Floating clamping jaw, retarder stator and rotor clamp and using method thereof

A floating jaw, stator and rotor technology, applied in the field of jaw fixtures, can solve the problems of large turning runout and unstable clamping, and achieve the effect of ensuring machining accuracy and fixing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are not limiting to the present invention.

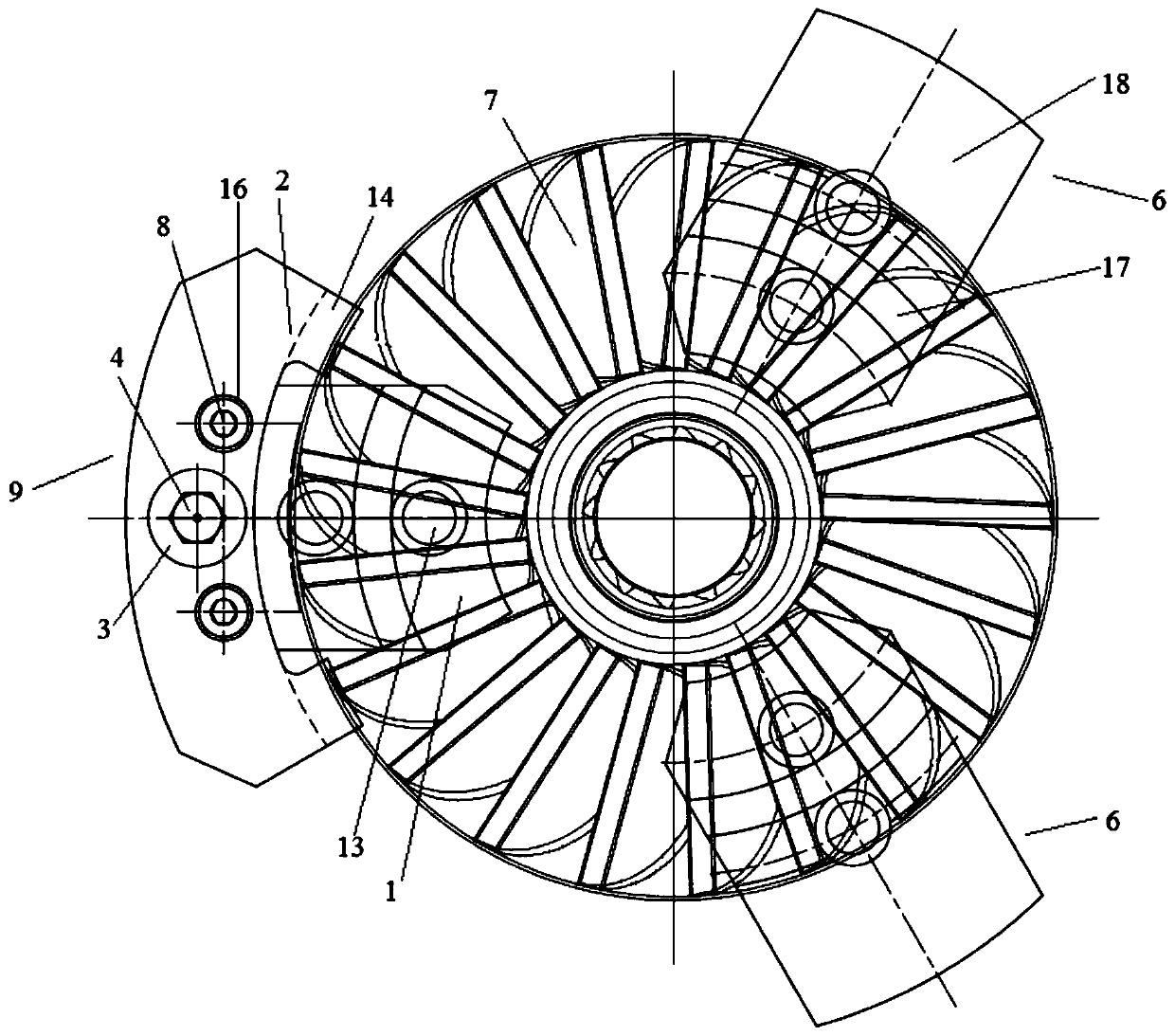

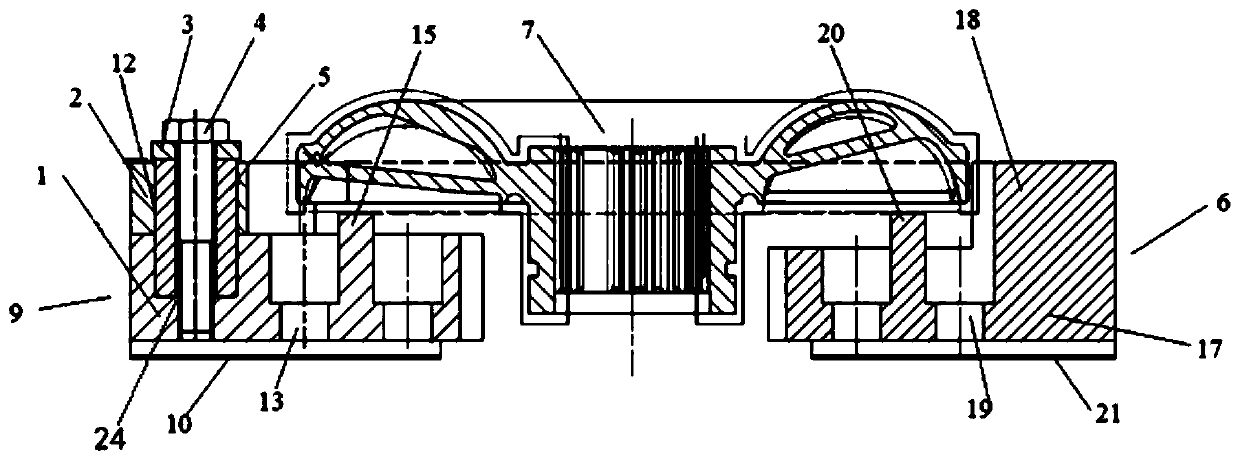

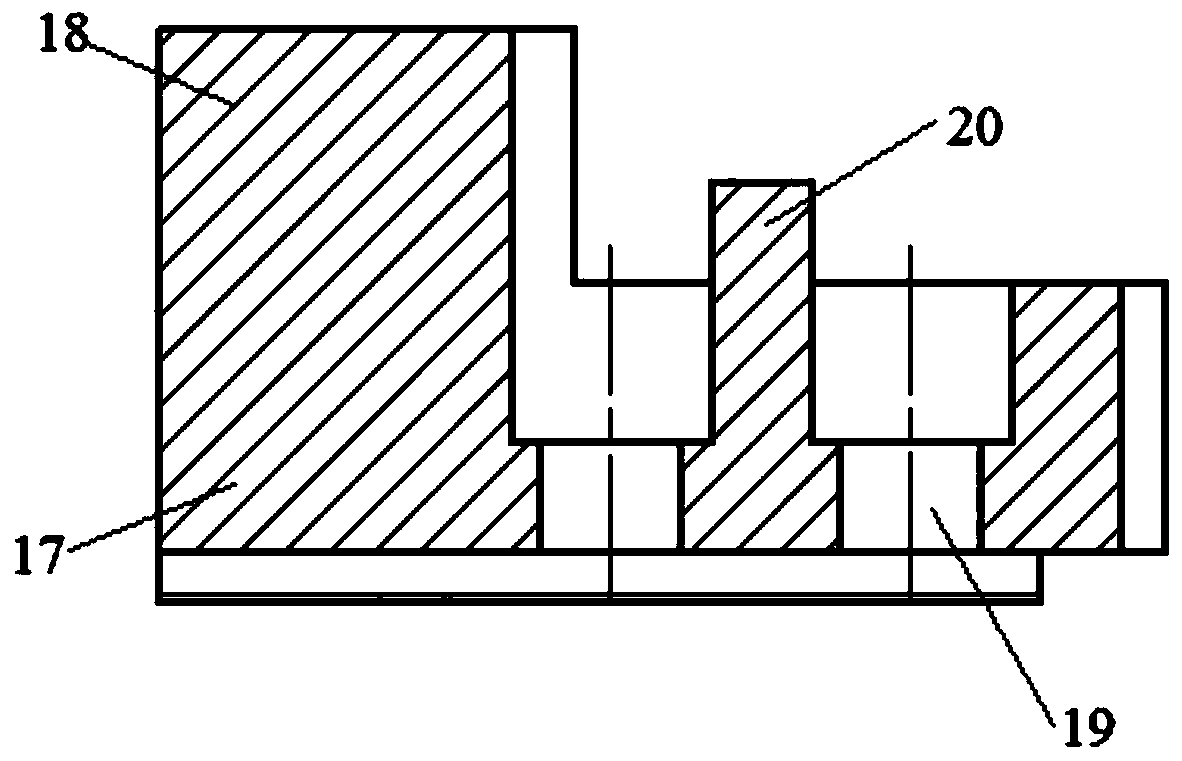

[0037] Reference figure 1 with figure 2 , A floating jaw of the present invention, the first jaw base 1 and the first jaw body 2 are both fan-shaped, and the first jaw body 2 is placed above the first jaw base 1, and its width is smaller than that of the first jaw. The arc length of the claw base 1 is greater than that of the first claw base 1, and the two side surfaces of the first claw body 2 extend beyond the two side surfaces of the first claw base 1, and the excess value is the same. The first jaw base 1 is provided with a stepped hole 24, and the small hole of the stepped hole 24 is provided with a thread; the large hole of the stepped hole 24 is arranged coaxially with the mandrel th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com