImprove handlingPercussion musical instrumentsEngineeringFront edge

The present invention provides a foot pedal for a drum that can clamp a hoop regardless of a board thickness of a hoop, improves an operability, handling and moreover, appearance, and increases a freedom of a setting the angle of a foot board. A pedal frame provides a hoop pushing apparatus that clamps a drum hoop. The hoop pushing apparatus includes: a hoop clamp with rotatability; a bolt that is provided at a front edge portion of the hoop clamp, piercing the hoop clamp, and can be adjusted in height; a hoop holding and binding lever that is provided at a bottom side of the hoop clamp with rotability; and a clamp holding mechanism that rotates and holds the hoop clamp at a certain height. The hoop pushing apparatus, upon clamping, holds and binds the hoop with a hoop receiving member and the hoop holding and binding lever.

Owner:YAMAHA CORP

Test-piece clamping pincers for CTOD testing

The invention provides test-piece clamping pincers for CTOD testing. The test-piece clamping pincers comprise a supporting frame, two sets of main pincers and two sets of auxiliary pincers. The supporting frame is an H-shaped member, and connecting rods arranged oppositely are arranged on the two sides of the supporting frame. The two connecting rods are connected through a middle rod. The connecting rods are arranged in parallel. Each set of main pincers is composed of two main pincers assemblies. Each set of auxiliary pincers is composed of two auxiliary pincers assemblies. Each main pincers assembly comprises a pincers handle, an adjusting rod, a large crutch, a pincers foot and a first pressing spring, all of which are connected in sequence. Each auxiliary pincers assembly is composed of a pincers crutch, a lengthening rod, a small crutch, a pincers claw and a second pressing spring, all of which are connected in sequence. Accordingly, the test-piece clamping pincers are safe, reliable and easy to use, the situation that when a medium or large test-piece is tested, due to falling of the test-piece, accidents are caused, or cooling liquid splashes, and operators are injured can be effectively avoided, and the safety of testing is improved.

Owner:CNPC OFFSHORE ENG

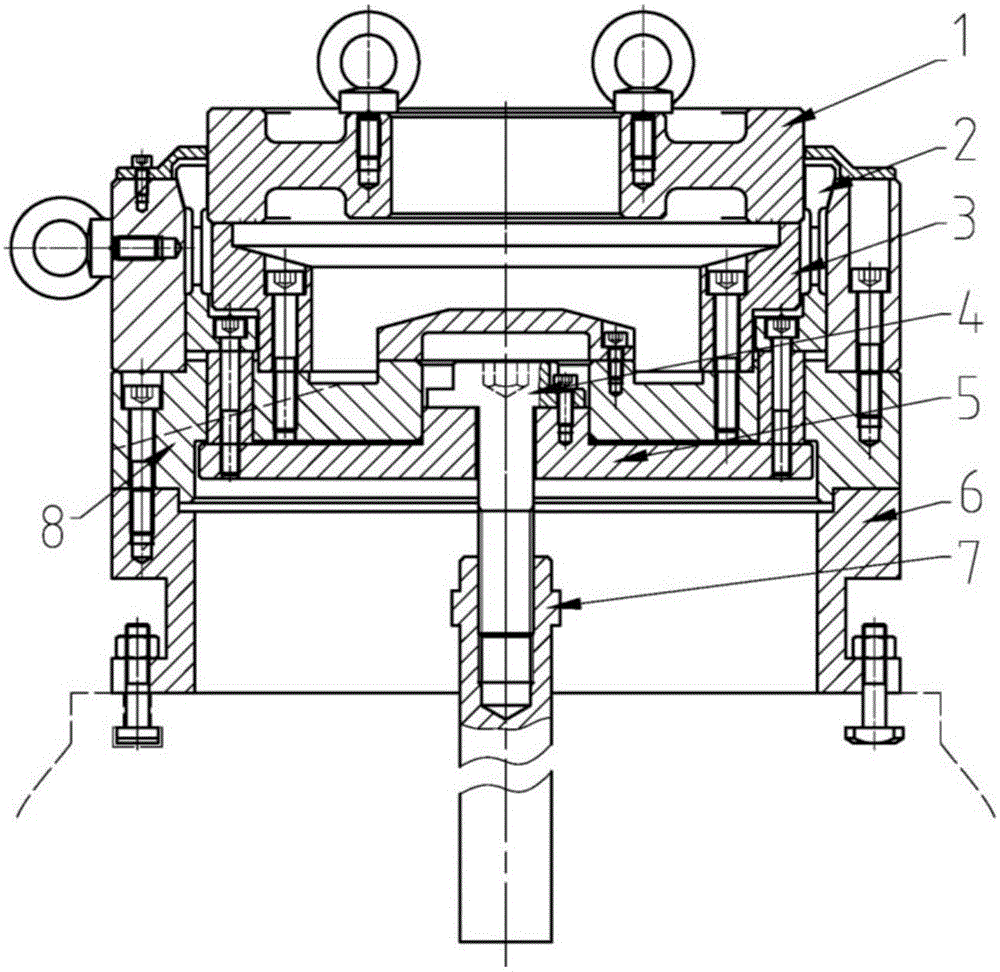

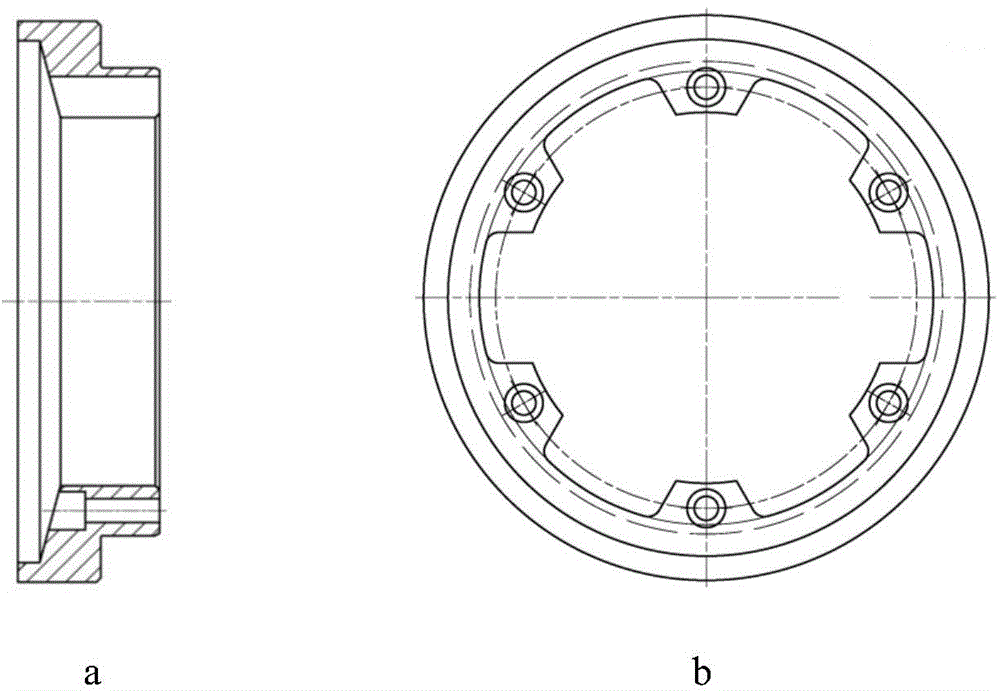

Large-ring-gear externally-expanded type efficient gear shaping clamp

InactiveCN104972181AAvoid deformationConstant clamping forceGear-cutting machinesGear teethEngineeringMachine tool

The invention discloses a large-ring-gear externally-expanded type efficient gear shaping clamp which comprises a base and a body arranged on the base. A connection disk, an expansion sleeve and a support are sequentially arranged on the inner side of the body from bottom to top. The base is fixedly connected with a machine tool table. Compared with a three-jaw chuck and manual clamping, the large-ring-gear externally-expanded type efficient gear shaping clamp is constant in clamping force, the clamping process is stable and reliable, and parts are not prone to deforming; the large-ring-gear externally-expanded type efficient gear shaping clamp is suitable for gear shaping machines of various specifications by replacing the base and a connection rod, and the large-ring-gear externally-expanded type efficient gear shaping clamp is suitable for parts of different size series by replacing the expansion sleeve and the support. The support can be designed of a petal type toothed structure and is paired with a chute arranged on the body, the chip removing speed is increased, and accumulated scrap iron is effectively prevented from affecting machining. The clamp is relatively simple in whole structure and convenient to manufacture, and an adjustment space is reserved for insufficient manufacturing and assembling precision. The clamp can be arranged as a whole or parts of the clamp are sequentially arranged, and the parts can be conveniently detected and replaced.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

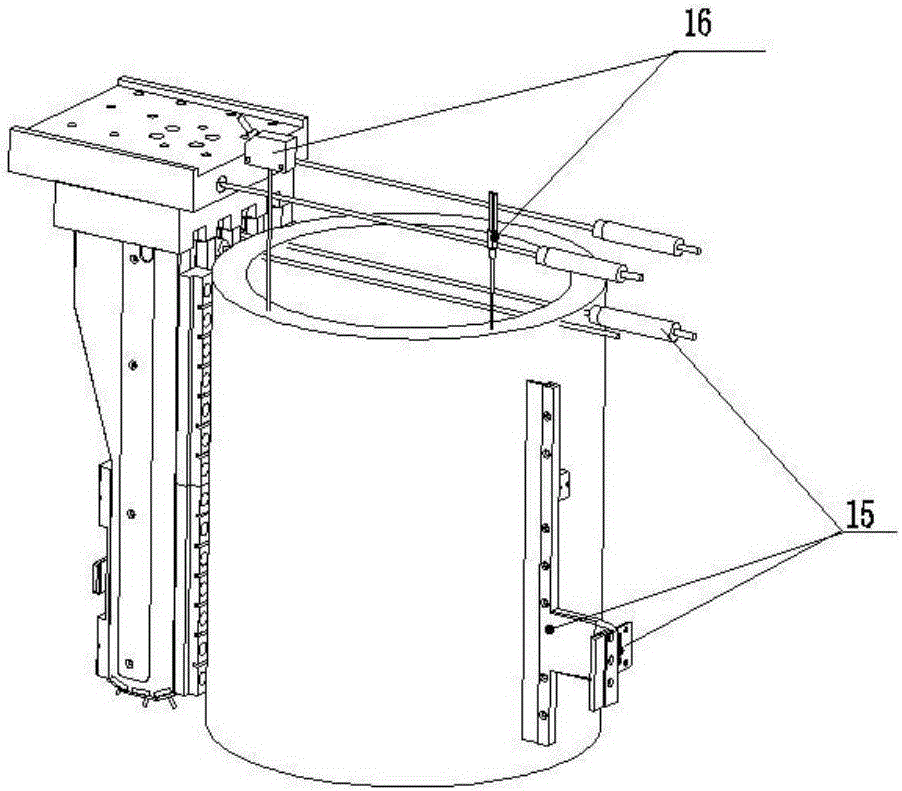

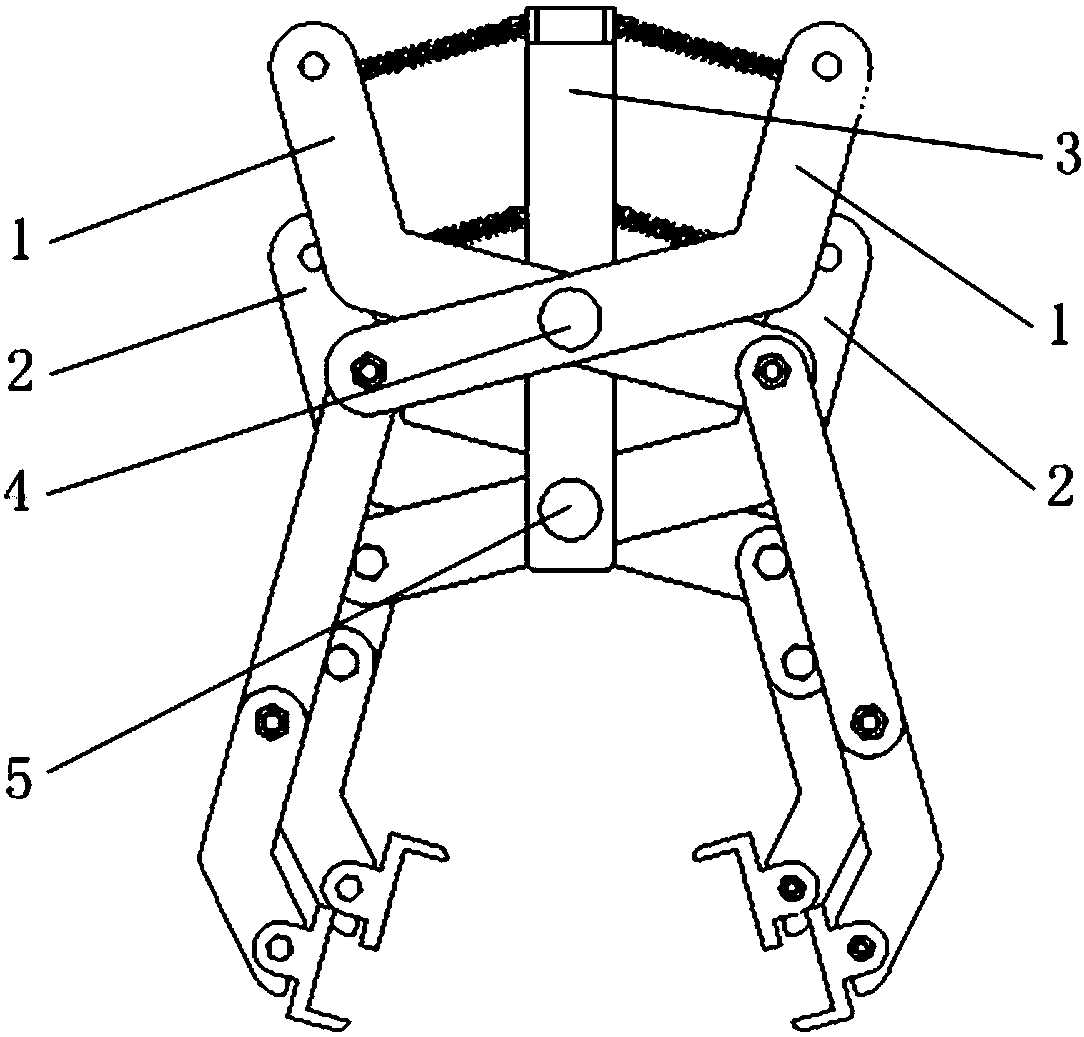

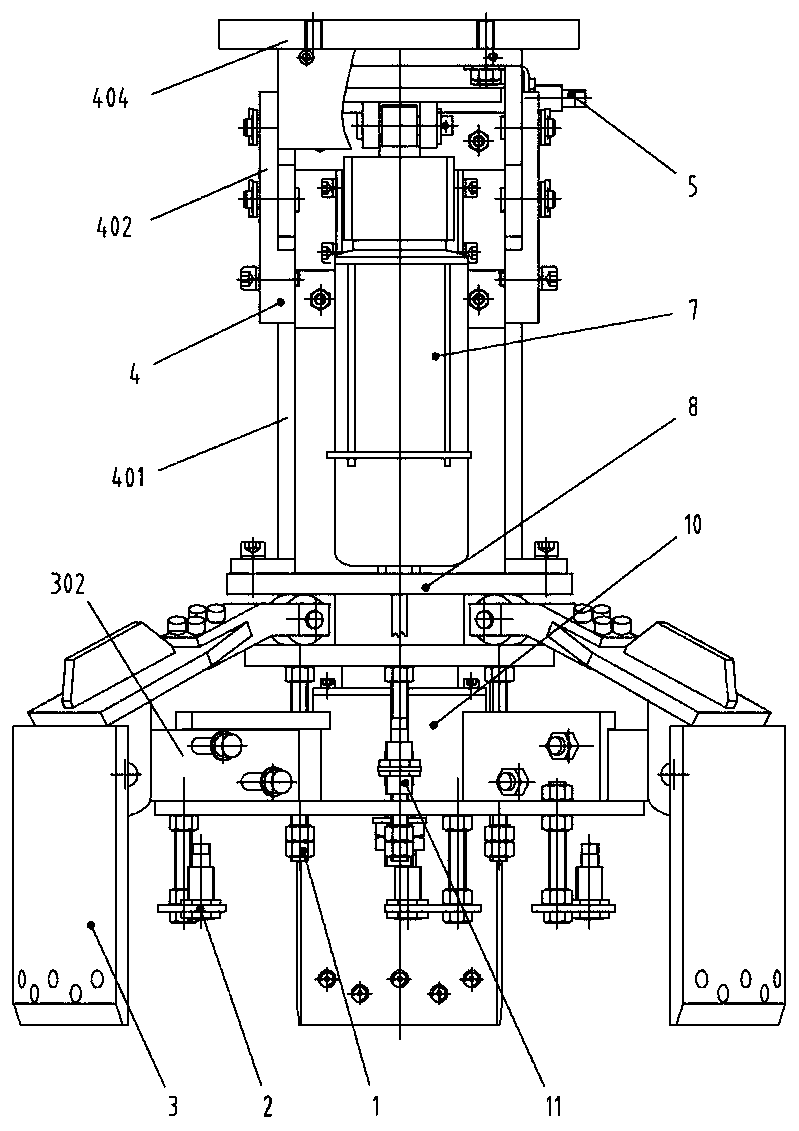

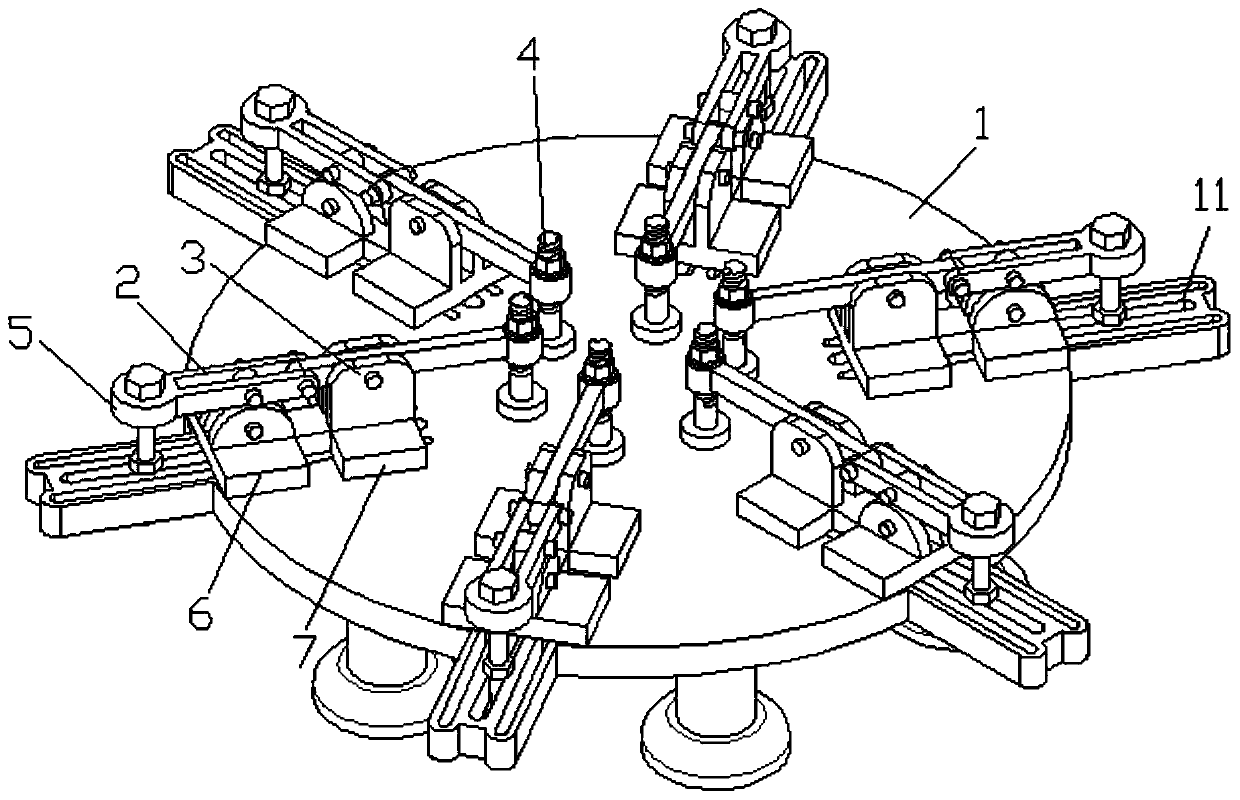

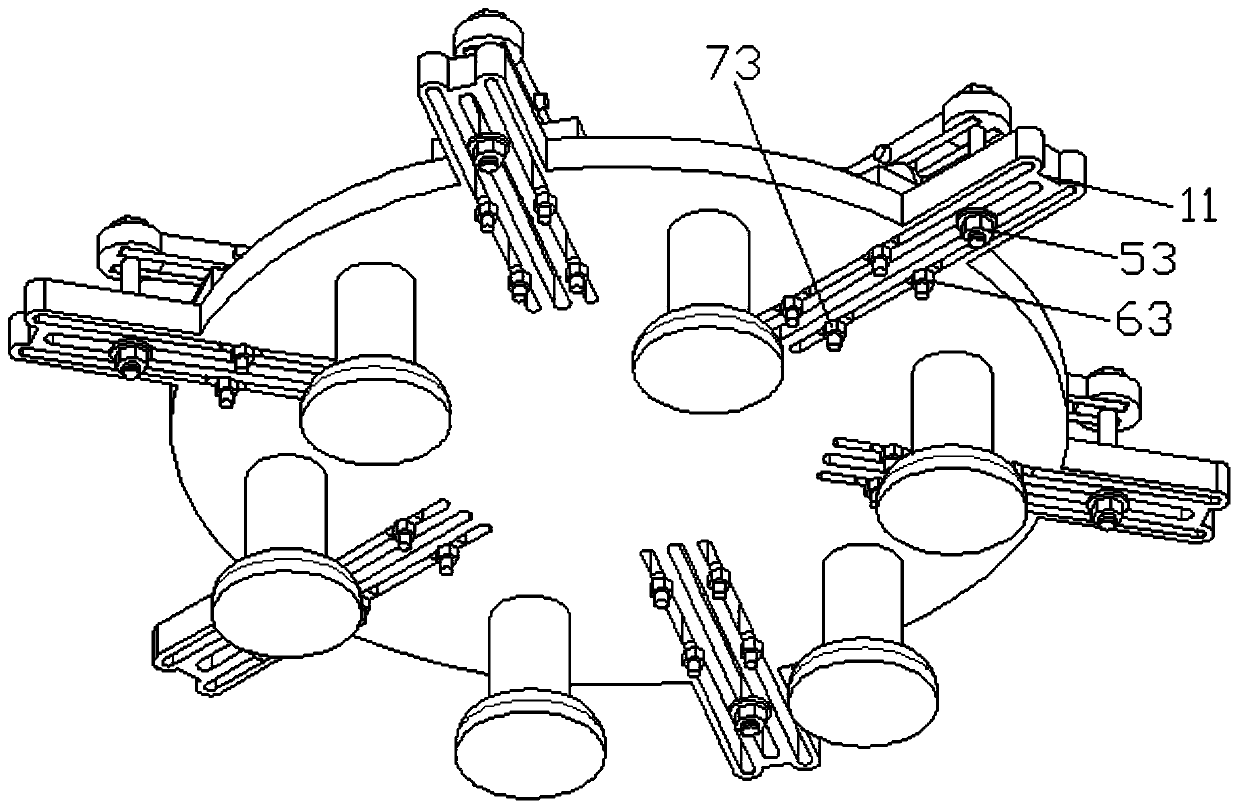

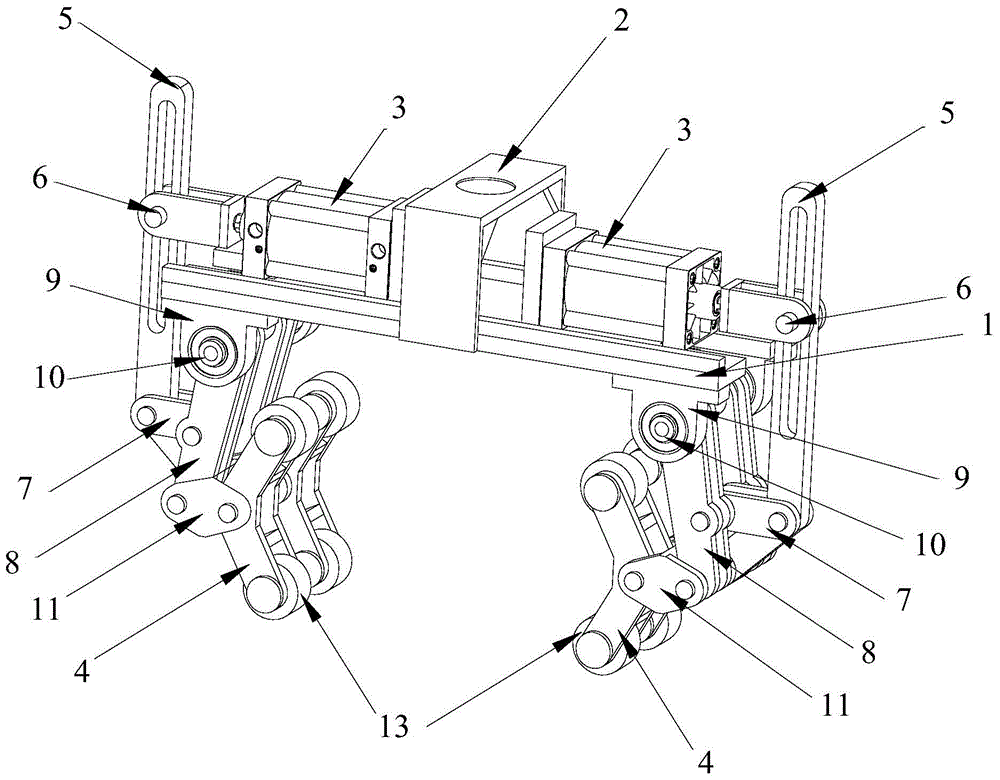

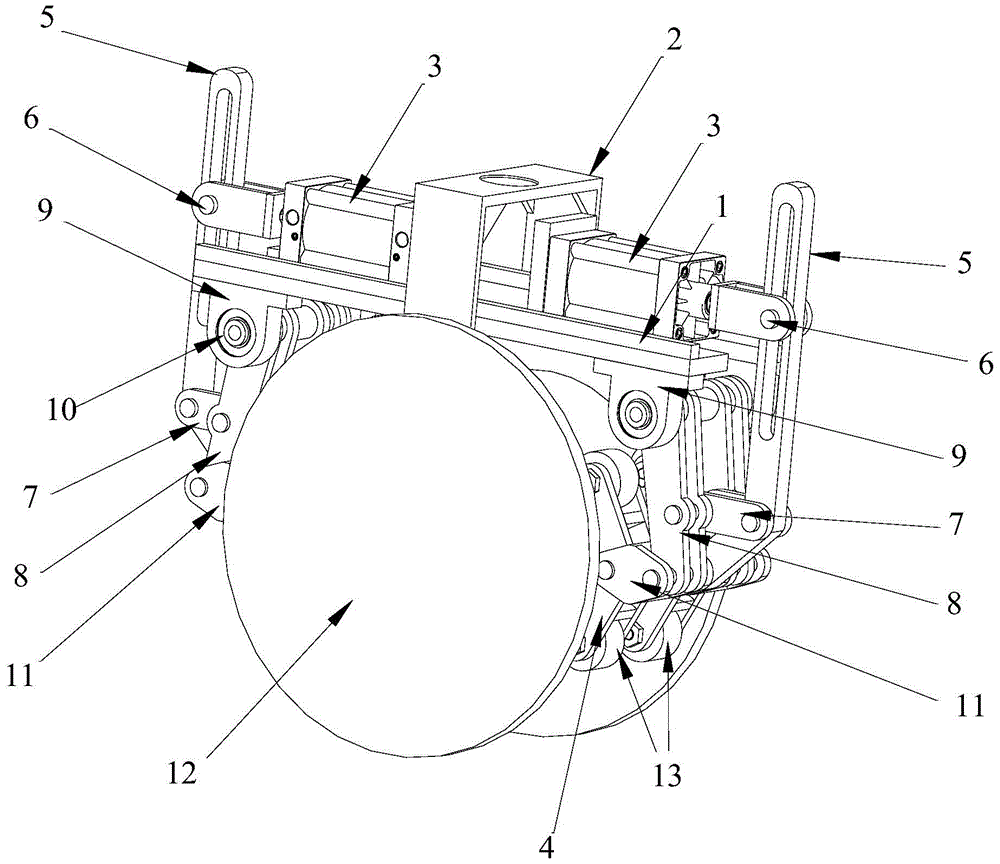

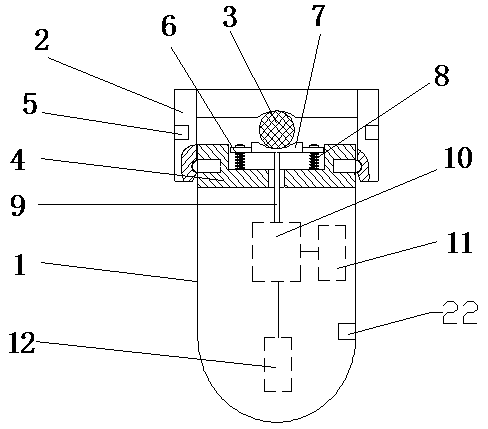

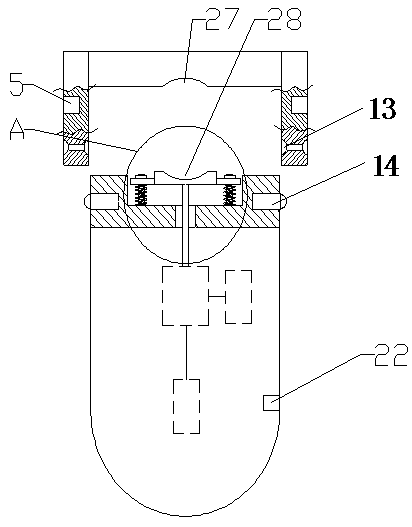

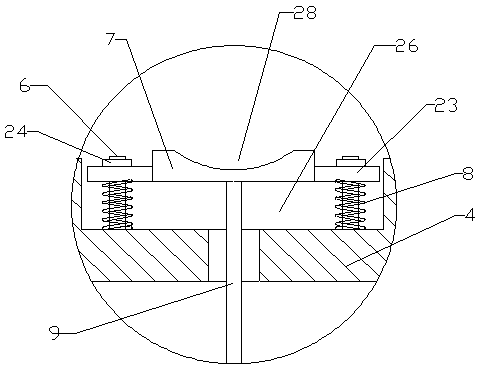

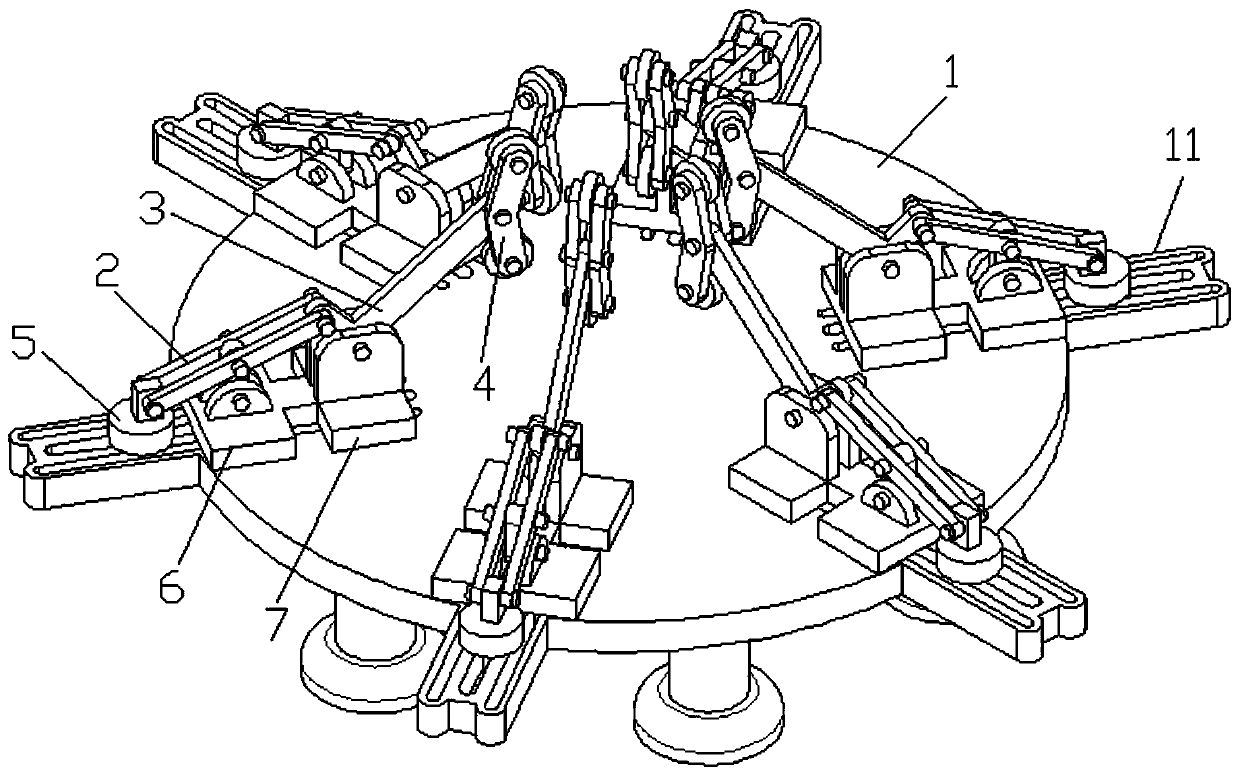

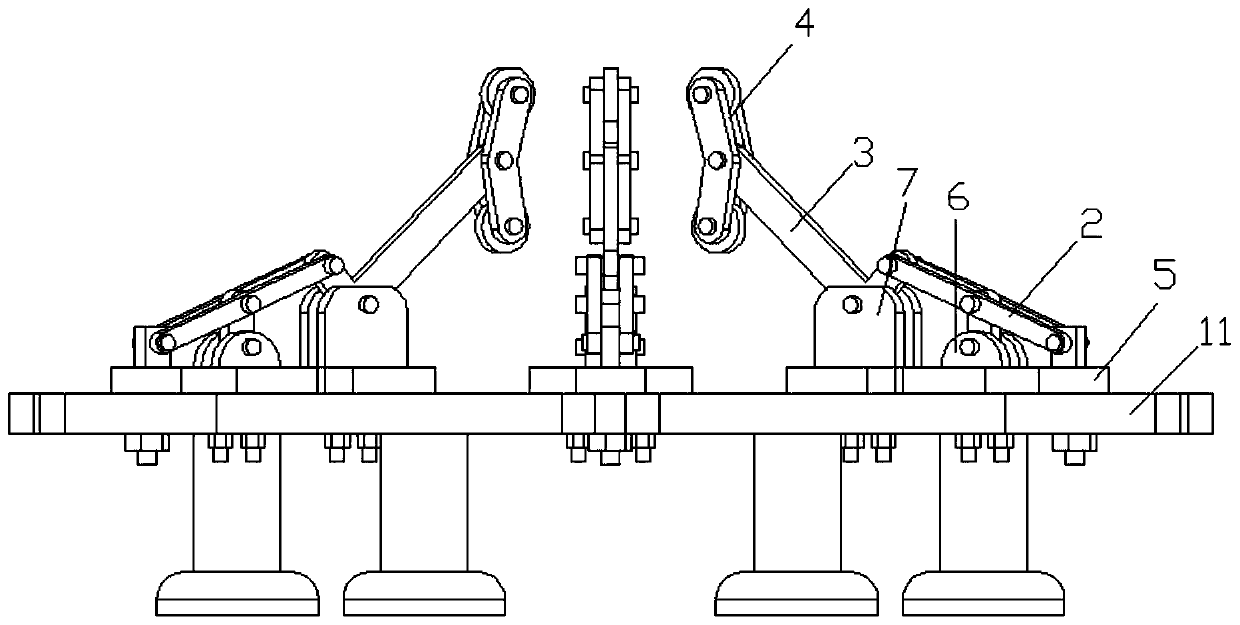

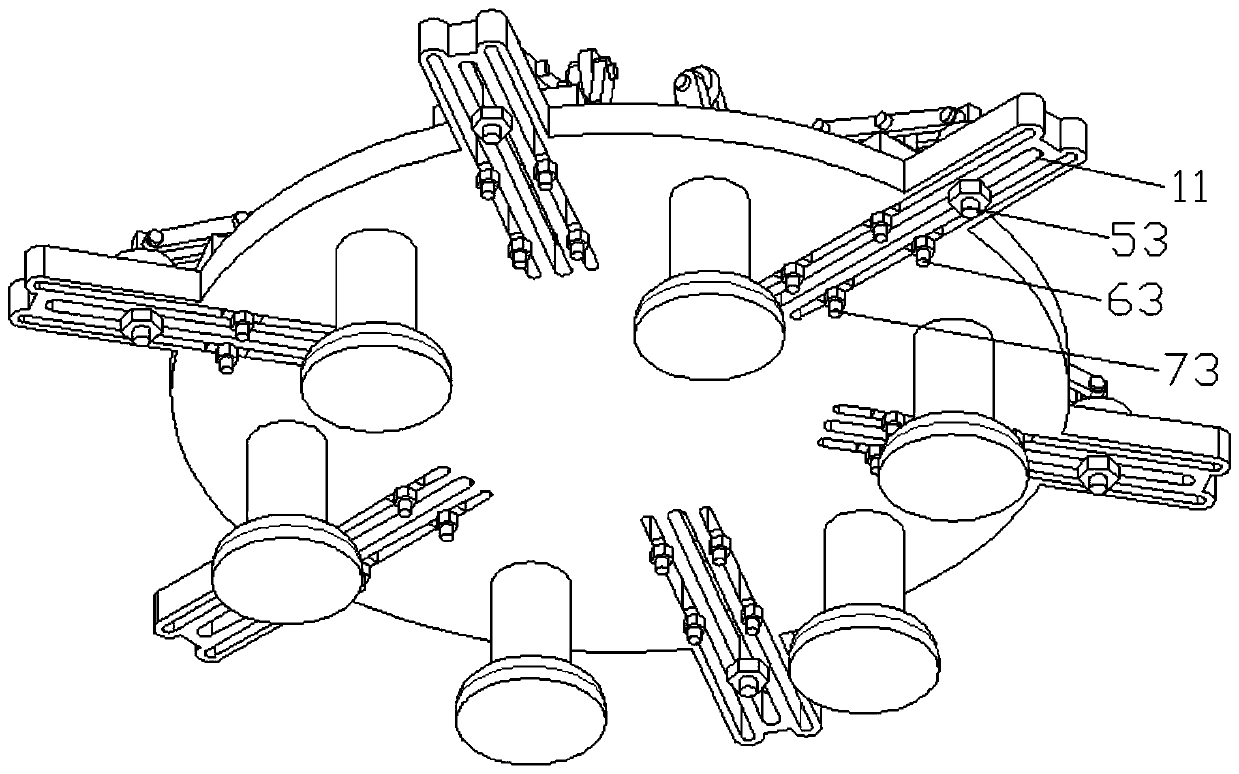

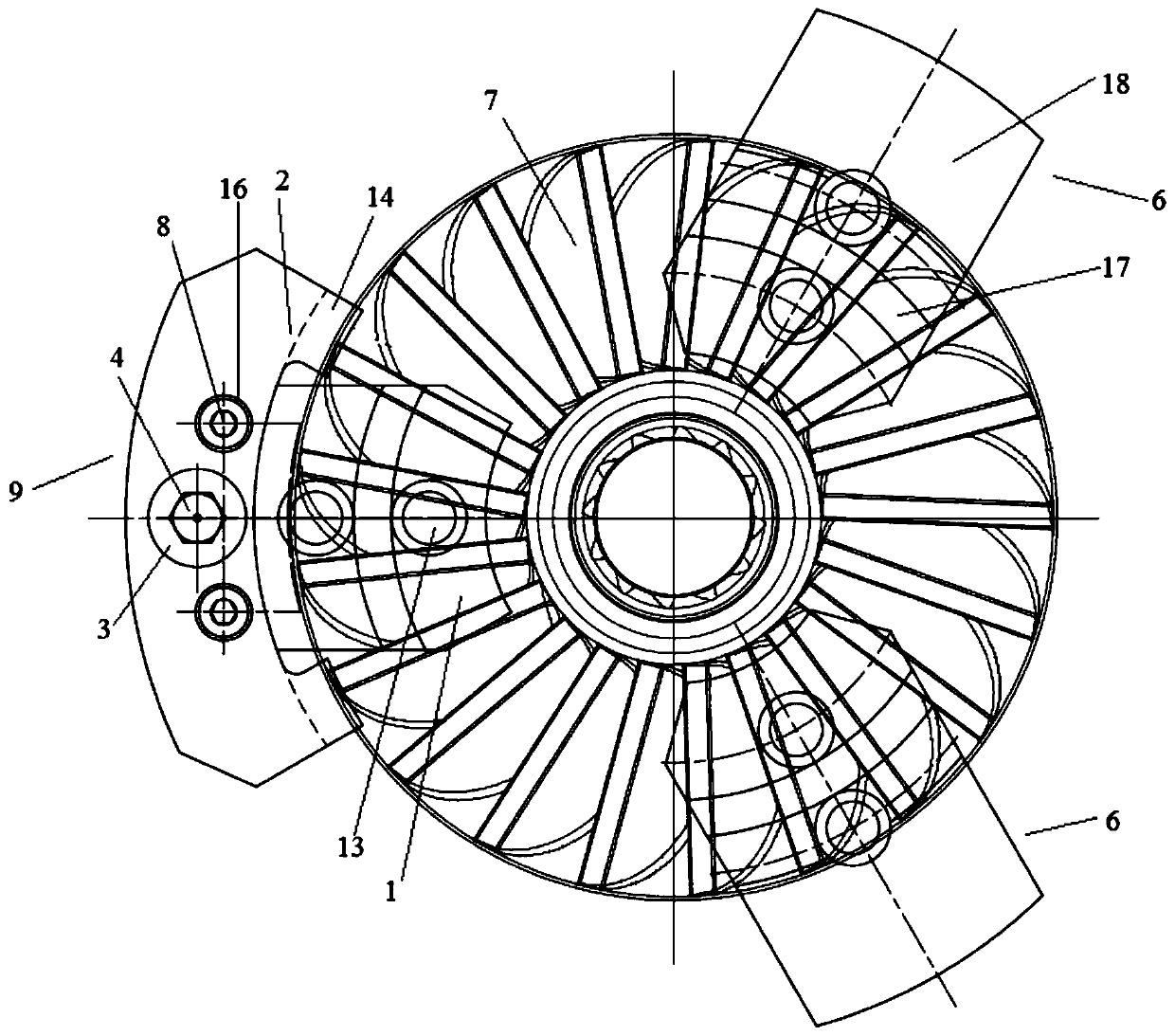

Circular material mechanical grabbing device

The invention discloses a circular material mechanical grabbing device, and belongs to the technical field of solid waste treatment. The device comprises a performer bracket for mounting a linear performer capable of vertically extending out and drawing back, wherein the performer bracket is fixedly connected to a ring-shaped upper circular disc; a pushing rod of the linear performer passes through the upper circular disc and is fixedly connected to the center of a lower circular disc; three fixed arms which extend in a radial direction are uniformly distributed and fixed in the peripheral direction of the lower circular disc; the outer ends of the fixed arms are hinged with the middle part of a clamping arm; the clamping arm defines a bent arm shape through a radial lower tilting arm anda vertical grabbing arm which are connected into an integer, the three grabbing arms surround a clamping circle; and the inner end of the lower tilting arm is equipped with a horizontal shaft roller which is positioned in a peripheral slide slot of the upper circular disc to define movable fit. Clamping of the circular material mechanical grabbing device is realized through relative perpendicularmotion of the upper circular disc and the lower circular disc, and radial drive is not needed, so that the structure is compact; and a structure that the roller at the inner end of the clamping arm isrestrained by the upper disc and the lower disc combines a movable pair with a hinge pair, so that the mechanism is obviously simplified, and therefore, blocking can be effectively avoided, and stable and reliable clamping is guaranteed.

Owner:AEROSUN CORP

Fairing clamp

PendingCN110216604AVersatileAccurate clamping positionWork holdersWind energy generationEngineeringCowling

The invention provides a fairing clamp. The clamp comprises a base plate and a plurality of clamping units uniformly distributed on the base plate, each clamping unit comprises a clamping part which is driven by a connecting rod assembly to move and locate; a sleeve part is arranged at the free end of the connecting rod assembly, and inner threads are arranged on the sleeve part; and the clampingpart comprises a clamping bolt and a pressing block which are arranged up and down and fixed by welding, the clamping bolt is in threaded fit with the sleeve part and is fixed by fastening a nut, andthe pressing block abuts against the lower edge of the fairing. The clamp is provided with the plurality of clamping units, the plurality of clamping units are matched to realize the clamping and fixation of the lower edge of the fairing, the plurality of clamping units are independent to one another and have a same structure, each clamping unit can realize the clamping with different or identicalstrength of the lower edge of the fairing through the cooperation of the connecting rod assembly and the clamping part, the clamping units can be applied to clamping fairings with different specifications and sizes, and the universality is high.

Owner:EULIKIND TIANJIN TECH

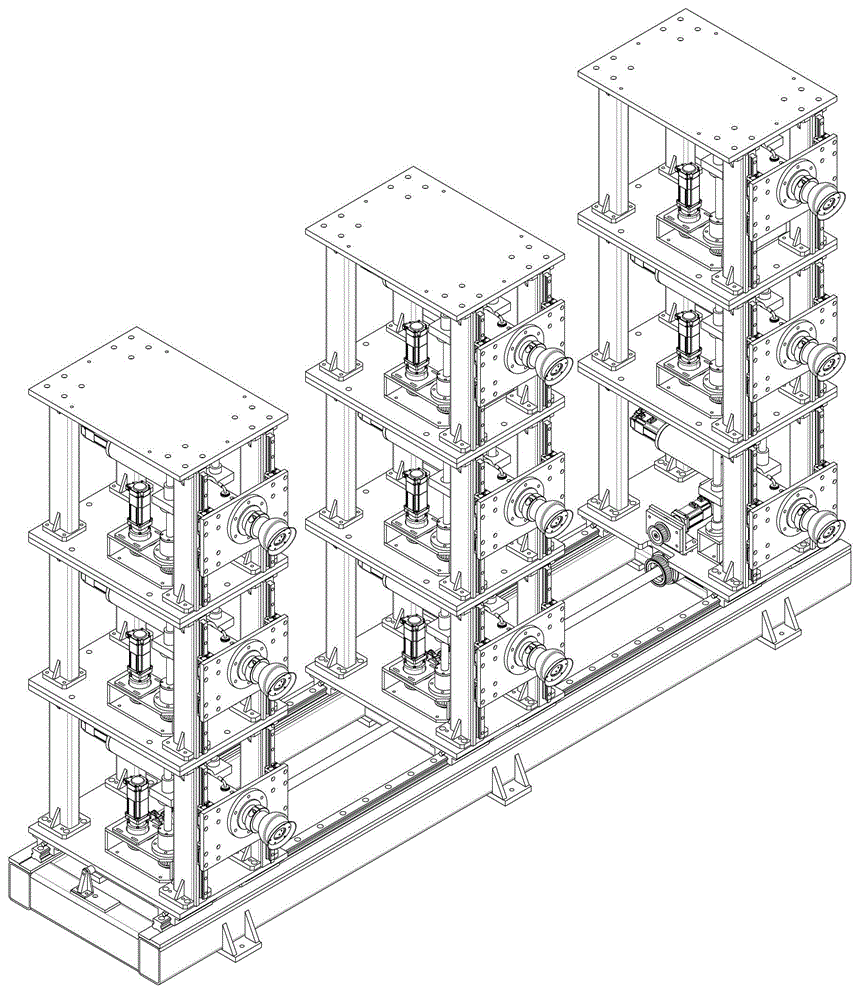

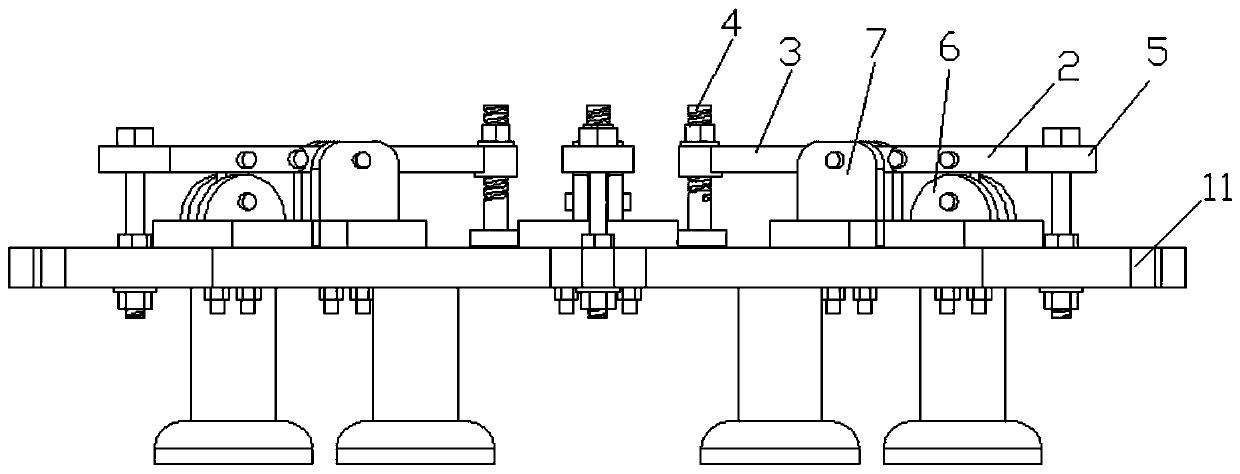

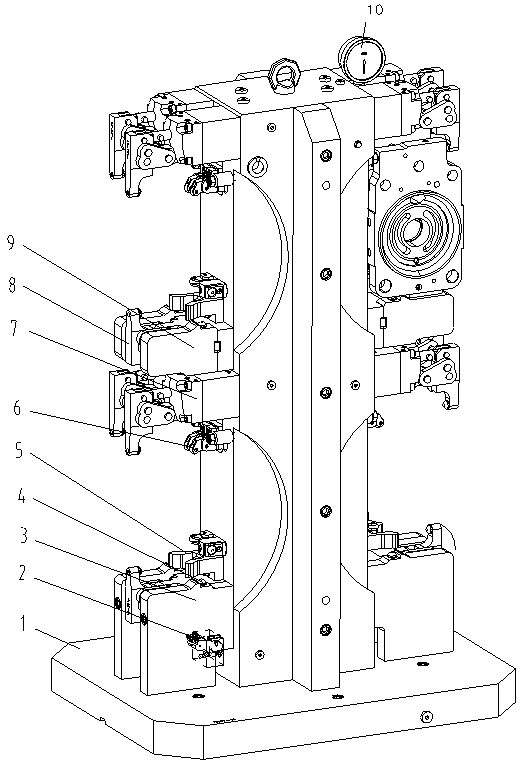

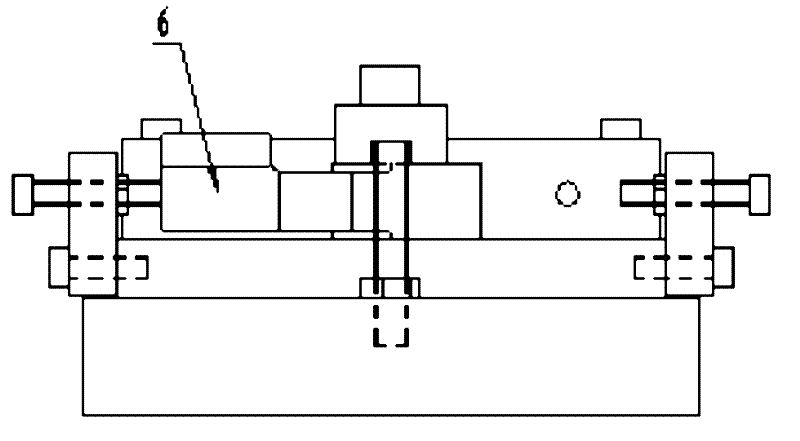

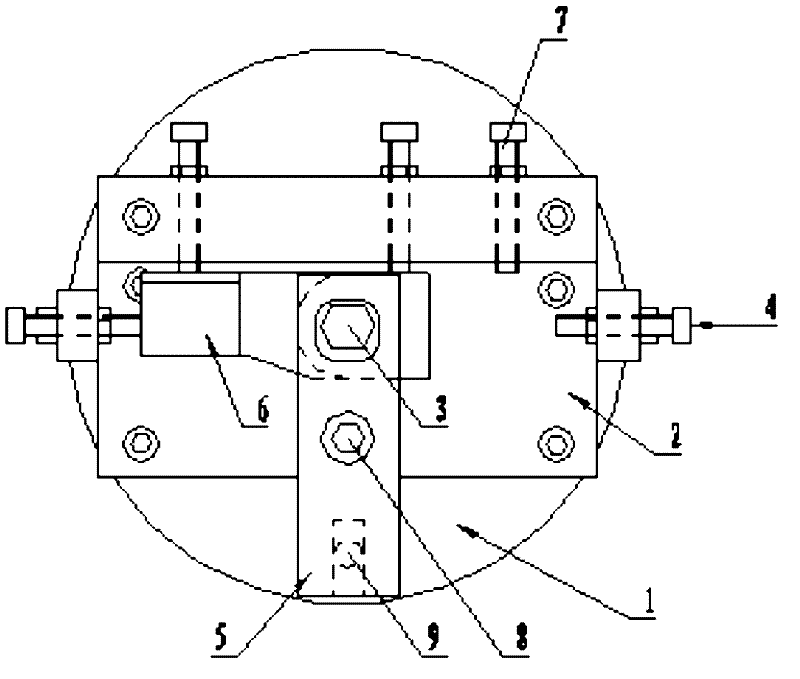

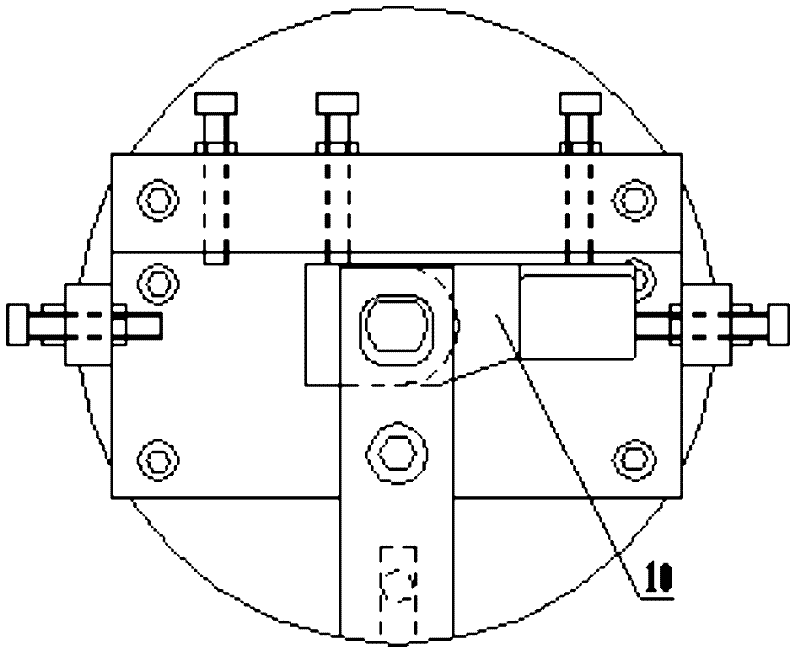

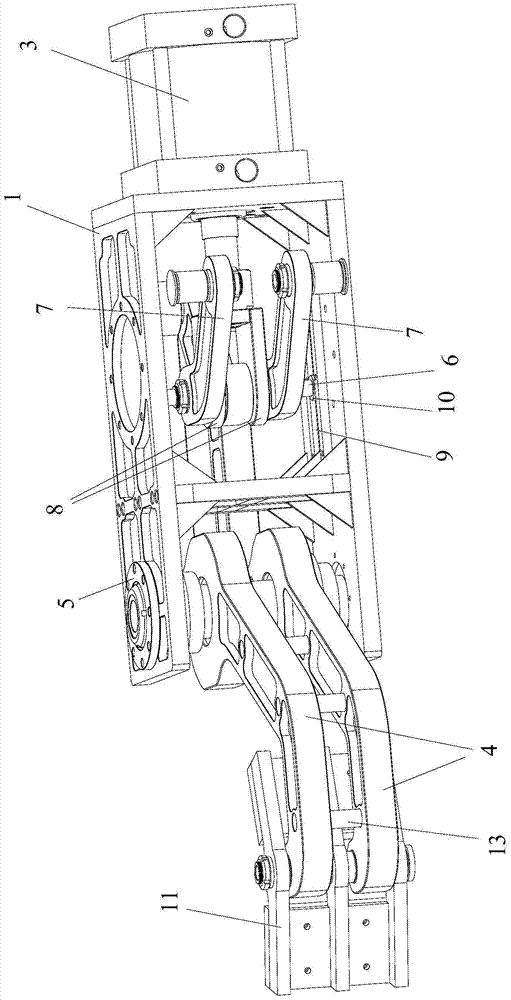

Hydraulic and pneumatic combined clamping device for machining shell

ActiveCN102380783AStable and reliable clampingThe workpiece is evenly stressedPositioning apparatusMetal-working holdersSelf lockingLower limit

The invention relates to a hydraulic and pneumatic combined clamping device for machining a shell, which comprises a base and four pairs of hydraulic cylinders, wherein the base has a reversed T-shaped structure and is formed by a bottom transverse base plate and a strut arranged on the base plate; the four pairs of hydraulic cylinders are arranged on the left and right two sides of the strut symmetrically two by two; and the four pair of hydraulic cylinders on the left and right two sides of the strut and an upper limiting plate and a lower limiting plate form four clamping areas for clamping a workpiece. In the invention, the vertical tower structure which is symmetric about an X-axis and a Y-axis along the Z axis of the base of the hydraulic and pneumatic combined clamping device for machining the shell is formed, the loading and clamping are stable and reliable, a hydraulic pressure self-locking function is realized, the stress on the workpiece is uniform, and the machining reliability is ensured completely; and the connection of an air path and an air path is reliable, gentle and free from leakage, the positioning precision is high, the synchronous automatic machining of multiple horizontal processing centers can be realized, the interchangeability is high, the workpiece is mounted and clamped in a stream manner, the production efficiency is improved, and the quality of the product is guaranteed.

Owner:SHANDONG CHANGLIN MACHINERY GRP

An assembled prefabricated road subgrade fixture

Owner:ZHONGTAI INT HIGH NEW TECH CO LTD

A robot gripper

The invention provides a fixture gripper of a robot. The fixture gripper is arranged at the movable end of the robot, and comprises a bracket, a connecting piece, driving devices and clamping arms, wherein the connecting piece, the driving devices and the clamping arms are connected with the movable end of the robot and are respectively connected with the bracket; the clamping arms and the driving devices are glidingly connected and are positioned at the two sides of the bracket; each clamping arm is provided with a fixture tail end; each fixture tail end is adjustably connected with the corresponding clamping arm, and each clamping arm is driven to do expansion and closing movement. The fixture gripper of the robot has the advantages that the structure is simple, the clamping force is large, and the operation is flexible, the certain flexibility is realized, the problem of matching of the gripper and a workpiece is effectively solved, the universality of the gripper is effectively improved, and the production and manufacturing cost is reduced; the fixture gripper is especially suitable for workpieces with larger size or heavier weight, and the workpiece can be stably and reliably clamped during the process that the robot quickly moves.

Owner:广东泰格威机器人科技有限公司

Special workpiece fixing equipment for boring

InactiveCN102284872AReduce typesIncrease profitPositioning apparatusMetal-working holdersEngineeringFront edge

The invention relates to a special workpiece fixing device for boring, which includes a workbench. A horizontal positioning screw is respectively installed on the left and right sides of the workbench. A group of longitudinal positioning screws are installed on the front side of the workbench. The horizontal positioning screw and the longitudinal positioning screw A workpiece processing area is formed on the workbench between the screws, and a pressing plate positioned above the workpiece processing area is installed on the rear side of the workbench, and the pressing plate is formed with through holes for boring. The invention is a special workpiece fixing device for boring with simple structure, scientific design and strong practicability. Using this device saves clamping time and improves processing accuracy. One clamp can process two kinds of parts, and the dimensions of the processed parts The accuracy has reached the requirements of the drawings, and the work efficiency has been increased by more than two times.

Owner:天津市臣涛精密机械设备有限公司

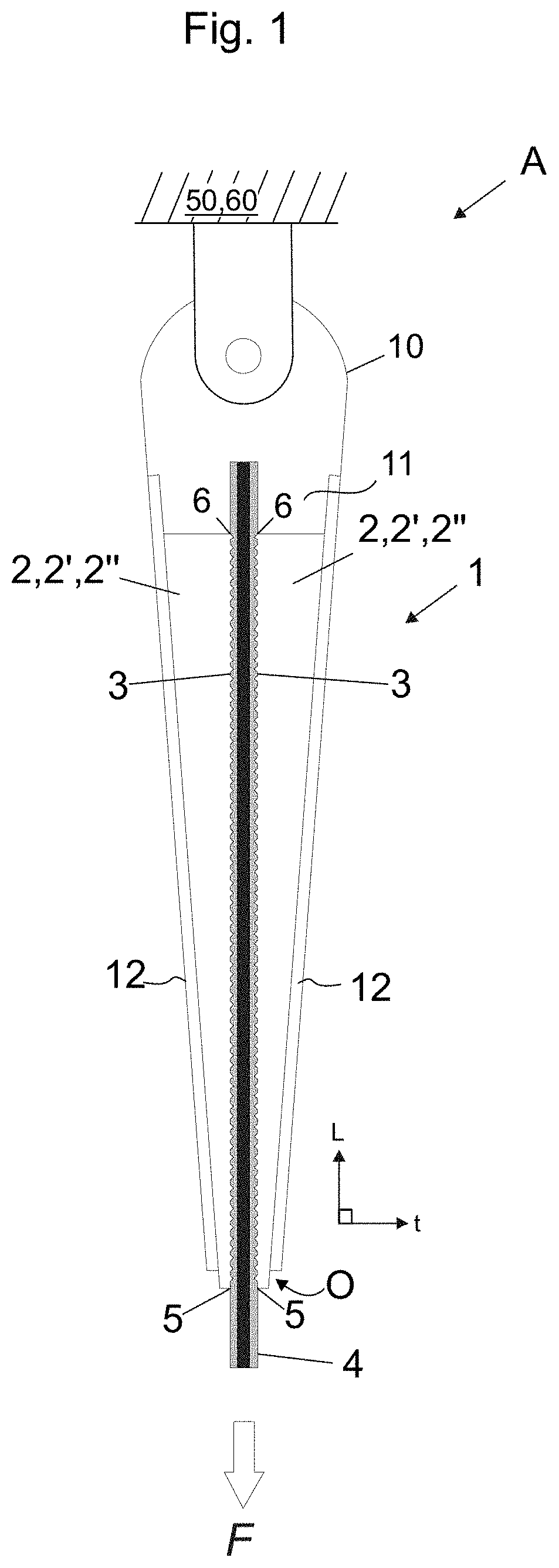

Rope gripping member of a hoisting apparatus, rope gripping device, terminal arrangement and hoisting apparatus

ActiveUS20200331725A1Reduce the possibilityShear stress can be made moreRopes and cables for vehicles/pulleyElevatorsClassical mechanicsFront edge

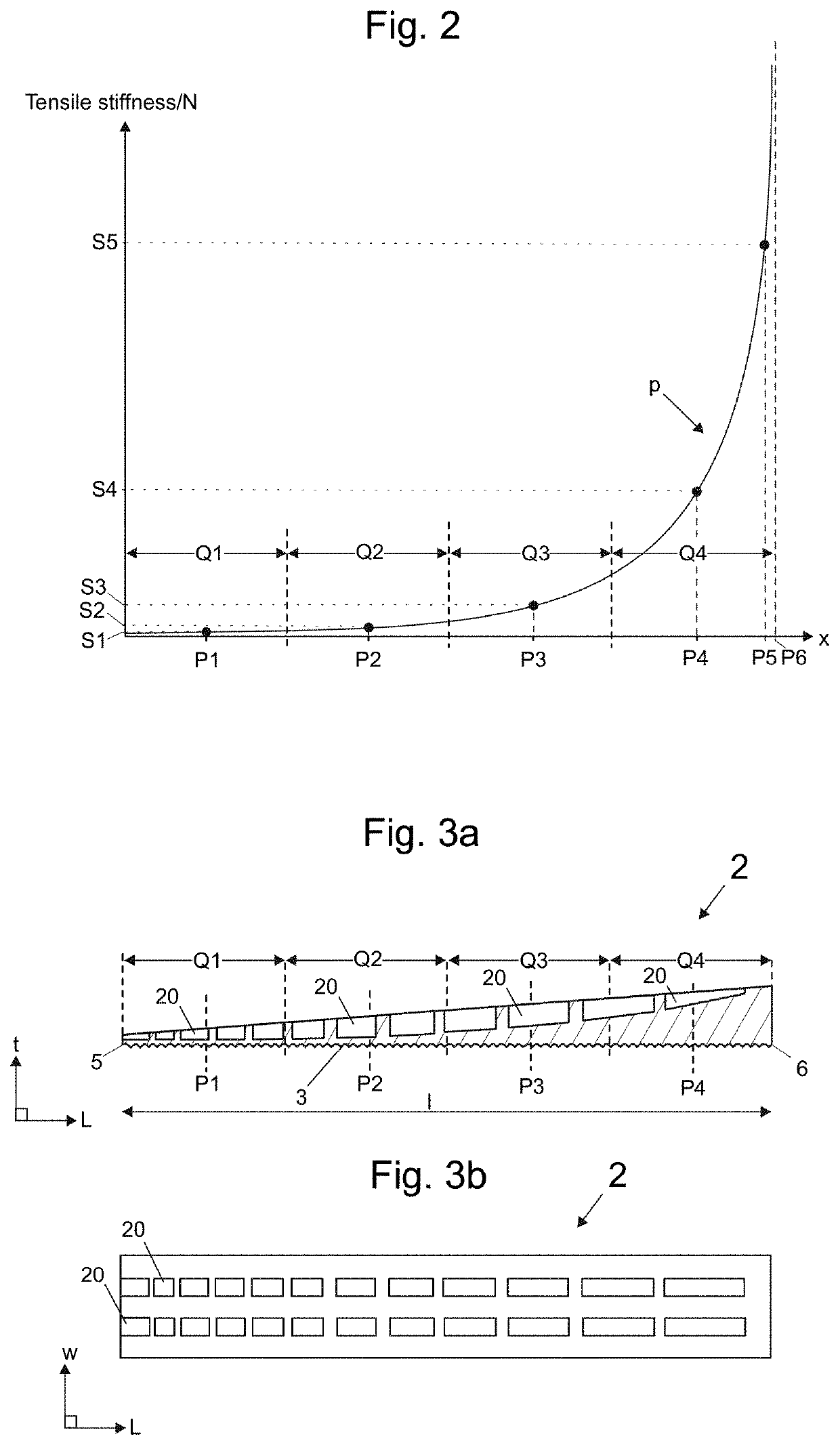

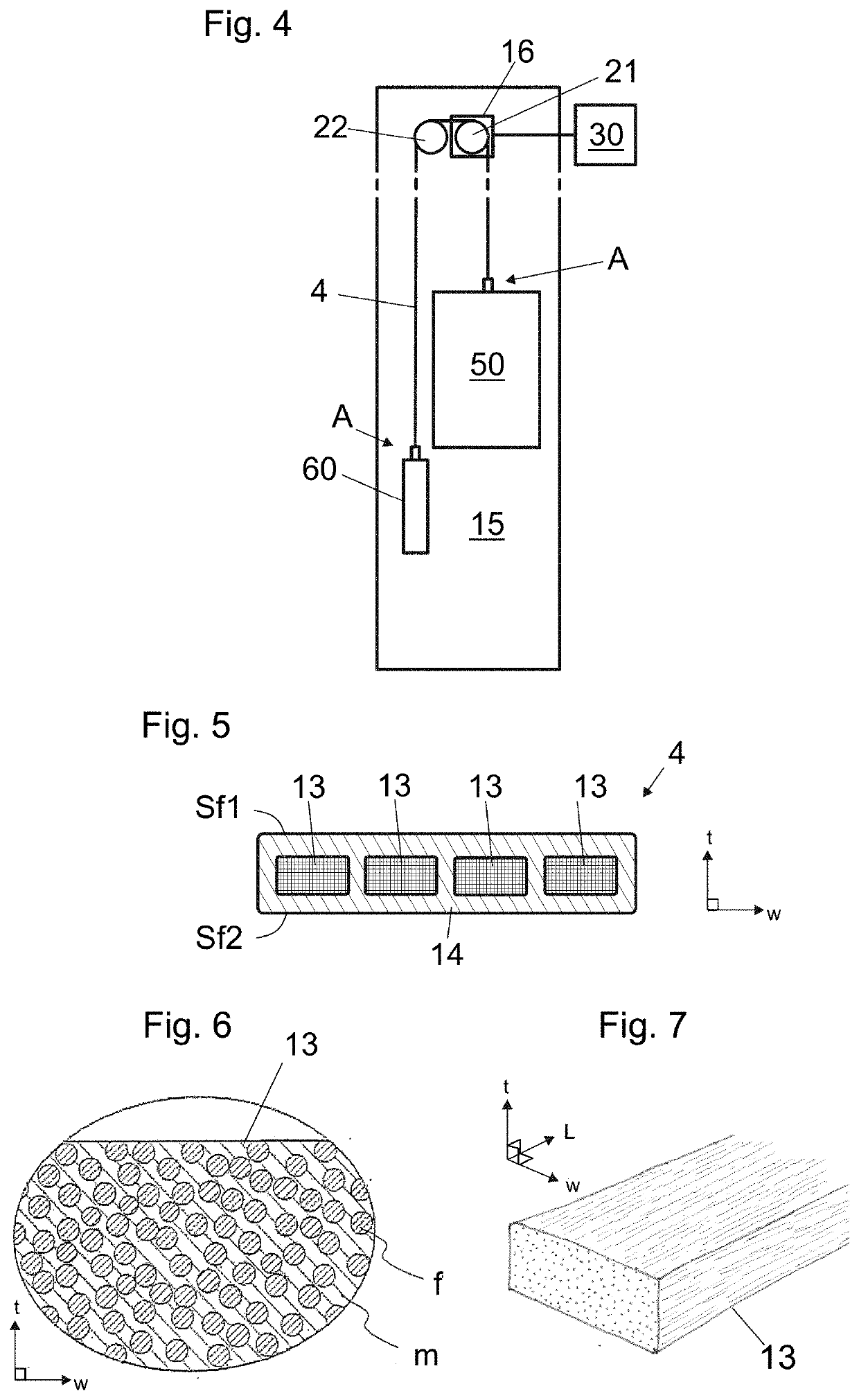

The invention relates to rope gripping member for a rope gripping device, the rope gripping member comprising an elongated rope gripping face for being pressed against an elongated side face of an end section of a rope, the elongated rope gripping face having a longitudinal direction and a front edge and a rear edge; wherein tensile stiffness of the rope gripping member in longitudinal direction of the gripping face increases non-linearly with accelerating rate from the front edge towards the rear edge of the gripping face. The invention also relates to a rope gripping device, a rope terminal arrangement and a hoisting apparatus implementing the rope gripping member.

Owner:KONE CORP

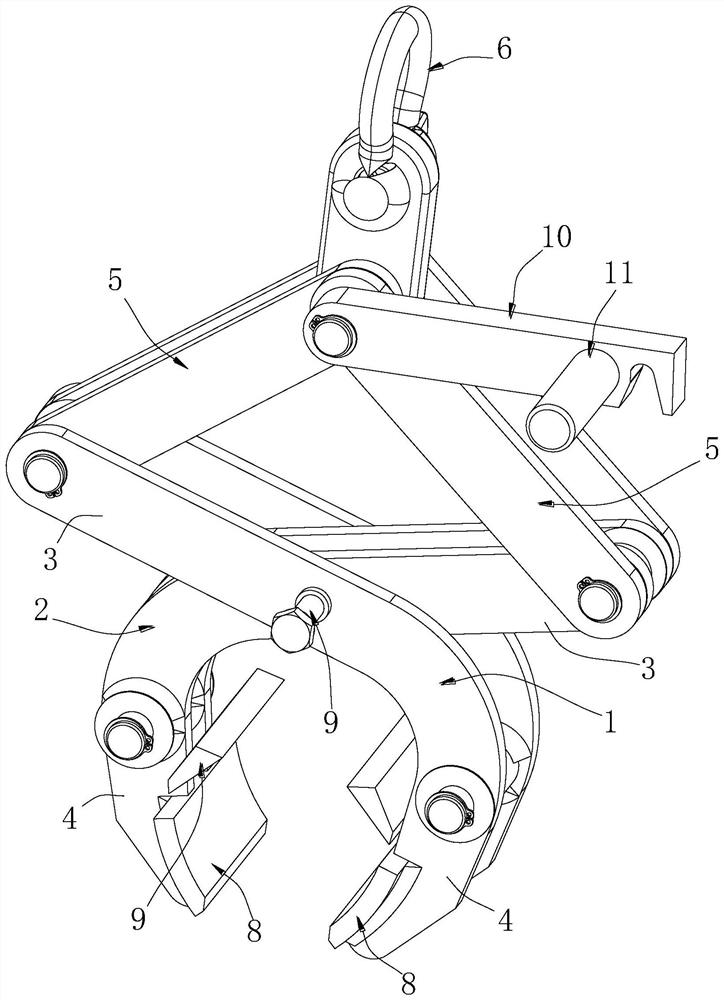

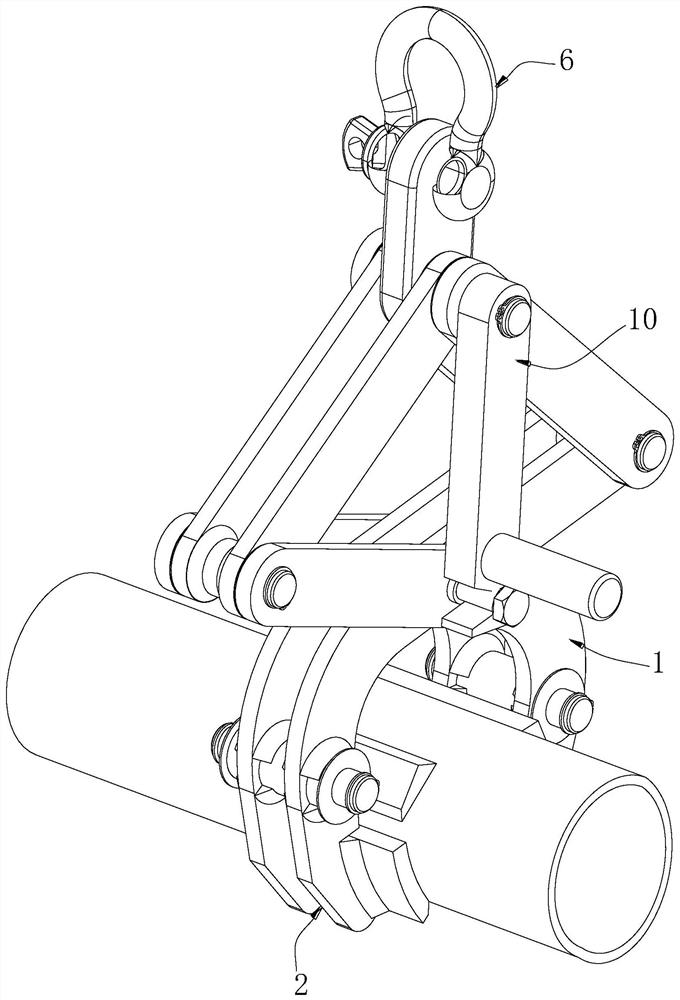

Plastic-coated pipeline carrying hanger

InactiveCN112249877AStable and reliable clampingEasy to useLoad-engaging elementsStructural engineeringMechanical engineering

The invention discloses a plastic-coated pipeline carrying hanger, comprising a first clamping arm and a second clamping arm which are both in an L shape. The first clamping arm and the second clamping arm are each provided with a connecting arm and a clamping arm; the connecting arms of the first clamping arm and the second clamping arm are mutually crossed and hinged together; the ends of the clamping arms face downwards; L-shaped bent openings of the first clamping arm and the second clamping arm are obliquely arranged downwards; connecting rods are hinged to the outer ends of the connecting arms of the first clamping arm and the second clamping arm, respectively; one ends of the connecting rods are hinged to the corresponding connecting arms, and the other ends are hinged to each other; and a hanging ring is arranged at the hinged position of the connecting rods. A first clamping block and a second clamping block are arranged on the clamping arms of the first clamping arm and the second clamping arm, respectively; and the first clamping block and the second clamping block are distributed up and down to form a V-shaped opening. The plastic-coated pipeline carrying hanger is usedfor clamping and grabbing a plastic-coated pipe when the plastic-coated pipe is carried, and then the plastic-coated pipe is transferred.

Owner:贵州创将管业科技有限公司

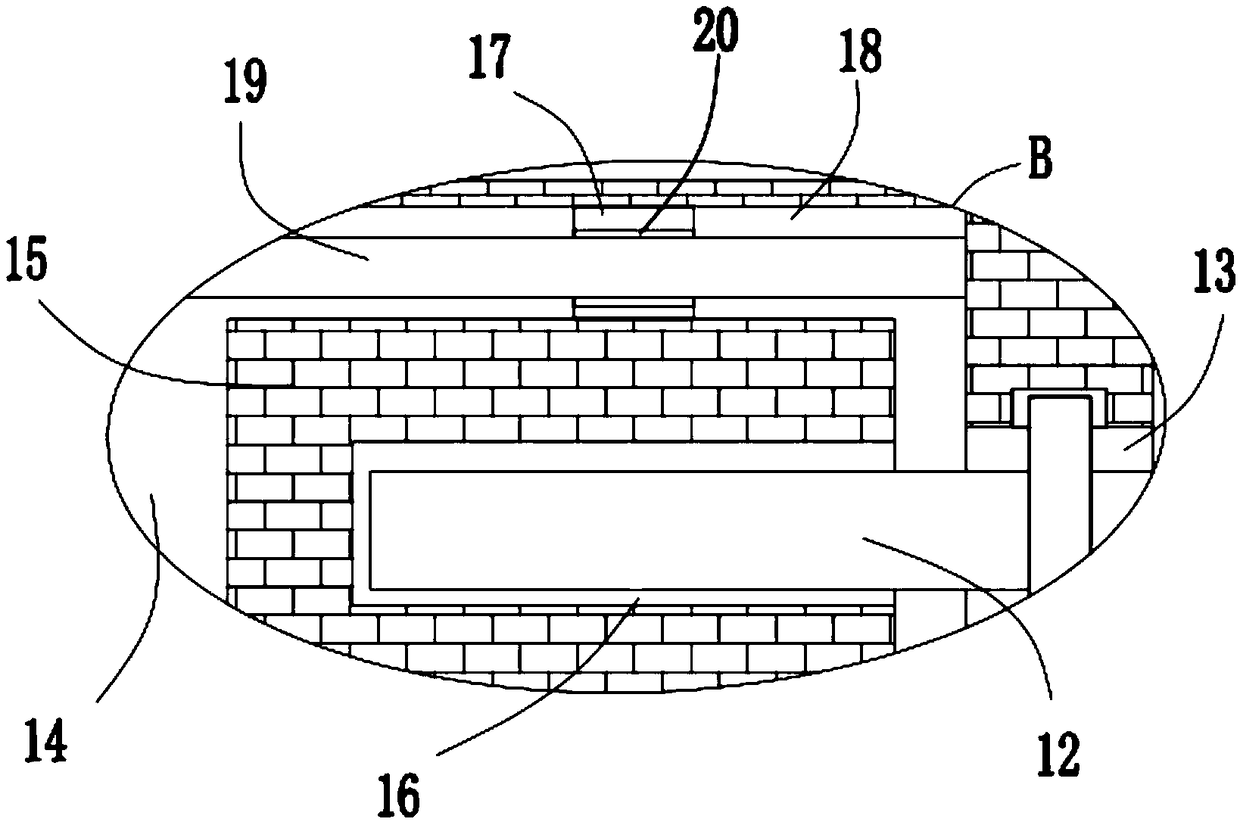

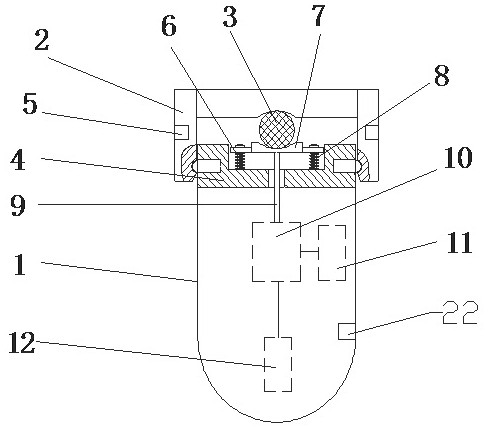

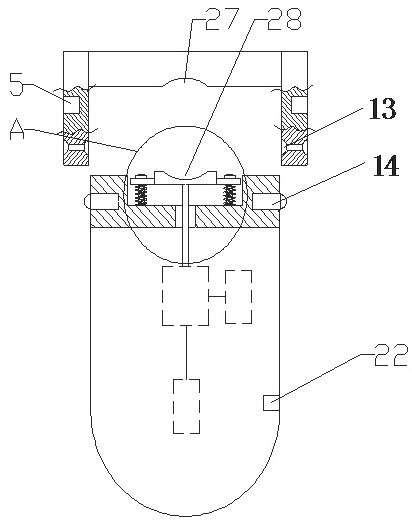

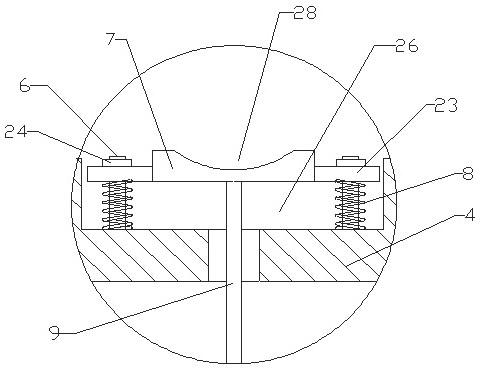

Intelligent fault monitoring system for 10 kV overhead line and special mounting rod of intelligent fault monitoring system

ActiveCN110646711AWith GPS positioning functionRealize intelligent monitoringFault location by conductor typesSatellite radio beaconingMonitoring systemData acquisition

The invention relates to the field of electric power metering facilities, and particularly discloses an intelligent fault monitoring system for a 10 kV overhead line. The intelligent fault monitoringsystem for the 10 kV overhead line comprises a fault alarm which can be fixed to the line and has a GPS positioning function. A data acquisition and processing unit electrically connected with the line and a wireless transmitting-receiving unit connected with the data acquisition and processing unit are arranged in the fault alarm. The fault alarm comprises a bottom shell, an upper clamping head and a lower clamping head, an upper arc-shaped groove is formed in the lower surface of an cross arm of the upper clamping head, a current-conducting plate is arranged on the lower clamping head, and alower arc-shaped groove is formed in the upper surface of the current-conducting plate. When the fault alarm is installed, a line cable is clamped and fixed to the line through the upper arc-shaped groove of the upper clamping head and the lower arc-shaped groove of the lower clamping head, and the data acquisition and processing unit is connected with the current-conducting plate through an electric wire for completing monitoring of the line. The fault alarm of the monitoring system can be conveniently installed on the overhead line.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

A flexible tooling for the assembly of row-column suction cup wall panels

InactiveCN102941545BReduce in quantityHigh positioning accuracyPositioning apparatusMetal-working holdersDot matrixEngineering

A flexible tool for assembling a row-line chuck type wall board comprises a guide rail base, an X-direction driving unit and an upright post shape-adjusting assembly unit, wherein the guide rail base is fixedly connected to the ground; the upright post shape-adjusting assembly unit is arranged on two X-direction linear guide rails of the guide rail base and can move along the X-direction linear guide rails; and the X-direction driving unit is positioned between the bottom of the upright post shape-adjusting assembly unit and the guide rail base, is fixedly connected with the guide rail base and is connected with the bottom of the upright post shape-adjusting assembly unit. According to the flexible tool disclosed by the invention, aircraft panel assemblies are adsorbed, clamped and digitally positioned by a dot matrix vacuum chuck and stability and reliability in clamping and positioning and high positioning precision are obtained; and the digitalized positioning and drilling and riveting assembly of different wall board assemblies can be realized by reconfiguration through the dot matrix chuck of the tool. The flexible tool has higher practical value and broad application prospect in the fields of mechanical engineering / aircraft assembly.

Owner:BEIHANG UNIV

Clamping device applied to flow guiding hood

PendingCN110314785AAccurate clamping positionConvenient follow-up operationSpraying apparatusAerodynamics improvementEngineeringChassis

The invention discloses a clamping device applied to a flow guiding hood. The clamping device applied to the flow guiding hood comprises a chassis and a plurality of clamping units evenly distributedon the chassis. E ach clamping unit comprises a clamping part driven by a connecting rod assembly to move and conduct positioning, and comprises two obtuse-angle plates, wherein three vertexes of thetwo obtuse-angle plates are fixedly connected through connecting shafts, the connecting shafts located on the two sides are each provided with a rolling wheel, the connecting shaft located in the middle is rotatably connected with the free end of the connecting rod assembly, and the rolling wheels are connected with the outer side face of the flow guiding hood in an abutting manner. The clamping device is provided with the multiple clamping units, the outer side face of the flow guiding hood can be clamped and fixed through cooperation of the multiple clamping units, the multiple clamping units are independent and have the same structure, and each clamping unit can clamp the outer side face of the flow guiding hood with the different or same force through cooperation of the corresponding connecting rod assembly and the corresponding clamping part; and in addition, the clamping device can be suitable for clamping flow guiding hoods with different types and sizes, and the universality ishigh.

Owner:EULIKIND TIANJIN TECH

Specimen clamping forceps for ctod test

The invention provides test-piece clamping pincers for CTOD testing. The test-piece clamping pincers comprise a supporting frame, two sets of main pincers and two sets of auxiliary pincers. The supporting frame is an H-shaped member, and connecting rods arranged oppositely are arranged on the two sides of the supporting frame. The two connecting rods are connected through a middle rod. The connecting rods are arranged in parallel. Each set of main pincers is composed of two main pincers assemblies. Each set of auxiliary pincers is composed of two auxiliary pincers assemblies. Each main pincers assembly comprises a pincers handle, an adjusting rod, a large crutch, a pincers foot and a first pressing spring, all of which are connected in sequence. Each auxiliary pincers assembly is composed of a pincers crutch, a lengthening rod, a small crutch, a pincers claw and a second pressing spring, all of which are connected in sequence. Accordingly, the test-piece clamping pincers are safe, reliable and easy to use, the situation that when a medium or large test-piece is tested, due to falling of the test-piece, accidents are caused, or cooling liquid splashes, and operators are injured can be effectively avoided, and the safety of testing is improved.

Owner:CNPC OFFSHORE ENG

Round material mechanical grabbing system

PendingCN110561481ACompact structureSimple organizationProgramme-controlled manipulatorGripping headsCircular discEngineering

The invention discloses a round material mechanical grabbing system and belongs to the technical field of solid waste treatment. The device comprise a steel bucket transferring roller bed and a material storing table; a truss with a manipulator is installed above the steel bucket transferring roller bed and the material storing table; the manipulator is provided with a lifting arm provided with around material mechanical grabbing device at the lower end; the grabbing device comprises an executor support installing a linear executor capable of stretching out and drawing back in the vertical direction; the executor support is fixedly connected with an annular upper disk; a push rod the linear executor penetrates through the upper disk and is fixedly connected with the center of a lower disk; three fixed arms extending in the radial direction are uniformly distributed and fixed in the circumferential direction of the lower disk; the outer end of each fixed arm is hinged to the middle portion of a clamping arm; each clamping arm forms a bent arm shape through a radial direction downward inclination arm and a vertical direction gripper arm which are connected into a whole; the three gripper arms encircle a clamping circle; the inner end of each downward inclination arm is provided with a horizontal shaft rolling wheel; and the rolling wheels are located in slide grooves in the circumference circle of the upper disk to form movable fit. The round material mechanical grabbing system is compact in structure, the mechanism is obviously simplified, clamping stagnation can be effectively avoided, and the clamping stability and reliability is guaranteed.

Owner:AEROSUN CORP

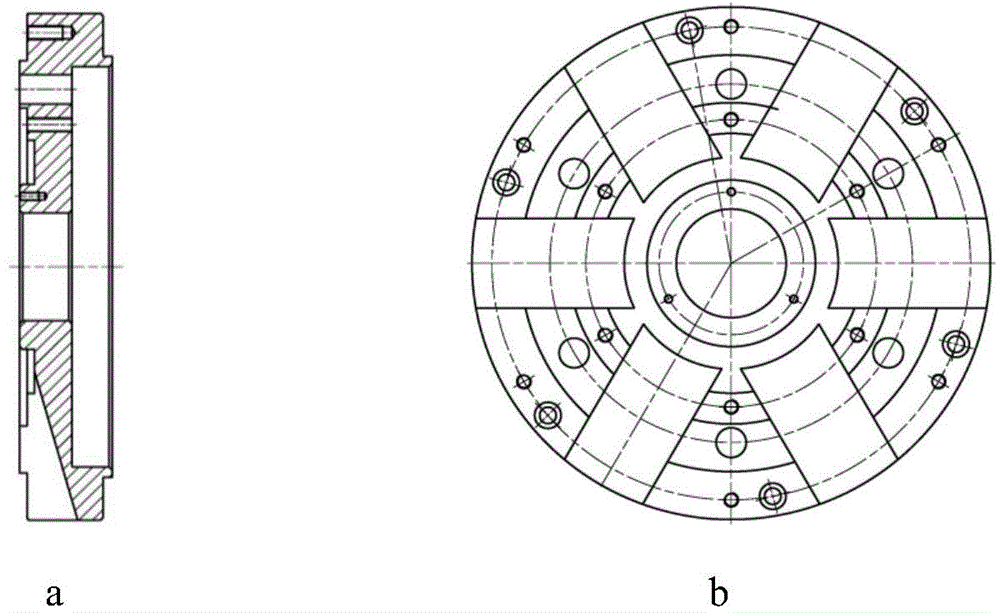

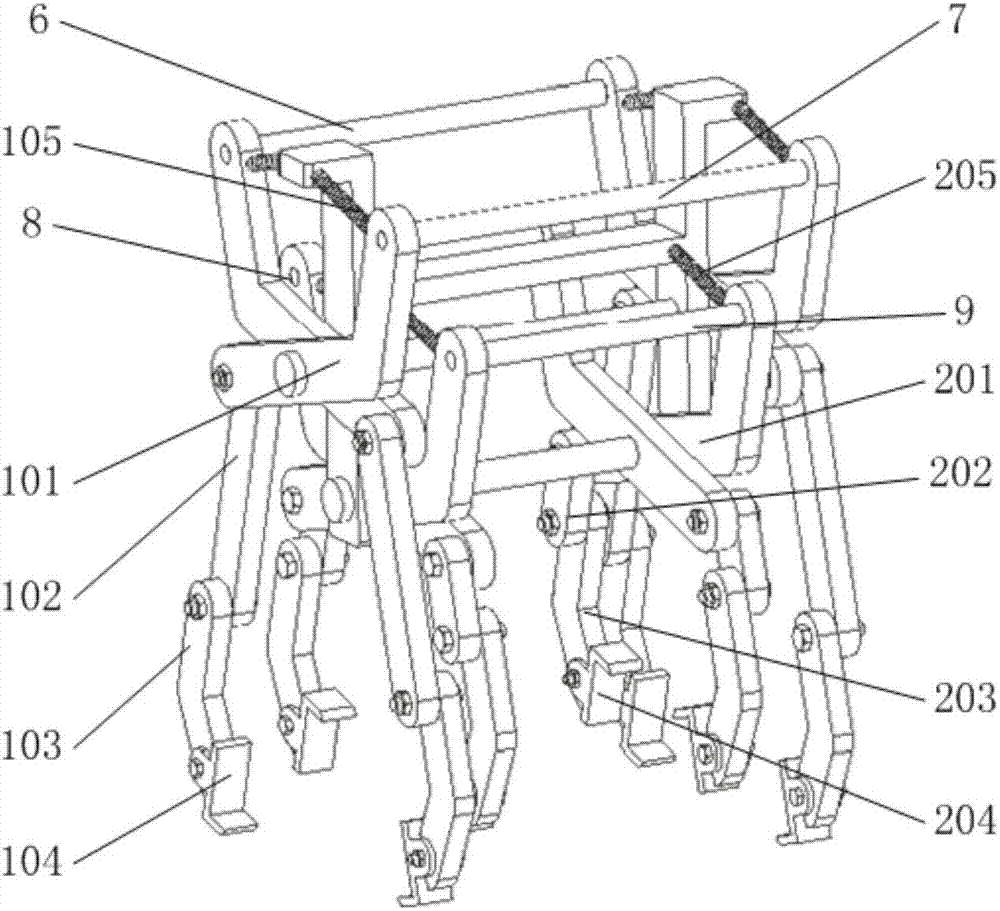

Floating clamping jaw, retarder stator and rotor clamp and using method thereof

The invention belongs to clamping jaw clamps, and particularly relates to a floating clamping jaw, a retarder stator and rotor clamp and a using method thereof. The problem of large turning jumping caused by unstable clamping due to the fact that an existing clamping jaw cannot avoid a stator and rotor blank rib is solved. A floating clamping jaw and two fixing clamping jaws are adopted, due to the arrangement of contact foot bosses, the contact between the inner surface of the floating clamping jaw and the surface of a stator and rotor work piece is reduced, a rib on the surface of the work piece can be well avoided, the processing instability caused by contact of a clamp and the rib is avoided, in addition, a stator and a rotor are clamped on the clamp, firstly, the two fixing clamping jaws are in contact with the outer wall of the work piece, then, one contact foot boss of the floating clamping jaw can be in contact with the outer wall of the work piece,due to the fact that the clamping jaws and a base can relatively rotate along a core shaft, slight floating can be generated in the clamping process until the other contact foot boss of the floating claw is also in contact with the outer wall of the work piece, so that clamping is realized under the condition that four ribs cast by the stator and the rotor are avoided.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

Conveniently used clamp for mold processing

InactiveCN108927749AEasy to holdClamping is firm and secureWork holdersEngineeringMechanical engineering

The invention discloses a conveniently used clamp for mold processing. The clamp comprises a clamp body. A first rotating hole is formed in the top of the clamp body, a motor is fixedly mounted on thetop of the clamp body, a placing cavity is formed in the clamp body, the placing cavity communicates to the first rotating hole, the output shaft of the motor penetrates the first rotating hole and stretches into the placing cavity and a first cone-shaped gear is welded to the output shaft, a second cone-shaped gear is engaged to the first cone-shaped gear, a rotating rod is fixedly arranged on the second cone-shaped gear in a sleeving mode, second rotating holes are formed in the two inner walls of the placing cavity, two rotating cavities are formed in the clamp body, the placing cavity isformed between the two rotating cavities, and the two rotating cavities communicate to the two corresponding rotating holes. The clamp disclosed by the invention can clamp parts more conveniently, andthe clamp body clamping the part is firmer and steadier. The clamp is simple in structure and convenient to use.

Owner:柳州通亿汽车配件制造有限公司

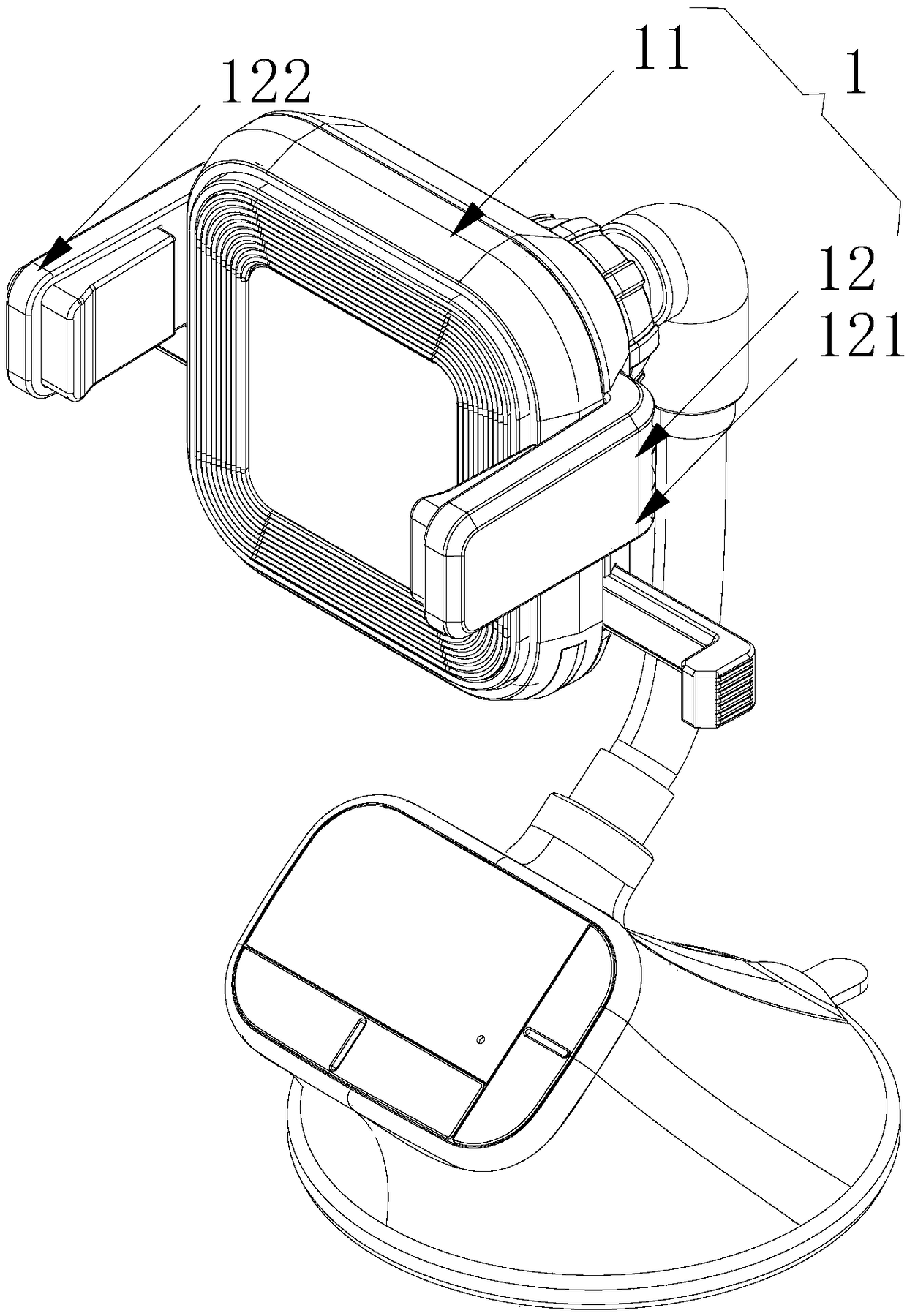

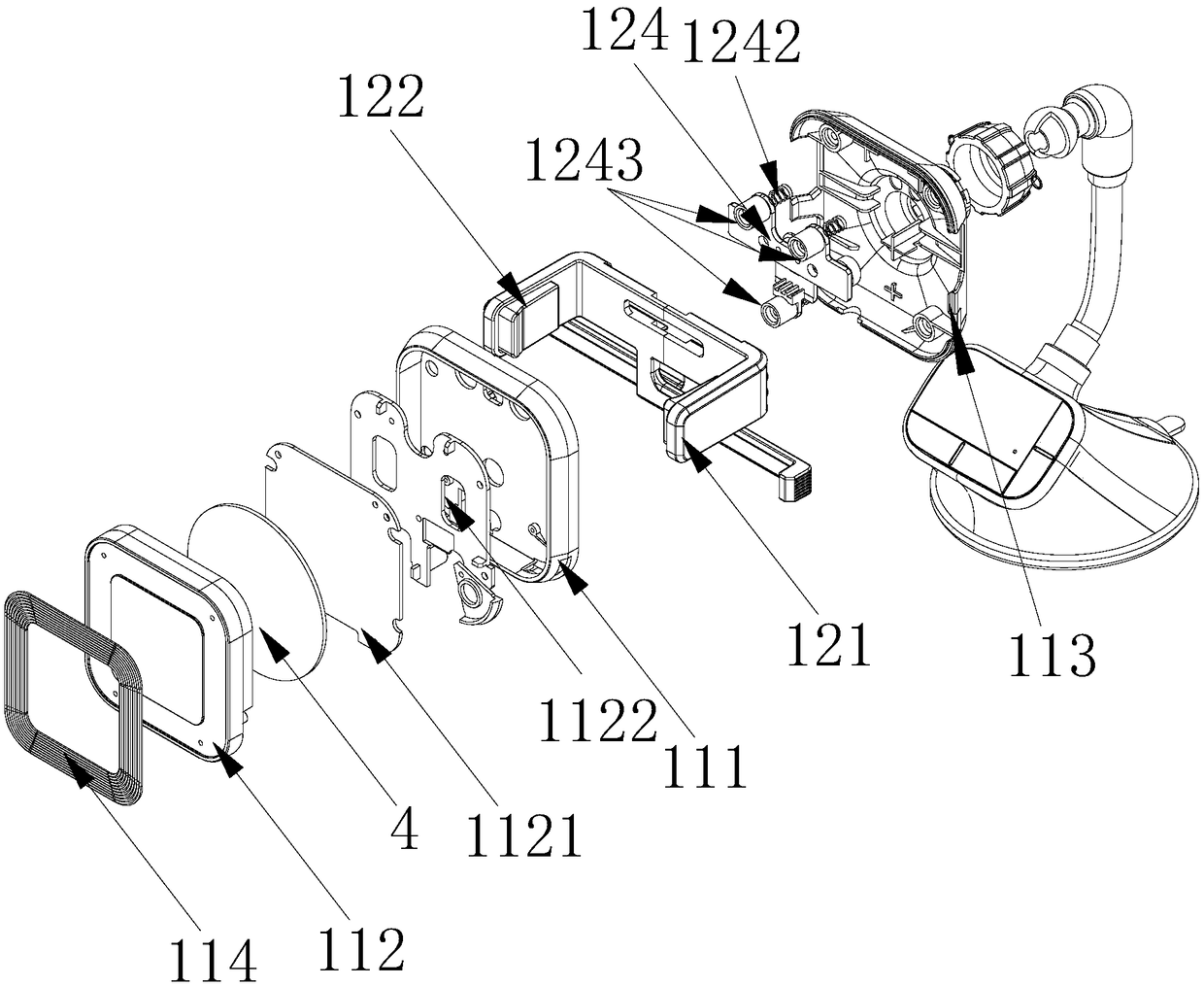

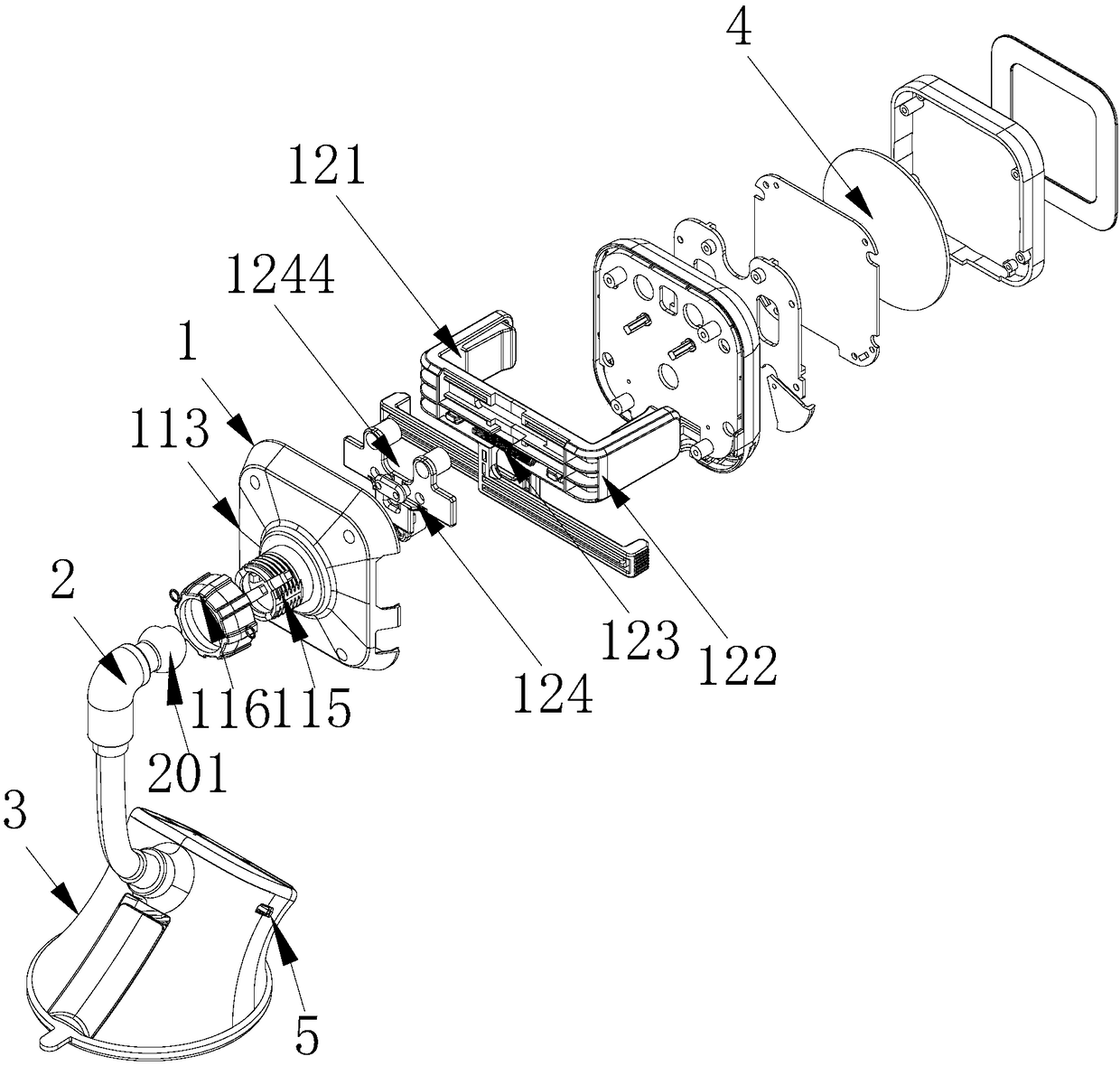

Vehicle bracket

PendingCN108494922AStable clampingStable and reliable clampingBatteries circuit arrangementsElectric powerIn vehicleBiomedical engineering

Owner:SHENZHEN JIEMEISI IND CO LTD

A robotic clamping device

ActiveCN104589364BImprove motor flexibilityStrong clamping forceGripping headsControl signalEngineering

The invention provides a clamping device for a robot, which includes a main frame, a connecting seat for connecting with the front end of a mechanical arm, a connecting mechanism arranged inside the main frame, a driving mechanism for driving the connecting mechanism to move, a control mechanism and a clamping mechanism. The connecting seat is set on the main frame; the two clamping arms are set on both sides of the main frame in the form of a cross, and one end is hinged with the connecting mechanism; the intersection is set on the main frame, and the two clamping arms are connected to the cross The connection can be rotated; the driving mechanism is connected with the control mechanism by signal, so as to realize the movement of the driving connection mechanism to drive the opening and closing movement of the clamping arm. The clamping device of the present invention has high action flexibility and strong clamping force, thereby realizing fast grabbing and stable and reliable clamping of workpieces, and greatly improving production efficiency and automation when used in conjunction with robots. The clamping device of the present invention has a simple structure, thereby making the device easy to operate and maintain, and reducing its use cost.

Owner:佛山市慧智智能装备有限公司

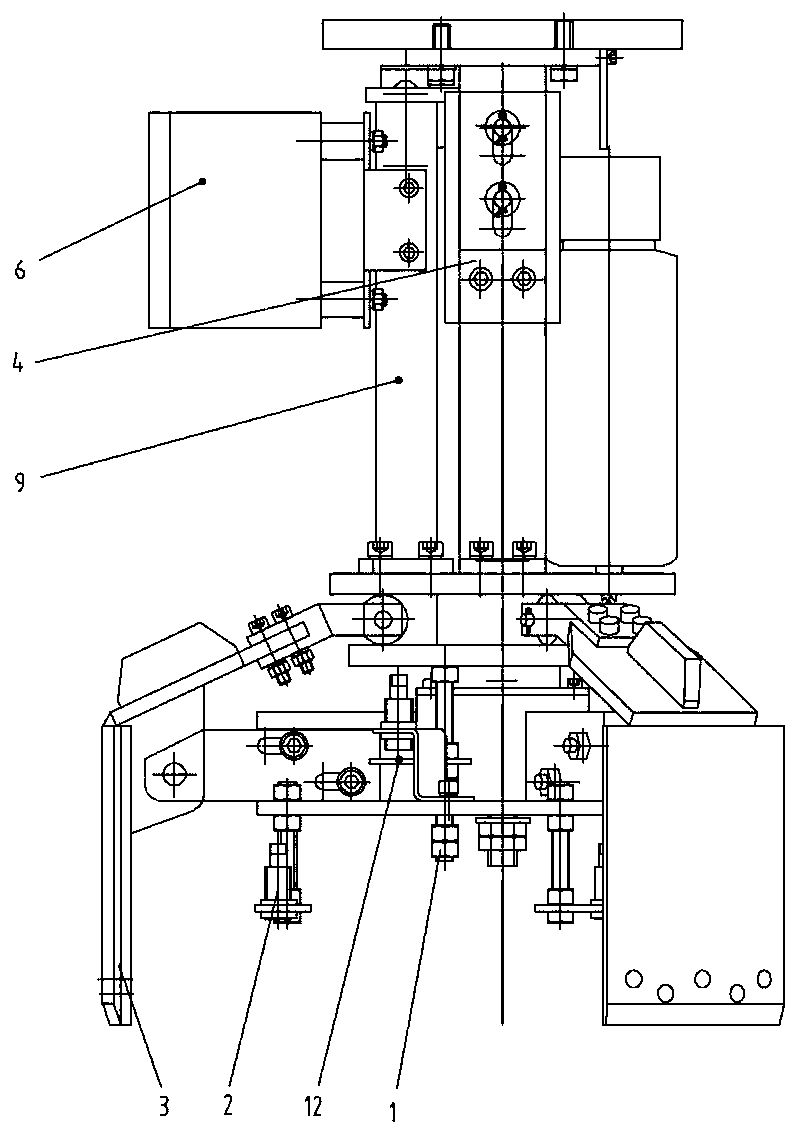

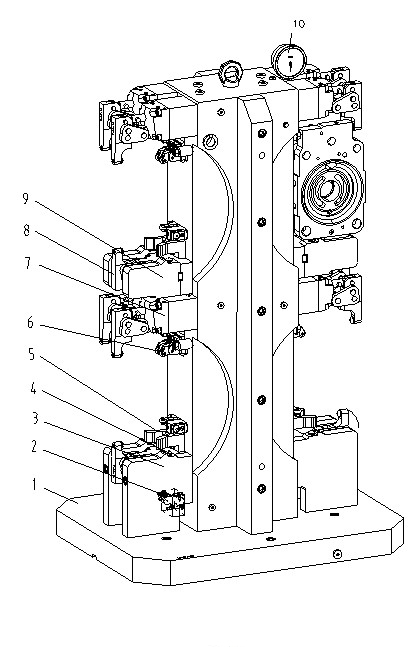

Clamping and vibrating device for plastic-dipped bearing retainer

InactiveCN113578696APrevent disengagement from clampingStable and reliable clampingLiquid surface applicatorsCoatingsRetainerEngineering

The invention discloses a clamping and vibrating device for a plastic-dipped bearing retainer. The clamping and vibrating device for the plastic-dipped bearing retainer comprises a radial moving mechanism, a clamping mechanism, vibrators and an axial lifting mechanism, wherein the radial moving mechanism comprises a driving part and at least three moving parts, and the driving part drives the moving parts to move along the radial direction of the retainer; the clamping mechanism comprises at least three clamping parts, and the clamping parts are connected with the moving parts and used for clamping the retainer; the vibrators are arranged on the clamping parts or the moving parts so as to vibrate the retainer; and the axial lifting mechanism is arranged above the radial moving mechanism and connected with the radial moving mechanism so as to drive the retainer to move in the vertical direction. According to the invention, redundant outer-side molding powder on the retainer can be removed, so that a plastic layer of the retainer is uniform, flat and firm.

Owner:SHANDONG GOLDEN EMPIRE PRECISION MACHINERY TECH CO LTD

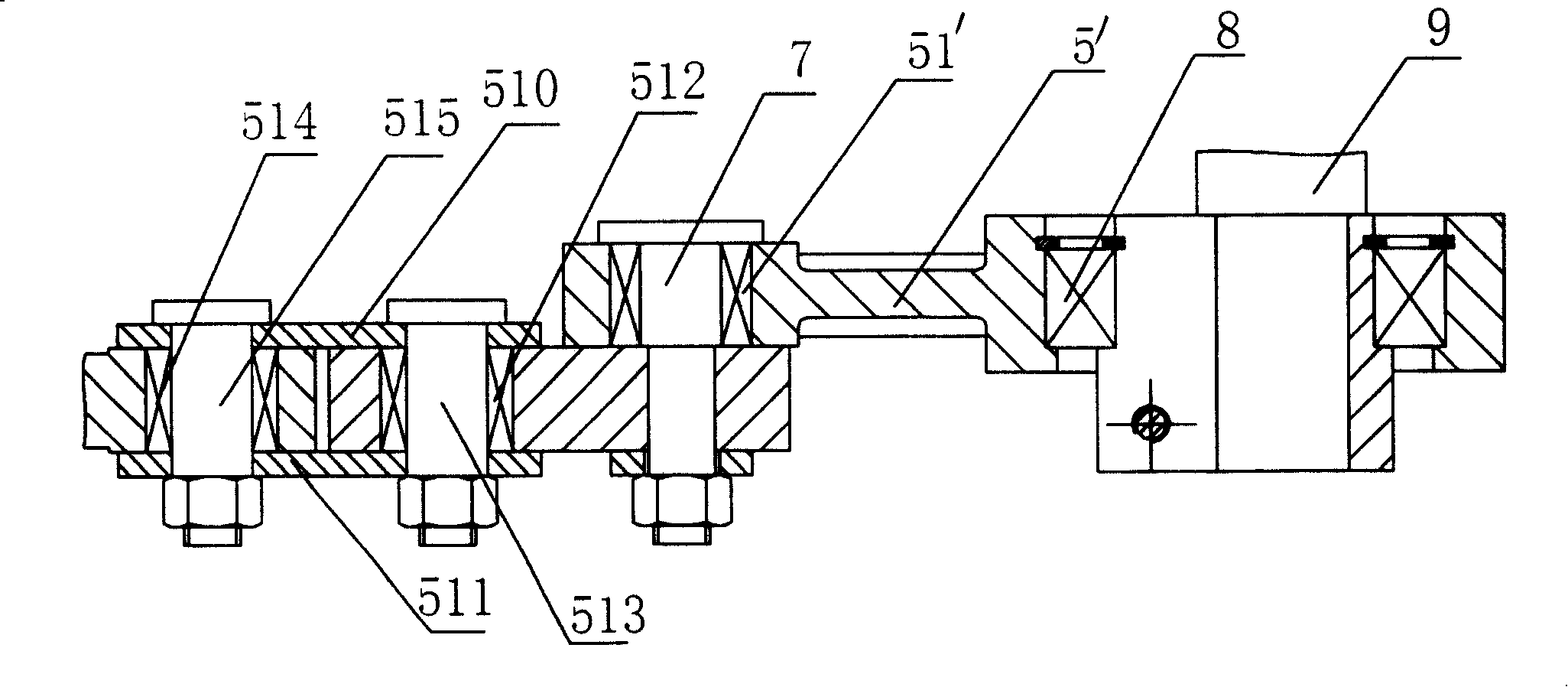

Plastic knitting cloth water jet loom

The water jet loom for weaving plastic knitting cloth includes wefting mechanism, length counter and weft accumulator. The wefting mechanism is provided with jet water pump; and the jet water pump includes pump body, plunger, water inlet valve, water outlet valve and nozzle. The plunger is fitted with one straightly reciprocating push rod, and the straightly reciprocating push rod is connected to the plunger on its one end and one eccentric wheel sheet on the other end, with the eccentric wheel sheet being connected via rolling bearing to the eccentric wheel on the driving shaft. The water jet loom of the present invention has fast water flow speed, high weft flying speed and other advantages, and can carry course fiber over 700 denier to pass through shed, so that it is suitable for use in weaving plastic fabric directly.

Owner:青岛东佳机械制造有限公司

A 10kV overhead line intelligent fault monitoring system and its dedicated installation pole

InactiveCN110646711BWith GPS positioning functionRealize intelligent monitoringFault location by conductor typesSatellite radio beaconingWireless transceiverElectrical connection

The invention relates to the field of power metering facilities, and particularly discloses an intelligent fault monitoring system for 10 kV overhead lines. It includes a fault alarm that can be fixed on the line and has a GPS positioning function. The fault alarm is equipped with a data acquisition and processing unit electrically connected to the line and a wireless transceiver unit connected to the data acquisition and processing unit. The fault alarm The bottom shell of the container, the upper chuck, and the lower chuck are provided with an upper arc-shaped groove on the lower surface of the cross arm of the upper chuck, and a conductive plate is arranged on the lower chuck, and a lower arc-shaped groove is arranged on the upper surface of the conductive plate. When the above-mentioned fault alarm is installed, the line cable is clamped and fixed on the line by the upper arc-shaped groove of the upper chuck and the lower arc-shaped groove of the lower chuck, and the data acquisition and processing unit is connected to the conductive plate through a wire for realizing Line monitoring. The fault alarm of this monitoring system can be installed on the overhead line very conveniently.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com