Multi-lead installation type shunt device

A shunt device, multi-conductor technology, applied in multi-conductor connectors, conductive connections, electrical components and other directions, can solve the problems of poor wire connection handling, weak wiring, cable shunt, etc., to achieve compact structure, flexible and convenient use, The effect of pressure equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

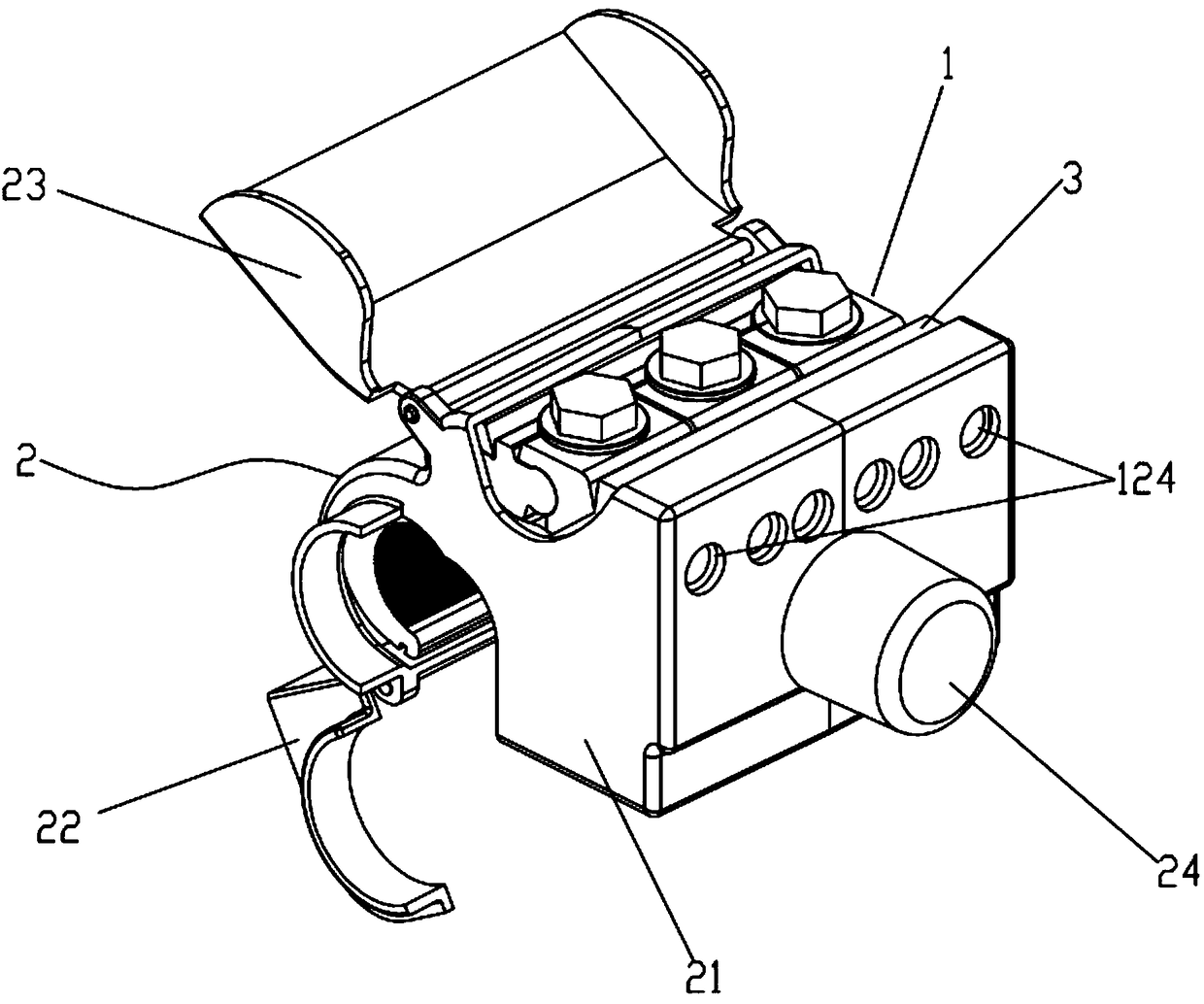

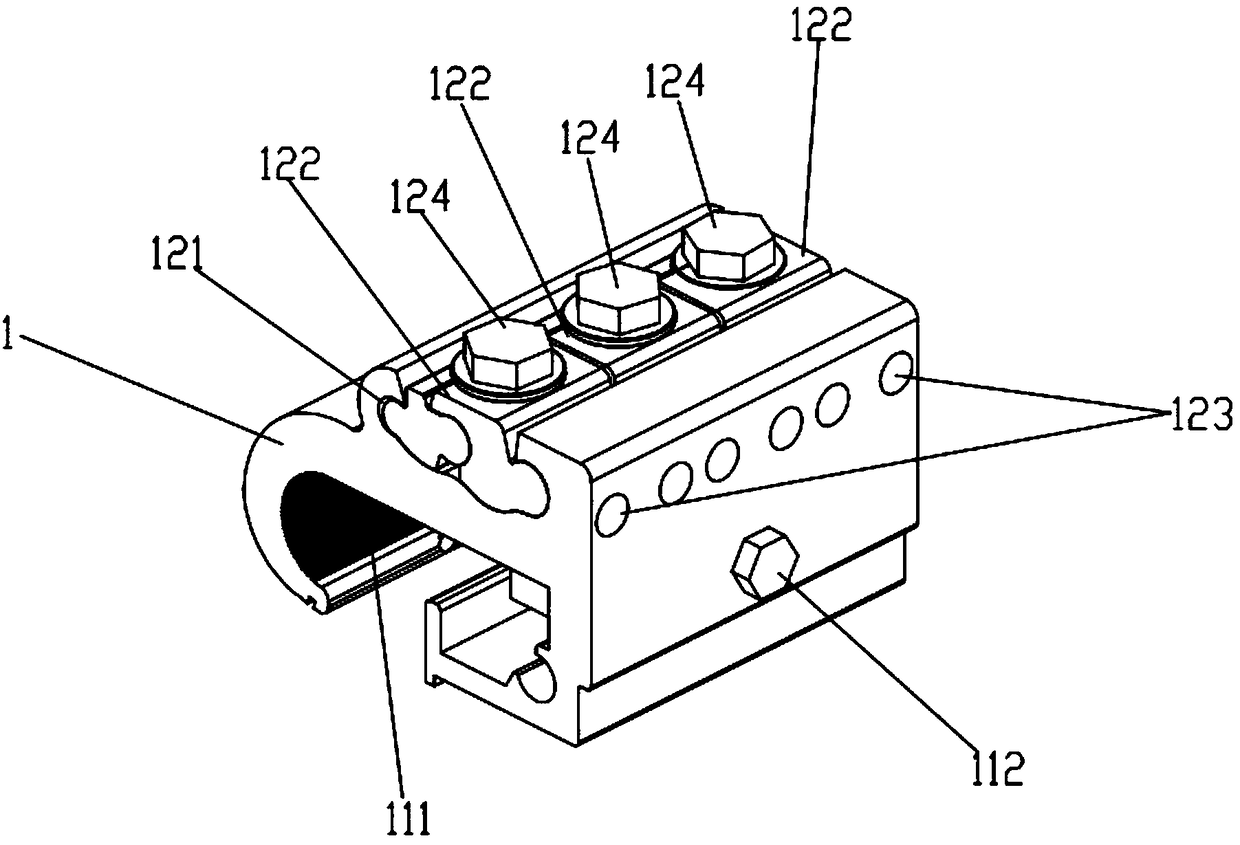

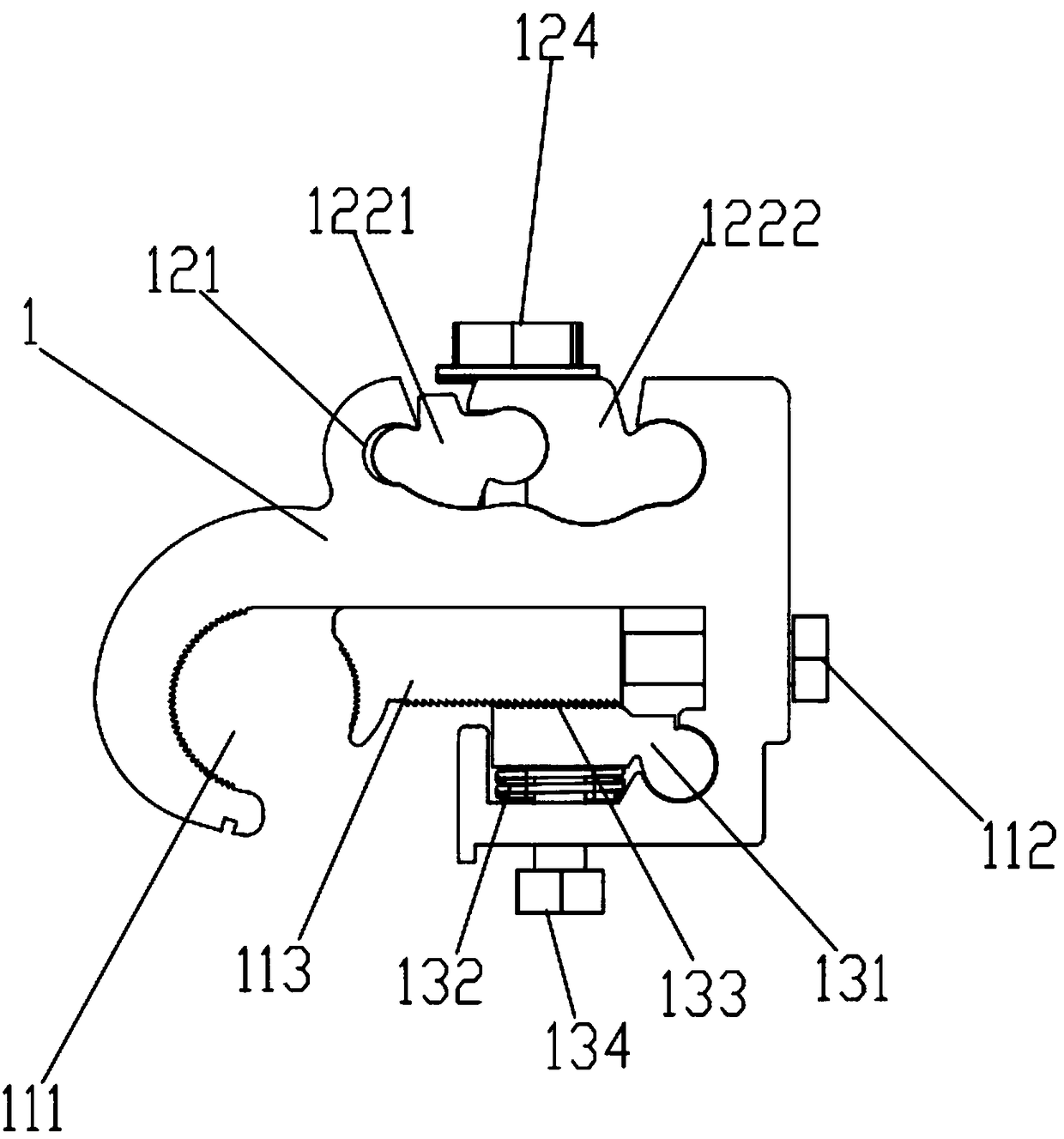

[0024] like Figure 1-4 As shown, the multi-wire installation type shunt device includes a conductive shunt seat 1 and an insulating shell 2 set outside the shunt seat 1, and a first groove 111 is provided on one side of the shunt seat 1, and the first groove 111 The main line screw 112 threaded on the groove wall at one end, the dynamic pressure block 113 placed in the first groove 111, the opposite sides of the first groove 111 are open for the main wire 4 to pass through, and one side of the dynamic pressure block 113 is connected to the main line. The screw 112 is rotatably connected, and the other side cooperates with the groove wall at the other end of the first groove 111 to form a main wire clamp for clamping the main wire 4; the other side of the diverter seat 1 is provided with a second groove 121, parallel Three locking blocks 122 placed in the second groove 121, six shunt wire holes 123 arranged on the groove wall of the second groove 121, each locking block 122 co...

Embodiment 2

[0034] On the basis of embodiment 1 technical scheme, carry out following improvement:

[0035] like Figure 5 As shown, five locking blocks 122 are arranged side by side in the second groove 121 of the diverter seat 1, and five diverter line holes 123 are arranged on the groove wall of the second groove 121, and each locking block 122 corresponds to a diverter The wire holes 123 and each locking block 122 are hinged to the inner cavity wall of the second groove 121 and cooperate to clamp the shunt wires protruding from the corresponding two shunt wire holes 123 .

[0036] The beneficial effect of the multi-wire installation type shunt device of the present invention is that several shunt wires are conductively connected to the main wire 4 through the shunt seat 1, and the main wire 4 and several shunt wires are connected to each other through the main wire clip and the shunt wire clip respectively. The shunt seat 1 is fixedly connected, suitable for cables and shunt wires of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com