Foot pedal for drum

a foot pedal and drum technology, applied in the field of foot pedals for drums, can solve the problems of troublesome adjustment operation, limited adjustment range of setting angle , difficulty in clamping the hoop with a large holding or binding force, etc., to achieve the effect of large external force, large external force, and extended contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Hereafter, the present invention is explained in detail based on an embodiment referring to figures.

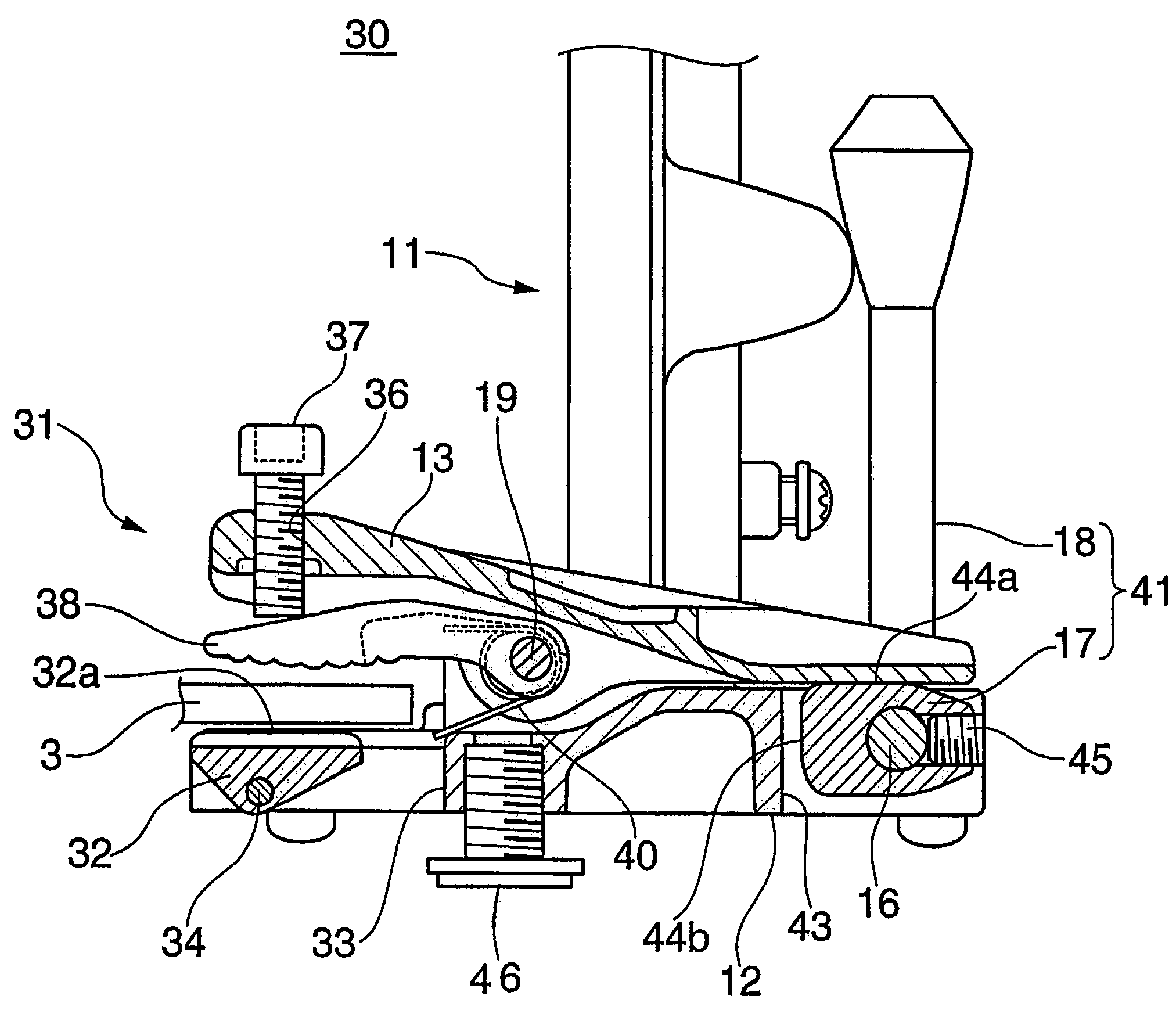

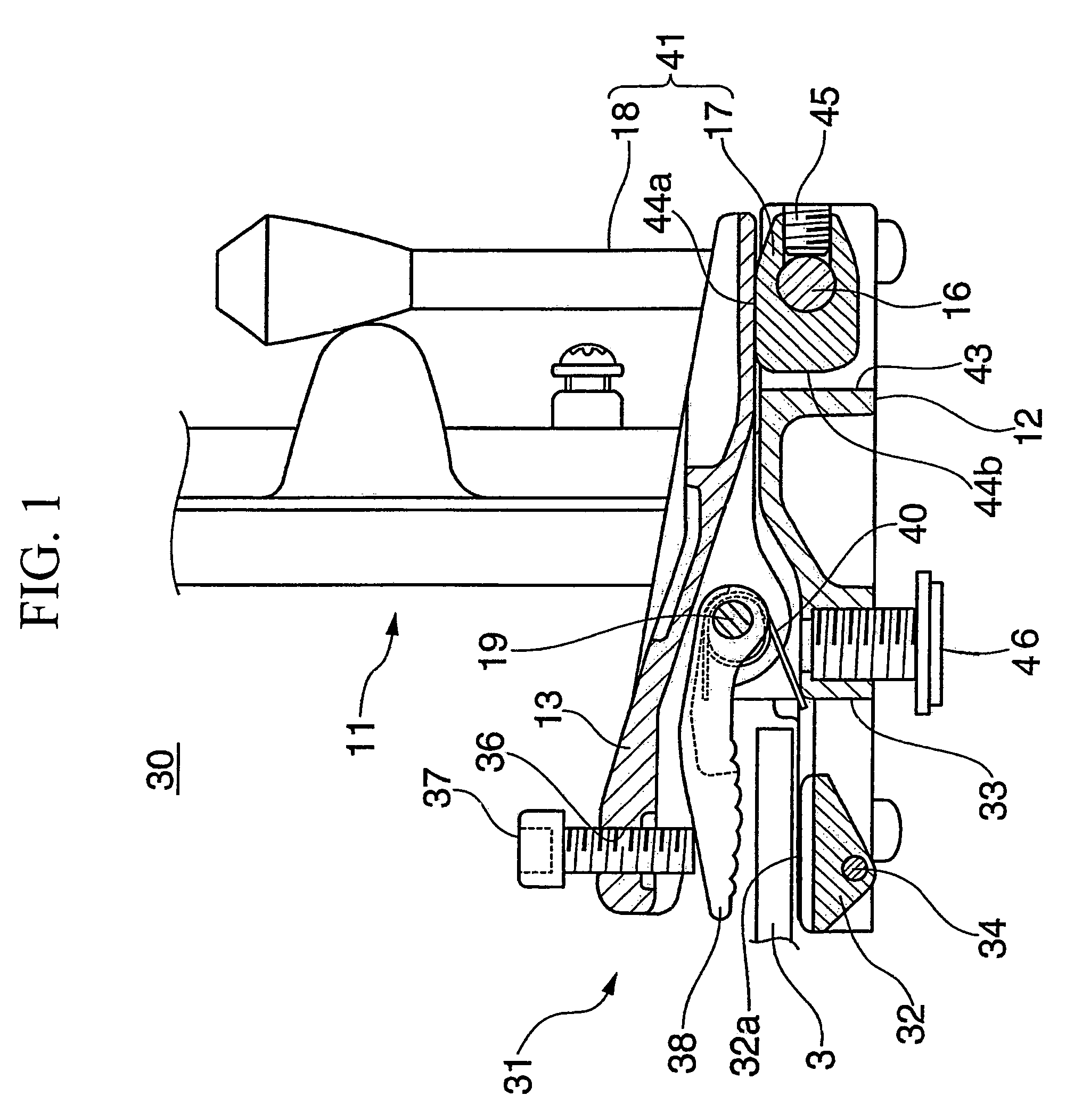

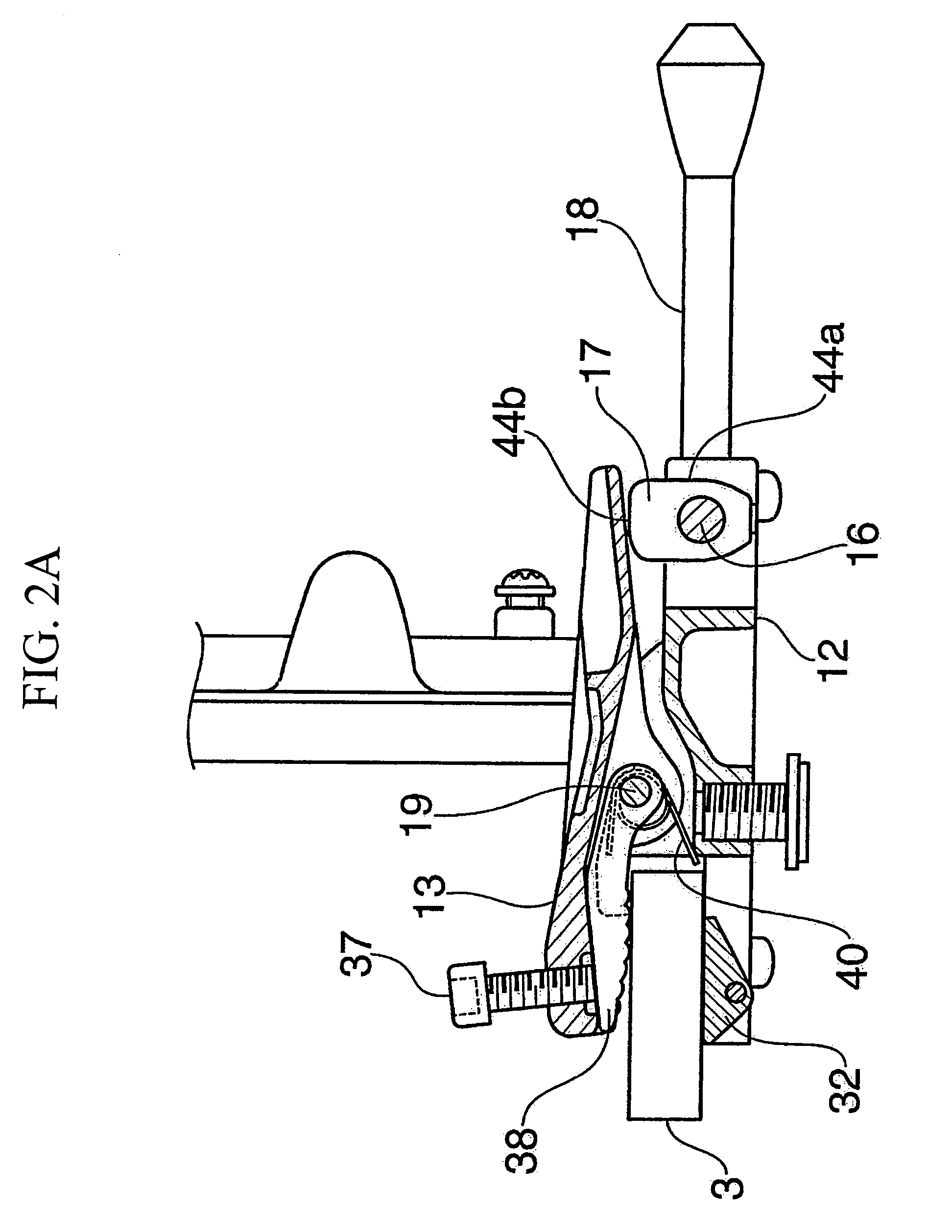

[0035]FIG. 1 shows a principal part of a foot pedal for a drum of the present invention when not clamped, and FIGS. 2A and 2B show states upon clamping hoops with a large board thickness and a small board thickness. It should be noted that the same portions and / or parts are referred by using the same symbols (reference numerals) for a foot pedal of the prior art shown in FIGS. 3 and 4.

[0036]In FIGS. 1 and 2, a foot pedal 30 of a drum of the present invention, as with the foot pedal for the drum of the prior art shown in FIG. 3, includes a pedal frame 11 in a square shape upon viewing from the front, a footboard 5 stepped on by a player with his / her foot, a beater 9 (see FIG. 3) which beats a drum head 10 and the like. However, there is a difference in a hoop clamping apparatus 31 provided at a supporting bar base 12 of the pedal frame 11 and clamping a hoop 3 of a bass drum 2, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com