Patents

Literature

96results about How to "Constant clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

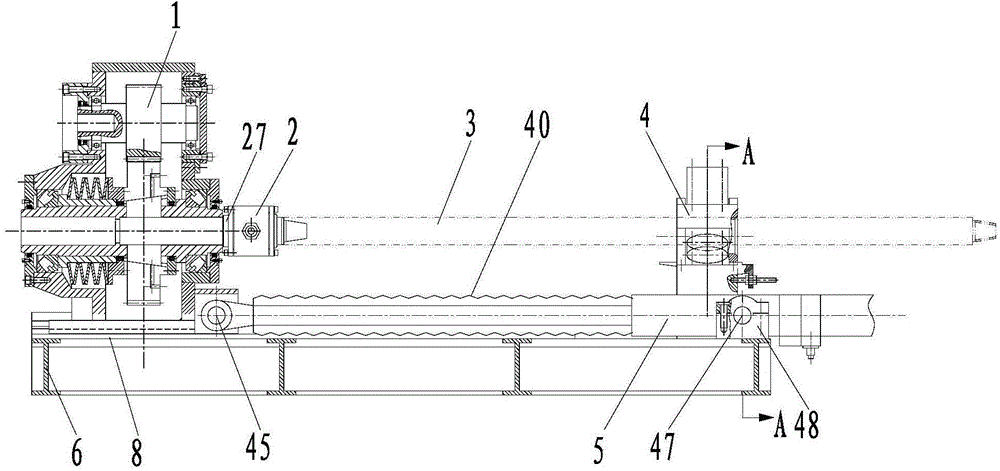

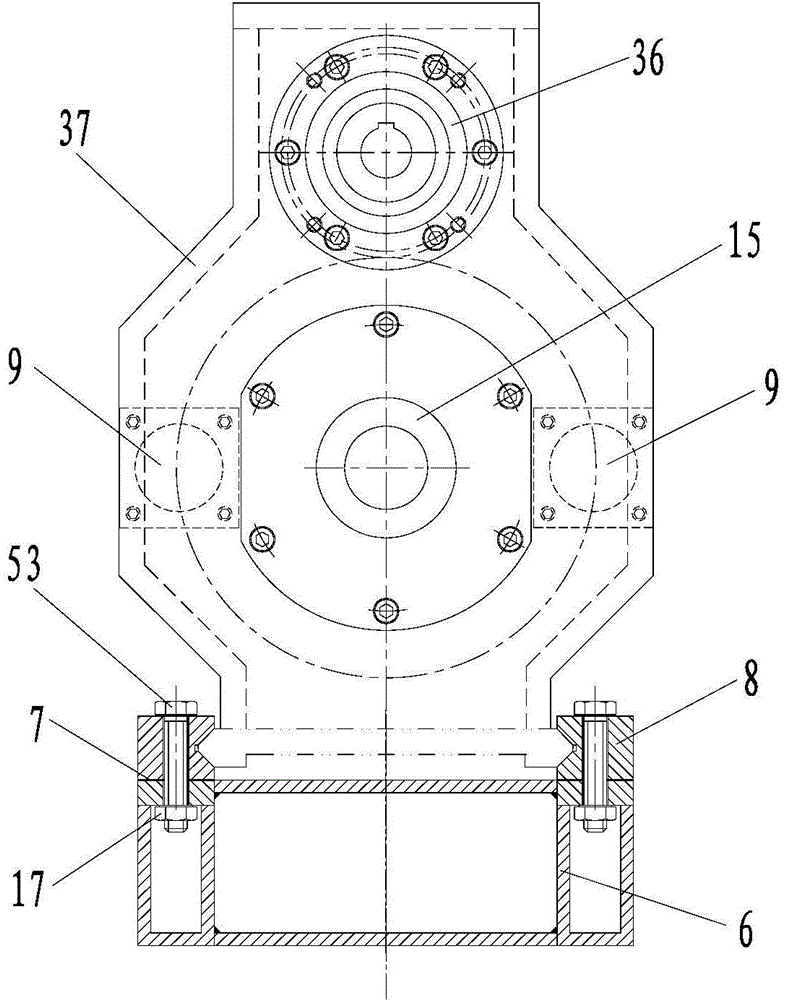

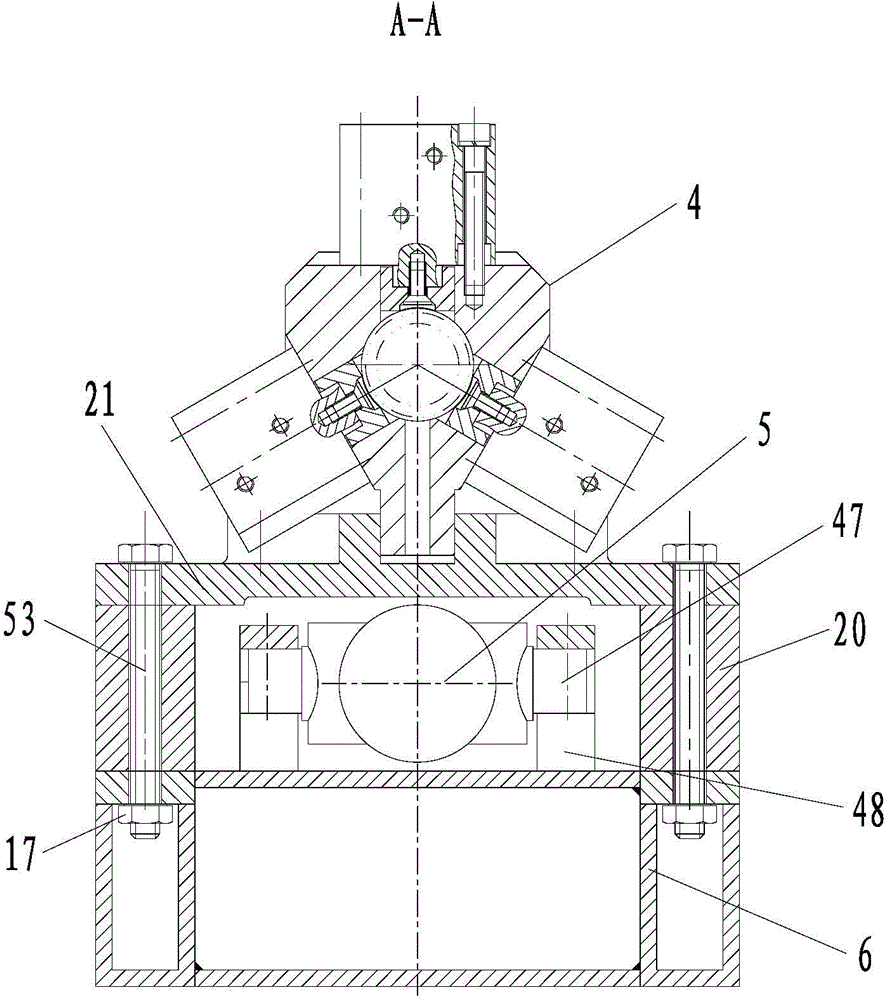

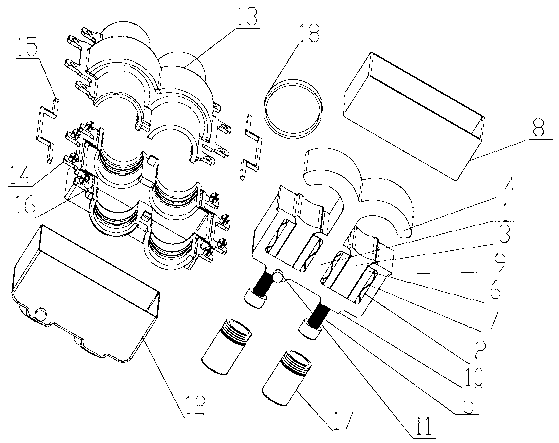

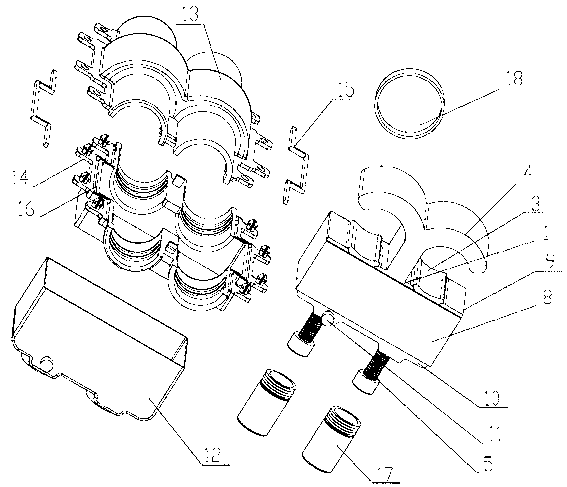

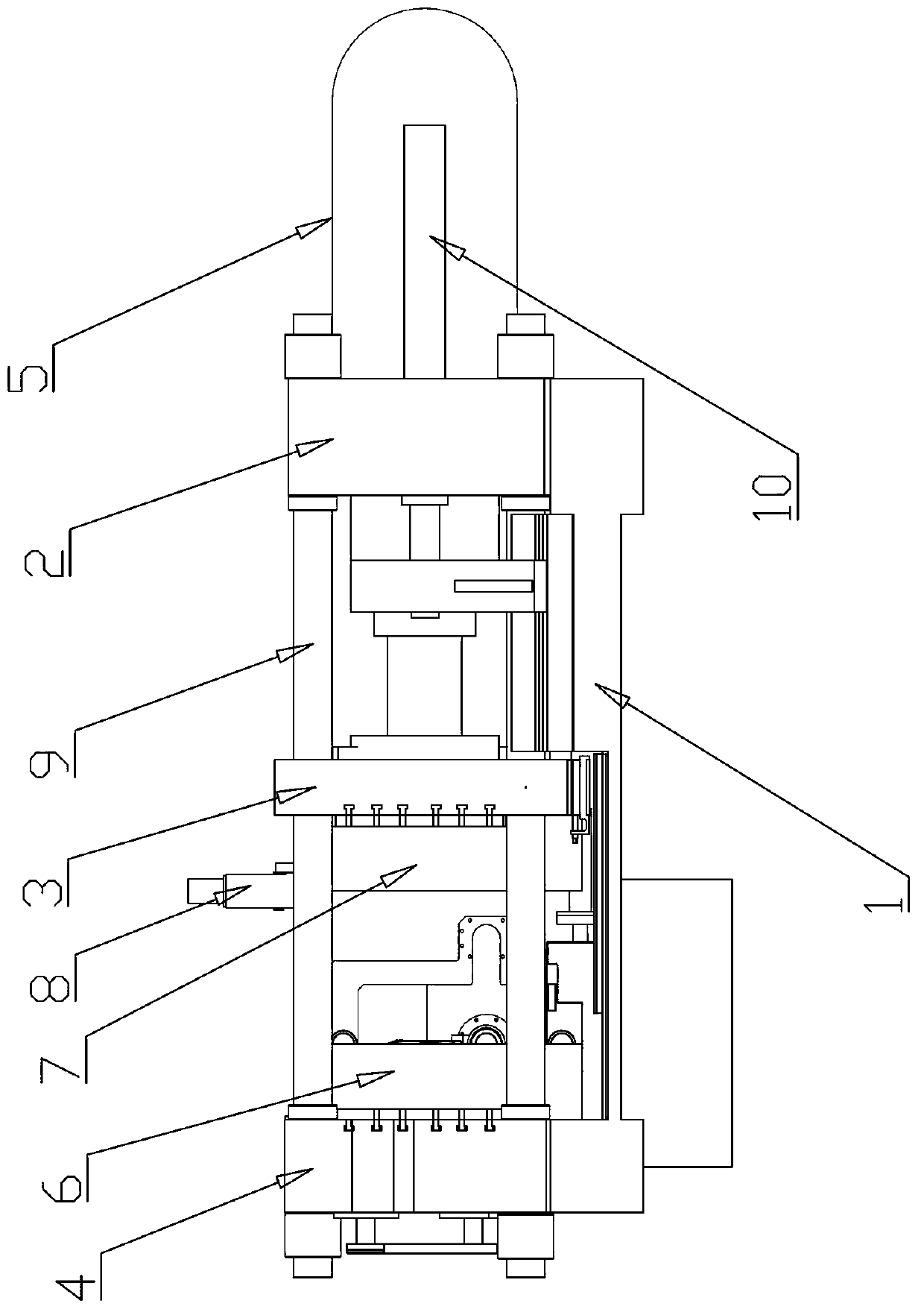

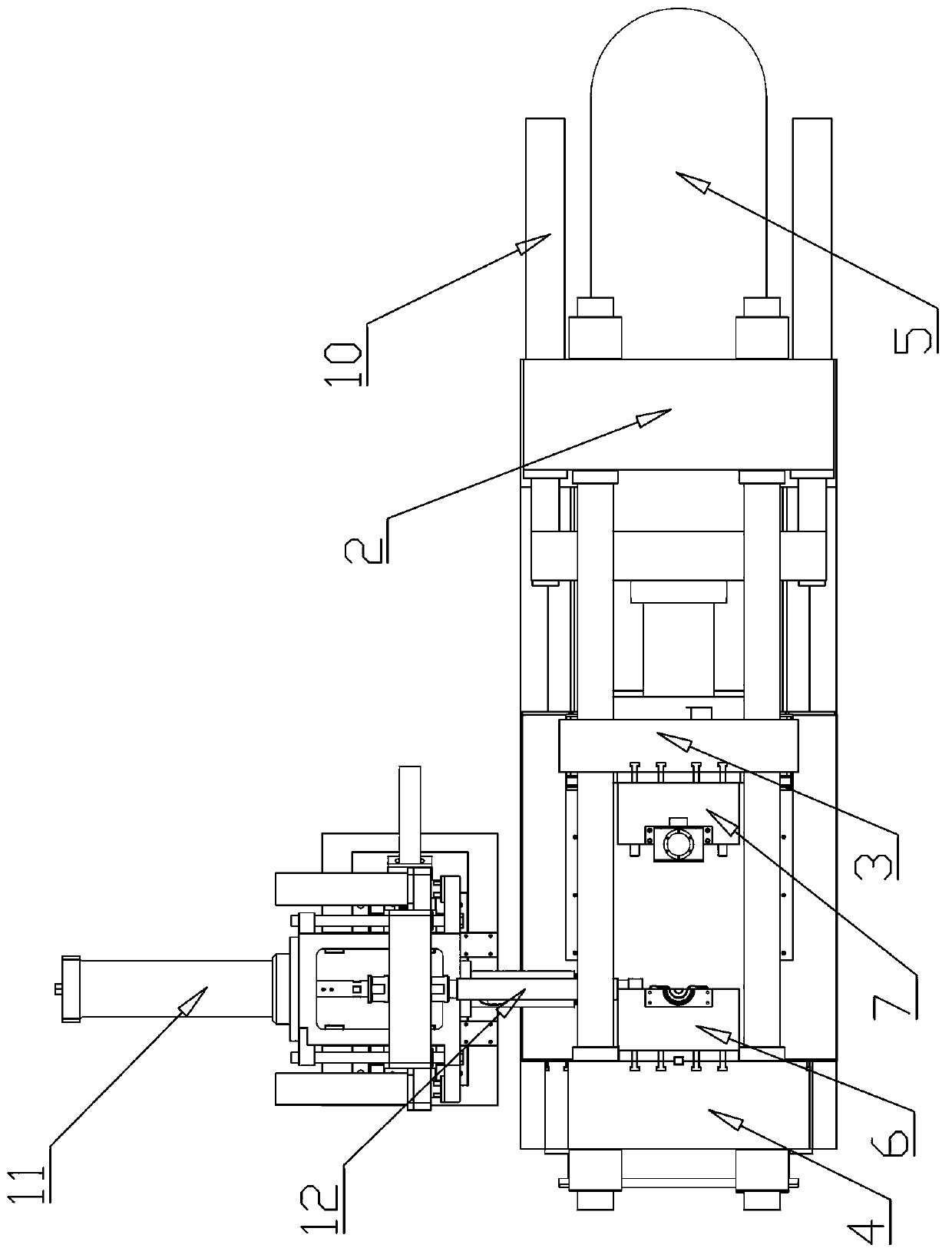

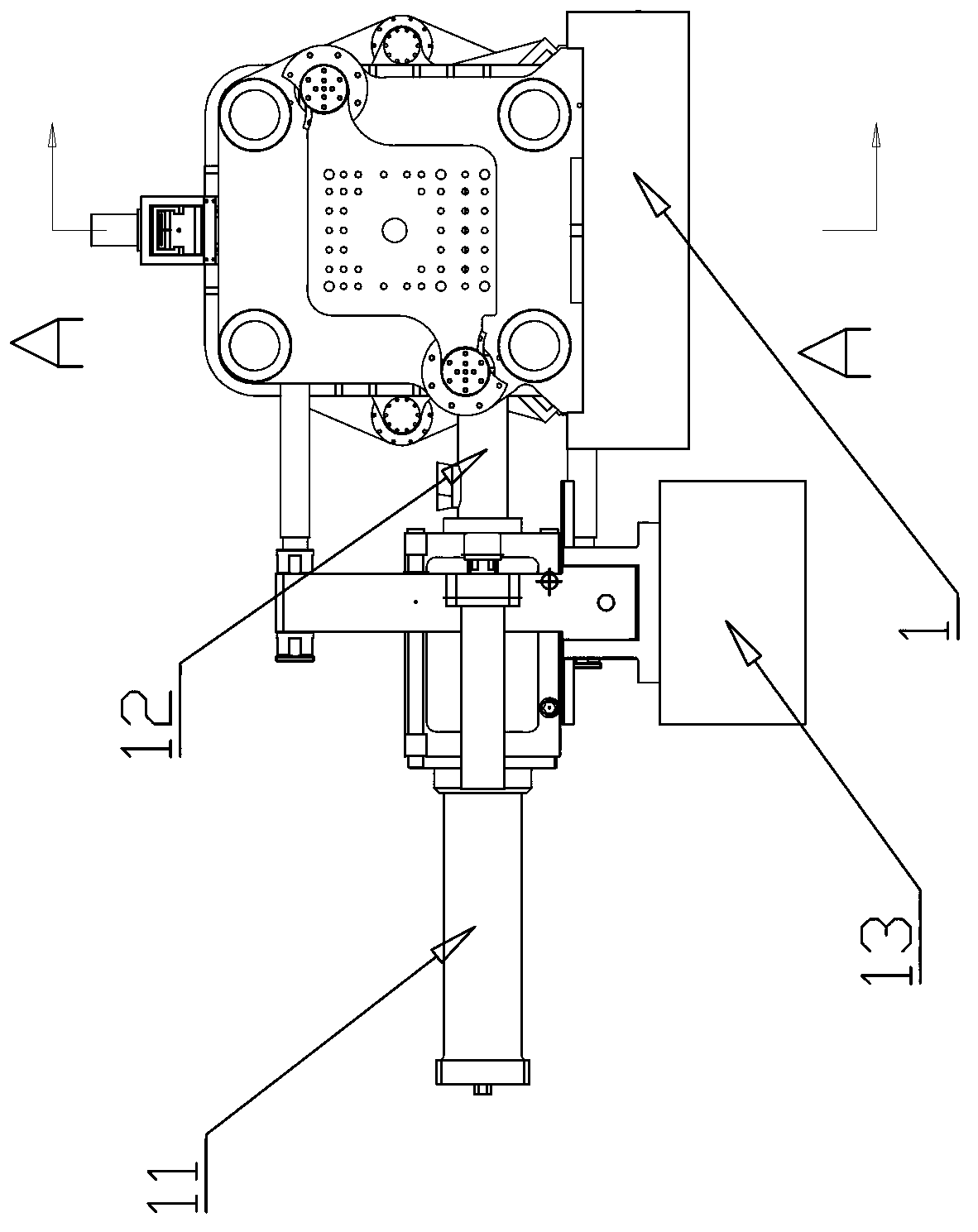

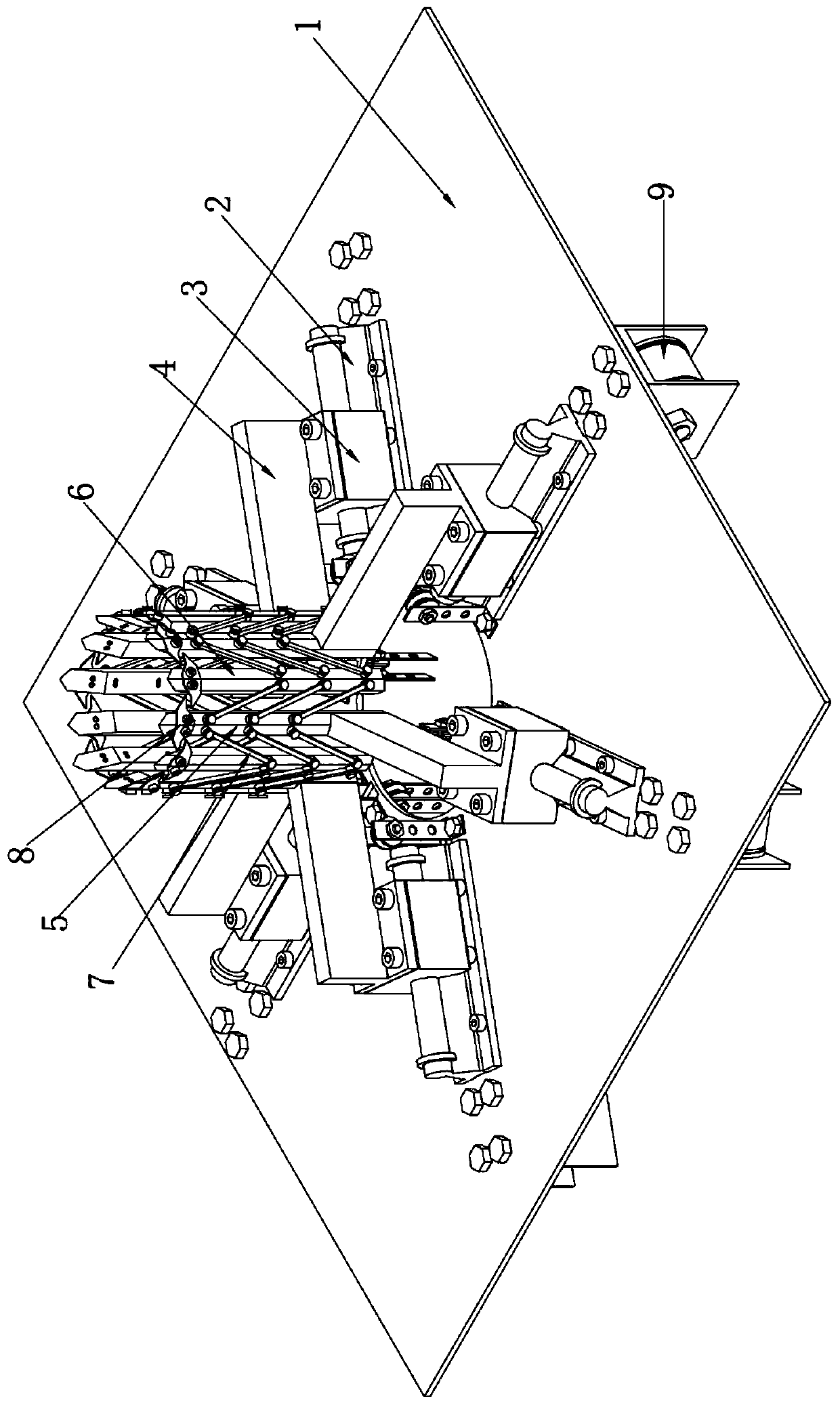

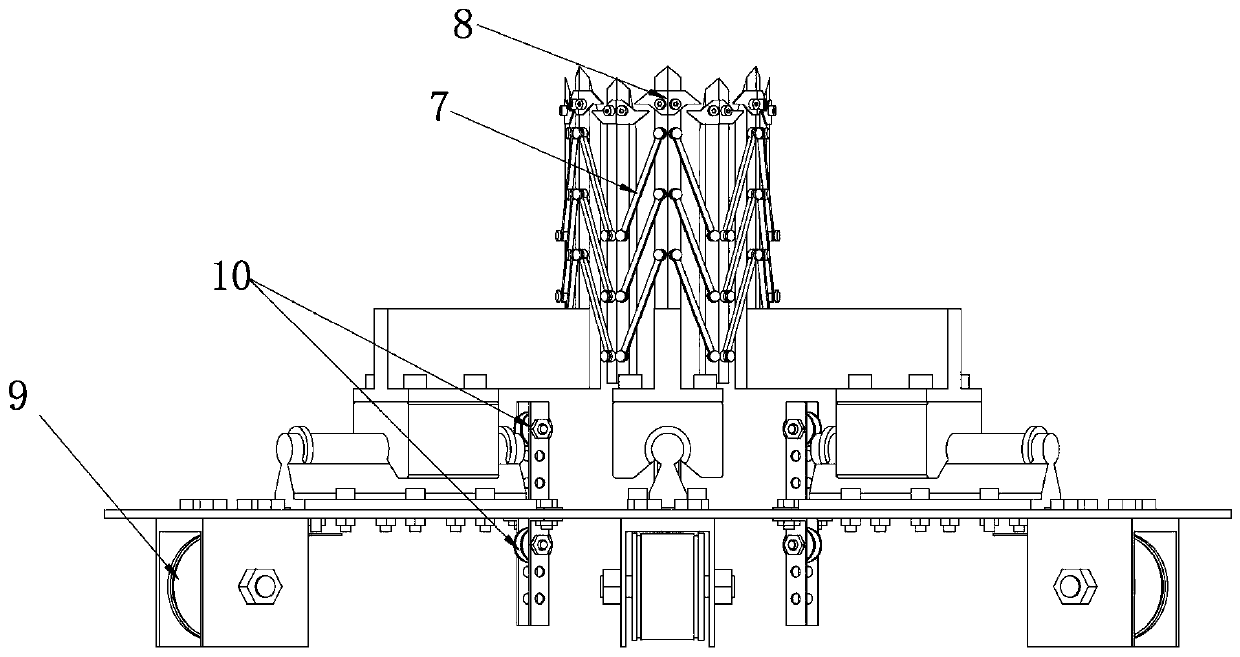

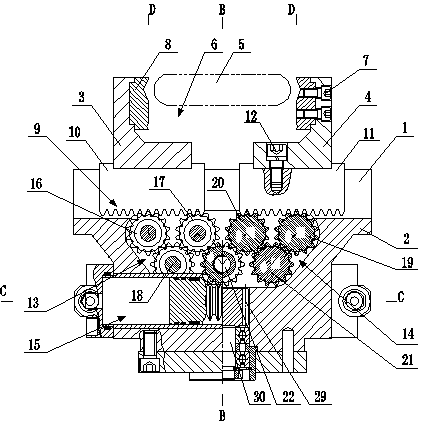

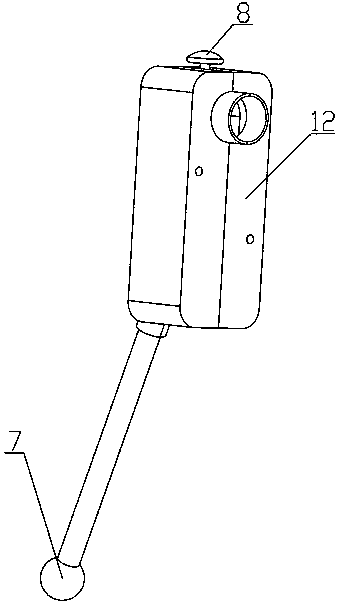

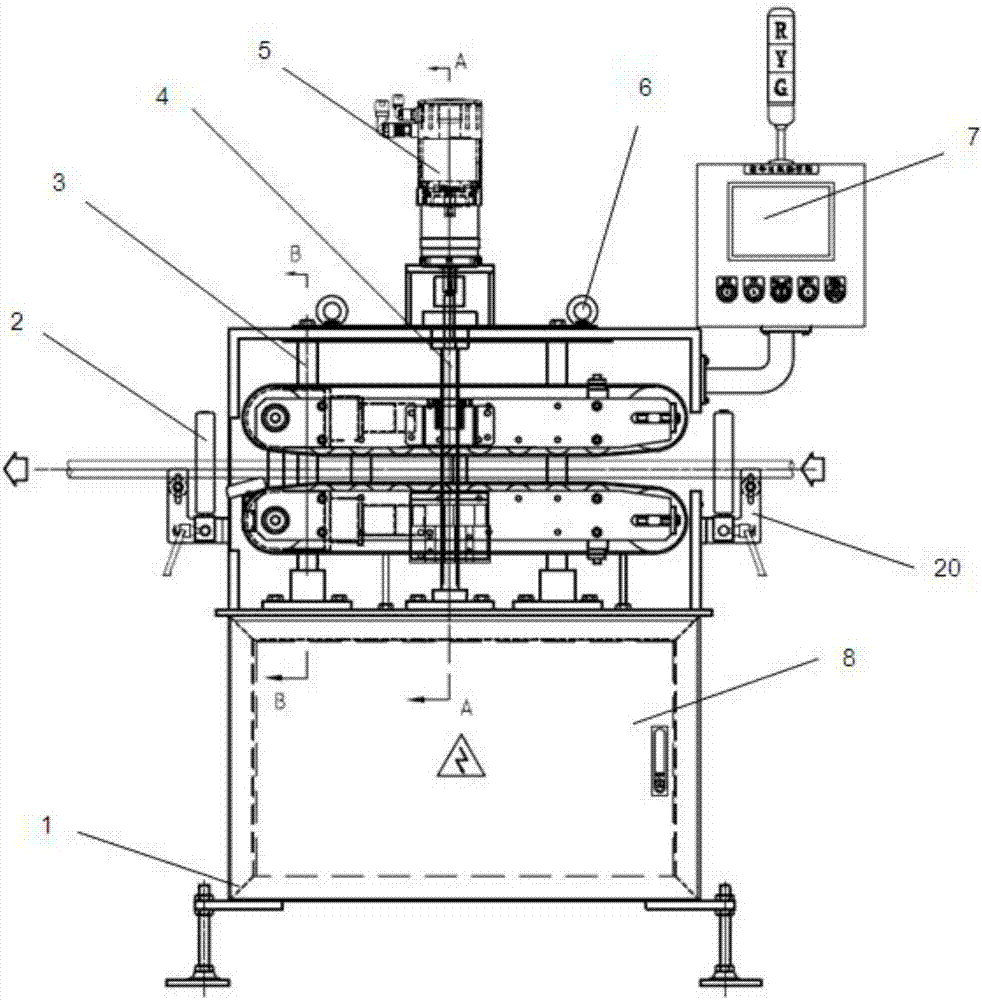

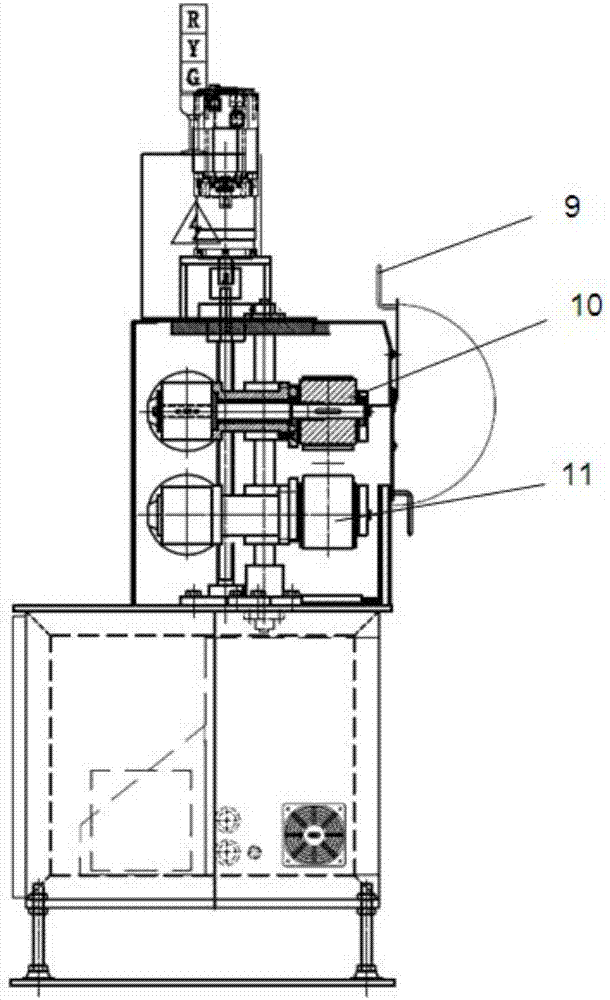

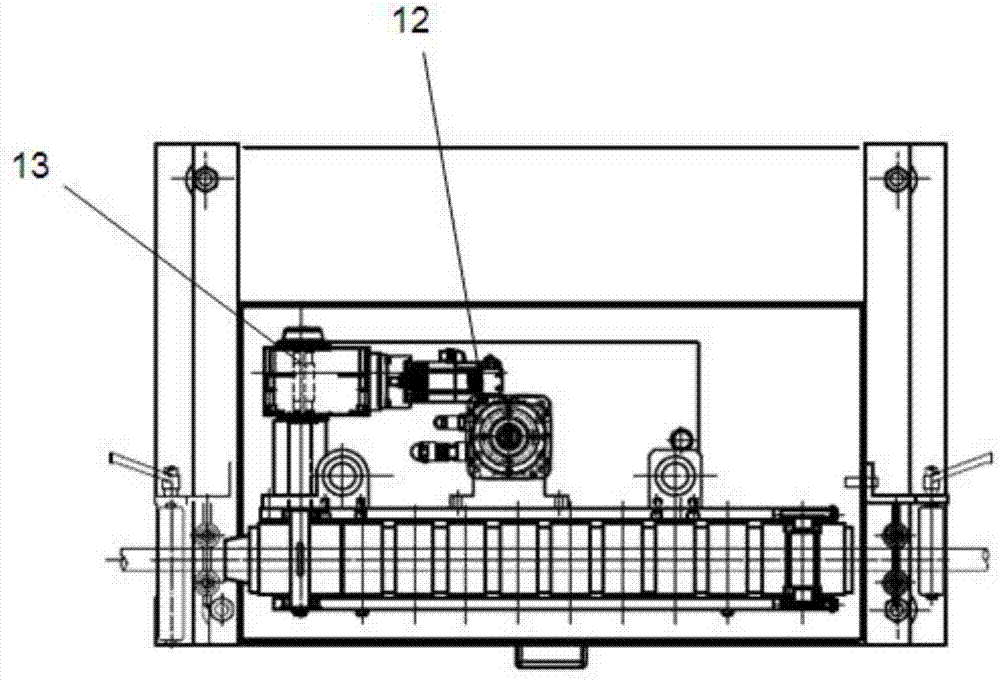

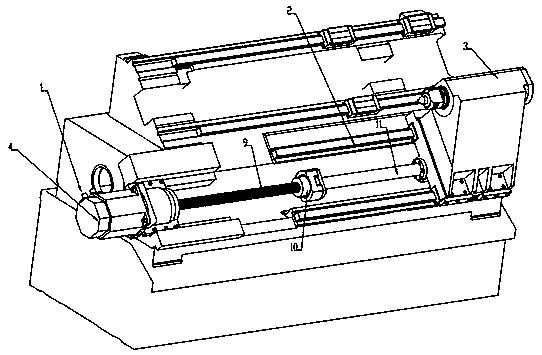

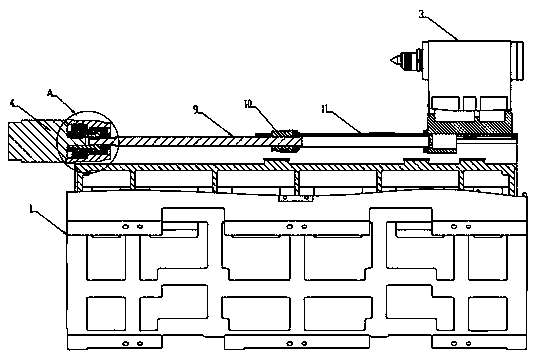

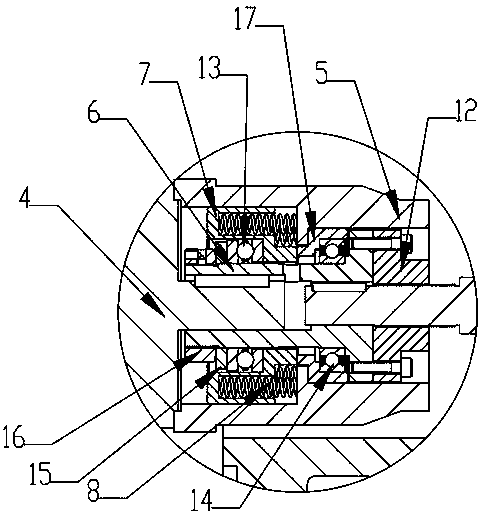

Light-type full-hydraulic drilling machine for underground drilling of coal mine

The invention discloses a light-type full-hydraulic drilling machine for underground drilling of a coal mine. The light-type full-hydraulic drilling machine comprises a stander, a drilling rod, a water braid, a guide rail, a propelling hydraulic cylinder, a hydraulic clamp and a drill power head, wherein the hydraulic clamp comprises a clamp base, a supporting seat, a clamping hydraulic cylinder and a clamp clamping tile; the water braid comprises a water braid shell, a water braid shaft, a water braid hollow shaft, two anti-abrasion ring, an isolating ring, a front end cover, a rear end cover and an anti-abrasion sealing ring; the drill power head comprises a speed reduction box body, a connection frame, a gear shaft, a hollow stepped shaft, a hydraulic motor, a spring mounting seat, a spring limiting seat, an end face check ring, a gear, a disk-type spring group, a power head clamping tile and a clamping hydraulic cylinder. The light-type full-hydraulic drilling machine is compact in structure, convenient and low in cost; the energy consumption is reduced, the power transmission efficiency is improved, and the clamping force on the drilling rod is stable and reliable; the service lives of the anti-abrasion sealing ring and the water braid shaft can be prolonged, the replacement trouble is reduced, the construction progress and safe production are guaranteed, vibration of the drilling machine is reduced, and the drilling rod is prevented from being broken.

Owner:XIAN UNIV OF SCI & TECH

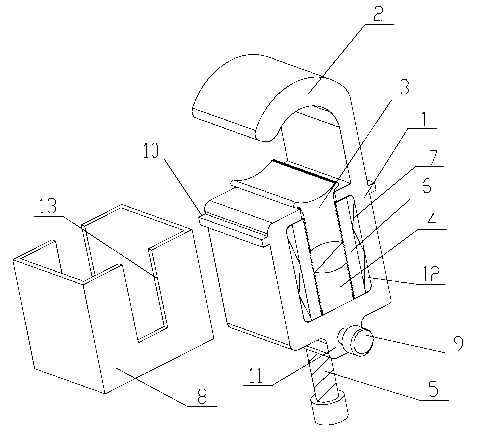

Cable connecting clamp with insulating sheath

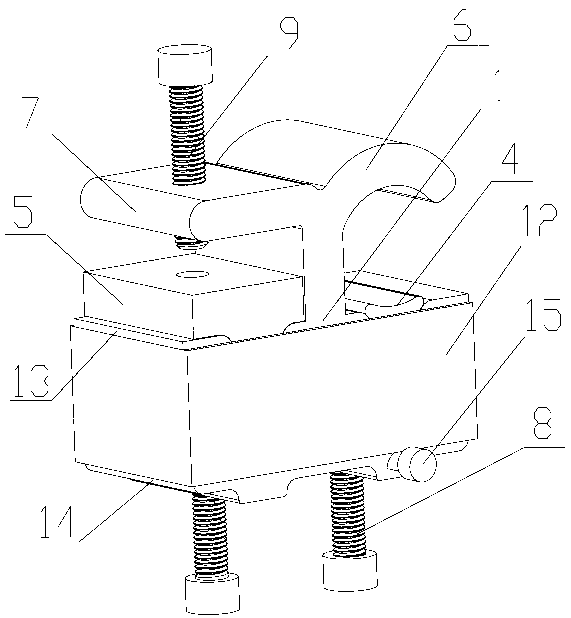

ActiveCN103022749APlay the role of insulationPlay the bare wire partElectric connection structural associationsClamped/spring connectionsEngineeringCircular cavity

The invention discloses a cable connecting clamp with an insulating sheath. The cable connecting clamp comprises two parallel fixedly connected cable clamps used for clamping cables, the cable clamps comprises cable clamp bodies, grooves are arranged in the cable clamp bodies, movable clamps are embedded in the grooves, a fixed clamp is fixed on the cable clamp bodies, adjusting bolts respectively penetrate bolt holes on the lower portions of the cable clamp bodies to be fixed with the cable clamp bodies and abutted against the movable clamps, an upper insulating shell is shaped on the fixed clamps, a lower insulating shell is correspondingly formed in a cable clamping cavity between the cable clamping bodies and the fixed clamp, the lower insulating shell is fixedly connected with the upper insulating shell, and cable passing portions of the lower insulating shell and the upper insulating shell form a circular cavity. The cable connecting clamp with the insulating sheath has the advantages of strong universality, applicability to various cables in different diameters, uniform and constant clamping force, small universality, insulation, water resistance and safety in utilization.

Owner:GUANGZHOU PANYU CABLE WORKS

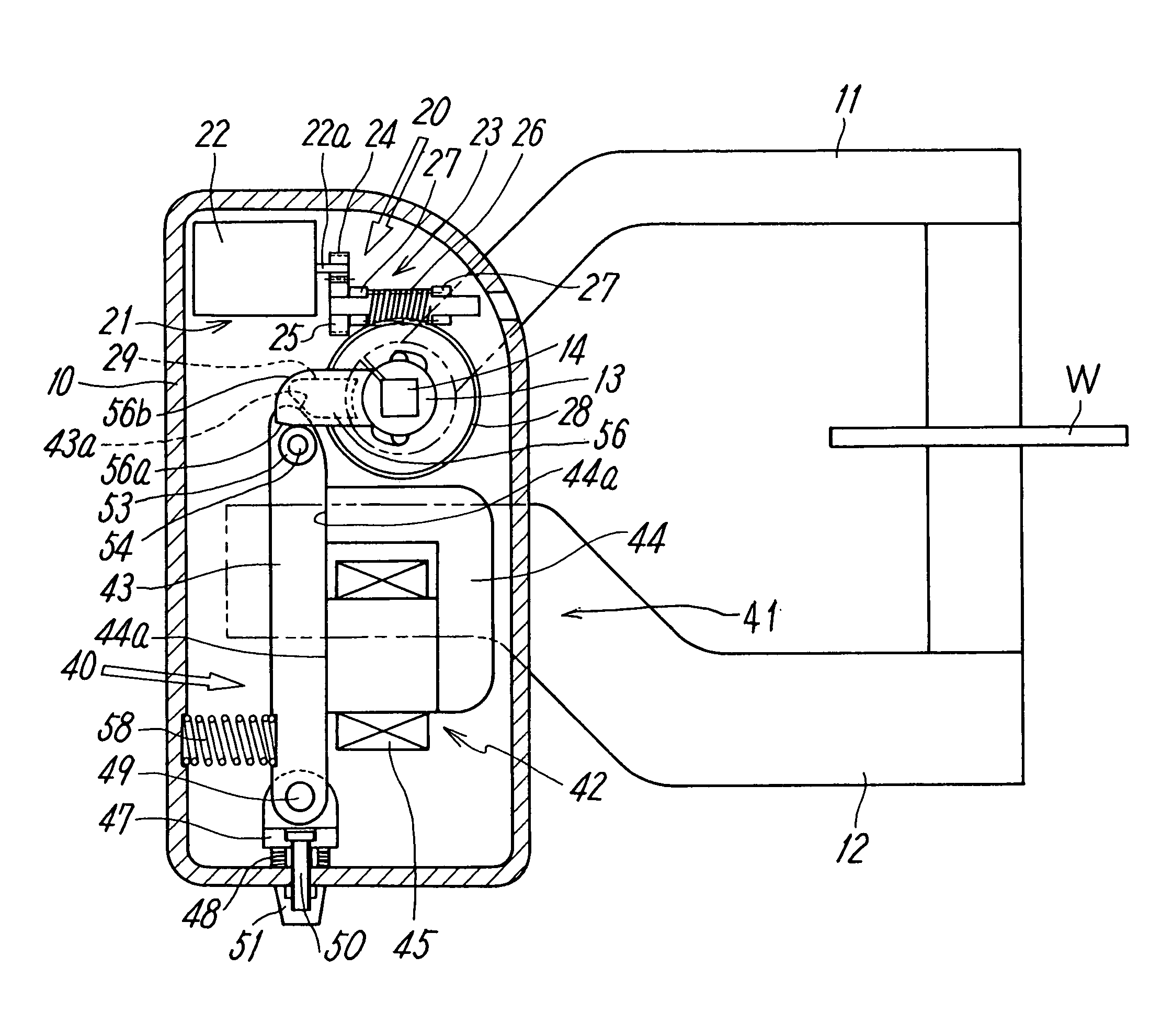

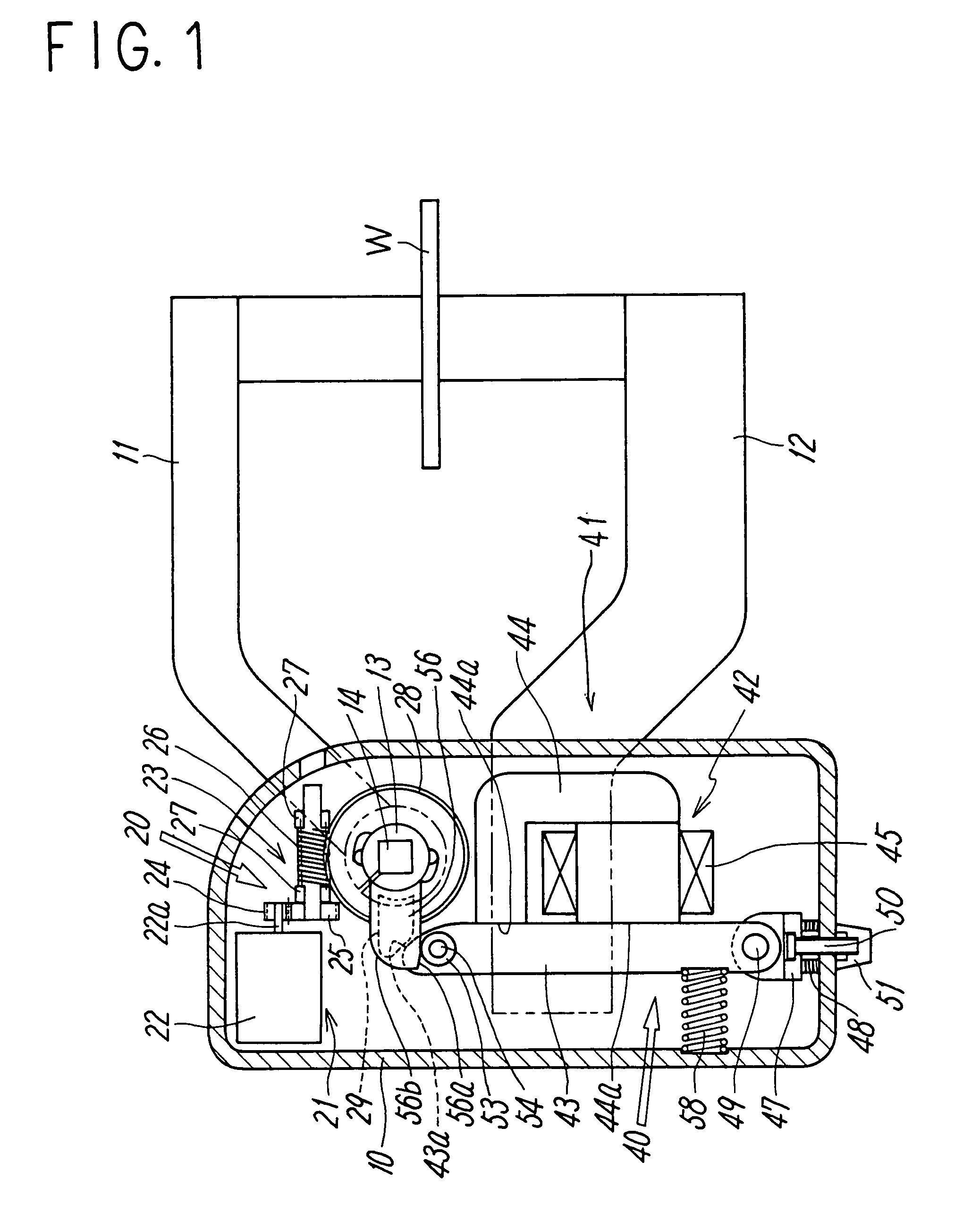

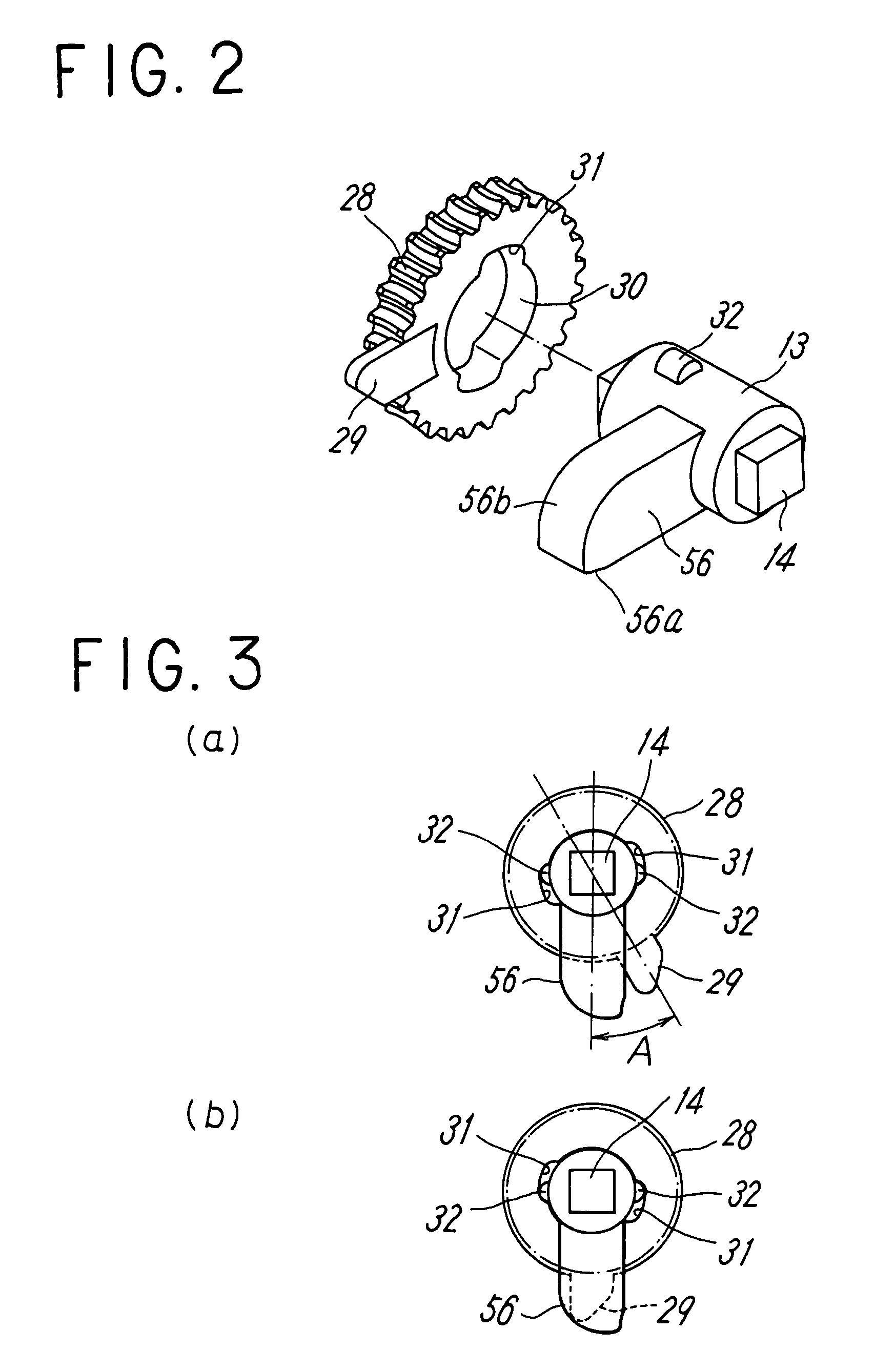

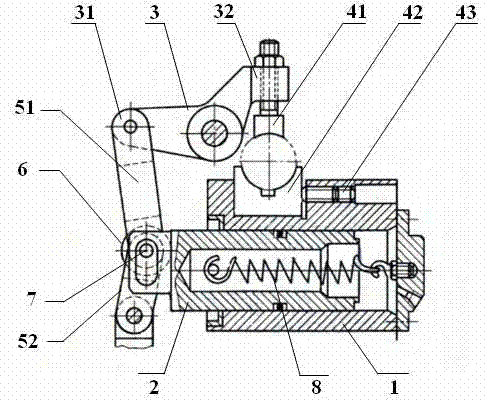

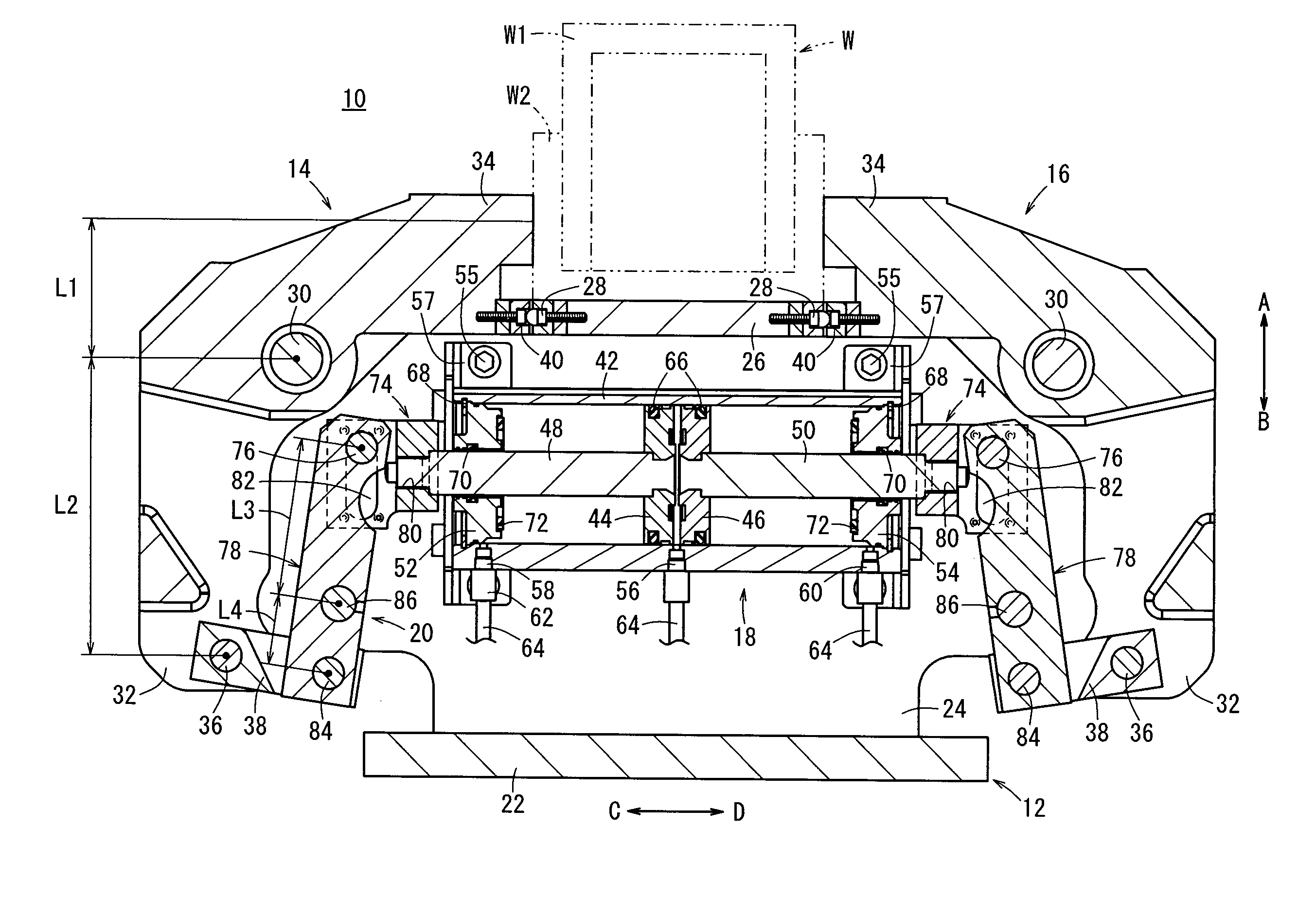

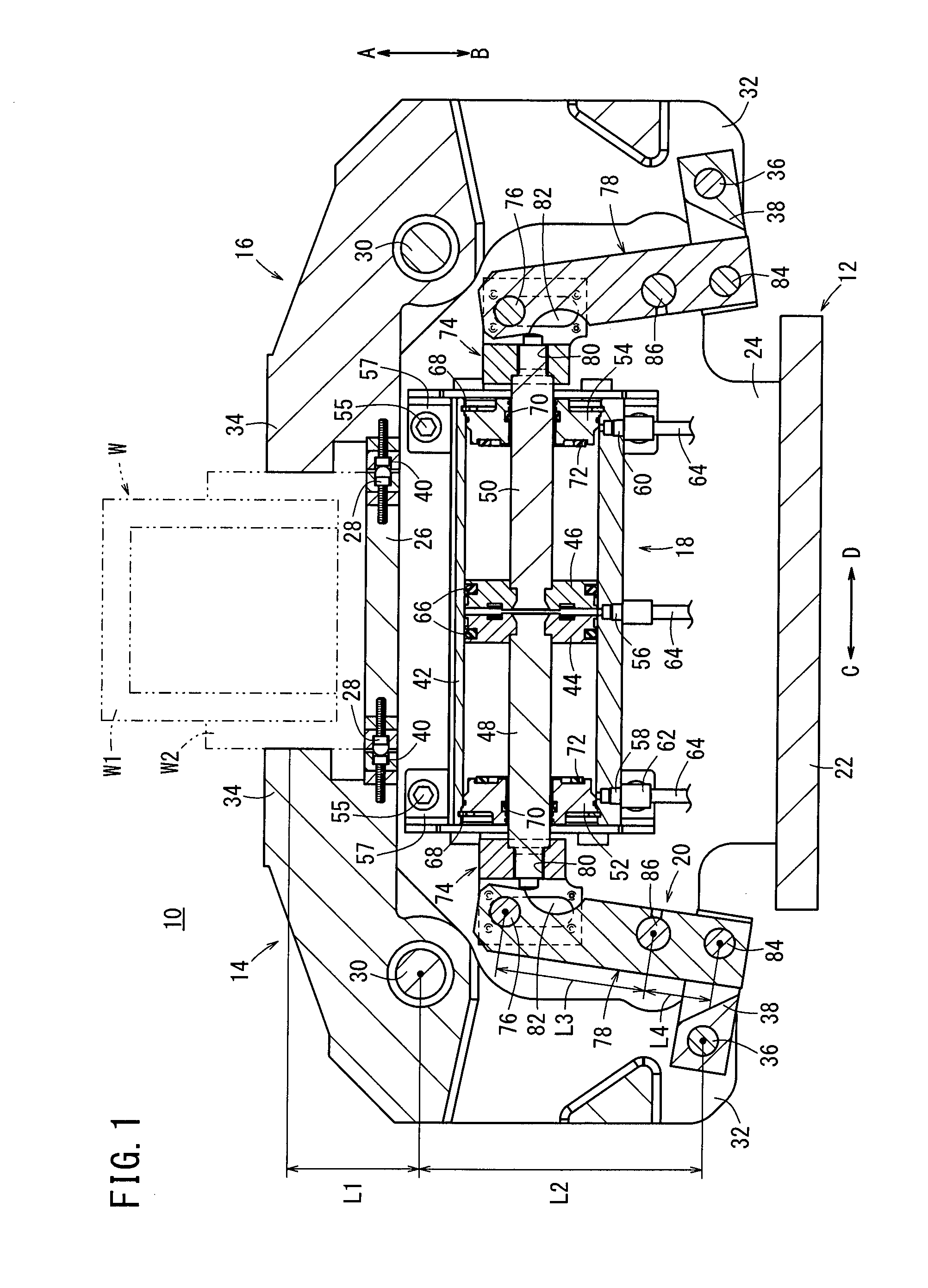

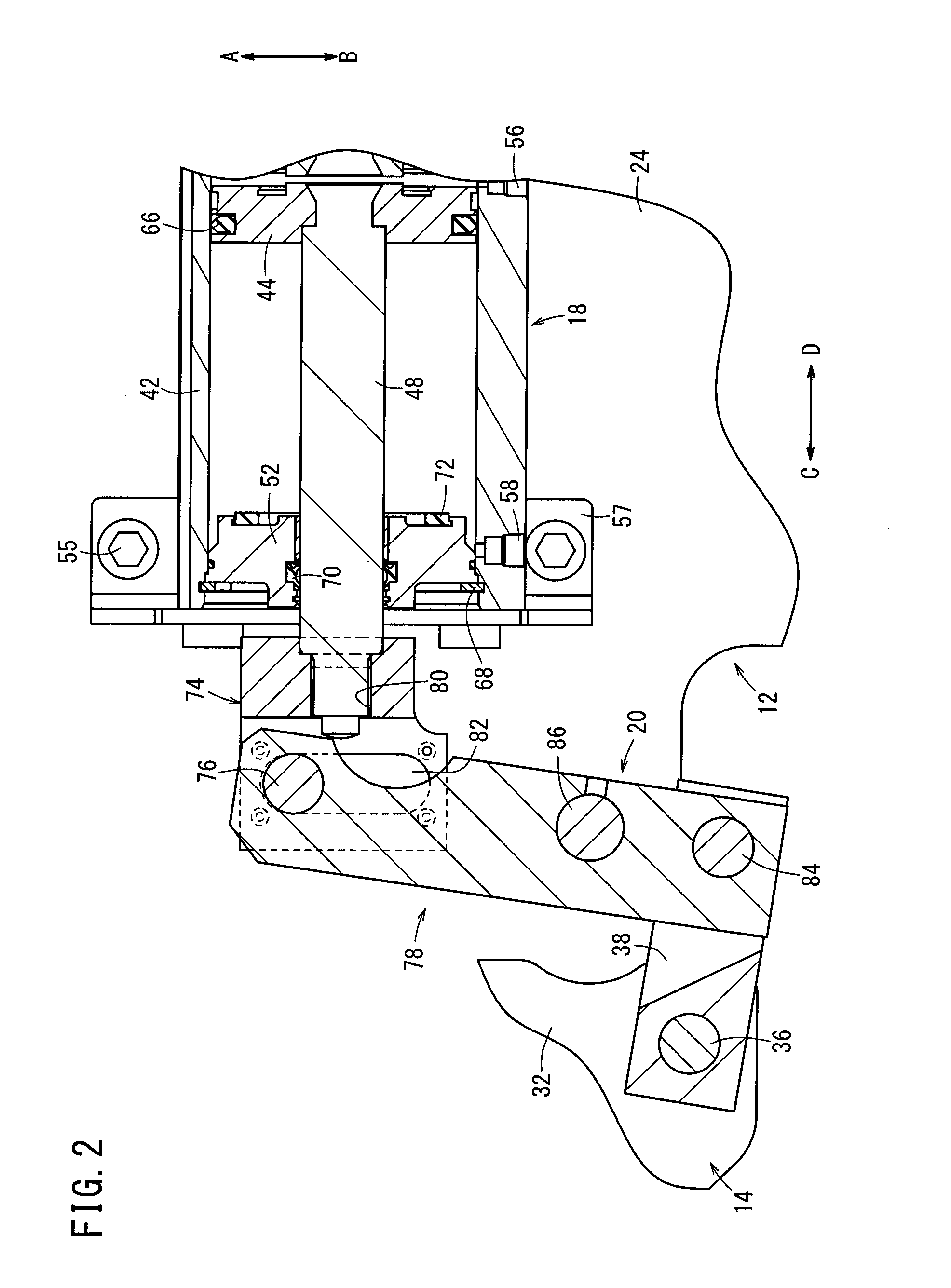

Clamping device

ActiveUS7004459B2Guaranteed uptimeSimple structurePositioning apparatusVicesMechanical engineeringPower transmission

A clamping device includes a first clamping arm and a second clamping arm, an arm driving portion for displacing the first clamping arm to a clamping position and a non-clamping position, and a clamping force applying portion for applying a required clamping force to the clamping arm. The arm driving portion has a first driving source for displacing the first clamping arm and a power transmission mechanism. The clamping force applying portion has a pressing member for applying the clamping force to the first clamping arm by applying a rotating force in a clamping direction to the rotary shaft and a second driving source for displacing the pressing member from a non-operating position to an operating position for applying the clamping force.

Owner:SMC CORP

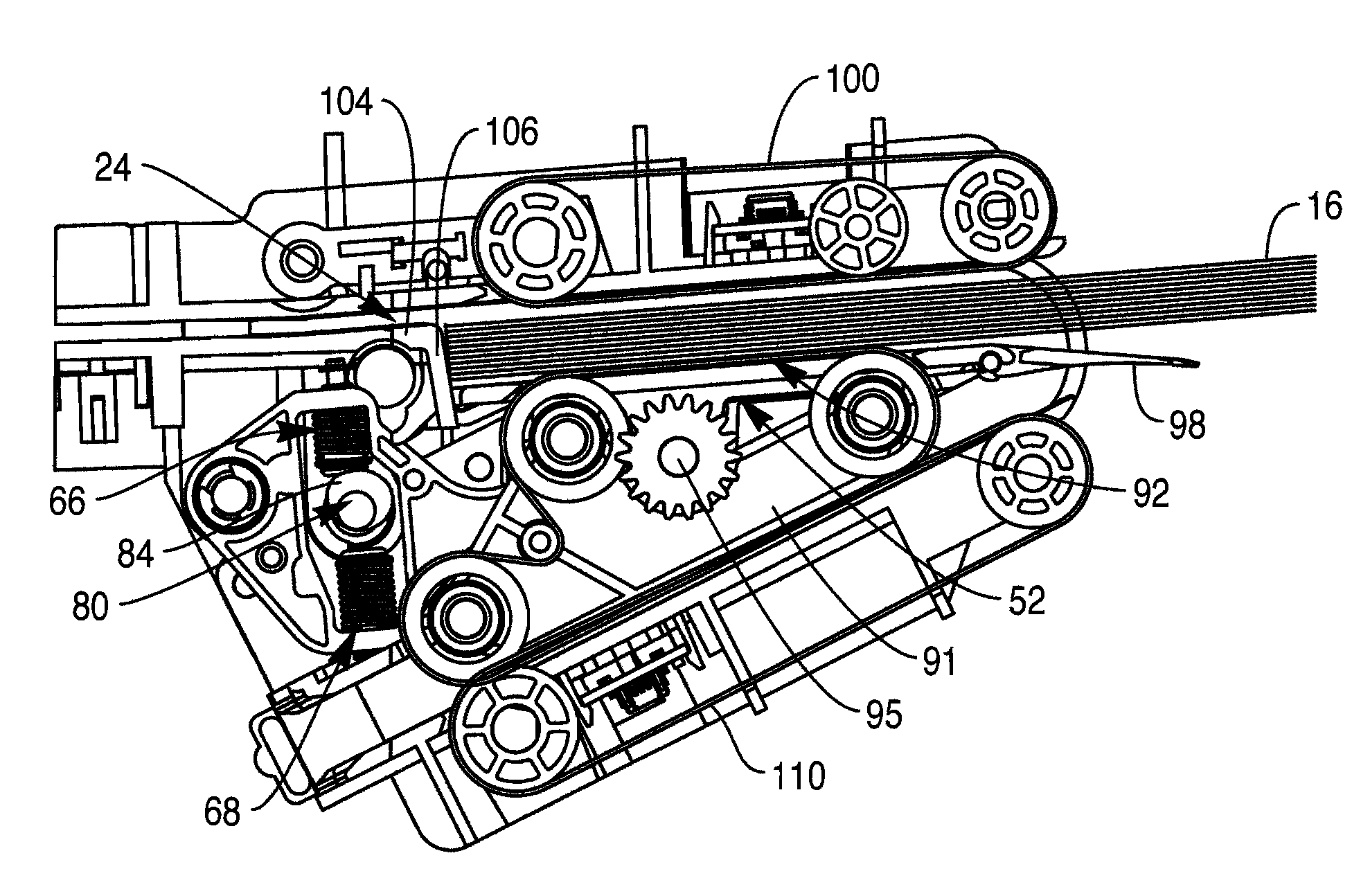

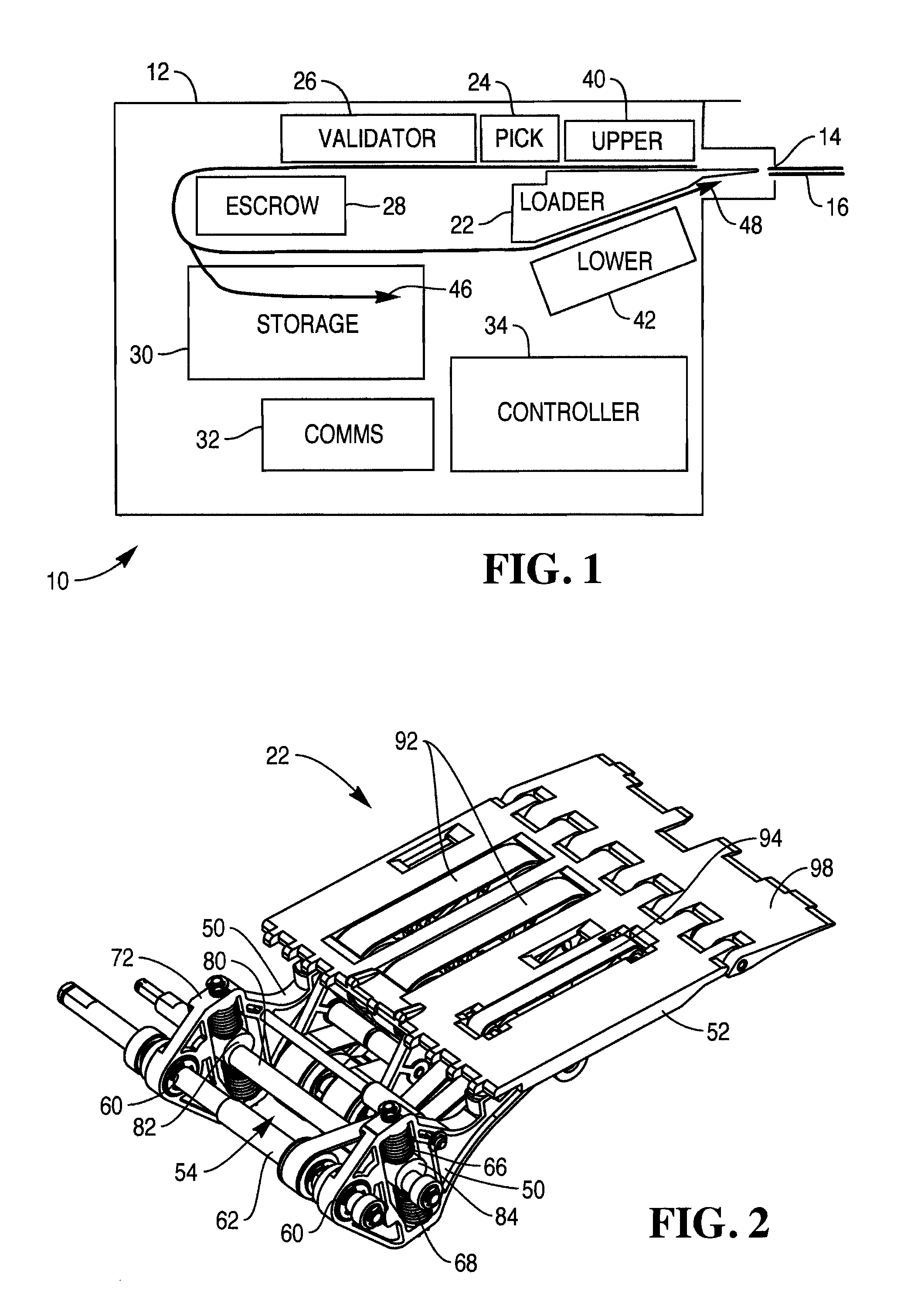

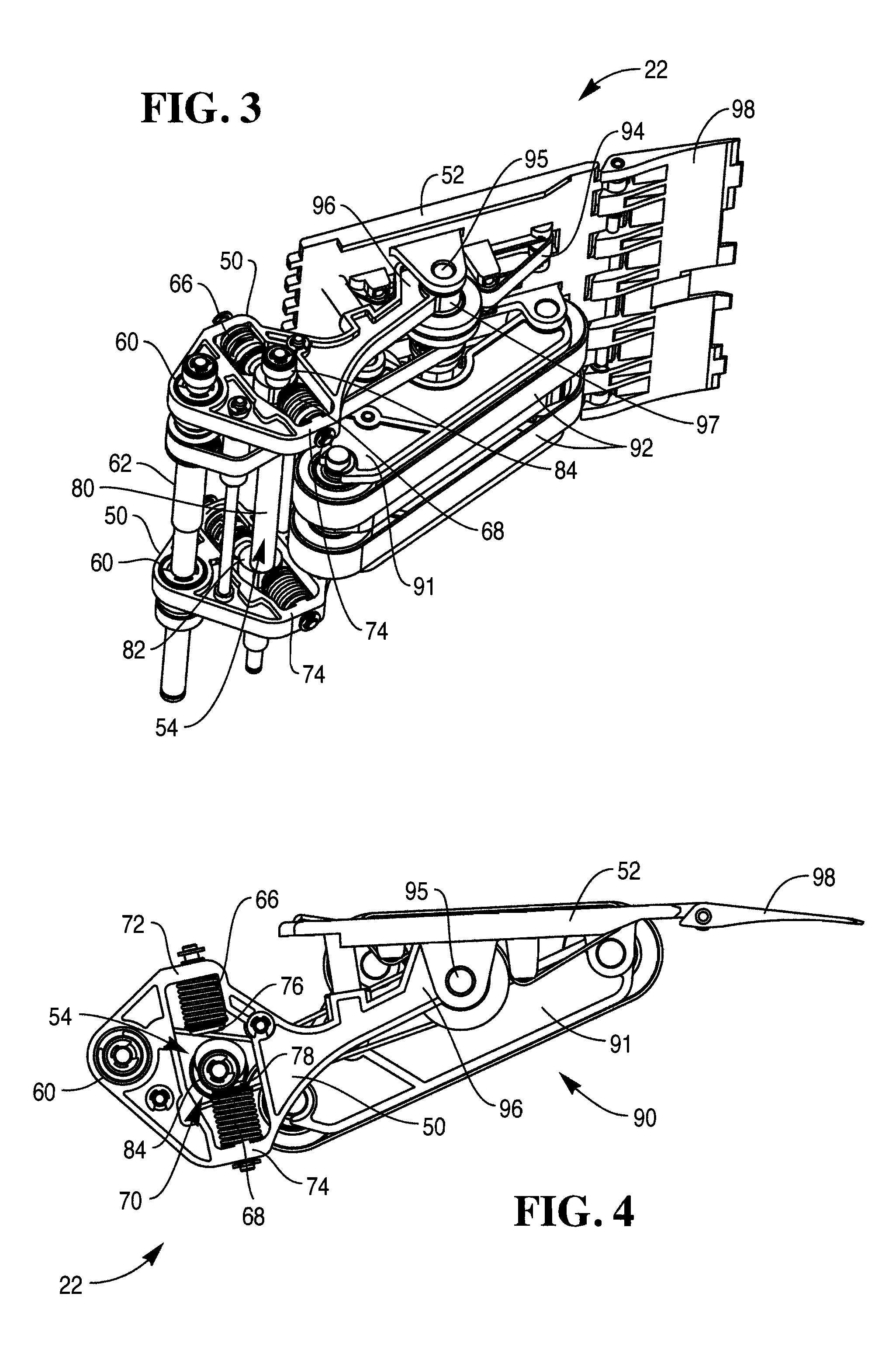

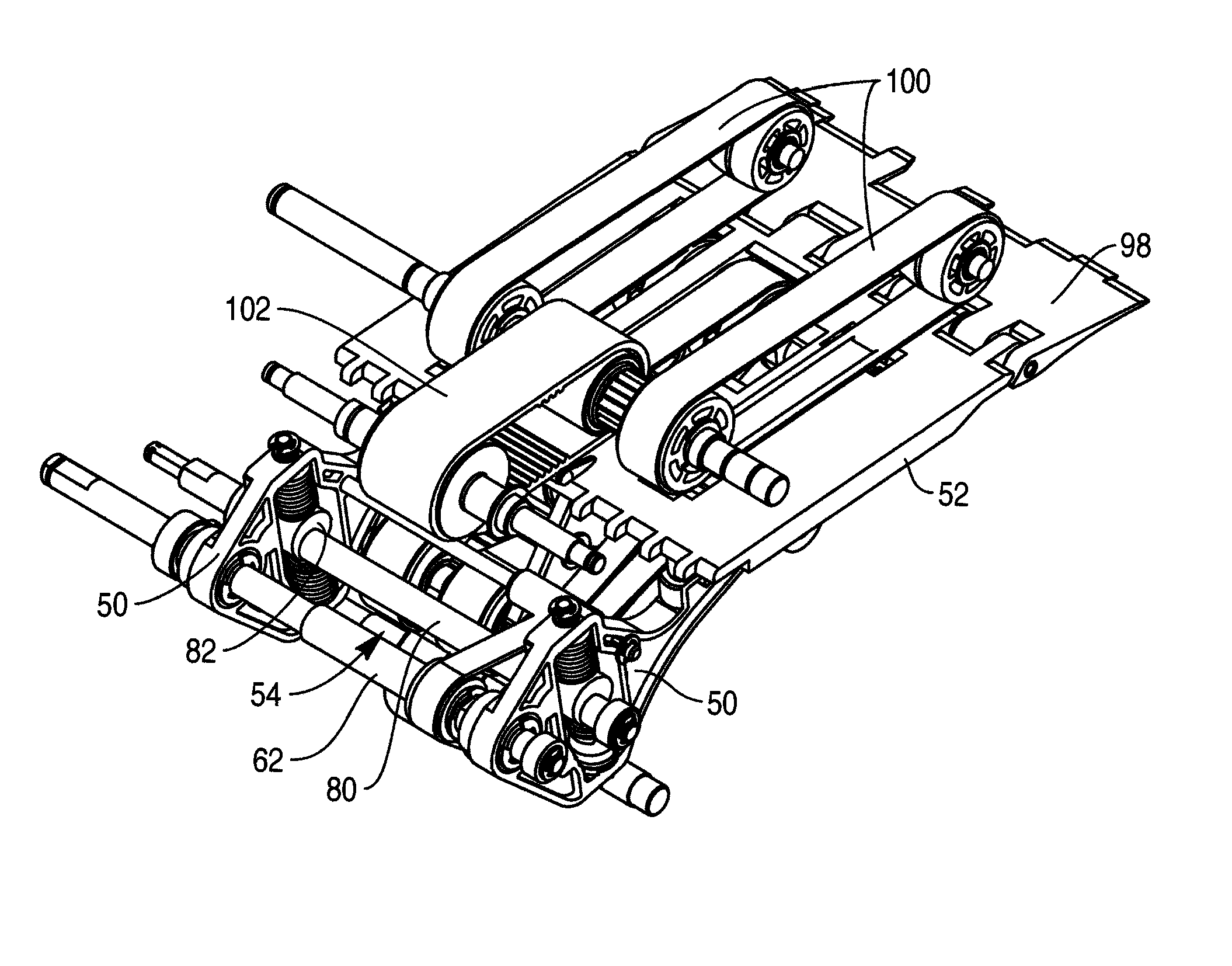

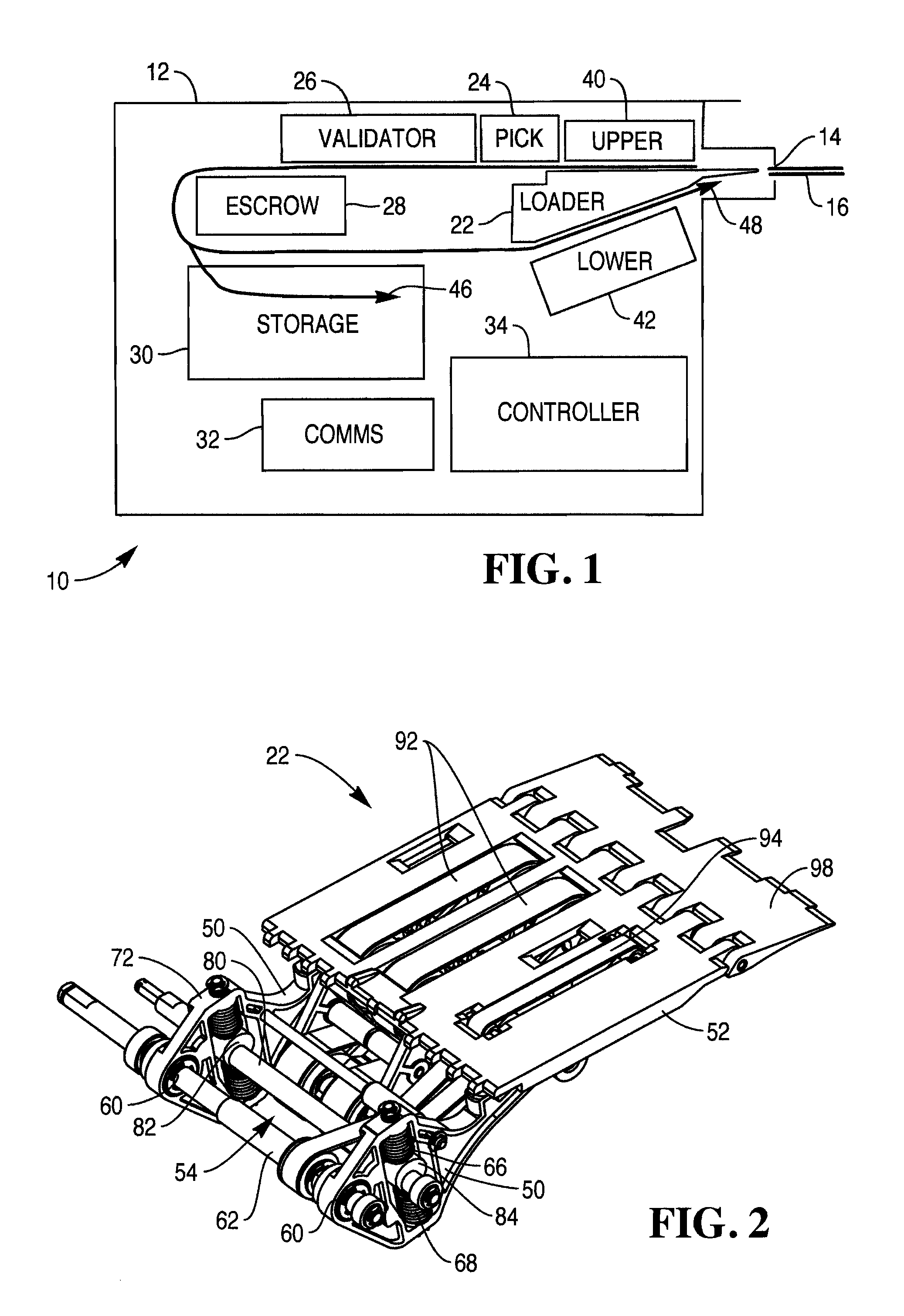

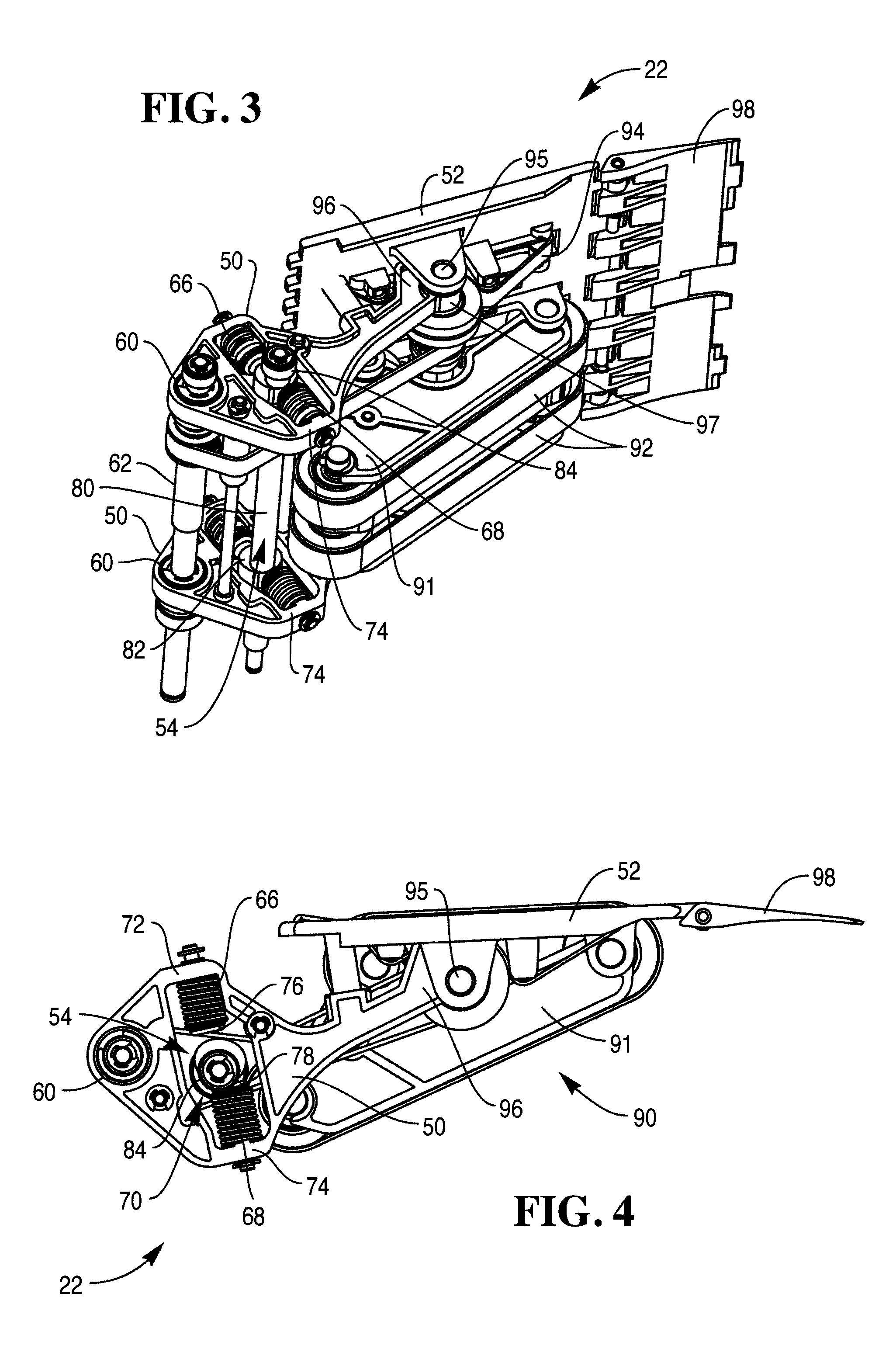

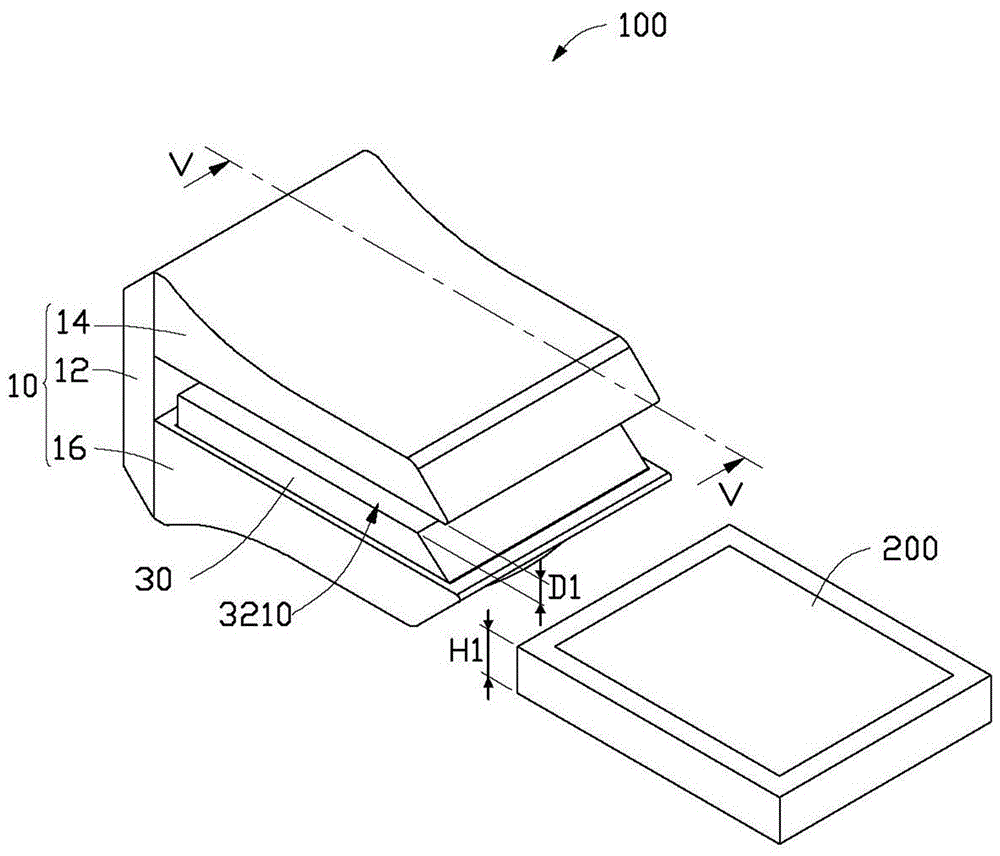

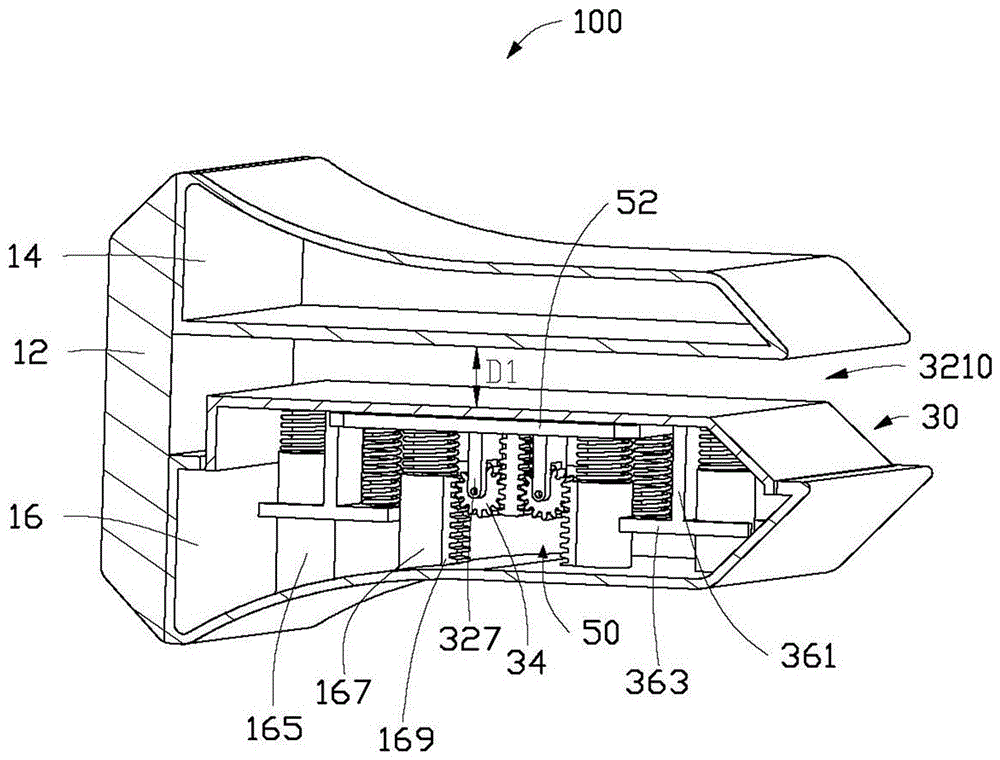

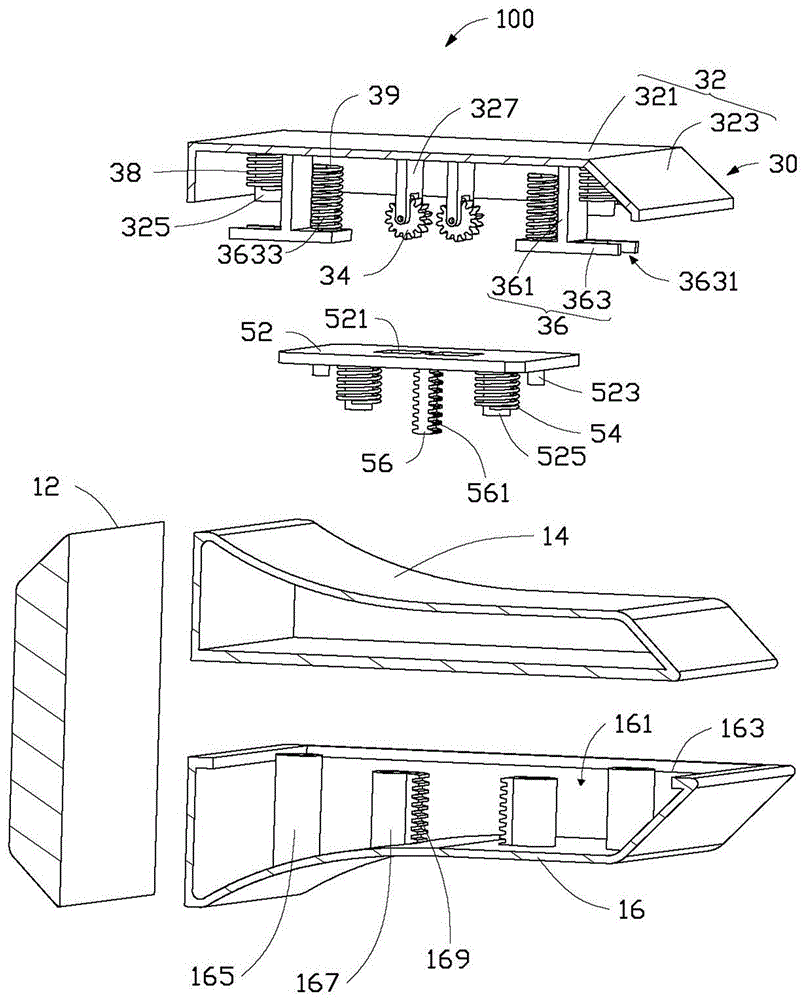

Media depository

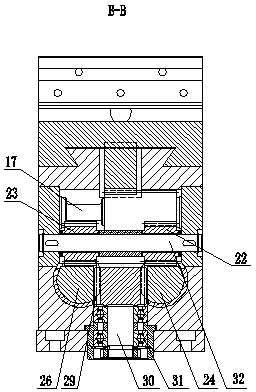

ActiveUS20120007304A1Increase pressureConstant clamping forceCoin/currency accepting devicesPile receiversEngineeringActuator

A bunch sheet depository is described. The depository comprises: a pressure plate for pressing on a bunch of sheets; a picker aligned with the pressure plate and arranged to remove sheets individually from the bunch of sheets; a link arm including (i) a pivot, (ii) an urging portion coupled to the pressure plate and (iii) a resilient member; and an actuator coupled to the resilient member. The actuator is operable, when actuated, to move the resilient member to rotate the link arm about the pivot and thereby cause compression of the bunch of sheets by the pressure plate using a force from the resilient member that reduces as the resilient member relaxes in response to the pressure plate moving as sheets are removed from the bunch of sheets.

Owner:NCR CORP

Media depository

ActiveUS8262076B2Constant clamping forceGuaranteed uptimeCoin/currency accepting devicesPile receiversActuatorPaper sheet

A bunch sheet depository is described. The depository comprises: a pressure plate for pressing on a bunch of sheets; a picker aligned with the pressure plate and arranged to remove sheets individually from the bunch of sheets; a link arm including (i) a pivot, (ii) an urging portion coupled to the pressure plate and (iii) a resilient member; and an actuator coupled to the resilient member. The actuator is operable, when actuated, to move the resilient member to rotate the link arm about the pivot and thereby cause compression of the bunch of sheets by the pressure plate using a force from the resilient member that reduces as the resilient member relaxes in response to the pressure plate moving as sheets are removed from the bunch of sheets.

Owner:NCR CORP

General laser welding machine for plate workpieces

InactiveCN105414760AConstant clamping forceImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Owner:SUZHOU RECEN PRECISION MACHINERY CO LTD

Hydraulic spotting mould clamping type liquid forging squeeze casting machine

The invention discloses a hydraulic spotting mould clamping type liquid forging squeeze casting machine. According to the hydraulic spotting mould clamping type liquid forging squeeze casting machine, a front seat, a movable template and a rear seat are installed on a machine frame in sequence in the horizontal direction, a fixed mould is installed on the front seat, a movable mould is installed on the movable template, a spotting stand column plug oil cylinder is installed on the rear seat, a spotting stand column plug is directly or indirectly connected with the movable template and then pushes the movable mould and the fixed mould to be spotting pressed, a vacuum system capable of vacuumizing a forging cavity body is installed on the upper end face of the movable mould or on the upper end face of the fixed mould, a feeding system is installed beside the machine frame, liquid metal can be injected into the forging cavity body through the injection end of the feeding system, and the working states of the spotting stand column plug oil cylinder, the vacuum system and the feeding system are all controlled by a control panel beside the machine frame automatically. According to the hydraulic spotting mould clamping type liquid forging squeeze casting machine, hydraulic mould clamping is achieved by means of the spotting stand column plug oil cylinder, and mould clamping force is constant and can be compensated and increased instantly by the spotting stand column plug oil cylinder during the freezing period; air in the forging cavity body is pumped out through the vacuum system, and therefore air entrapment of a workpiece in a mold filling process is reduced, and product quality and the rate of finished products are improved.

Owner:GUANGZHOU ALUMINUM MATERIAL PLANT

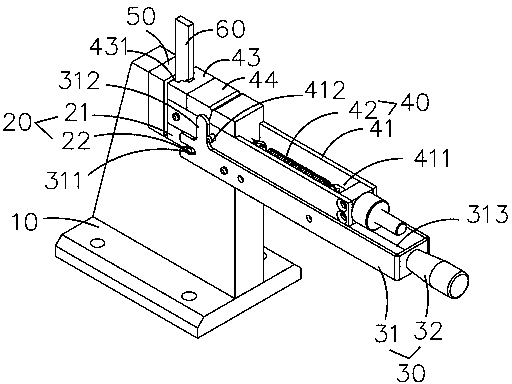

Pneumatic type raised head clamping device

InactiveCN103111870AFast clamping actionConstant clamping forcePositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:CHONGQING MING SHIELD ELECTROMAGNETIC VALVE

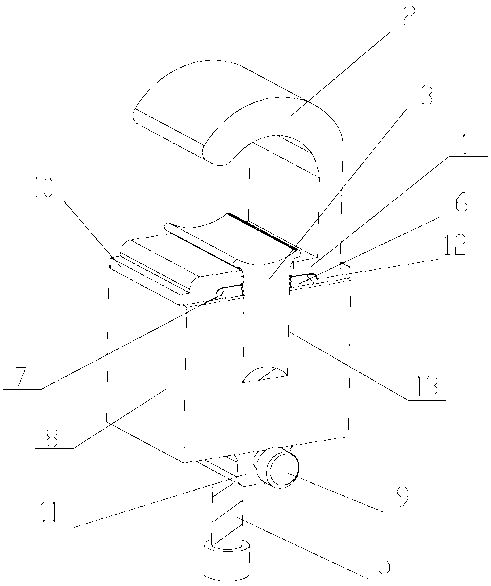

Multifunctional one-way cable clamp

ActiveCN103001016AImprove general performanceSimple structureElectric connection structural associationsClamped/spring connectionsBiochemical engineeringContact resistance

The invention discloses a multifunctional one-way cable clamp. The clamp comprises a clamp body and is characterized in that a groove is arranged in the clamp body, a first movable chuck and a second movable chuck are embedded into the groove from top to bottom and can move up and down, clamping structures are arranged at two ends of the first movable chuck and at the upper end of the second movable chuck, a fixed chuck opposite to the first movable chuck is fixedly connected to the upper side of the clamp body, a bolt hole is arranged on the lower side of the clamp body, and an adjusting bolt penetrates through the bolt hole, is fixedly connected with the clamp body and abuts against the second movable chuck. The clamp is high in generality, capable of being suitable for various diameters of cables, simple in structure, reasonable in design, balanced in pressure, constant in clamping force, small in contact resistance, stable and reliable in connection and convenient and safe in use.

Owner:GUANGZHOU PANYU CABLE WORKS

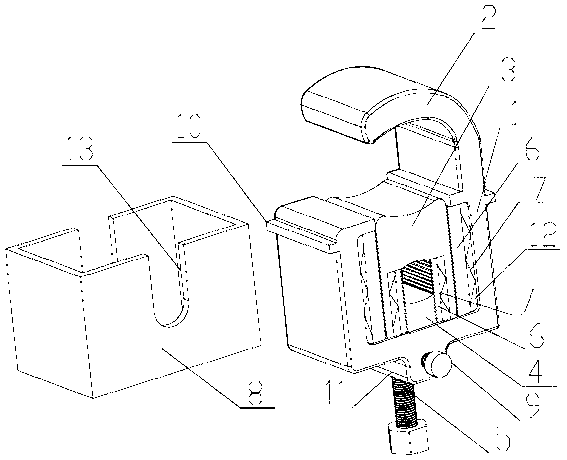

Combination clamp for flat connection terminals and cables

ActiveCN103022747AImprove general performanceSimple structureElectric connection structural associationsClamped/spring connectionsMechanical engineeringContact resistance

The invention discloses a combination clamp for flat connection terminals and cables. The combination clamp comprises a wire clamp body, and is characterized in that a first groove and a second groove are arranged in the wire clamp body, a first movable clamping head and a second movable clamping head which can move up and down are respectively embedded in the first groove and the second groove, a first fixed clamping head and a second fixed clamping head which are respectively opposite to the first movable clamping head and the second movable clamping head are fixedly connected to the upper side of the wire clamp body, two bolt holes are arranged on the lower side of the wire clamp body, and two adjusting bolts are respectively abutted to the first movable clamping head and the second movable clamping head while penetrating through the two bolt holes to be fixedly connected with the wire clamp body. The combination clamp for the flat connection terminals and the cables is high in universality, is applicable to the cables with various wire diameters, is simple in structure, reasonable in design and firm and reliable in connection, and can be used conveniently and safely, the pressure is balanced, clamping force is constant, and contact resistance is low.

Owner:GUANGZHOU PANYU CABLE WORKS

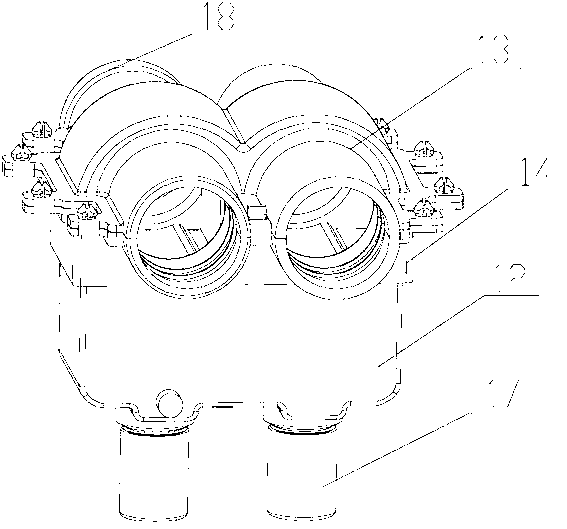

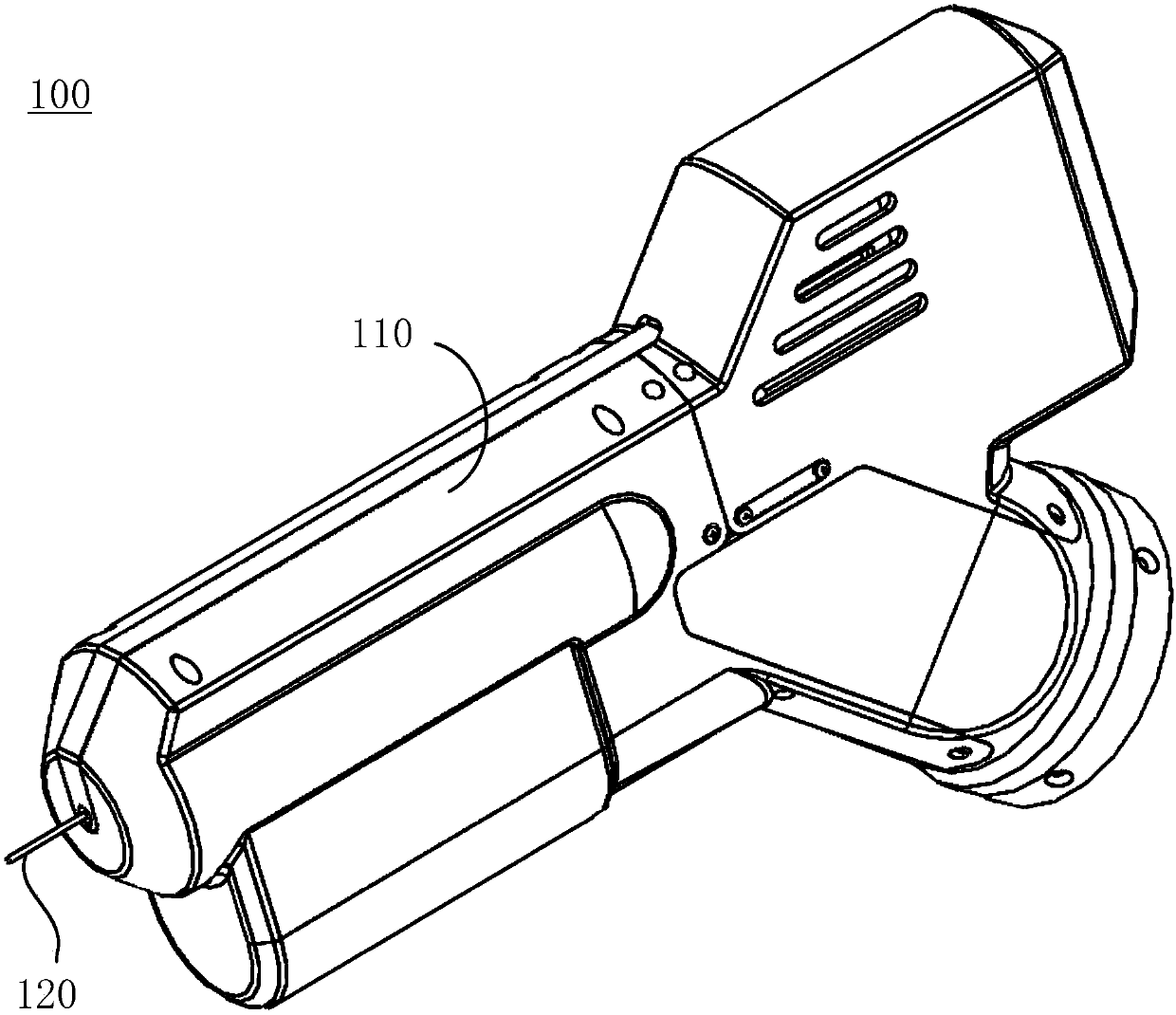

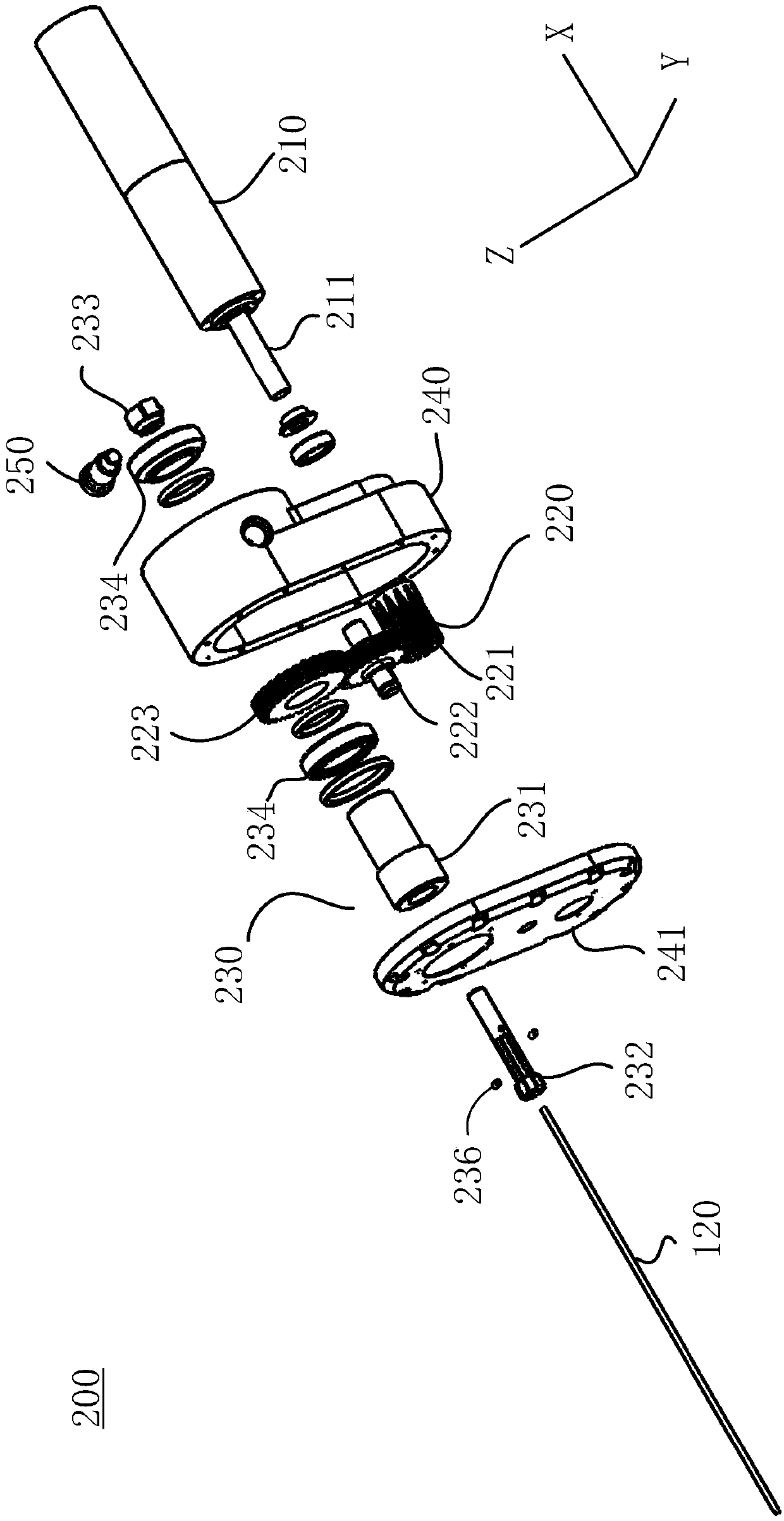

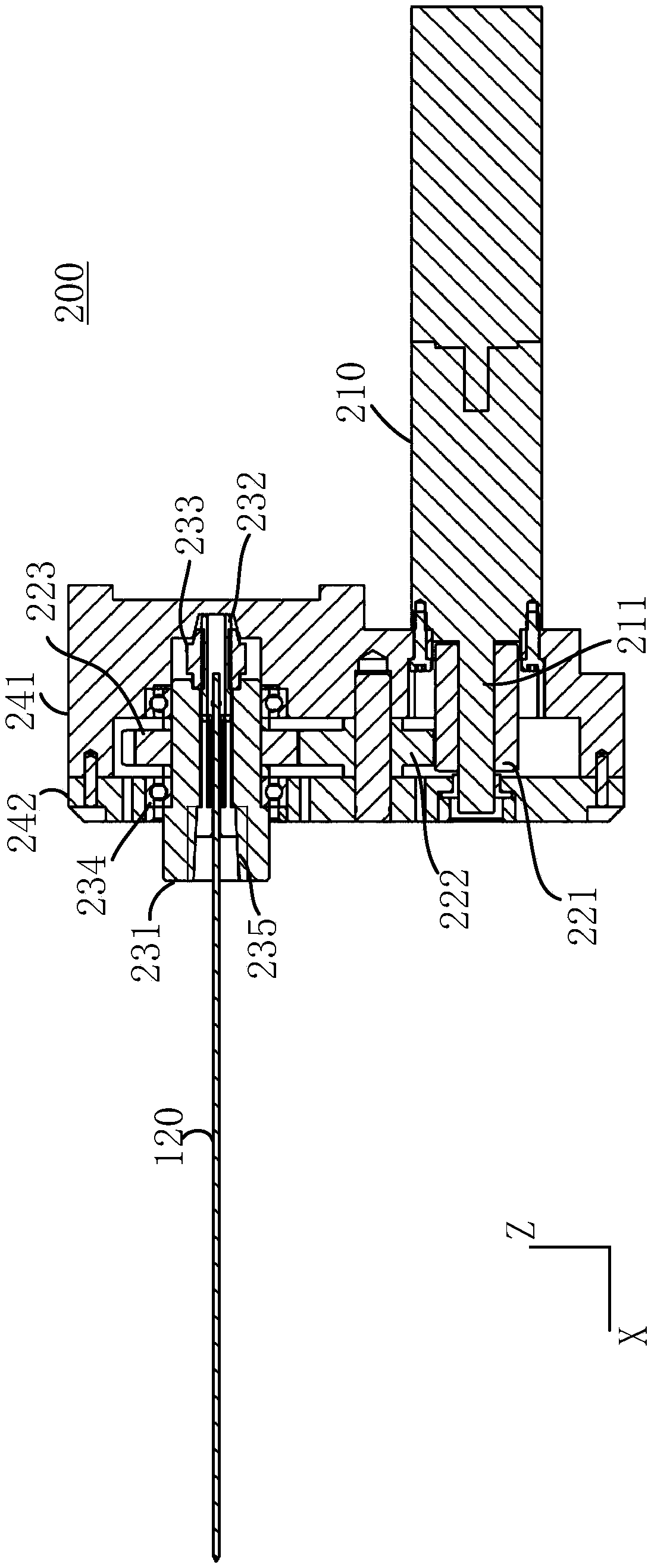

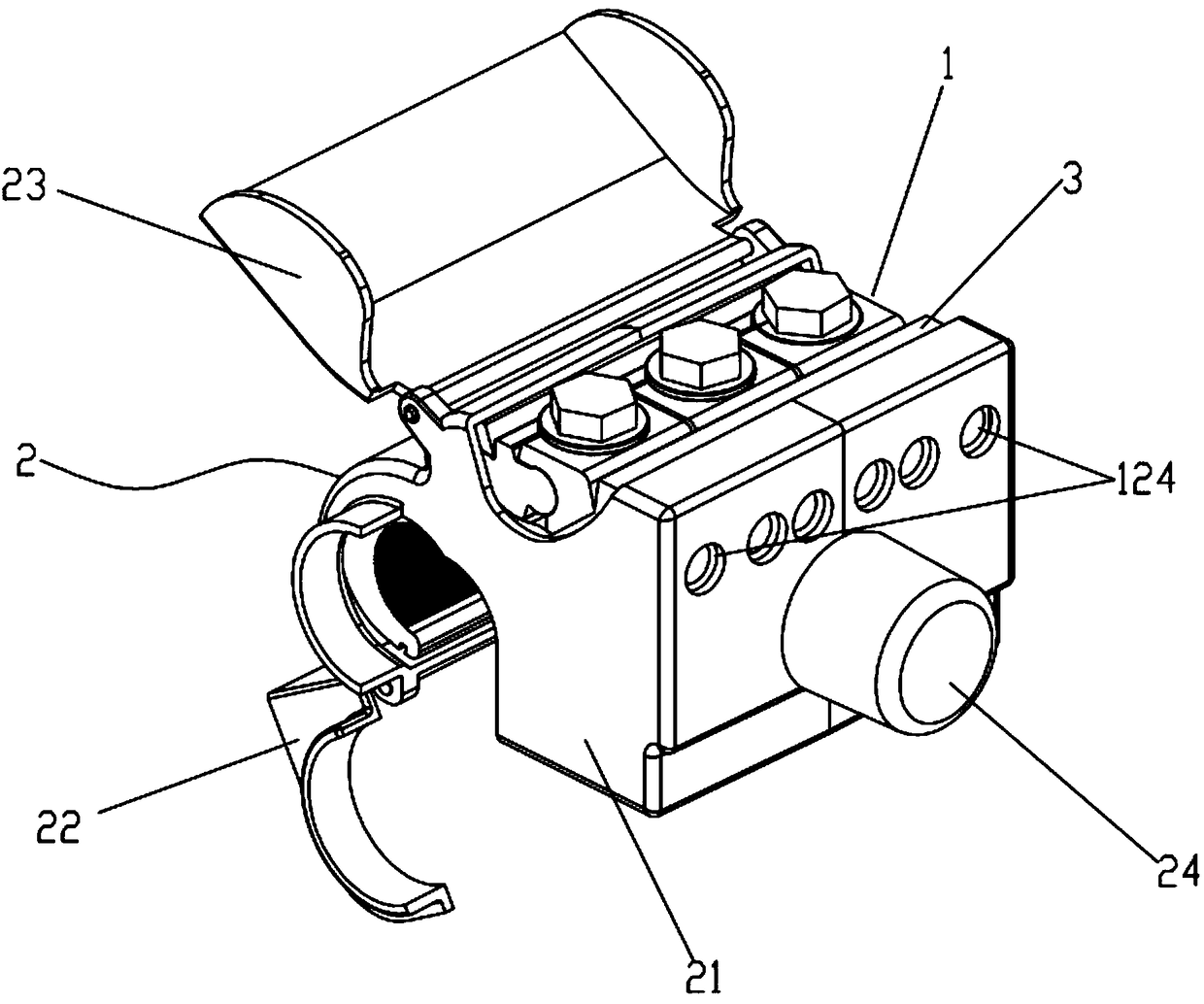

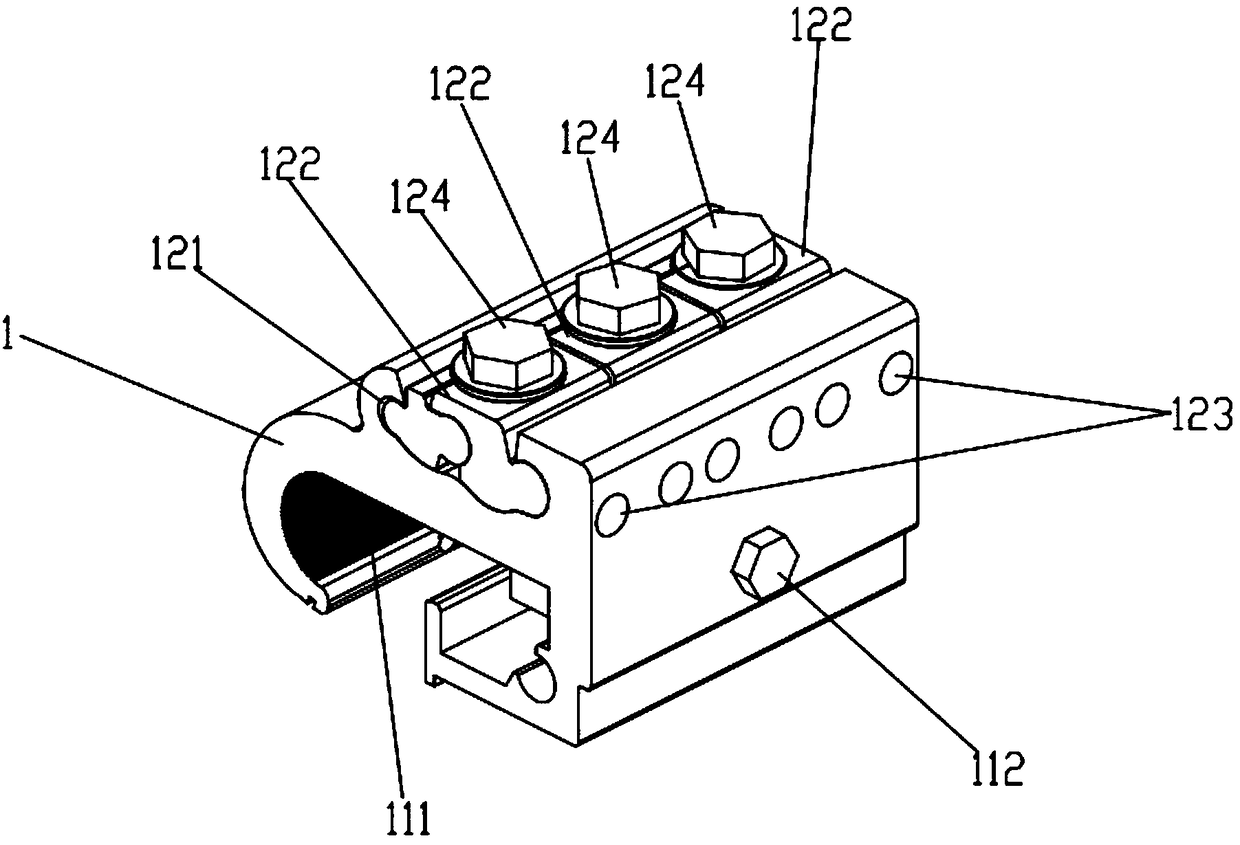

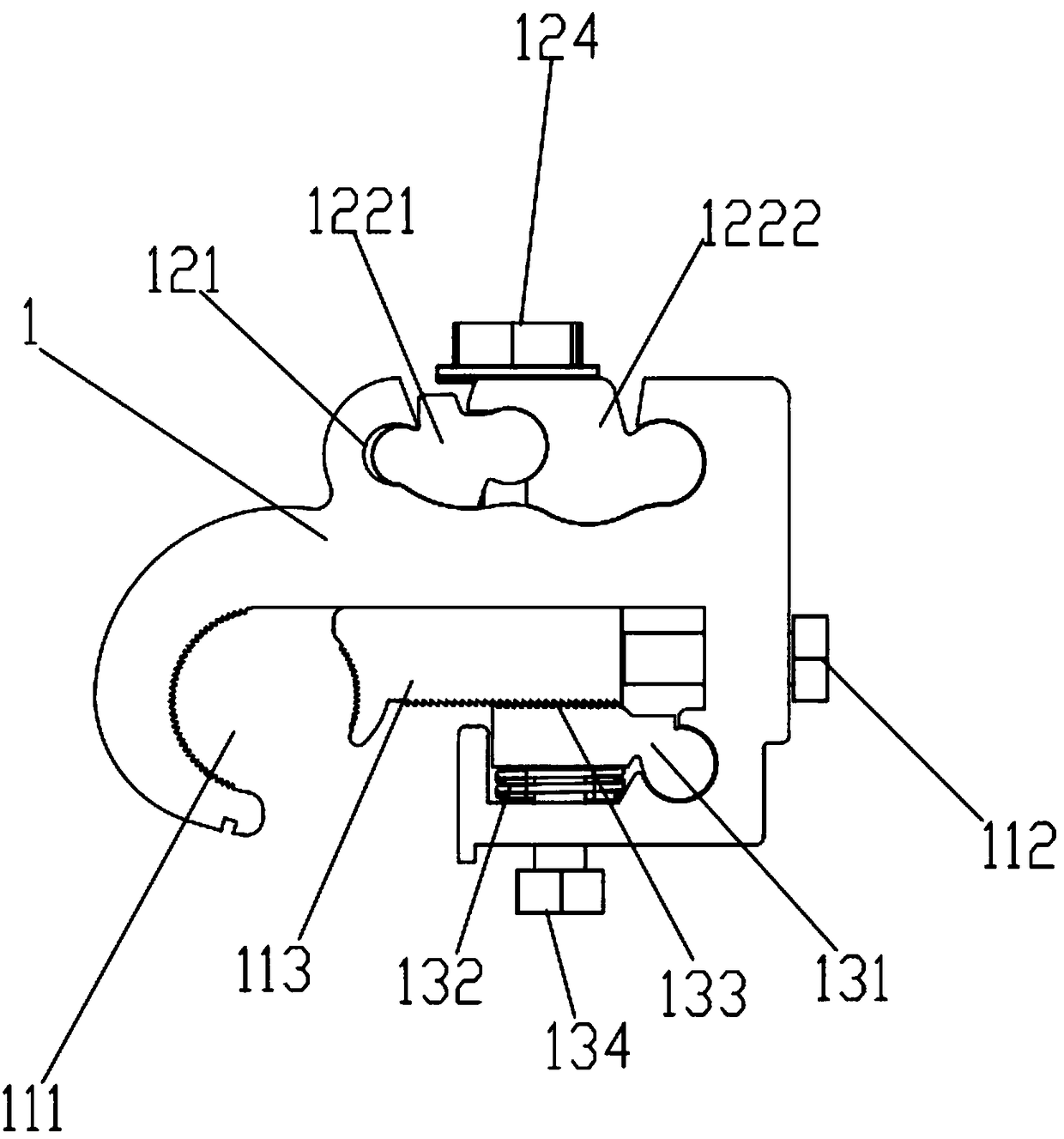

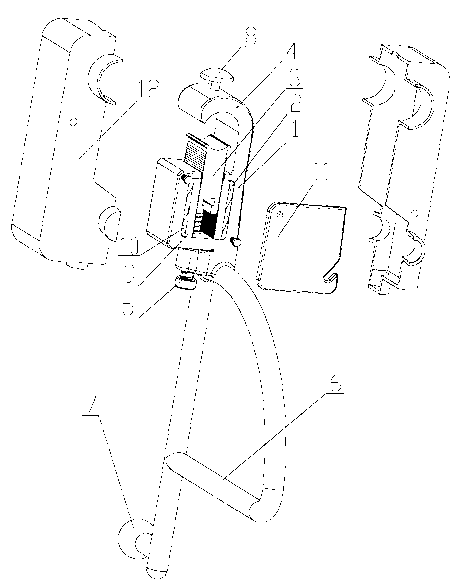

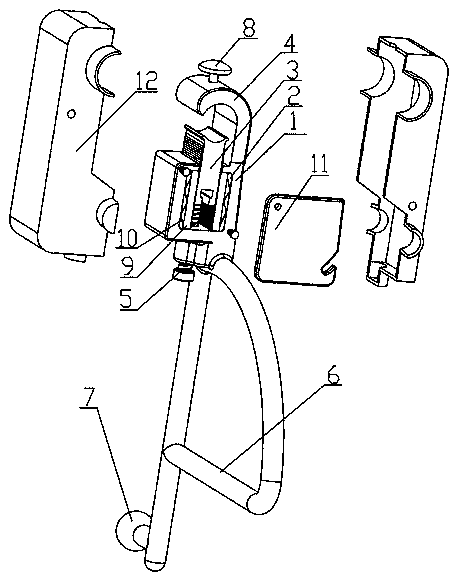

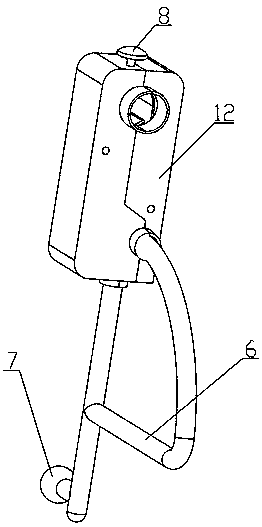

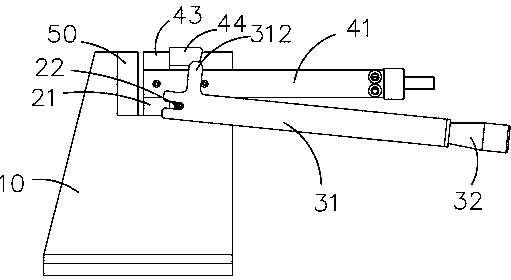

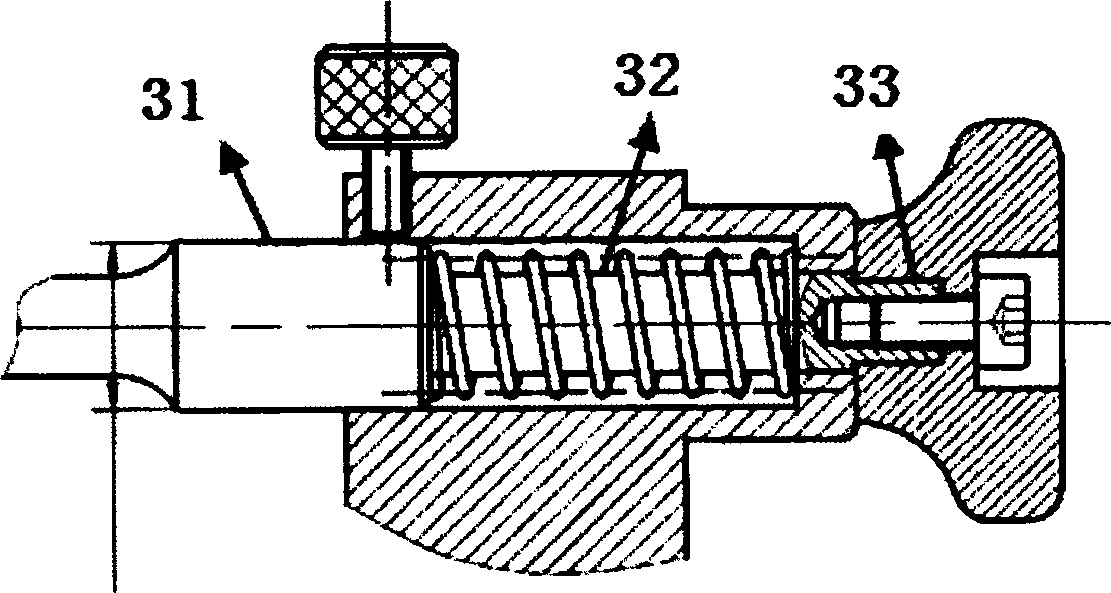

Kirschner wire clamping device and drilling device

The present invention discloses a Kirschner wire clamping device. The Kirschner wire clamping device comprises an outer shell, and a motor, a gear set and a clamping head mechanism arranged in the outer shell, the gear set is connected with a driving shaft of the motor, and the clamping head mechanism comprises a first sleeve, a second sleeve and a nut; the first sleeve is connected with the gearset and also provided with a front end and a rear end; the second sleeve is sleeved in the first sleeve and matched with a conical surface of the first sleeve, besides, the second sleeve is provided with a first end and a second end, Kirschner wire penetrates through the second sleeve and extends through the first end of the second sleeve and out of the front end of the first sleeve, and the second end of the second sleeve extends out of the rear end of the first sleeve; and the nut is arranged at the rear end of the first sleeve and detachable from the first sleeve, and besides, the second end of the second sleeve is screwed into the nut. A Kirschner wire drilling device is provided with the Kirschner wire clamping device and a pushing device, and the pushing device is connected with theKirschner wire clamping device to apply pushing force to the Kirschner wire clamping device.

Owner:北京精准大艾机器人科技有限公司

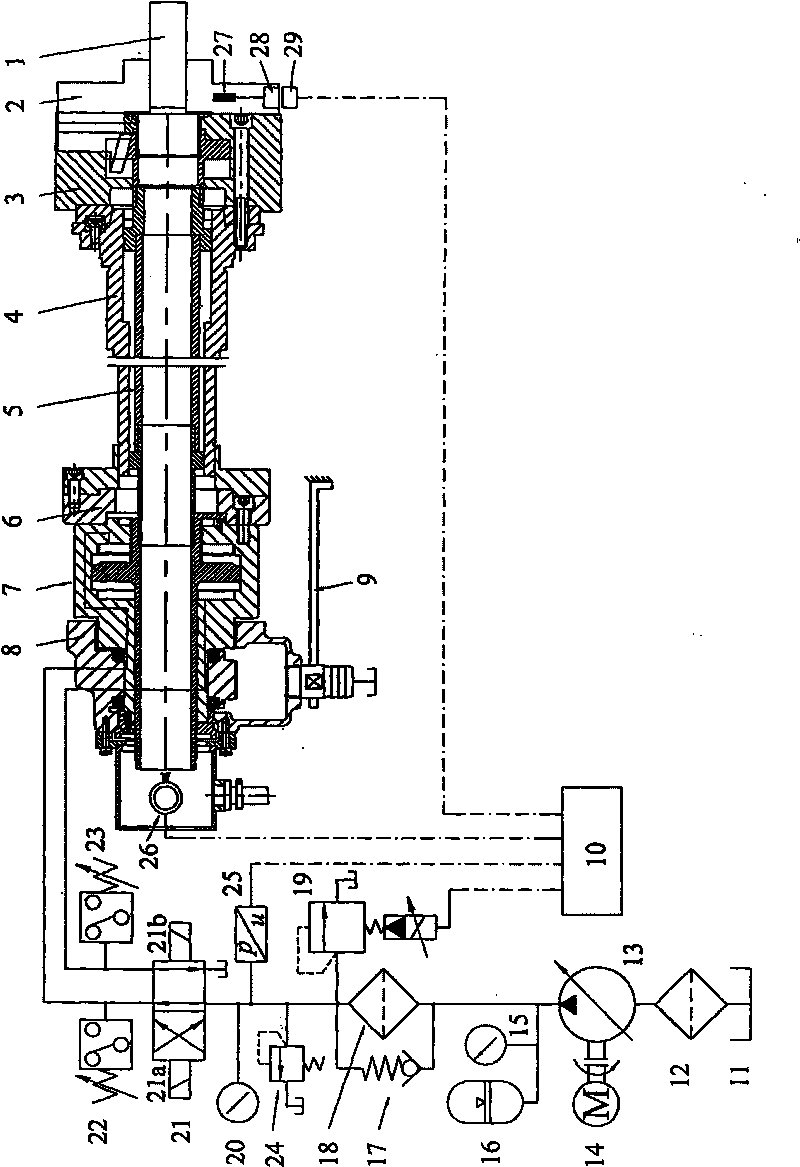

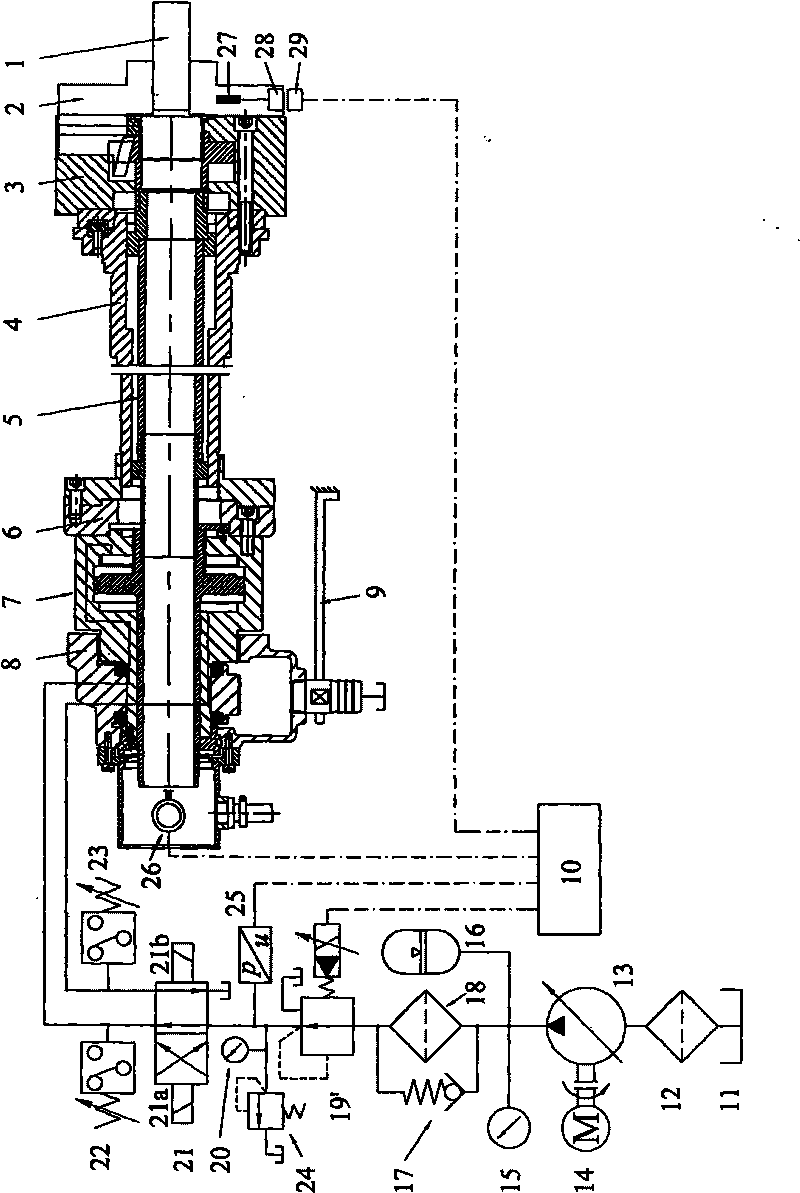

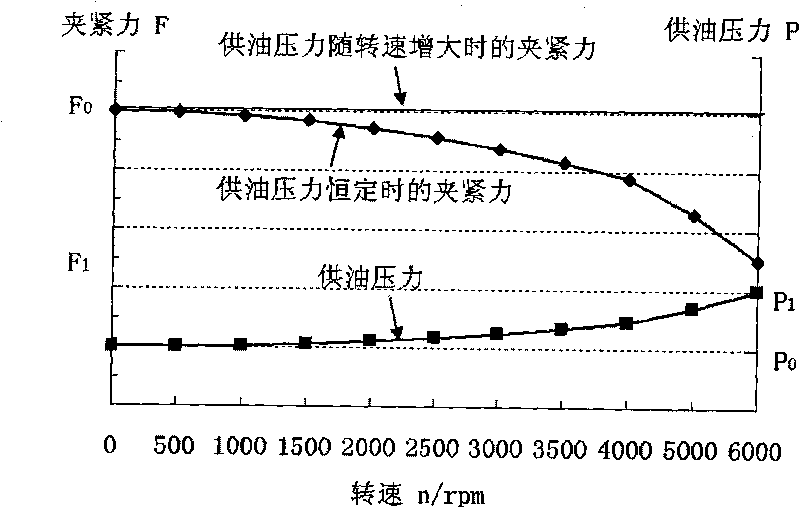

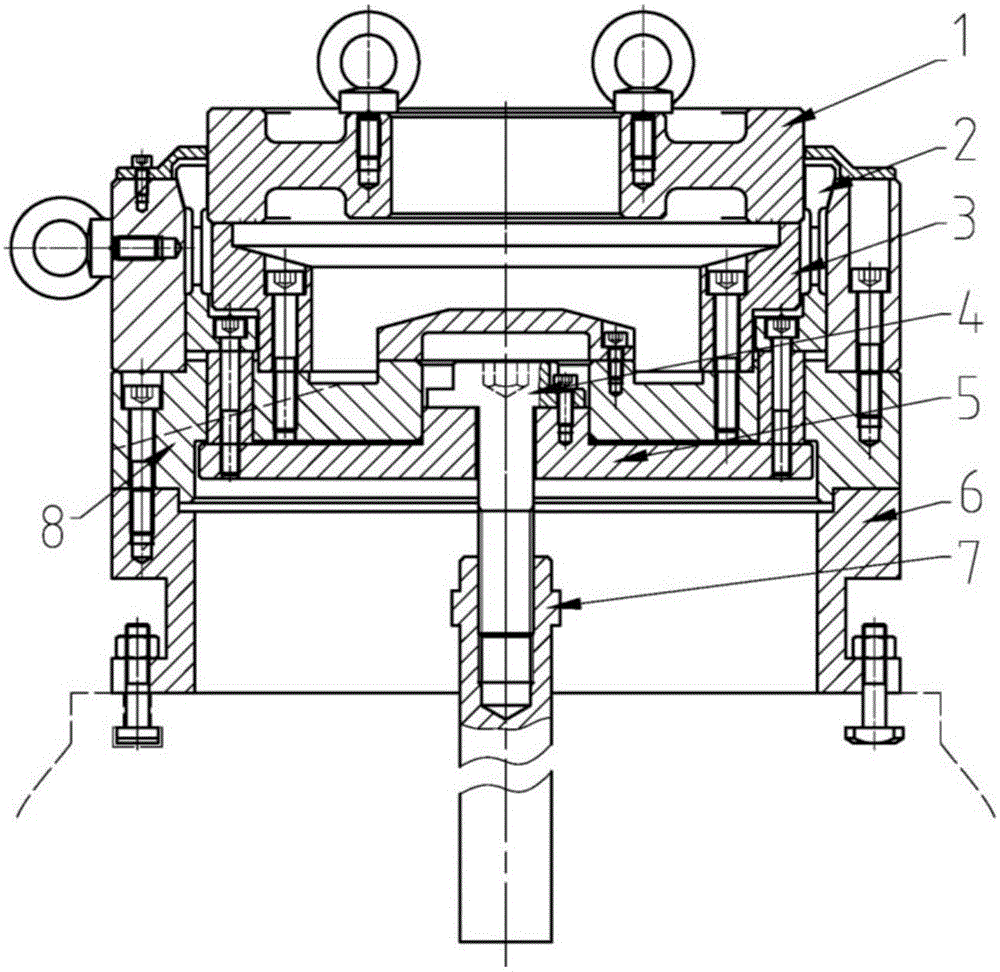

Hydraulic power chuck controlled by electro-hydraulic proportional pressure valve

The invention discloses a hydraulic power chuck controlled by an electro-hydraulic proportional pressure valve, comprising a hydraulic power chuck, a hydraulic pump station and a signal collection and control system, wherein the hydraulic pump station consists of an oil supply device, an oil pressure adjusting device, an oil supply direction control device and an oil supply pressure monitoring device. The oil pressure adjusting device is realized by adopting an electro-hydraulic proportional overflow valve or an electro-hydraulic proportional reducing valve; the signal collection and control system comprises a controller and a rotate speed transducer arranged at the end part of a lathe main shaft; and a control electrical signal end of the rotating speed transducer and a control electrical signal end of the electro-hydraulic proportional overflow valve or the electro-hydraulic proportional reducing valve are respectively and electrically connected with a controller. When the lathe main shaft changes speed, the output oil pressure of the hydraulic pump station and the oil supply pressure of a rotation hydraulic cylinder can be regulated in a stepless mode so as to keep the clamping force of the hydraulic power chuck constant. When the hydraulic power chuck is used for clamping finish machining workpieces or easily deformed workpieces, both reliable clamping and high rotate speed can be realized, and requirement of high-speed cutting can be satisfied.

Owner:ZHEJIANG UNIV

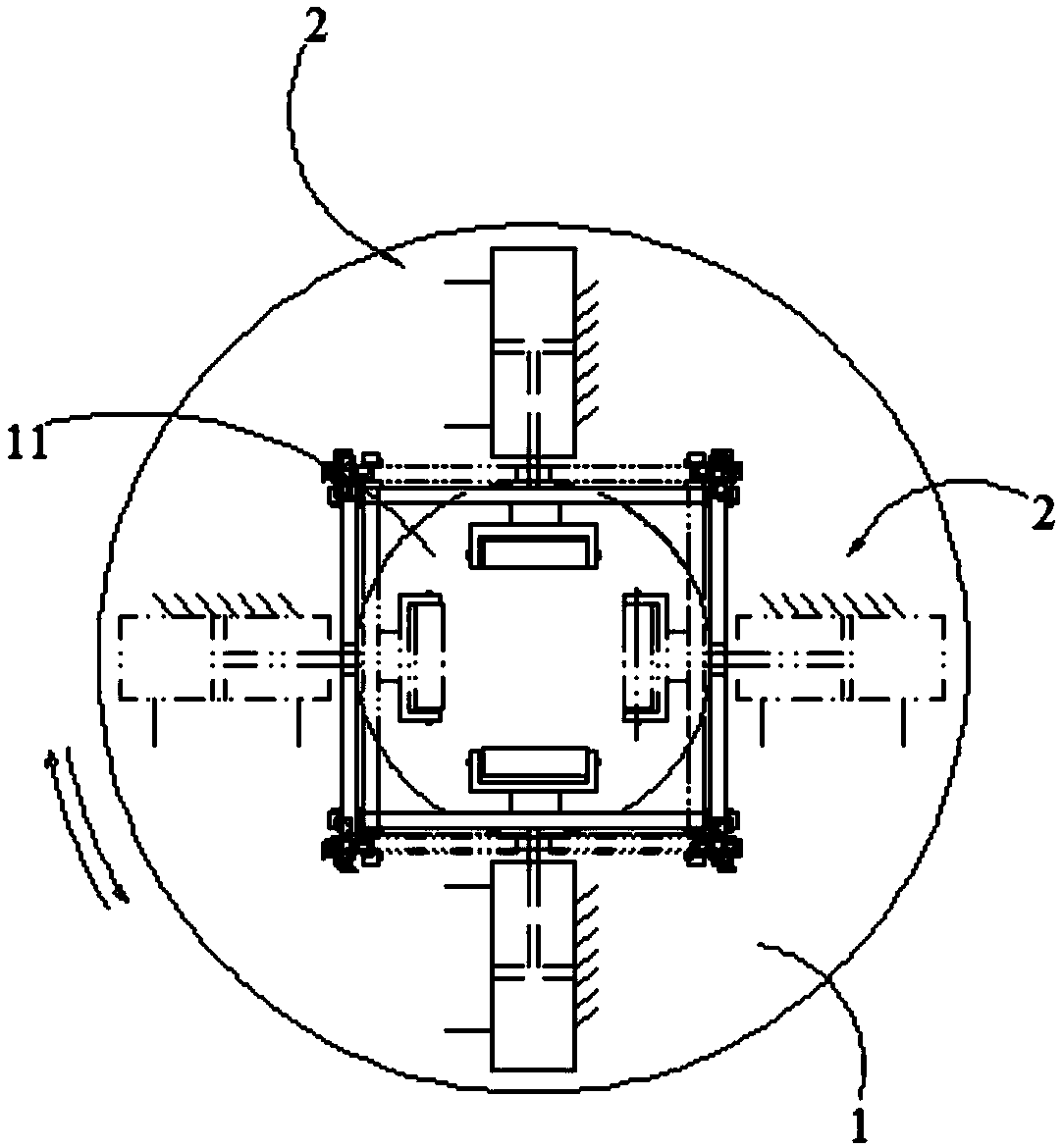

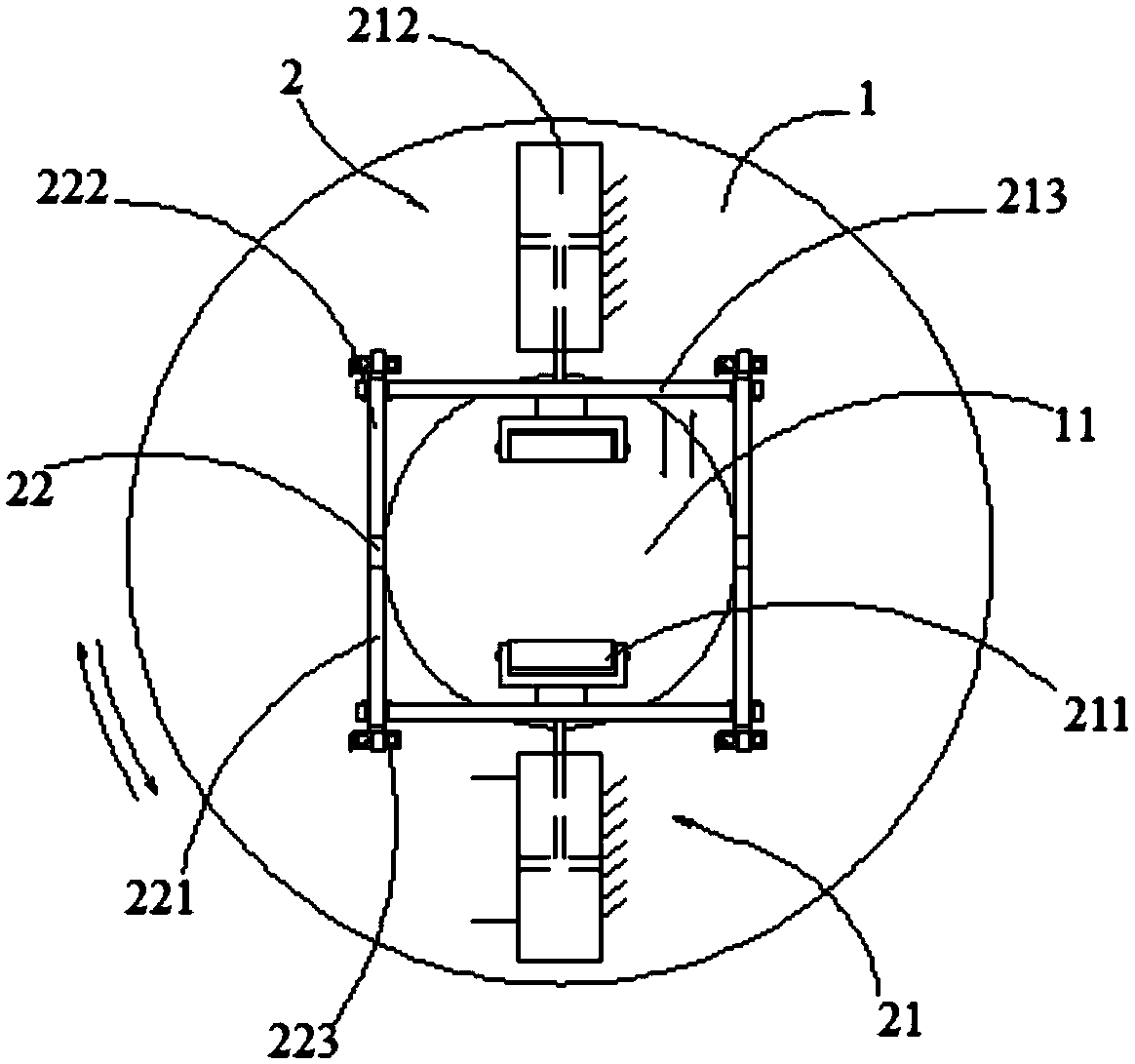

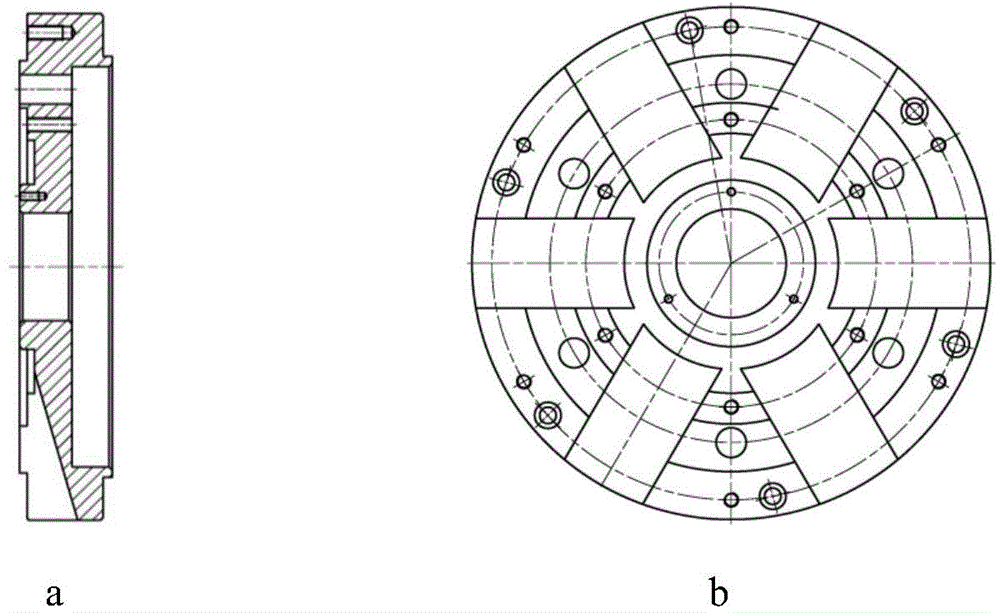

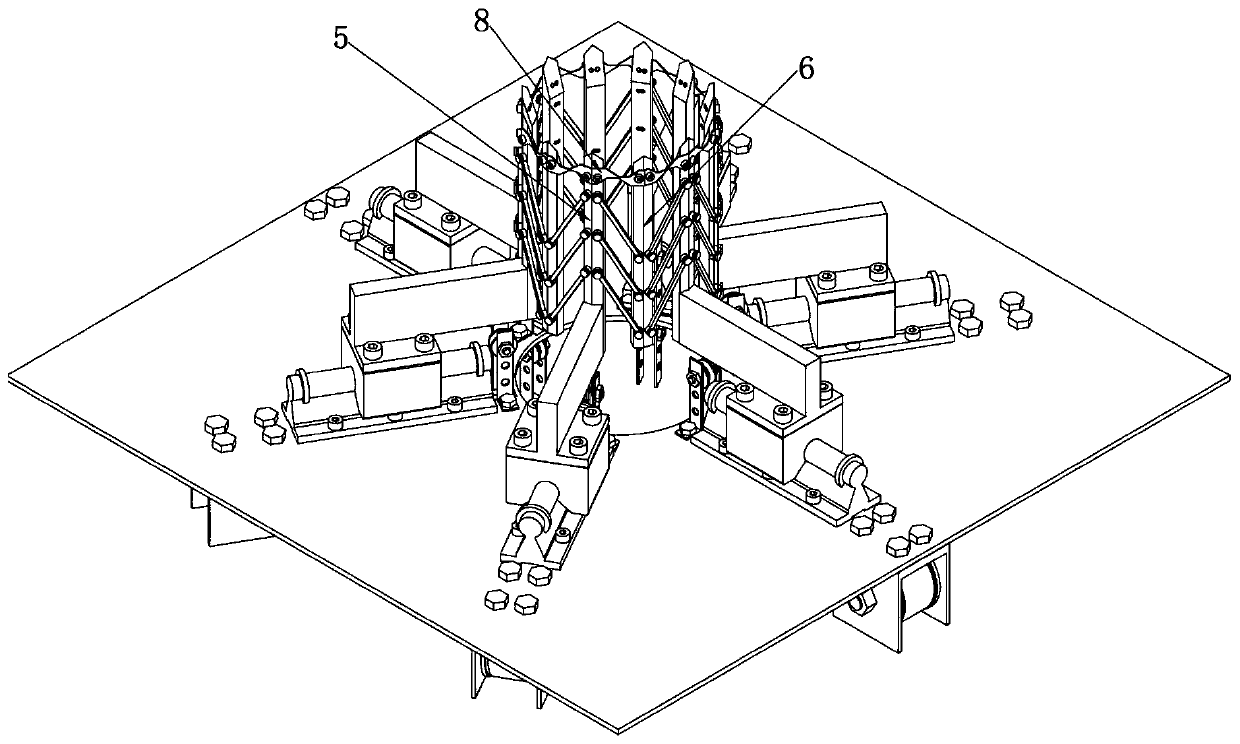

Four-claw automatic centering chuck and machine tool

PendingCN108526501AConstant clamping forceLarge clamping rangeChucksLaser beam welding apparatusEngineeringMachine tool

The invention relates to machine tool clamping, and provides a four-claw automatic centering chuck. The four-claw automatic centering chuck comprises a rotary base. The rotary base is provided with amounting hole. The four-claw automatic centering chuck further comprises two sets of two-claw clamping mechanisms. Each two-claw clamping mechanism comprises two sets of clamp claw assemblies and a screw. The screws of the two sets of two-claw clamping mechanisms cross with each other. Each clamp claw assembly comprises a rotary clamping claw and a drive part, and the rotary clamping claws are distributed on the mounting hole. The two rotary clamping claws of each two-claw clamping mechanism are arranged oppositely, and the moving paths of the two rotary clamping claws of each two-claw clamping mechanism are located on the same straight line. In each two-claw clamping mechanism, one rotary clamping claw is in right-hand thread connection with the screw, and the other rotary clamping claw is in left-hand thread connection with the screw. The invention further provides a machine tool which comprises the above chuck. The rotary clamping claws of the chuck are synchronously closed or opened under the action of the drive parts, clamping force is constant and can be adjusted according to the actual condition, and when clamped, a workpiece can move and penetrate from the middle of the rotary base; and the clamping range is wide, the speed is high, and the locating precision is high.

Owner:WUHAN GUANYOU TECH CO LTD

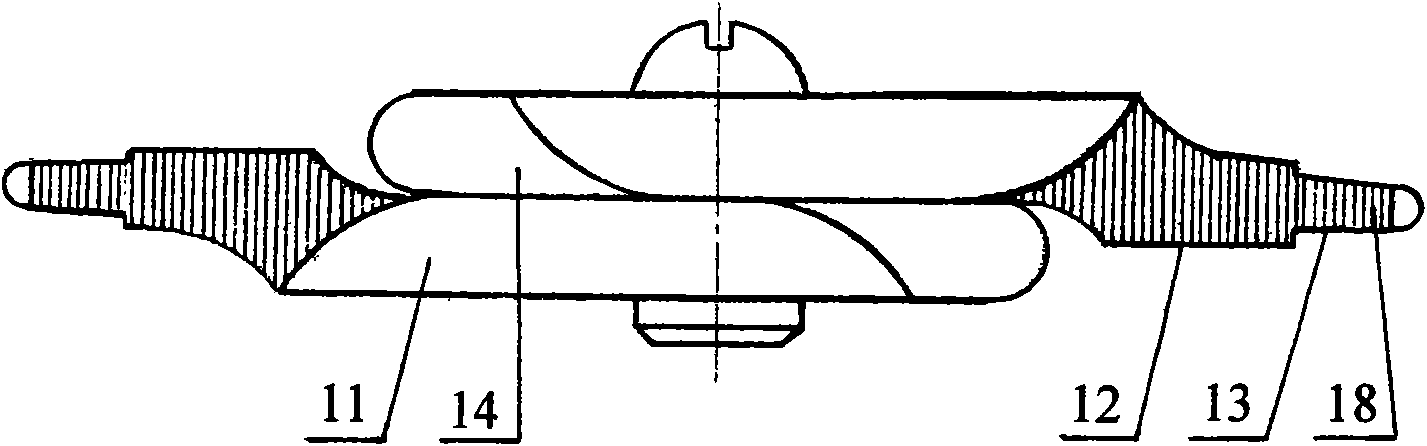

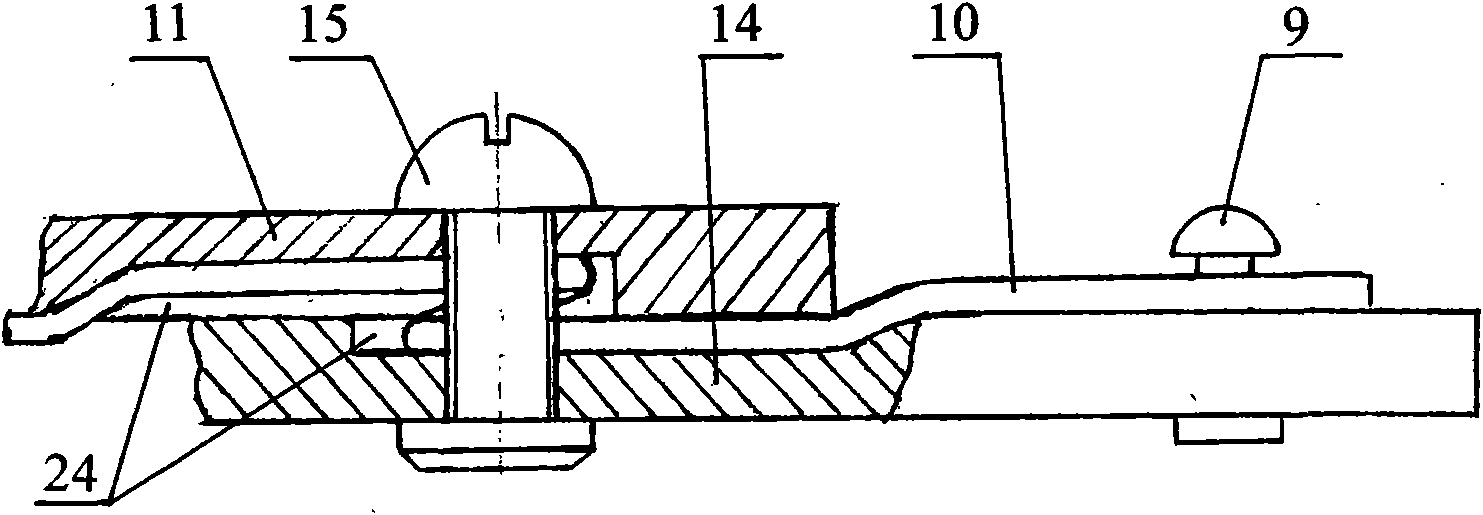

Multi-core belt-shaped optical fiber fixture with self-locking and anti-skidding function

The invention discloses a multi-core belt-shaped optical fiber fixture with a self-locking and anti-skidding function. The multi-core belt-shaped optical fiber fixture with the self-locking and anti-skidding function comprises a belt-shaped optical fiber limiting device, a clamping device, a transmission device, a self-locking round eccentric wheel and the like, and belongs to the technical field of belt-shaped optical fibers. A push plate of the transmission device can rotate around a central push plate pin to ensure that clamped portions of the belt-shaped optical fibers are evenly stressed, and damage of an outer coating layer is avoided; by adjusting rotating angles of the self-locking round eccentric wheel, different clamping force of the fixture to the optical fibers can be achieved, the belt-shaped optical fibers can be fixed under the conditions that the belt-shaped optical fibers are overall stressed or each belt-shaped optical fiber is dispersedly stressed, the self-locking function is placed, after being clamped, the belt-shaped optical fibers are constantly stressed, by adjusting a width maintaining plate of the belt-shaped optical fiber limiting device, the belt-shaped optical fibers with different numbers of cores can be limited, and the fixture is good in generality. The whole device is simple and reliable in structure, convenient to operate, capable of effectively and stably clamping the belt-shaped optical fibers composed of each single fiber capable of bearing drawing force of lower than five Newton, and applicable for aspects like mass production of belt-shaped optical fiber array optical gratings.

Owner:YANSHAN UNIV

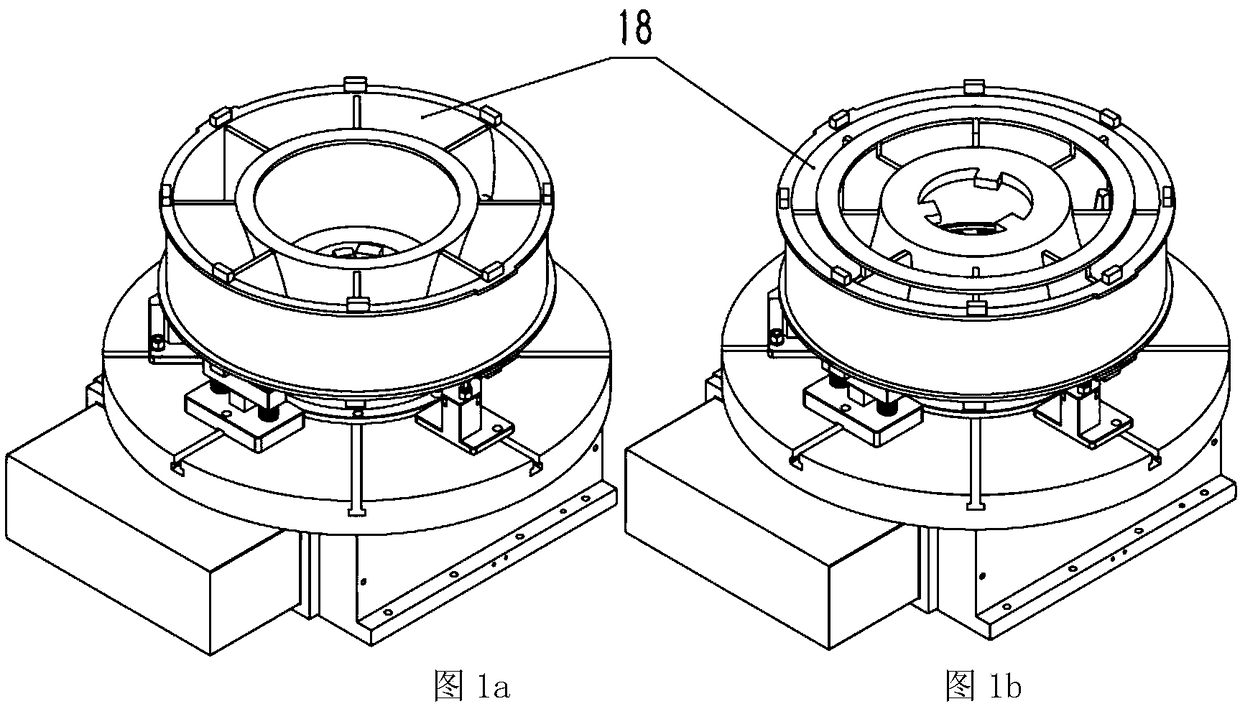

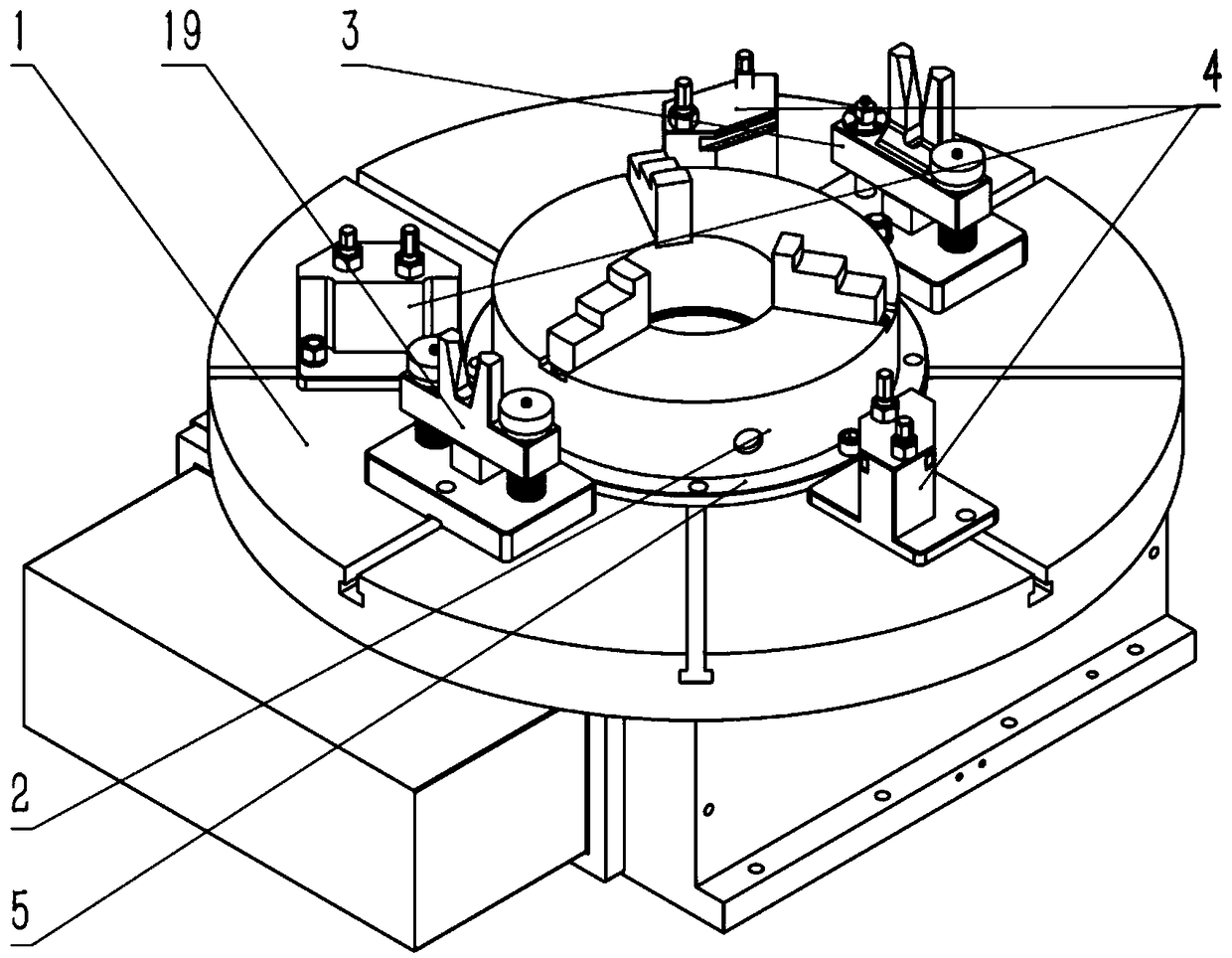

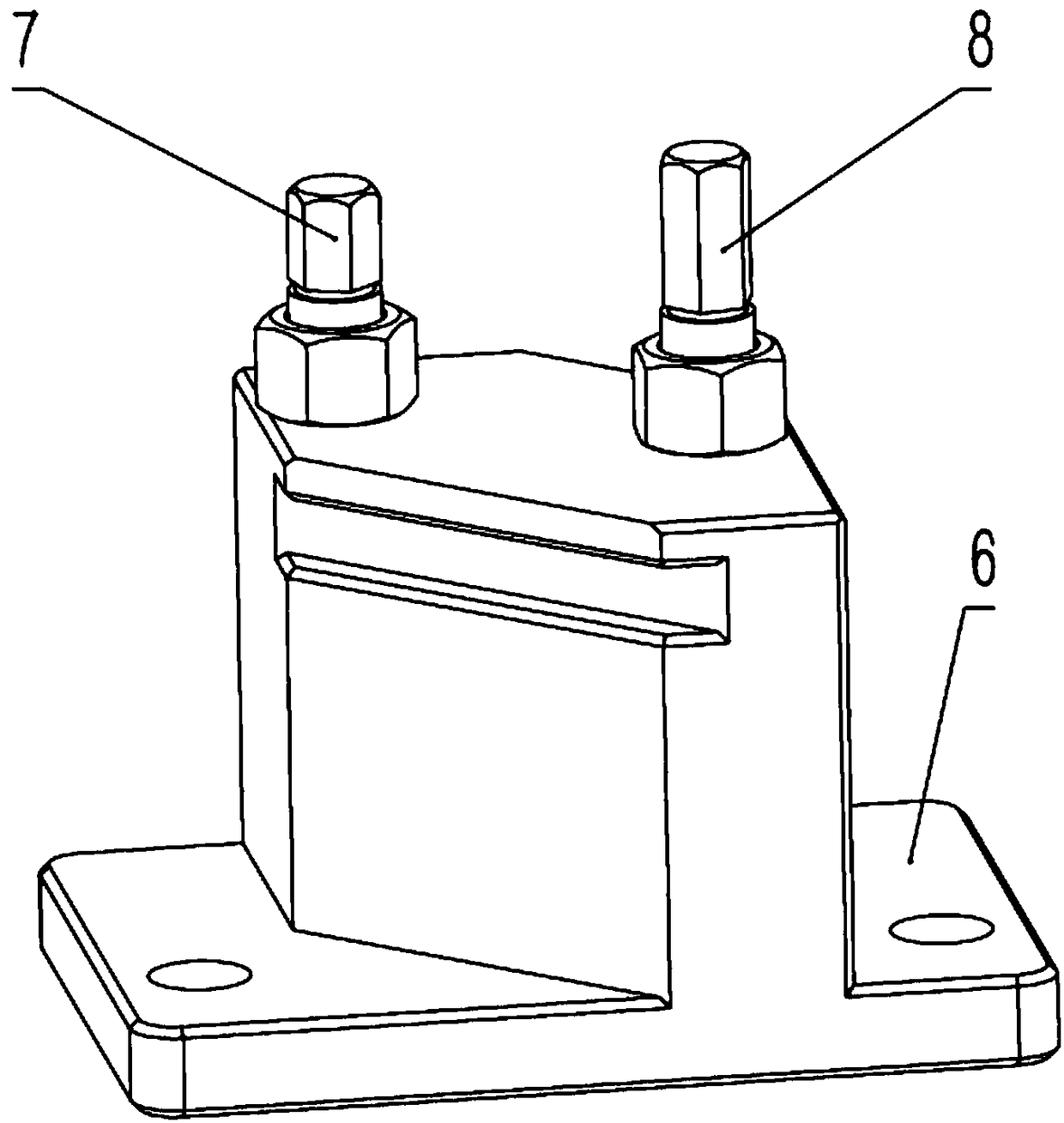

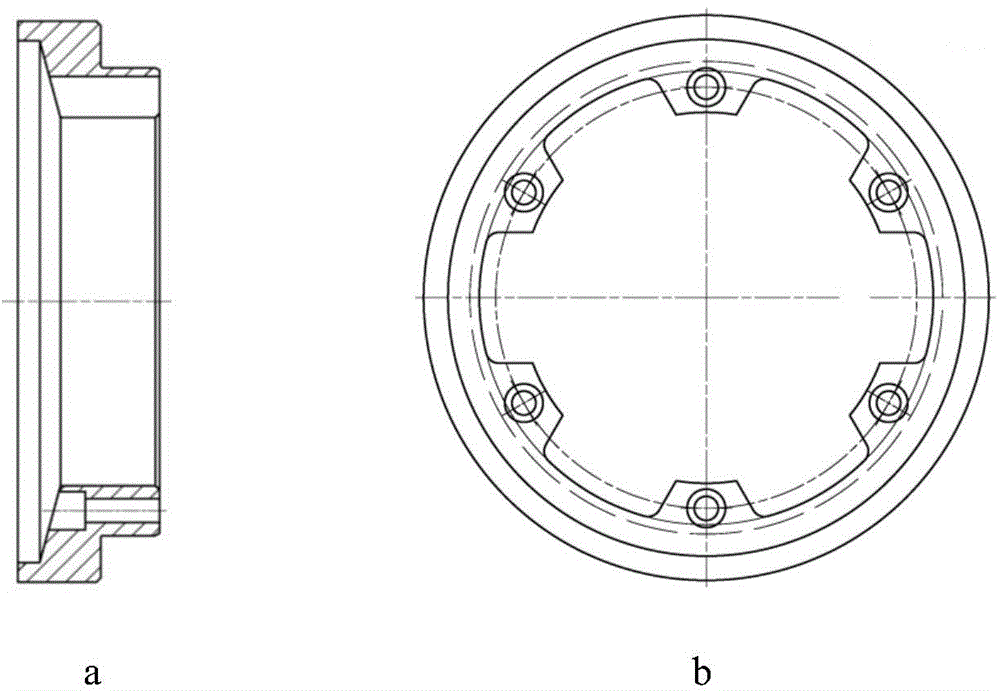

Positioning clamp used for titanium alloy ring-shaped casting and clamping method

ActiveCN109129186AAchieve circumferential positioningAchieving a centering effectGrinding work supportsRotational degrees of freedomTitanium alloy

The invention provides a positioning clamp used for a titanium alloy ring-shaped casting and a clamping method. The positioning clamp mainly comprises a rotating worktable, two floating V-shaped blockassemblies, three pin assemblies and one three-claw chuck. The titanium alloy ring-shaped casting is positioned through a clamp and is clamped to the surface of the rotating worktable. Three positioning pins are matched with the end face of the titanium alloy ring-shaped casting so as to limit the linear freedom degree of the titanium alloy ring-shaped casting in the height direction and two rotation freedom degrees. V-shaped blocks are matched with an elliptical structure on the titanium alloy ring-shaped casting to limit the circumferential rotation freedom degree of the titanium alloy ring-shaped casting. The three-claw chuck is matched with a circular inner hole of the titanium alloy ring-shaped casting to limit the linear freedom degree of the titanium alloy ring-shaped casting on the plane, and clamping is achieved. By means of the clamp, complete positioning of the titanium alloy ring-shaped casting is achieved, the clamp is suitable for front-face and back-face clamping of thetitanium alloy ring-shaped casting, and a servo motor arranged in a rotating worktable can be controlled to make the rotating worktable drive the clamp and the titanium alloy ring-shaped casting to rotate to the designated angle after clamping is completed.

Owner:WUHAN UNIV OF TECH

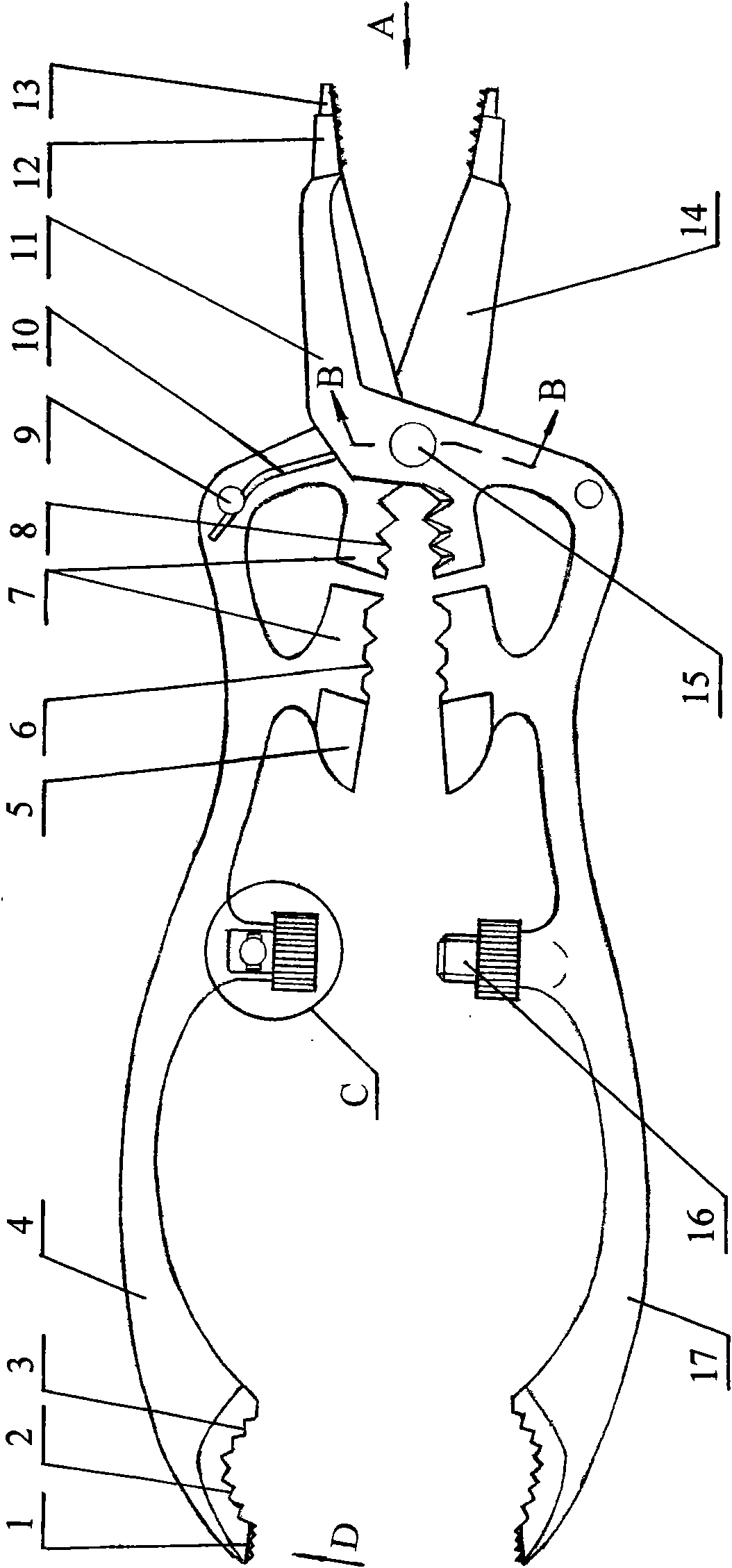

Cutting nippers having nine functions

InactiveCN101870113AReduce operating forcePrevent slippingPliersMetal working apparatusPipe wrenchWire cutter

The invention relates to a pair of cutting nippers having nine functions. An upper scissors body and a lower scissors body are hinged through hinging bolts, wherein the extending ends of the upper and lower scissors are a snap spring nipper and a nipper pliers; a torsion spring which is embedded in the groove of the upper and lower scissors is sleeved on the hinging bolt; two ends of the torsion spring extend outwards and are resisted on a baffle pin of the torsion spring so as to actuate the heads of the upper and lower scissors to open; interiors of the upper part of left and right handles extend into a support stem; a wire stripper, a wire presser and a diagonal pliers are arranged on the support stem; the tail end of the support stem is provided with a wrench, a pipe wrench and a wire cutter; a clamping force regulating mechanism which comprises a double-end bolt, a locking nut, a pressure spring cassette, a pressure spring, a cassette pin, and the like, is arranged on the inside middle part of the left and right handles. The cutting nipper of the invention is provided with nine functions in order to meet the demands of daily work and life. The operation is labor-saving and the clamping force can be regulated and fixed so as to smoothly and safely operate.

Owner:包长仁

Large-ring-gear externally-expanded type efficient gear shaping clamp

InactiveCN104972181AAvoid deformationConstant clamping forceGear-cutting machinesGear teethEngineeringMachine tool

The invention discloses a large-ring-gear externally-expanded type efficient gear shaping clamp which comprises a base and a body arranged on the base. A connection disk, an expansion sleeve and a support are sequentially arranged on the inner side of the body from bottom to top. The base is fixedly connected with a machine tool table. Compared with a three-jaw chuck and manual clamping, the large-ring-gear externally-expanded type efficient gear shaping clamp is constant in clamping force, the clamping process is stable and reliable, and parts are not prone to deforming; the large-ring-gear externally-expanded type efficient gear shaping clamp is suitable for gear shaping machines of various specifications by replacing the base and a connection rod, and the large-ring-gear externally-expanded type efficient gear shaping clamp is suitable for parts of different size series by replacing the expansion sleeve and the support. The support can be designed of a petal type toothed structure and is paired with a chute arranged on the body, the chip removing speed is increased, and accumulated scrap iron is effectively prevented from affecting machining. The clamp is relatively simple in whole structure and convenient to manufacture, and an adjustment space is reserved for insufficient manufacturing and assembling precision. The clamp can be arranged as a whole or parts of the clamp are sequentially arranged, and the parts can be conveniently detected and replaced.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

Multi-lead installation type shunt device

PendingCN108493639AUniform pressureConstant clamping forceClamped/spring connectionsMultiple conductors connectorShunt DeviceEngineering

The invention relates to the electric power fitting technology field and especially discloses a multi-lead installation type shunt device. The device comprises a shunt seat and an insulation shell. One side of the shunt seat is provided with a first groove, a main wire screw and a dynamic pressing block. One side of the dynamic pressing block is rotatably connected to the main wire screw, and theother side and the groove wall of the other end of the first groove are cooperated to form a main wire clamp used for clamping a main lead. The other side of the shunt sea is provided with a second groove, several locking blocks and shunt wire holes. Each locking block corresponds to one or two shunt wire holes. Each locking block and the inner cavity wall of the second groove are hinged and cooperated to form a shunt wire clamp. The device has advantages that through the shunt seat, several shunt wires and the main lead are conductively connected, and a clamping force is constant; the shunt wire clamp includes the several independent locking blocks, each locking block can be used to fix one or two shunt wires; and when the shunt wires are installed, removed and overhauled, the other shuntwires are not influenced, and usage is flexible and convenient.

Owner:GUANGZHOU PANYU CABLE WORKS

Multidirectional rotary connection cable clamp

ActiveCN103001017AImprove general performanceSimple structureElectric connection structural associationsClamped/spring connectionsEngineeringMechanical engineering

The invention discloses a multidirectional rotary connection cable clamp. The clamp is characterized by comprising two movably connected cable clamps, wherein each cable clamp comprises a clamp body, a groove is arranged in the clamp body, a movable chuck capable of moving up and down is embedded into the groove, a fixed chuck opposite to the clamping end of the movable chuck is fixedly connected to the clamp body, a bolt hole is arranged on one side of the clamp body opposite to the opening direction of the groove, and an adjusting bolt penetrates through the bolt hole, is fixedly connected with the clamp body and abuts against the movable chuck. The clamp is high in generality, capable of being suitable for various diameters of cables, simple in structure, reasonable in design, balanced in pressure, constant in clamping force, small in contact resistance, reliable in connection and safe in use.

Owner:GUANGZHOU PANYU CABLE WORKS

Constant-force comb falling cutter with self-adaption to banana fruit shafts based on extensible mechanism

ActiveCN110973670ANo chance of missing a banana comb handleEven by forceFood treatmentStructural engineeringKnife blades

The invention discloses a constant-force comb falling cutter with self-adaption to banana fruit shafts based on an extensible mechanism. The comb falling cutter comprises a comb falling cutter head, linear guide rails, sliding blocks, main hard cutter connecting blocks, main hard blades, auxiliary hard blades, a connecting rod, soft blades and constant-force assemblies; a plurality of linear guiderails are radially and uniformly distributed on the comb falling cutter head around the center of the through hole of the comb falling cutter head; a sliding block is mounted on each linear guide rail in a sliding manner; the top of each sliding block is connected to a main hard cutter connecting block; one side, close to the center of the comb falling cutter head, of each main hard blade connecting block is connected to a main hard blade extending upwards, and an auxiliary hard blade is arranged between every two adjacent main hard blades; the top of each main hard blade and the top of eachauxiliary hard blade are each provided with a transverse soft blade; and each sliding block is connected to a constant force assembly. The comb falling cutter can effectively solve the problems that existing cutters are poor in self-adaptation to banana fruit shafts, have small variable-diameter stroke, and have too large gap.

Owner:SOUTH CHINA AGRI UNIV

Grounding cable clamp

ActiveCN103022751AEasy to installImprove general performanceCoupling device detailsElectric connection structural associationsEngineeringMechanical engineering

The invention discloses a grounding cable clamp comprising a cable clamp body provided with a groove. A movable clamp head capable of moving vertically is embedded into the groove. The cable clamp body is provided with a grounding connection device. A fixed clamp head opposite to the movable clamp head is fixedly connected above the cable clamp body, a bolt hole is arranged below the cable clamp body, and an adjustable bolt penetrates through the bolt hole to be fixedly connected with the cable clamp body while connectedly butts against the movable clamp head. Nonreturn sawteeth which is nonreturn down is arranged on one or two sides of the movable clamp head. Anti-loosing nonreturn sawteeth pieces are matched with the nonreturn sawteeth and arranged at outside of the nonreturn sawteeth of the movable clamp head. A pressure spring is arranged between the anti-loosing nonreturn sawteeth piece and the cable clamp body at at least one side. The movable clamp head and the anti-loosing nonreturn sawteeth pieces are pressed tightly by the pressure spring. The grounding cable clamp is high in universality, simple in structure, balanced in pressure, constant in clamping force, small in contact resistance, stable and reliable in connection, convenient for mounting of a grounding wire, convenient to use and safe to mount, and even can trigger lightning discharge so as to protect the cables.

Owner:GUANGZHOU PANYU CABLE WORKS

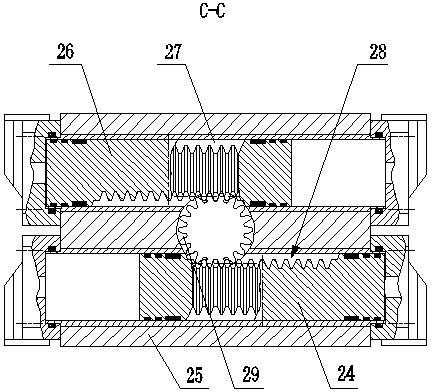

Industrial robot gripper with compact space, large clamping force and long stroke

The invention discloses an industrial robot gripper with compact space, large clamping force and a long stroke. The industrial robot gripper comprises a frame body provided with a sliding rail. A left gripper body and a right gripper body which are symmetric to each other and are in sliding fit with the sliding rail are arranged on the frame body. A grasping area used for grasping a workpiece is formed between the left gripper body and the right gripper body or grasping areas are formed at the two sides of the left gripper body and the right gripper body. The industrial robot gripper is characterized in that a left sliding base and a right sliding base which can be in sliding fit along the sliding rail are arranged in the length direction of the sliding rail, the bottom of the left sliding base and the bottom of the right sliding base are provided with racks, the left gripper body and the right gripper body are fixedly connected with the left sliding base and the right sliding base respectively, a first gear train and a second gear train which are in meshed fit with the two racks respectively are arranged inside the frame body, and a synchronous power device used for synchronously driving the two sliding bases to synchronously move in the opposite direction or the reverse direction is arranged between the first gear train and the second gear train. According to the industrial robot gripper, the stroke of the gripper bodies can be effectively lengthened, the two gripper bodies can synchronously move, and the central position of an object can be kept unchanged without the adjustment of the gripper.

Owner:远洋探海机器人东台有限公司 +1

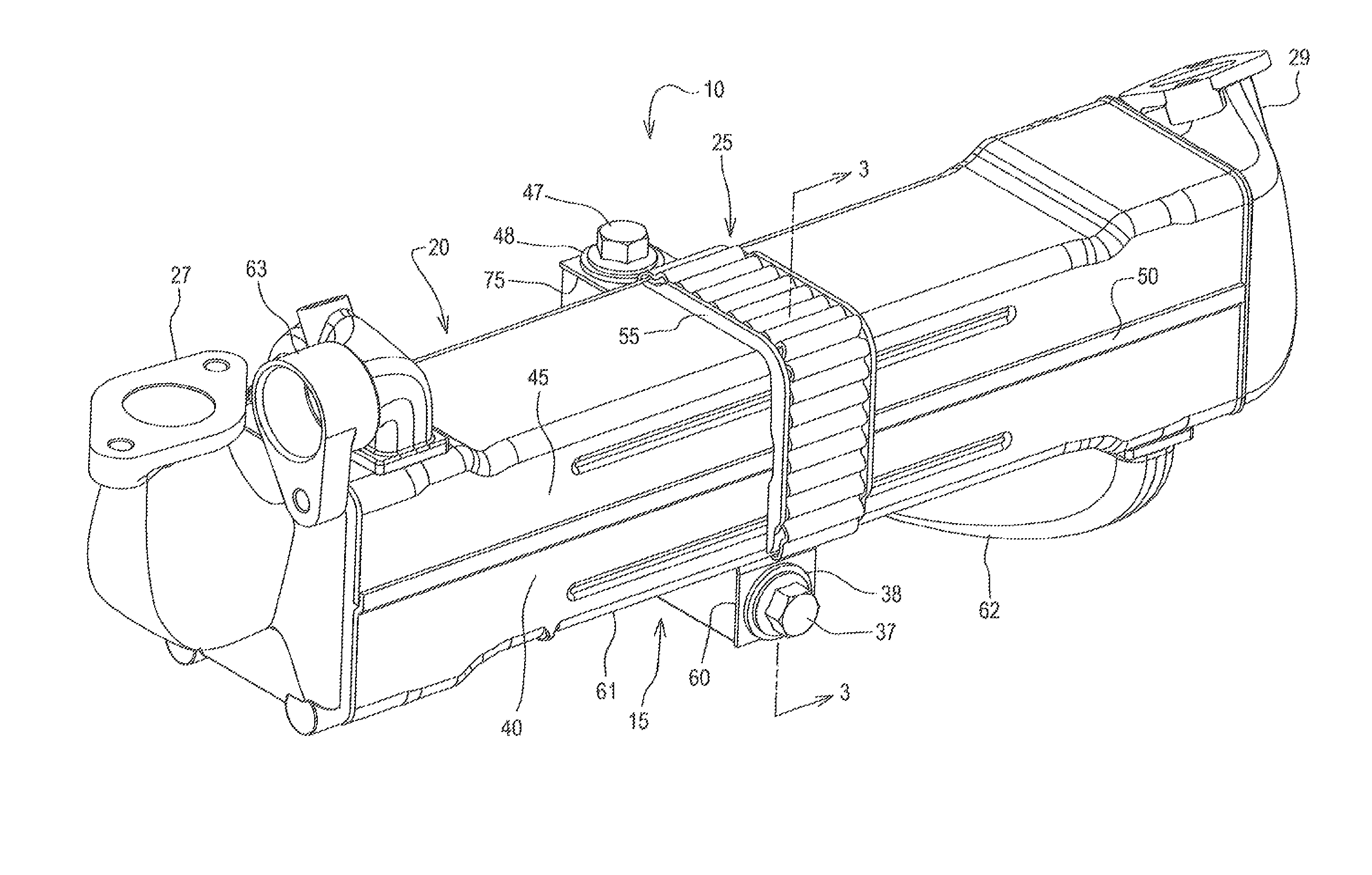

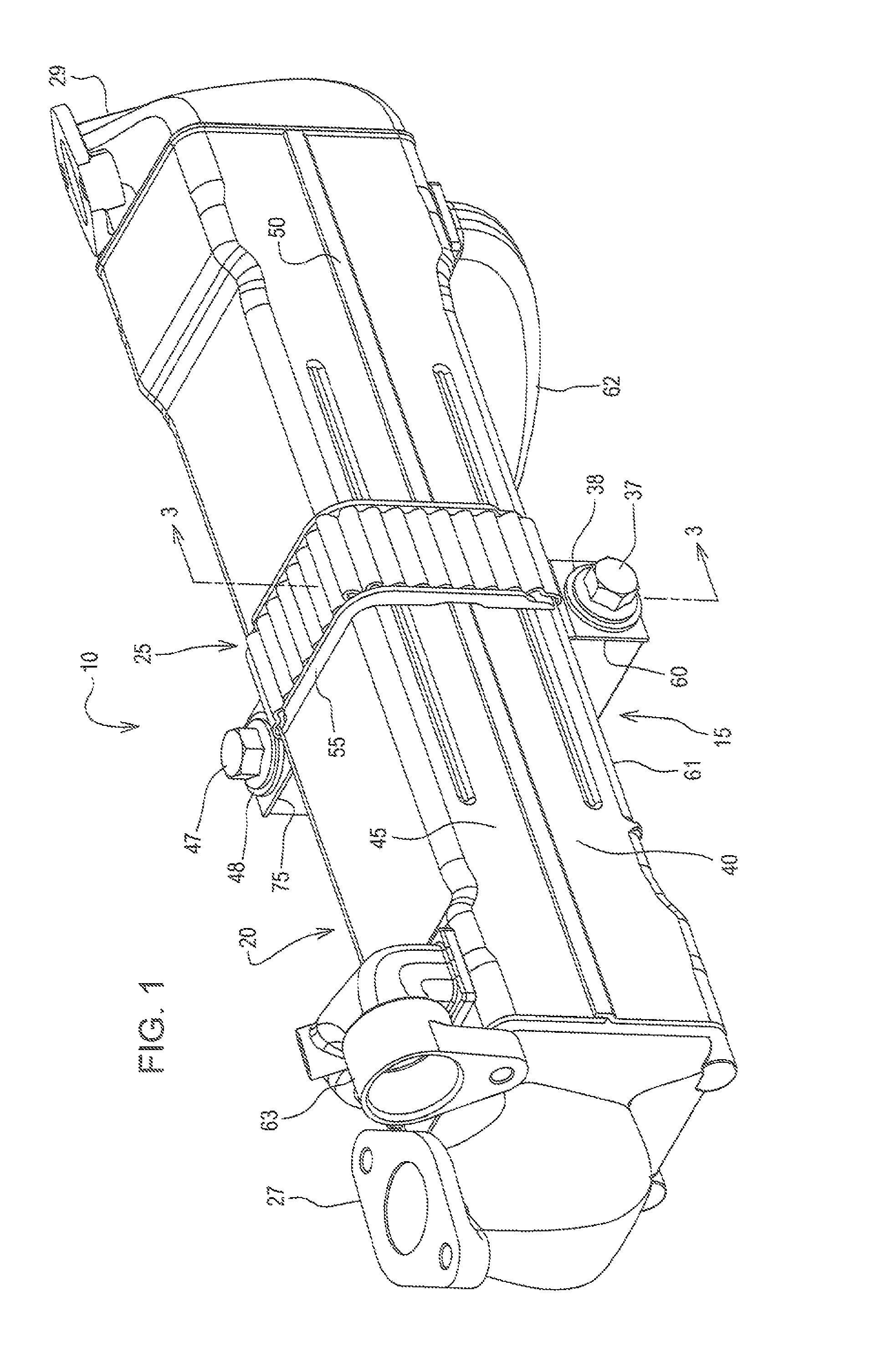

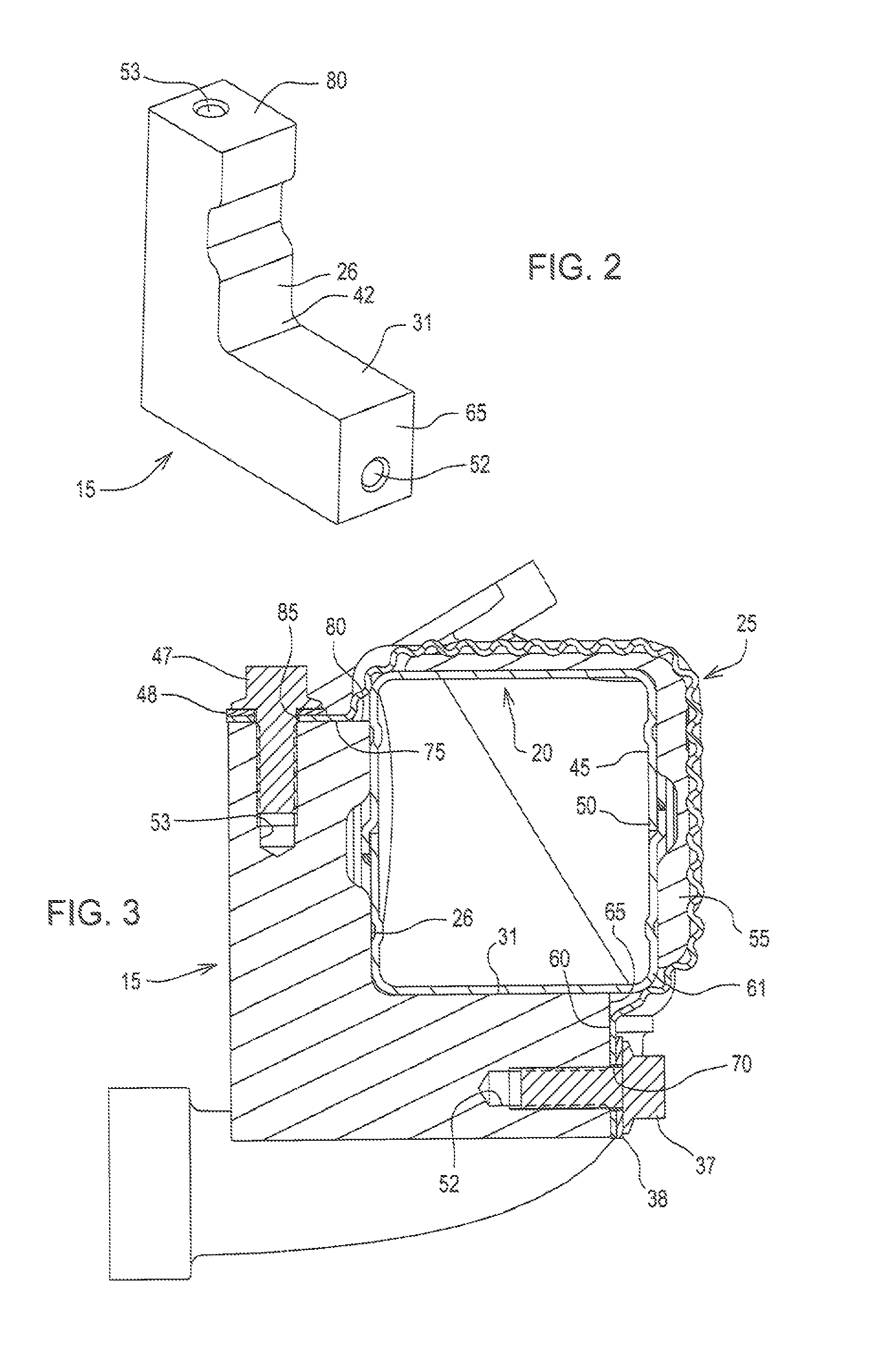

Corrugated strap for securing a heat exchanger

ActiveUS8770177B2Constant clamping forceEffective heat exchangeNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringHeat exchanger

Owner:DEERE & CO

Grounding cable clamp

ActiveCN103022751BEasy to installImprove general performanceCoupling device detailsElectric connection structural associationsMechanical engineeringGround line

The invention discloses a grounding cable clamp comprising a cable clamp body. The grounding cable clamp is characterized in that a groove is arranged in the cable clamp body, a movable clamp head capable of moving vertically is embedded into the groove, a fixed clamp head opposite to the movable clamp head is fixedly connected above the cable clamp body, a bolt hole is arranged below the cable clamp body, and an adjustable bolt penetrates through the bolt hole to be fixedly connected with the cable clamp body while connectedly butts against the movable clamp head. A grounding connecting device is arranged on the grounding cable clamp. The grounding cable clamp is high in universality so as to be applicable to cables with various cable diameters, is simple in structure, reasonable in design, balanced in pressure, constant in clamping force, small in contact resistance, stable and reliable in connection, convenient for mounting of a grounding wire, convenient to use and safe to mount, and even can trigger lightning discharge so as to protect the cables.

Owner:GUANGZHOU PANYU CABLE WORKS

Clamping device

The invention discloses a clamping device which comprises a first seat body and a second seat body. The first seat body and the second seat body are oppositely arranged. A containing cavity is formed in the second seat body, and a first rack is arranged on the bottom wall of the containing groove. The clamping device further comprises an abutting assembly and a constant-pressure assembly arranged on the abutting assembly. The abutting assembly comprises a movable part, a first elastic part, a gear, a pressure bearing part and a second elastic part. One end of the first elastic part abuts against the movable part, and the other end of the first elastic part abuts against the bottom wall of the containing cavity. The gear is rotationally arranged on the movable part, one side of the gear is meshed with the first rack, and the pressure bearing part is connected to the movable part and comprises a pressure bearing portion opposite to the movable part. The constant-pressure assembly comprises a pressing plate and a second rack, the pressing plate is adjacent to the pressure bearing portion and is arranged on the movable part, one end of the second elastic part abuts against the pressing plate, and the other end of the second elastic part abuts against the pressure bearing portion. The elastic coefficient of the first elastic part is equal to the elastic coefficient of the second elastic part, and the second rack is arranged on the pressing plate and meshed with the other side of the gear. When electronic devices with different thicknesses are clamped, the clamping device can keep the constant clamping force.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

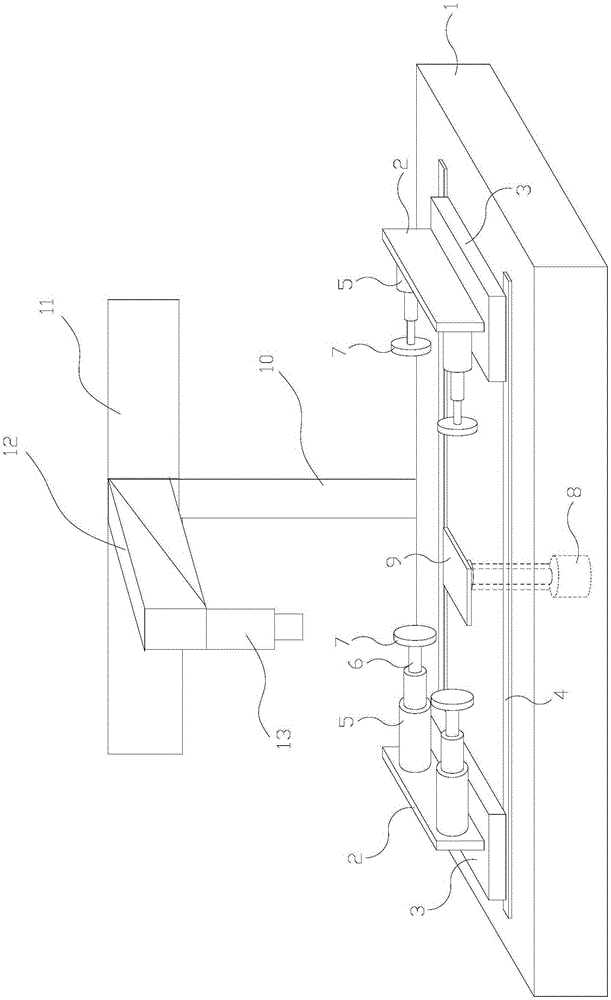

Servo drive traction machine

InactiveCN107953534AEasy to adjust clamping pressureStable line speedTubular articlesEngineeringControl theory

The invention discloses a servo drive traction machine. The servo drive traction machine comprises a machine frame, an electric box, an operation box and a transmission mechanism, wherein the electricbox is arranged on the machine frame. The transmission mechanism comprises a linear polish rod, a screw rod, an opening and closing servo motor, an upper side traction device, a lower side traction device, a driving servo motor and a reduction gearbox, wherein the linear polish rod is connected with the upper side traction device and the lower side traction device through a linear bearing, the opening and closing servo motor is connected with the screw rod, the lower side traction device and the lower side traction device are installed on the side part of the screw rod through a nut and a nutseat, an air cylinder is further connected between the lower side traction device and the nut seat, and the air cylinder is driven by the opening and closing servo motor to provide the transaction opening and closing power for the upper side traction device and the lower side traction device. A belt pulley of the upper side traction device and a belt pulley of the lower side traction device provide the driving power by the driving servo motor and the reduction gearbox, the belt pulleys drive belts to carry out traction, and guide mechanisms are further arranged at the two ends of the upper side traction device and the lower side traction device. According to the servo drive traction machine, the clamping pressure is conveniently adjusted, the constant clamping force can be provided, and the stable wire production speed can be provided.

Owner:NANJING ORIENTLEADER TECH CO LTD

Clamp mechanism of digit impact testing machine

InactiveCN103743536ASimple structureReasonable designShock testingStrength propertiesTest samplePush pull

The invention discloses a clamp mechanism of a digit impact testing machine. The clamp mechanism comprises a base; a fixing structure, a push-pull structure and a mobile structure are arranged on the base; the fixing structure is arranged on the base and is connected with the push-pull structure which is connected with the mobile structure. The fixing structure is fixedly connected with the base; the end part of the push-pull structure is movably connected with the fixing structure. The push-pull structure rotates around the fixing structure and the push-pull structure drives the mobile structure to move. The clamp mechanism of the digit impact testing machine is simple in structure, reasonable in design, capable of fast mounting a test sample and accurate in positioning and has a constant clamping force.

Owner:GOTECH TESTING MACHINES DONGGUAN

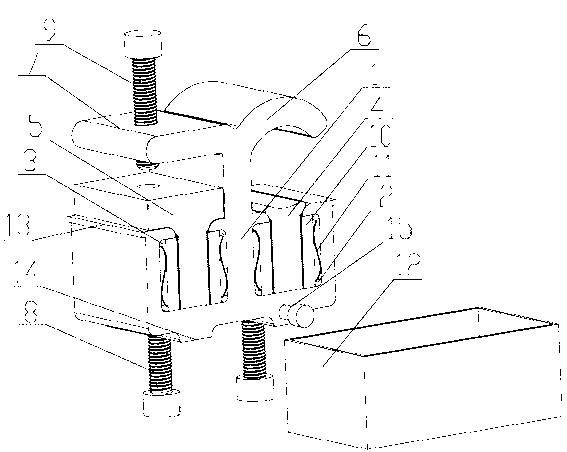

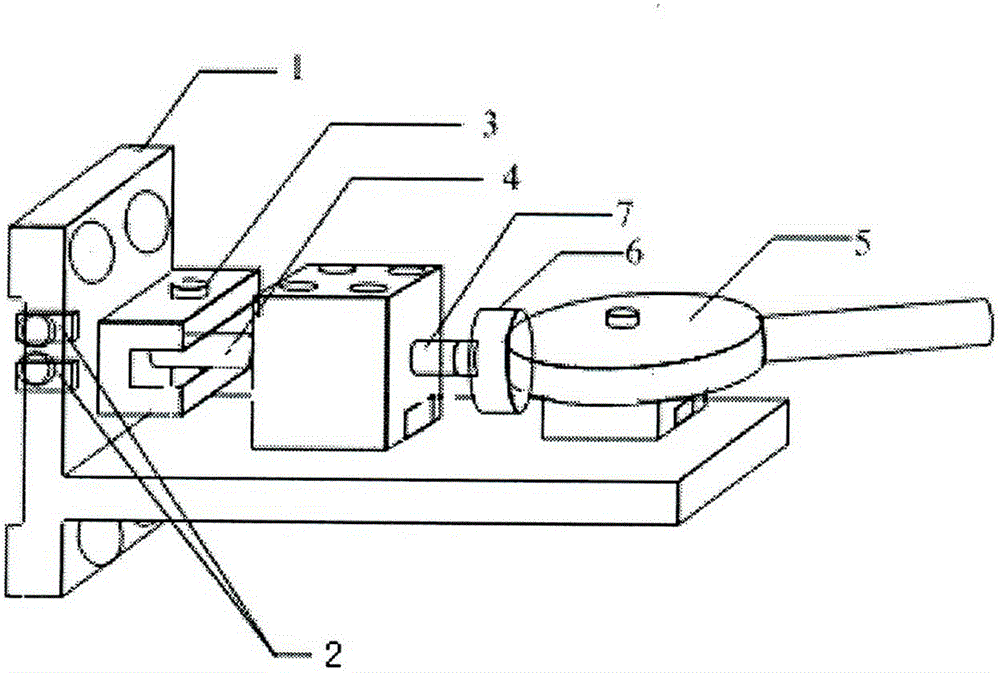

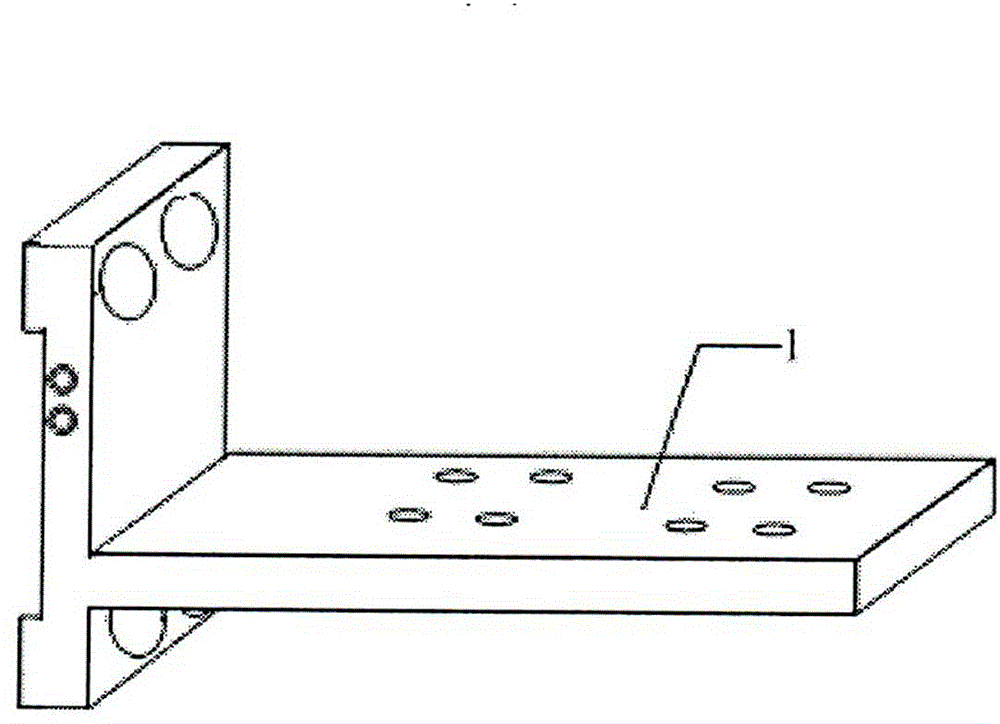

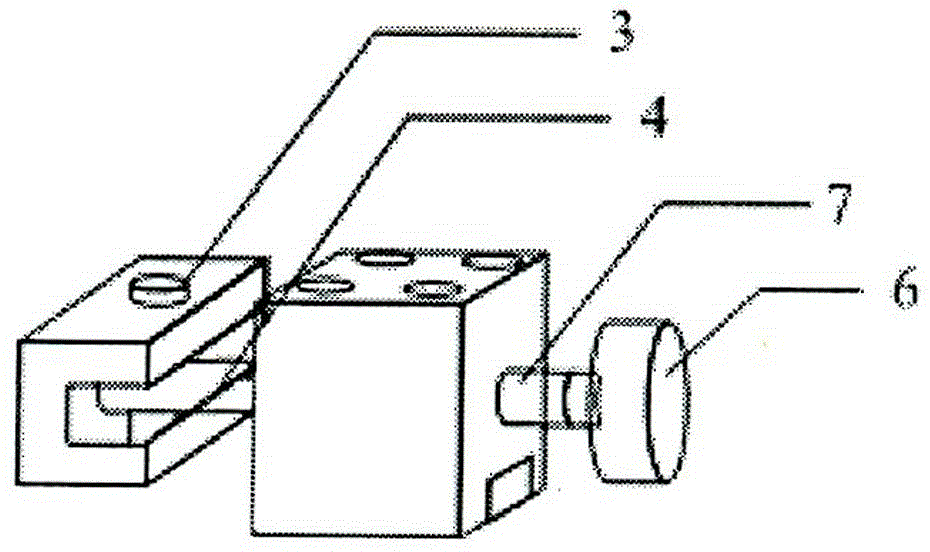

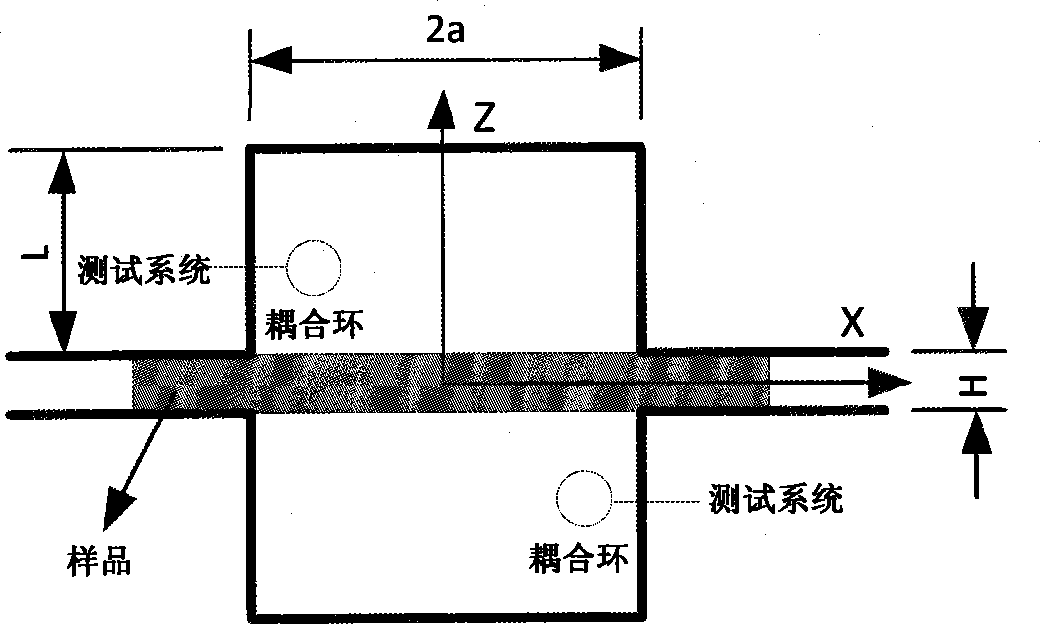

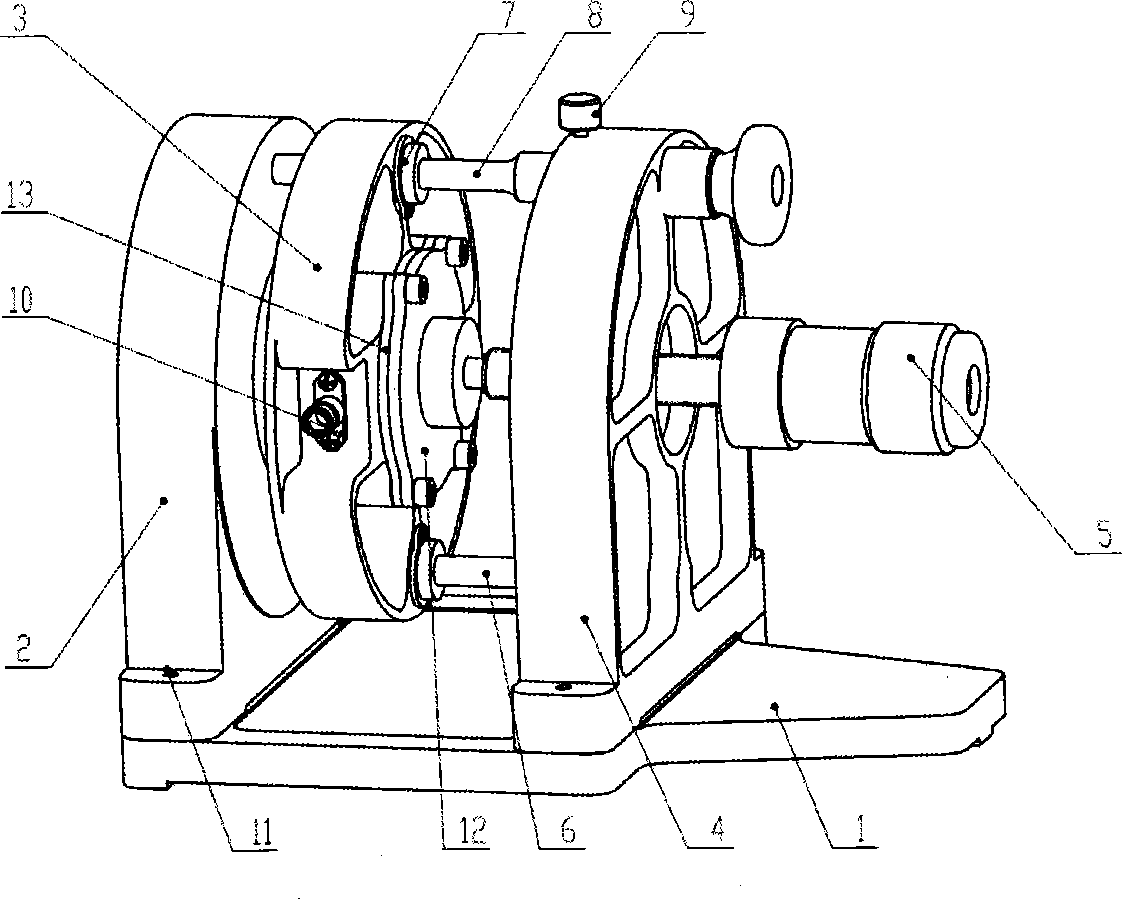

Low-loss material dielectric property measurement device adopting split-cylinder resonator method

ActiveCN104297572APrecise alignmentSmooth motionResistance/reactance/impedenceResonant cavityElectricity

The invention provides a low-loss material dielectric property measurement device adopting a split-cylinder resonator method. The low-loss material dielectric property measurement device adopting the split-cylinder resonator method comprises a base plate, a fixed cavity, a movable cavity, a supporting seat, a force moment handle, a lower guide rod, a precise linear bearing, an upper guide rod, a locking screw, a coaxial connector, a positioning pin, a connecting plate, a protective plate and a stop block. By means of the scheme, the theoretical advantage that the accuracy of low-loss material dielectric property measurement by means of the split-cylinder resonator method is high can be fully played. In addition, measured samples are simple in preparation and quick and convenient to measure. For different measured samples, clamping forces of two resonant cavities can be adjusted through the force moment handle, accordingly measurement distortion caused by improper clamping is decreased, and measurement accuracy is ensured. For the same samples, the clamping forces are constant, and consistency of measurement results can be ensured.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

Ejection self-adaption tail base advancement system

ActiveCN110605410APlay the role of radial limitTight and reliable installationTailstocks/centresBall bearingCoupling

The invention discloses an ejection self-adaption tail base advancement system. The system comprises a guide rail mounted on a machine body of a machine tool, a tail base slidingly arranged on the guide rail, and a driving mechanism connected with the tail base and driving the tail base to move on the guide rail; the driving mechanism comprises a servo motor, a mounting base and a flange coupling;the mounting base is fixedly arranged on the machine body; the flange coupling is directly connected with a motor shaft and a rod end of a lead screw; a front cover of the flange coupling is providedwith a deep groove ball bearing for rotary supporting; and an output shaft of the servo motor and the end part of the lead screw are mounted in the front cover of the flange coupling through a key connecting mode for synchronous rotation, and drive the tail base to linearly move on the guide rail by a spiral transmission mode. The system can guarantee stable workpiece machining precision, achieves a tail base ejection self-adaption effect, can reduce machining errors, and improves the machining precision.

Owner:YANGTZE NORMAL UNIVERSITY

Clamp apparatus

A clamp apparatus is equipped with first and second clamp arms supported rotatably with respect to a body, and a drive unit having a pair of first and second pistons displaced under the supply of a pressure fluid. A driving force of the drive unit is transmitted to the first and second clamp arms through knuckle joints, which are connected to first and second piston rods, power-boost levers, and link arms. The power-boost levers are formed such that the length from a support pin toward the knuckle joint is longer than the length from the support pin toward the link arm.

Owner:SMC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com