Ejection self-adaption tail base advancement system

An adaptive and tailstock technology, which is applied in the direction of tailstock/top, tool holder accessories, turning equipment, etc., can solve problems such as wasting energy, reducing the service life of hydraulic pumps, and limiting the width of machine tool guide rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

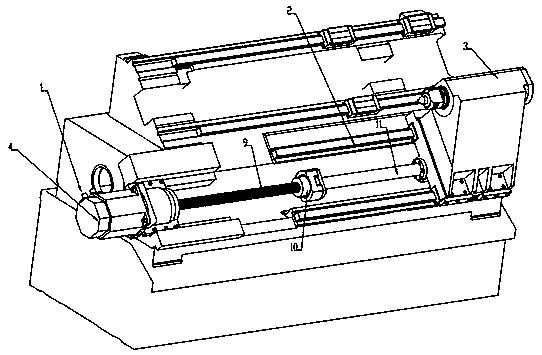

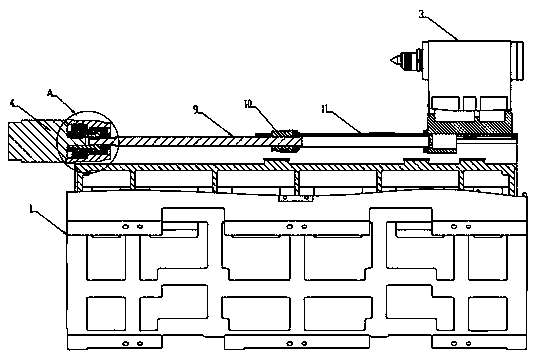

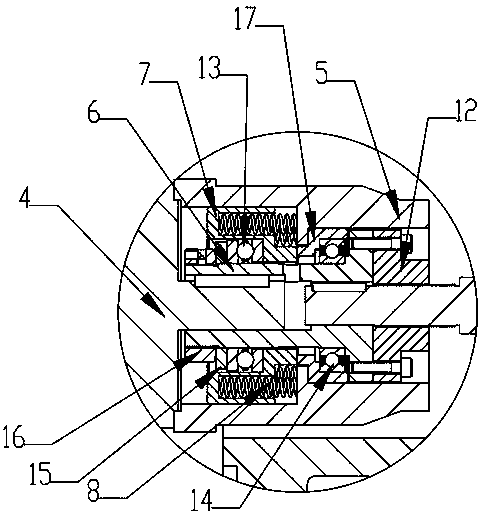

[0020] For specific implementation: see Figure 1 to Figure 3 , a top-tight self-adaptive tailstock travel system, including a guide rail 2 installed on the machine bed 1, a tailstock 3 slidably arranged on the guide rail 2, and a drive that is connected with the tailstock 3 and drives it to move on the guide rail mechanism, the drive mechanism includes a servo motor 4, a mounting seat 5, and a flange coupling front cover 6, the mounting seat 5 is fixedly arranged on the bed 1, and the flange coupling front cover 6 can be moved through a bearing Rotation is installed in the through hole opened in the axial direction of the mounting base 5, the output shaft of the servo motor 4 is inserted in the front end of the front sleeve 6 of the flange coupling and rotates with it, the flange coupling The rear end of the front sleeve 6 of the device is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com