Patents

Literature

73results about How to "Achieve circumferential positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

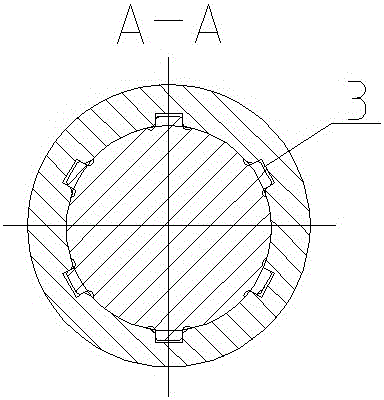

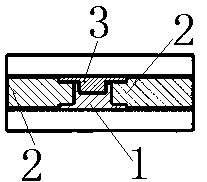

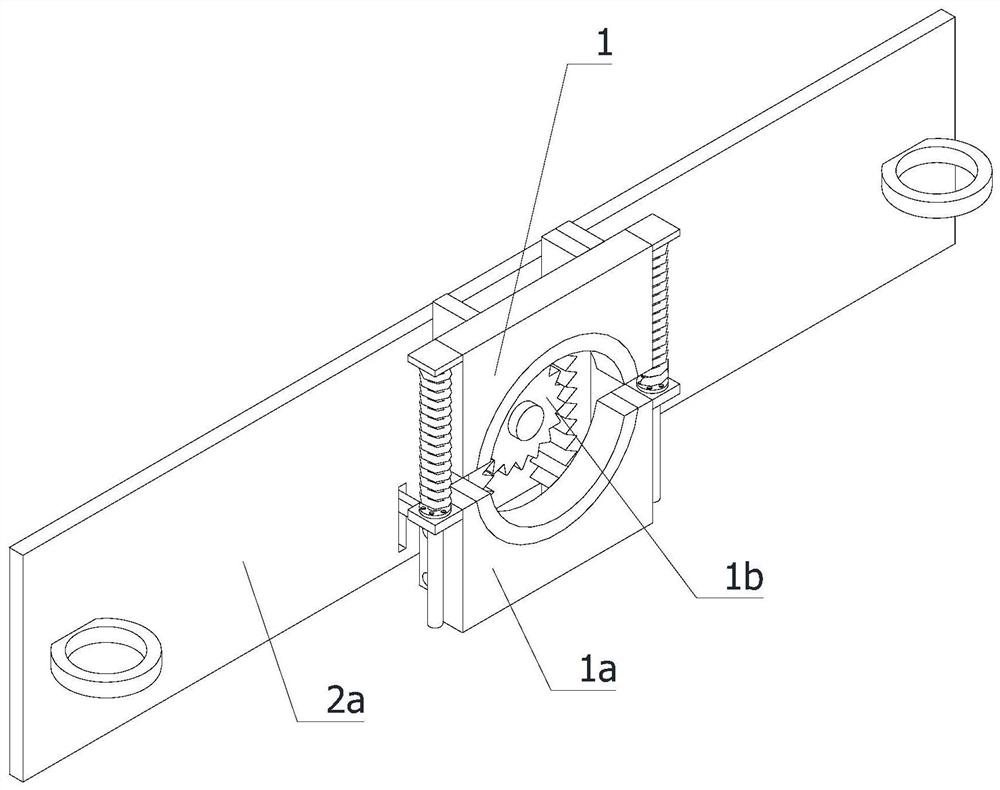

Reversible wedge-type overrunning clutch with grooves in inner ring

ActiveCN103122953AImprove carrying capacityAchieve circumferential positioningFreewheel clutchesTransmitted powerCoupling

The invention relates to a reversible wedge-type overrunning clutch with grooves in an inner ring. The reversible wedge-type overrunning clutch comprises an outer ring, the inner ring, a plurality of wedges, a spring and a shift fork, wherein arc-shaped grooves are formed in the inner ring and distributed along the peripheral direction. According to the reversible wedge-type overrunning clutch, the inner ring is provided with the arc-shaped grooves distributed along the peripheral direction, mutual conversion of overrunning relationship between the outer ring and the inner ring is achieved through manipulation of the shift fork, mutual locking between the outer ring and the inner ring also can be achieved, and a coupler which transmits power in a bidirectional mode is formed.

Owner:LUOYANG BEST PRECISION MACHINERY MFG

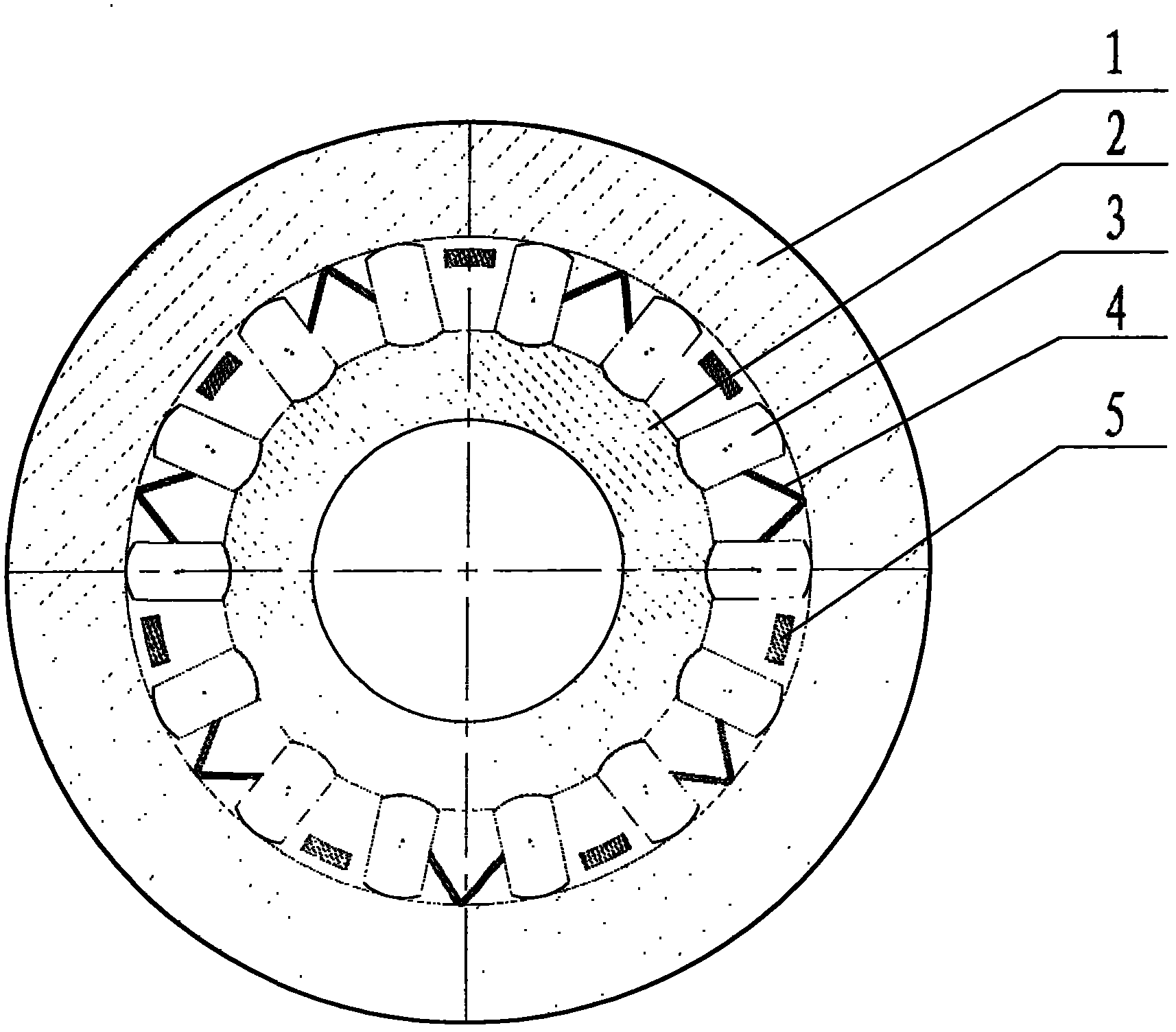

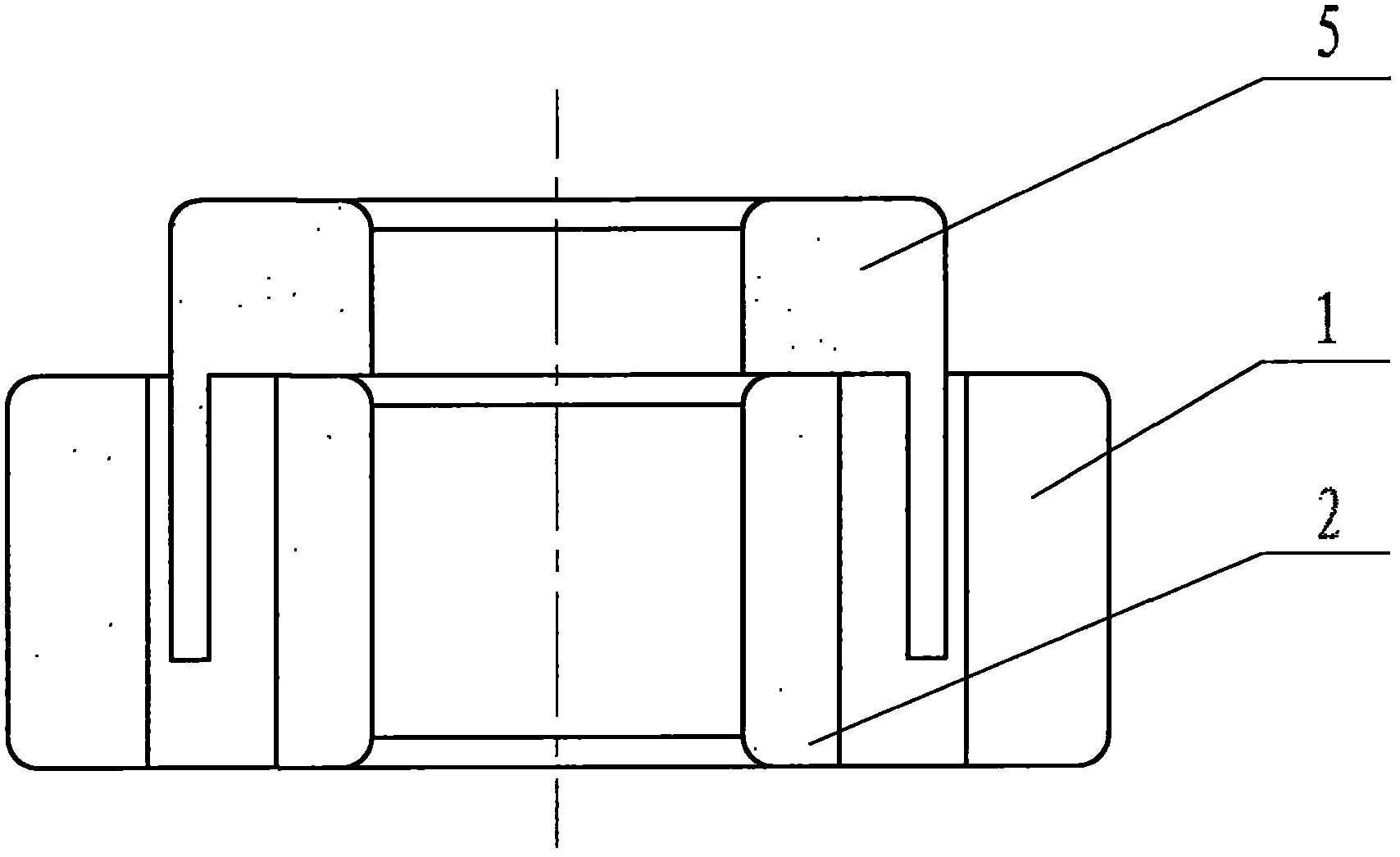

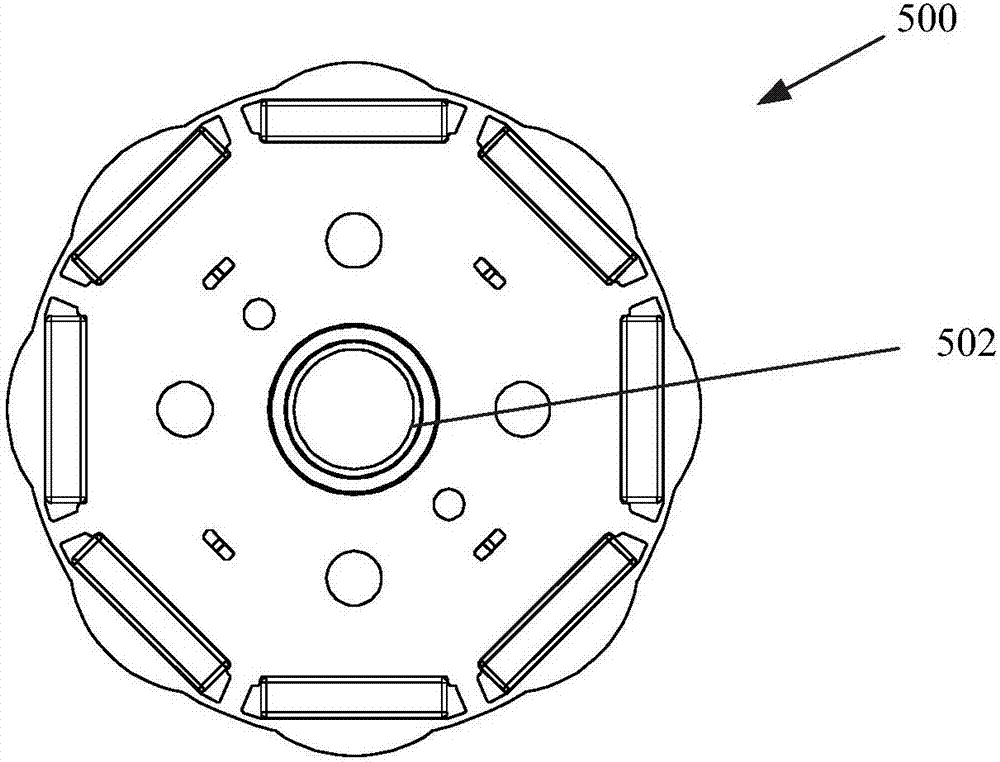

Rotor, magnetic steel fixing structure thereof, and motor

InactiveCN106130225AAchieve radial positioningAchieve circumferential positioningMagnetic circuit rotating partsPunchingMagnet

The present invention relates to a rotor, a magnet steel fixing structure thereof, and a motor. The motor magnet steel fixing structure includes a rotor core, magnet steels sequentially distributed in the circumferential direction of the rotor core, and stoppers located between two adjacent magnet steels, wherein each stopper includes a connecting portion and two pressing plates both fixedly connected with the connecting portion, the two pressing plates are respectively pressed on two adjacent magnet steels, and the connecting portion is in positioning connection with the rotor core in a radial direction through a concave-convex cooperative structure. In the magnet steel fixing structure, the connecting portion is in positioning connection with the rotor core in a radial direction through a concave-convex cooperative structure, and the structure required by the concave-convex cooperative structure can be formed in a rotor core punching process, so that compared with the prior art, a processing flow is reduced, the rotor core production process is simplified, thereby the production of a whole rotor is simplified, and rotor production efficiency is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

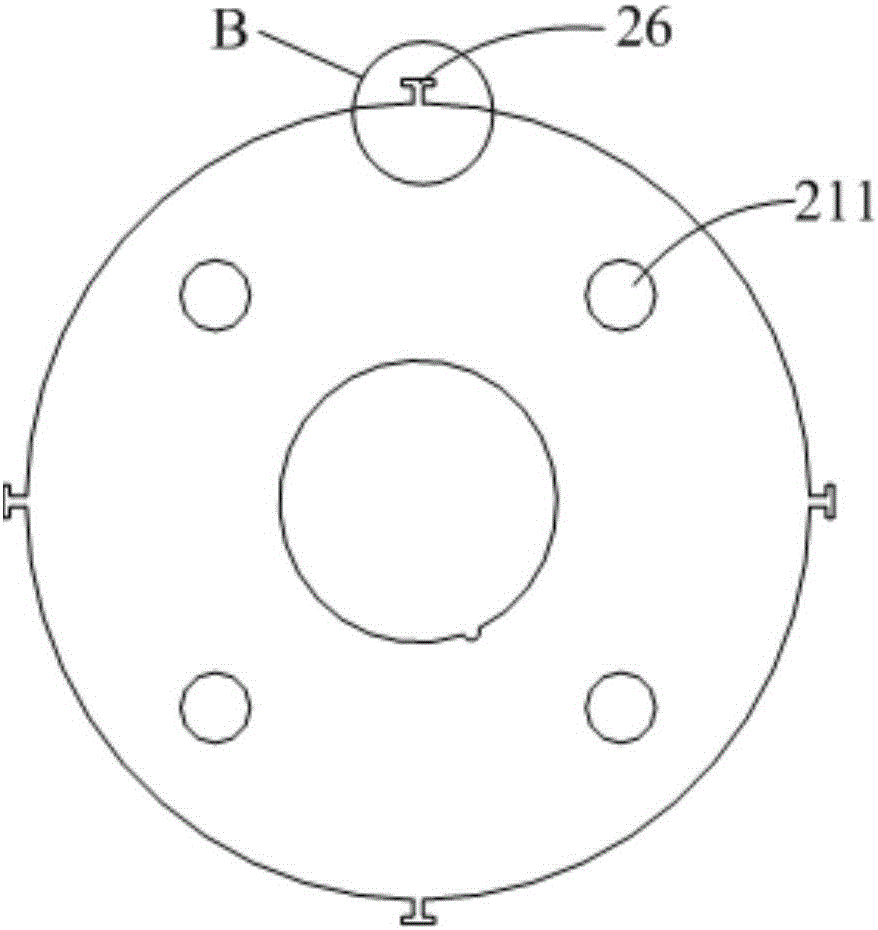

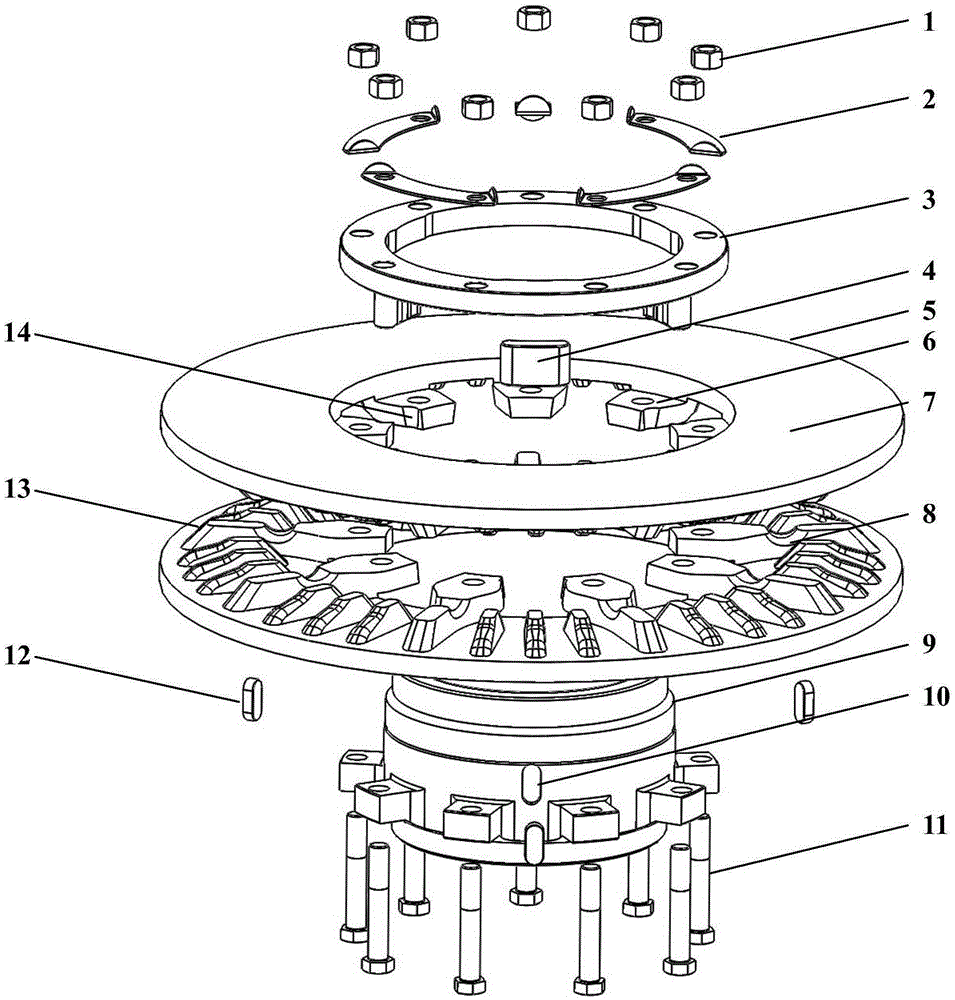

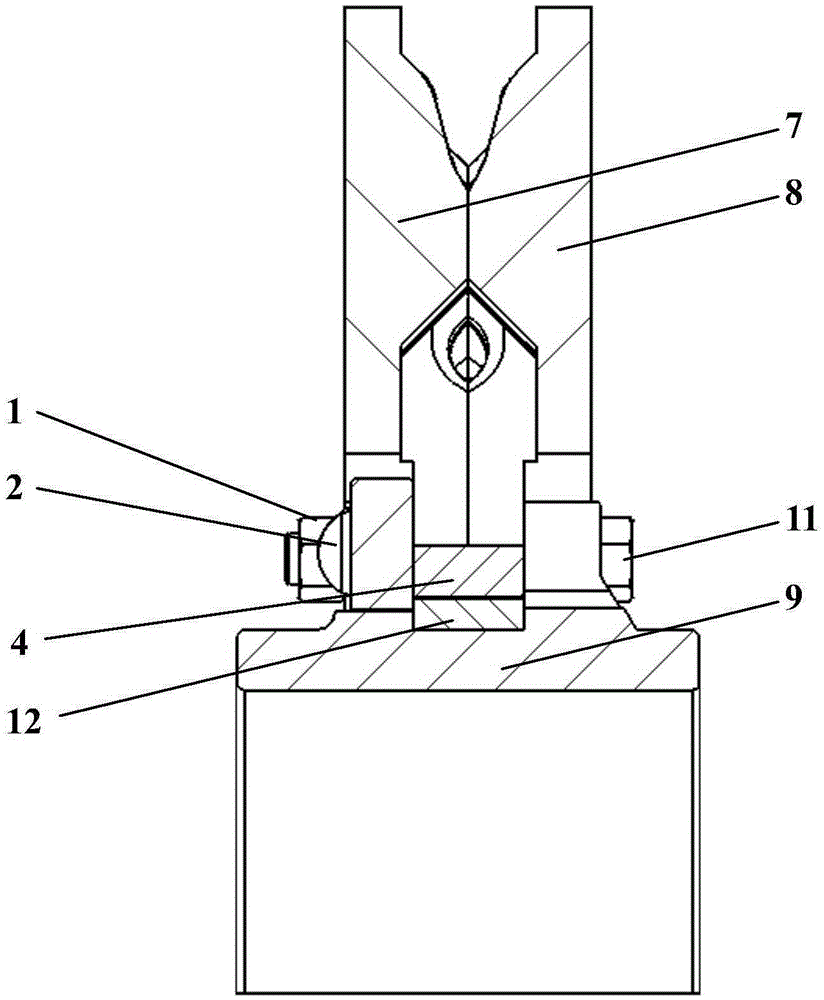

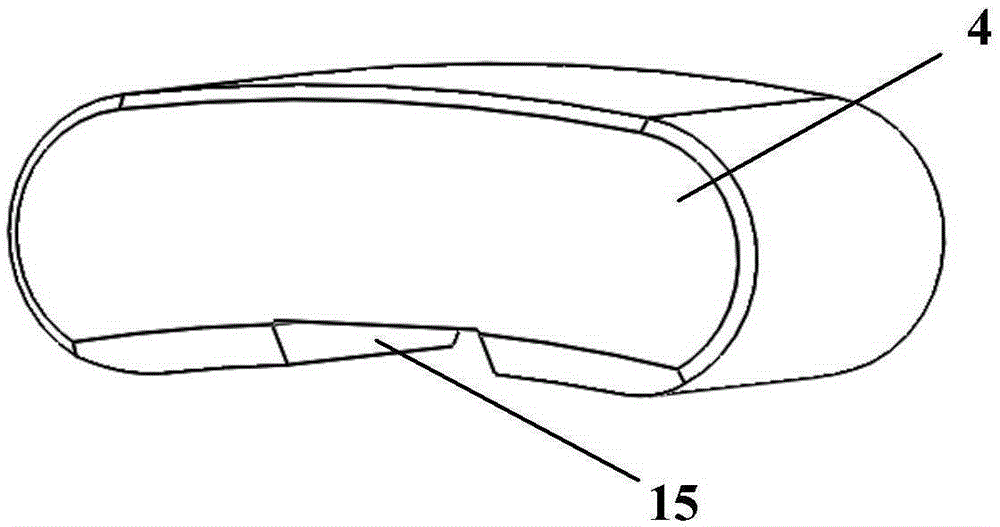

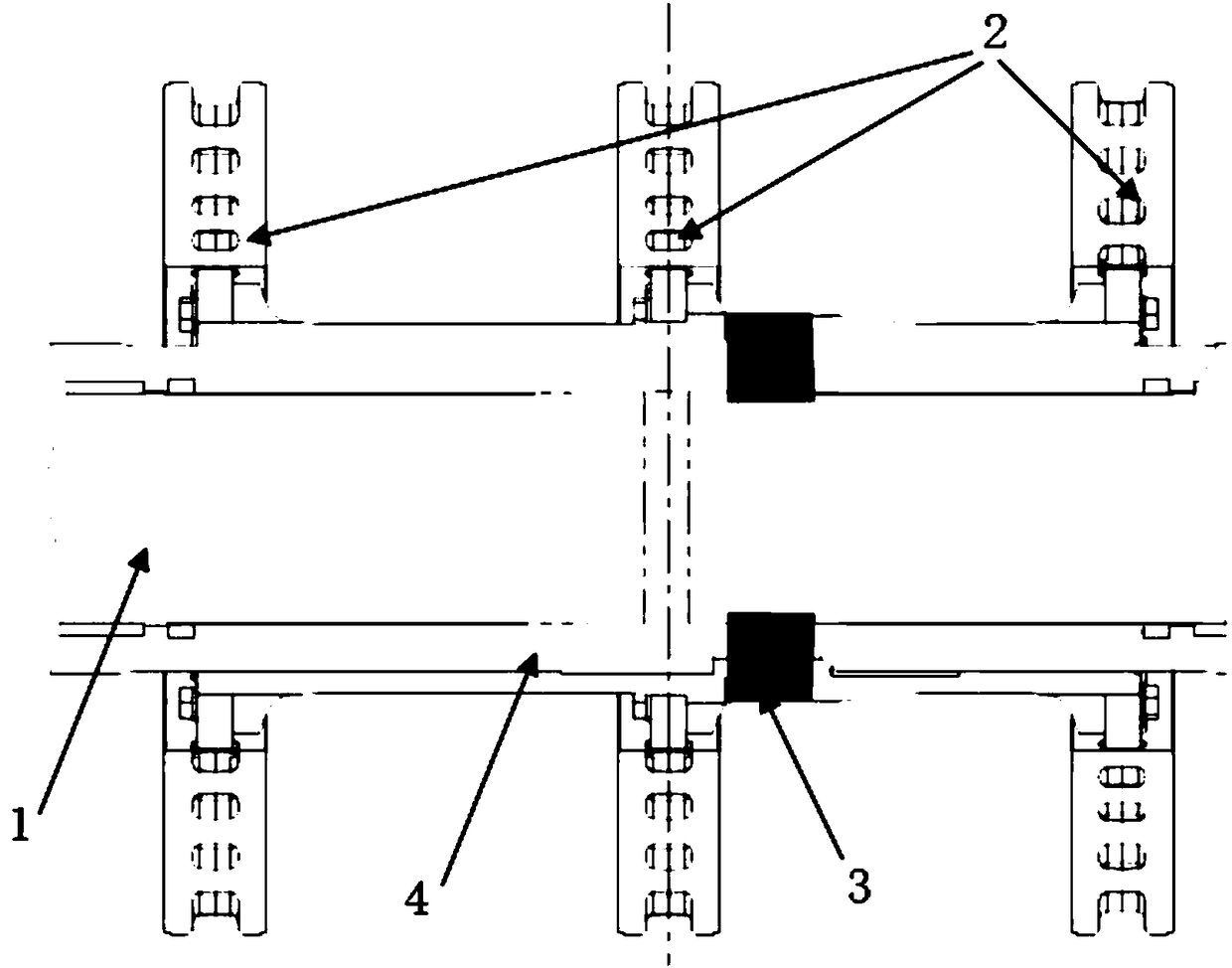

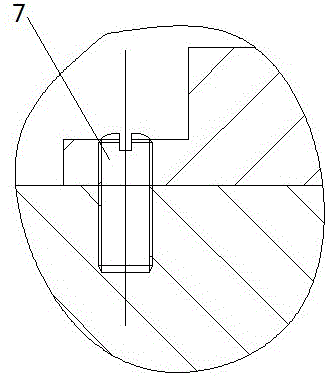

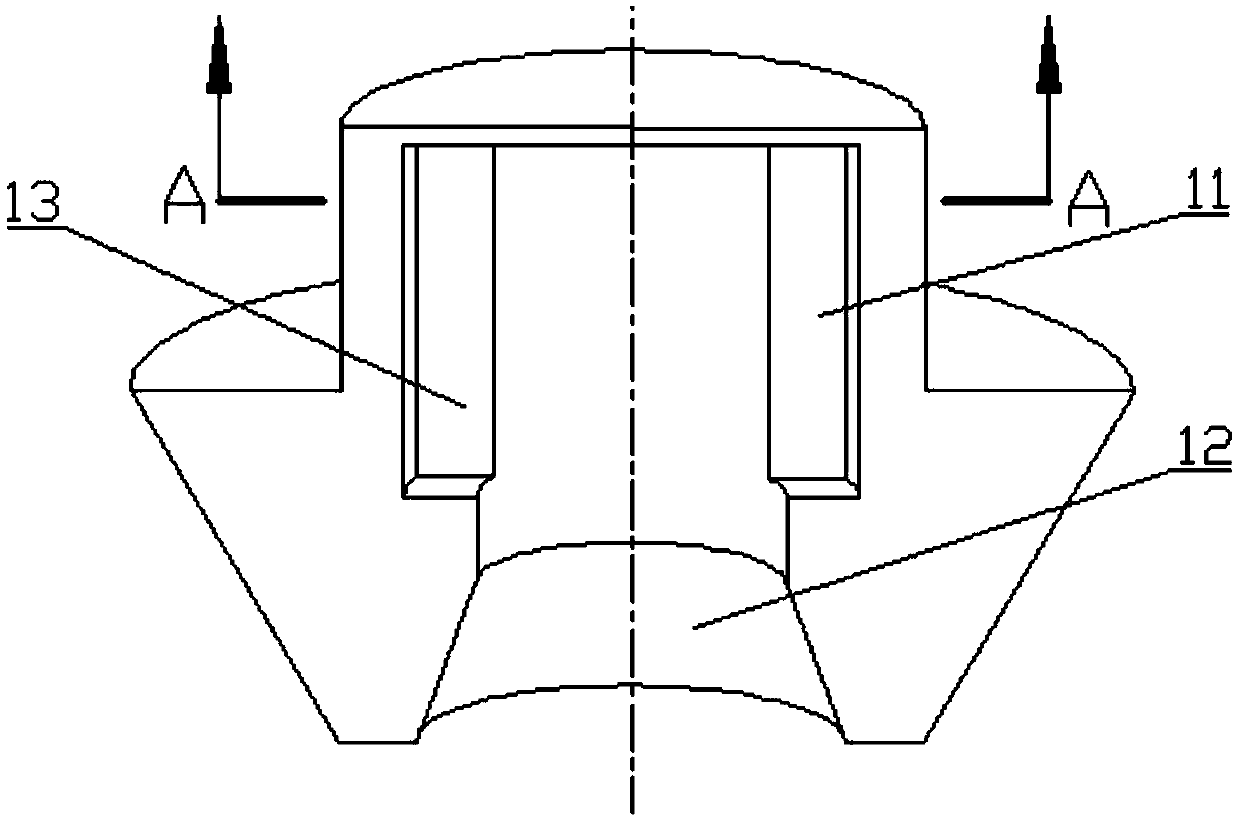

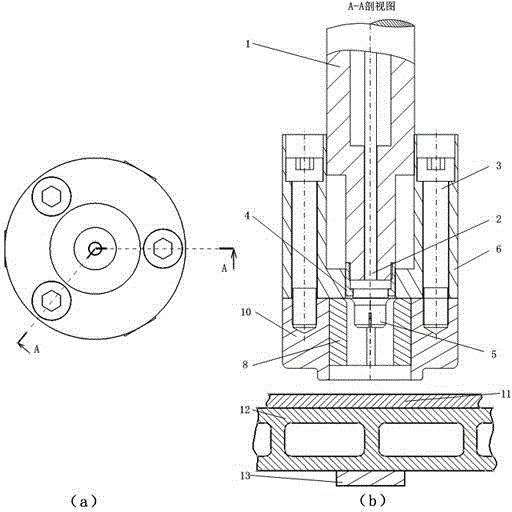

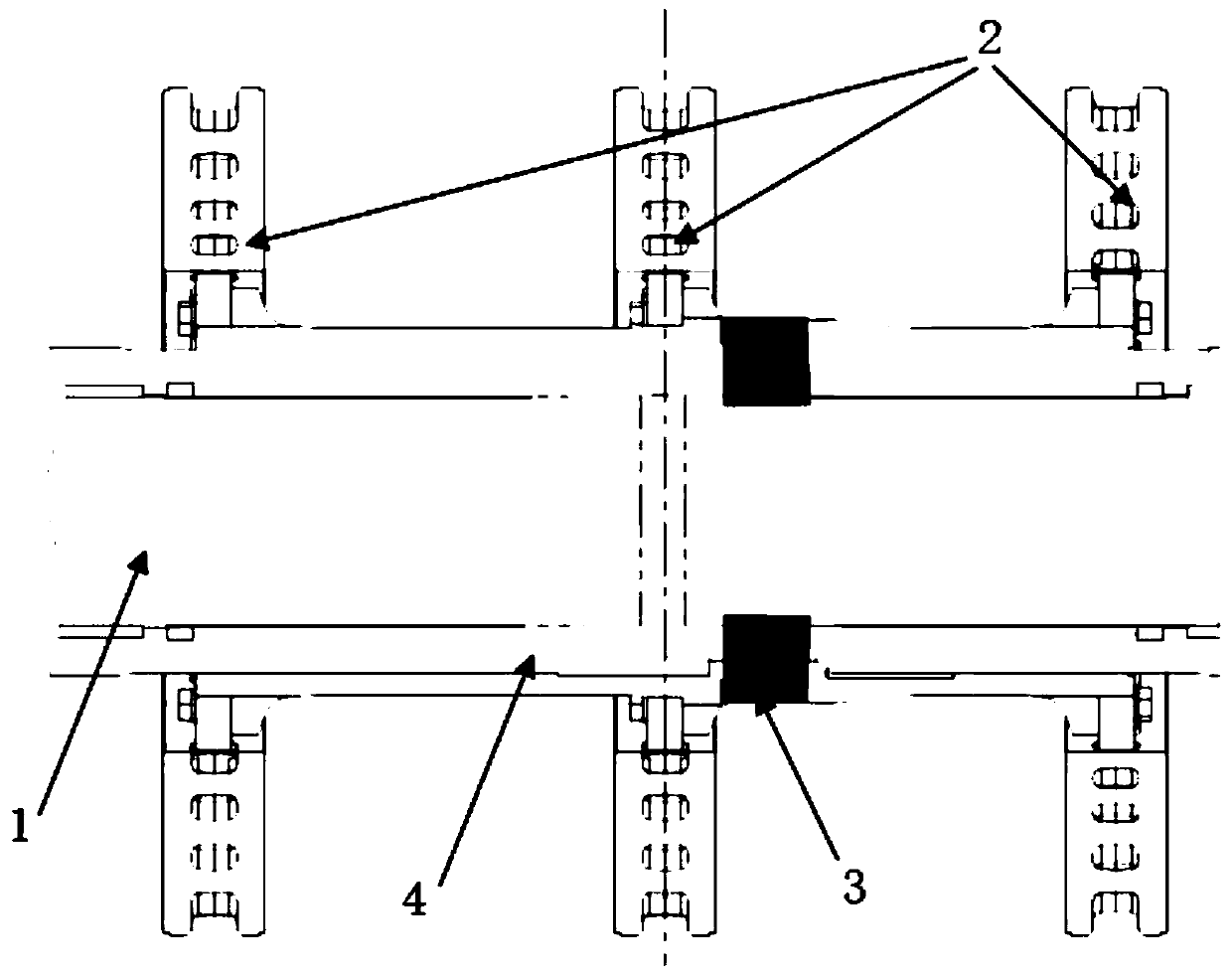

Connecting structure of shaft-mounted brake disc and disc hub of railway vehicle

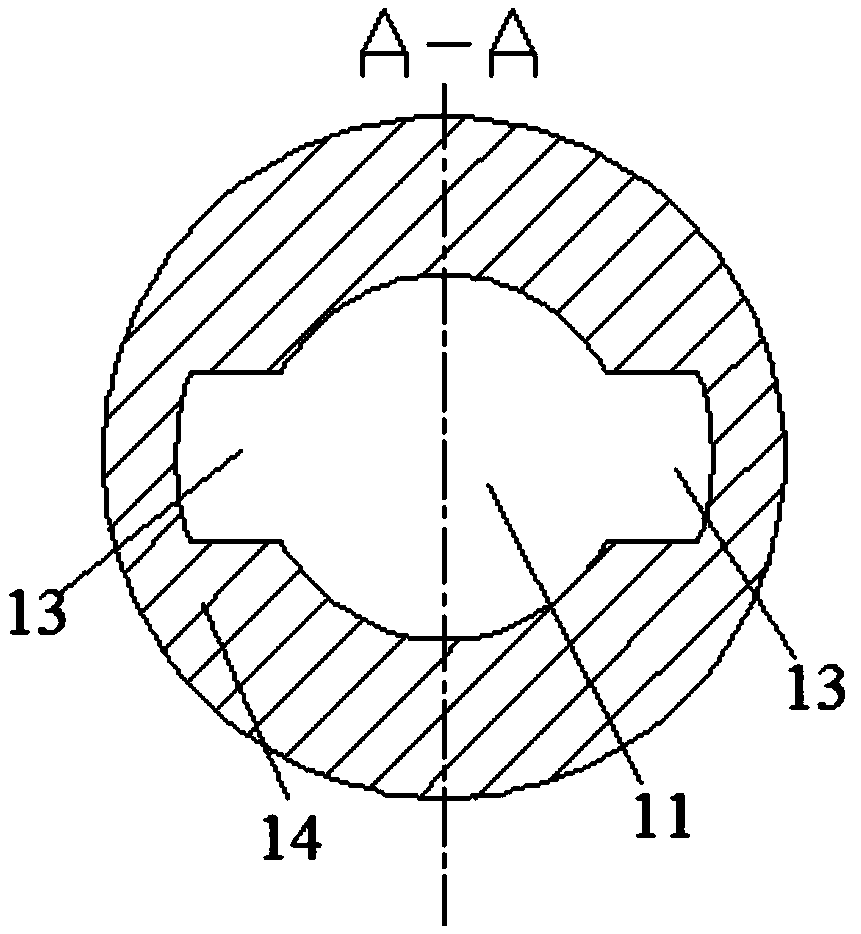

The invention discloses a shaft-mounted brake disc of a railway vehicle. The structure of a disc body (7) is the same as the structure of a disc body (8). The disc bodies form a whole through flanges (6), friction rings (5) and radiation ribs (13). Through holes are evenly distributed in the circumferential direction of each flange (6). The radiation ribs (13) are evenly distributed in the circumferential direction. Through holes are evenly distributed in the circumferential direction of a disc hub (9), and the number of the through holes is the same as the number of the through holes in the flanges (6). U-shaped grooves (14) are evenly distributed in the flanges (6) of the disc body (7) and the flanges (6) of the disc body (8) in the circumferential direction, and after the disc body (7) and the disc body (8) are buckled, circumferential fixing can be achieved by press fitting of pressing blocks (4) into the U-shaped grooves (14). Key grooves (10) are evenly distributed in the circumferential direction of the disc hub (9), the pressing blocks (4) are provided with through grooves (15), and the number of the pressing blocks (4) and the number of the U-shaped grooves (14) are the same as the number of the key grooves (10) in the disc hub (9). When the disc body (7) and the disc body (8) are installed on the disc hub (9), centering and circumferential positioning of the disc body (7) and the disc body (8) together with the disc hub (9) are achieved through the matching of the through grooves (15) in the pressing blocks (4) and positioning keys (12). Fastening bolts (11) sequentially penetrate through the disc hub (9), the disc body (8), the disc body (7), a pressing ring (3) and gaskets (2), and the disc hub (9), the disc body (7) and the disc body (8) can be fixed in the axial direction by connecting nuts (1) and the fastening bolts (11). The problems that an existing brake disc body and a disc hub are staggered and the brake torque can only be transmitted through friction force are solved.

Owner:BEIJING JIAOTONG UNIV

Axle-mounted brake device for gauge-changeable wheel set

ActiveCN108407845ARealize the braking effectAchieve circumferential positioningSelf-applying brakesVehicle brakeVehicle braking

The invention relates to the technical field of rail vehicle braking and discloses an axle-mounted brake device for a gauge-changeable wheel set. The axle-mounted brake device for the gauge-changeablewheel set comprises a transitional sleeve, a locating mechanism and a plurality of axle-mounted brake discs; the plurality of axle-mounted brake discs are fixed on the transitional sleeve at intervals; the transitional sleeve is connected with an axle of the gauge-changeable wheel set through a spline in a matched manner; and the locating mechanism is used for connecting the transitional sleeve with the axle so as to axially locate the transitional sleeve relative to the axle. According to the axle-mounted brake device for the gauge-changeable wheel set, by improving the connection modes between the axle-mounted brake discs and the axle, the relative positions of a brake clamp and the axle-mounted brake discs can be kept invariable during changing the gauge so that braking effects at different gauges are realized.

Owner:CRRC QINGDAO SIFANG CO LTD

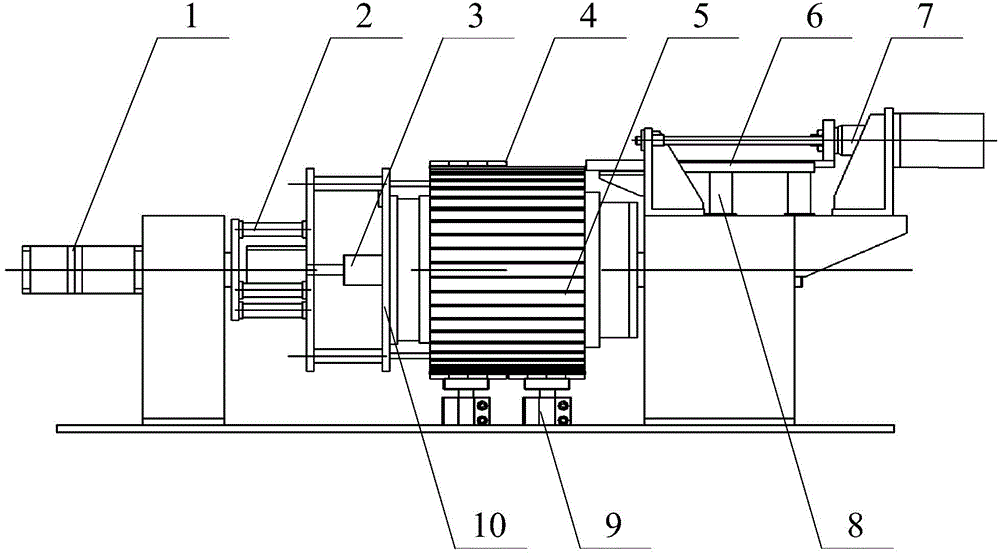

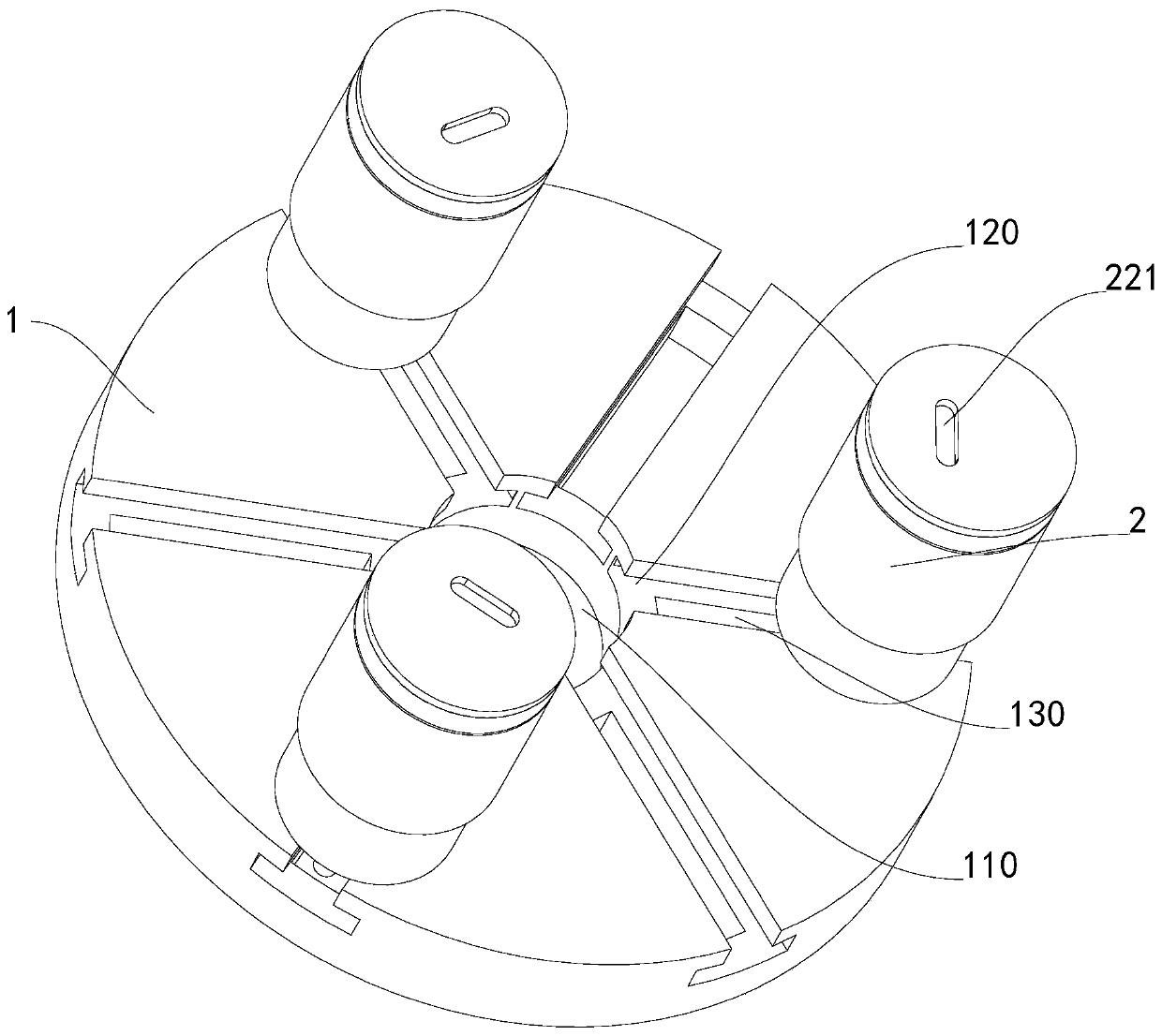

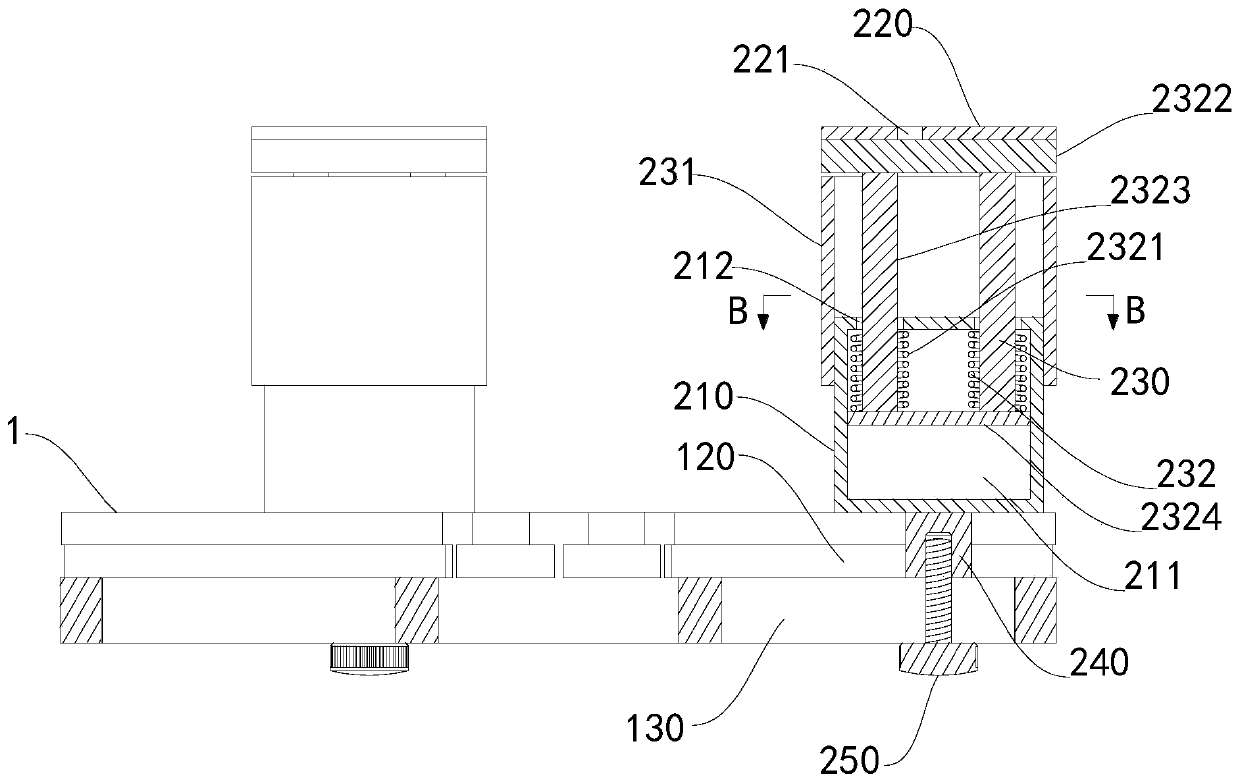

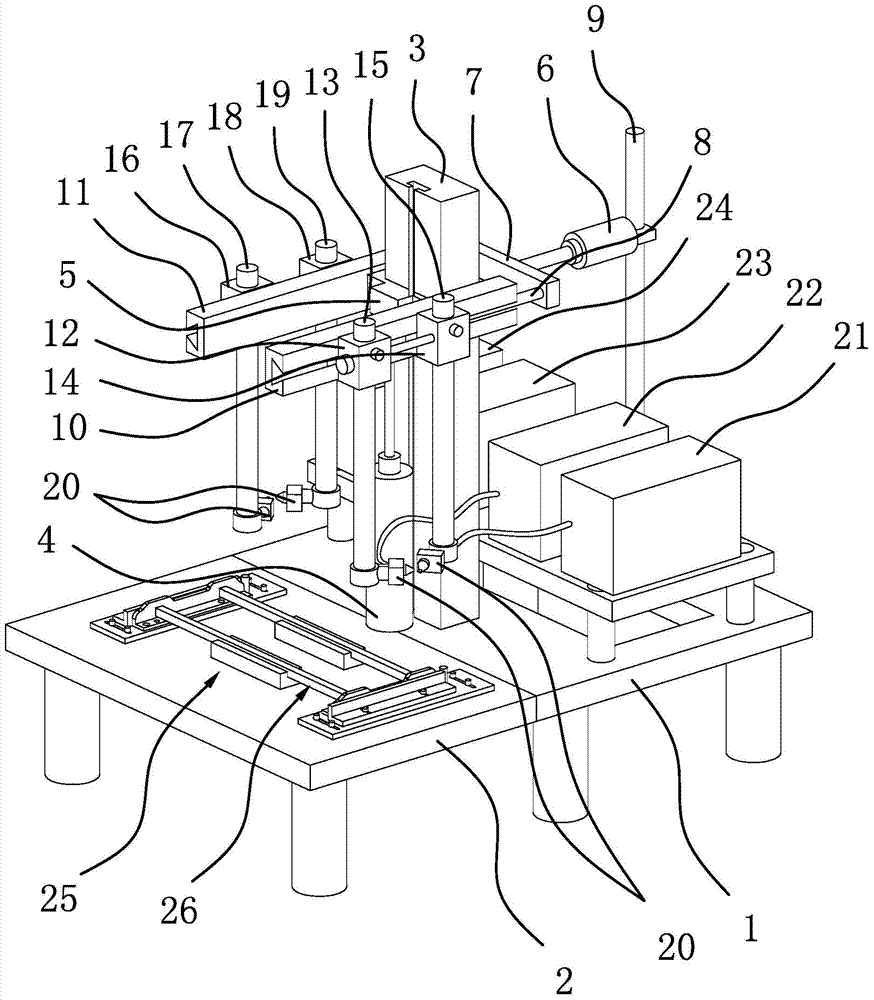

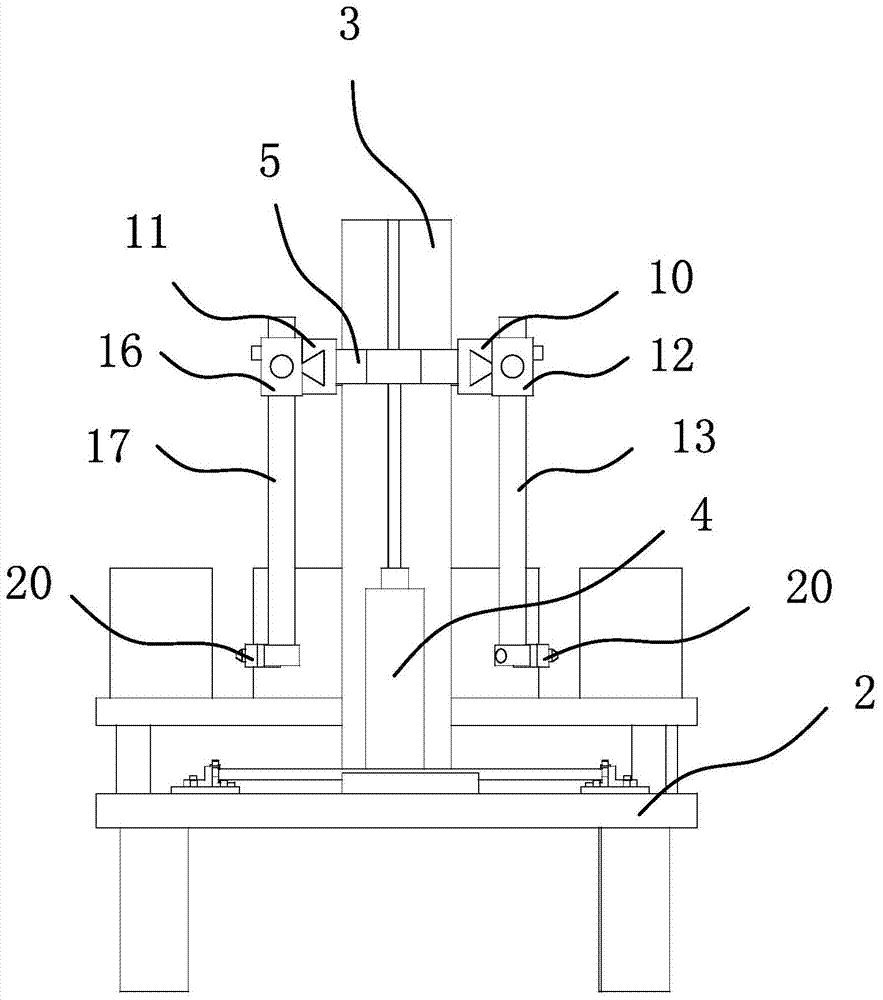

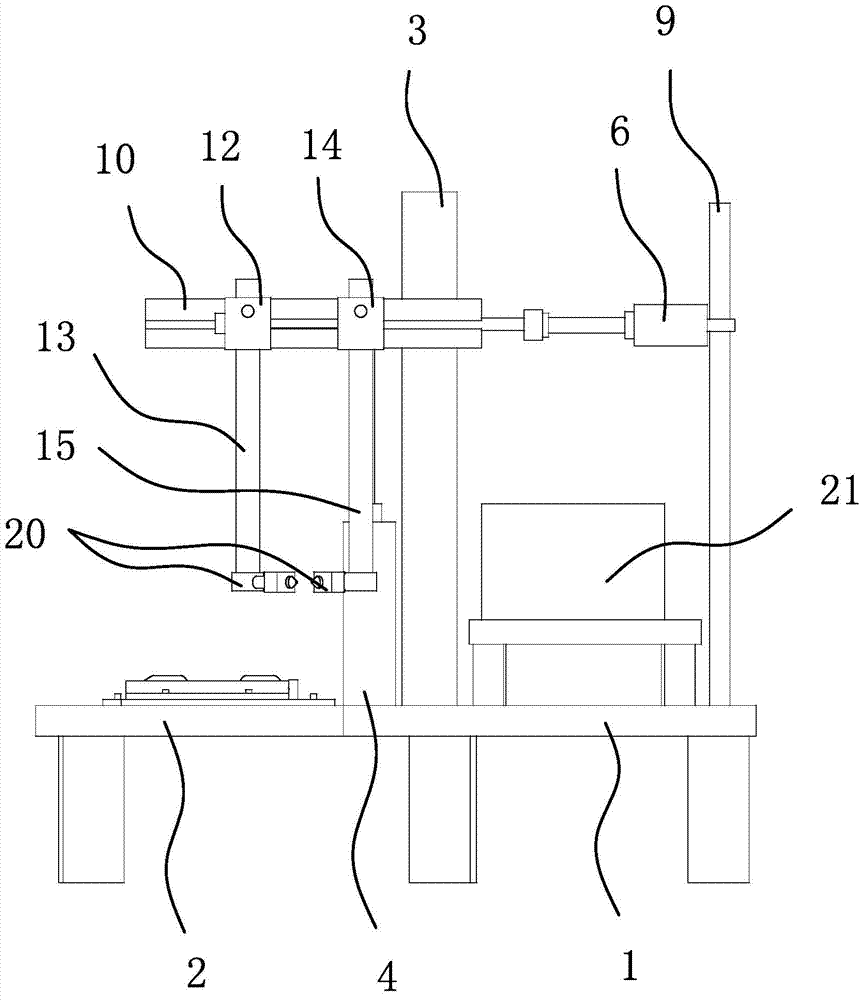

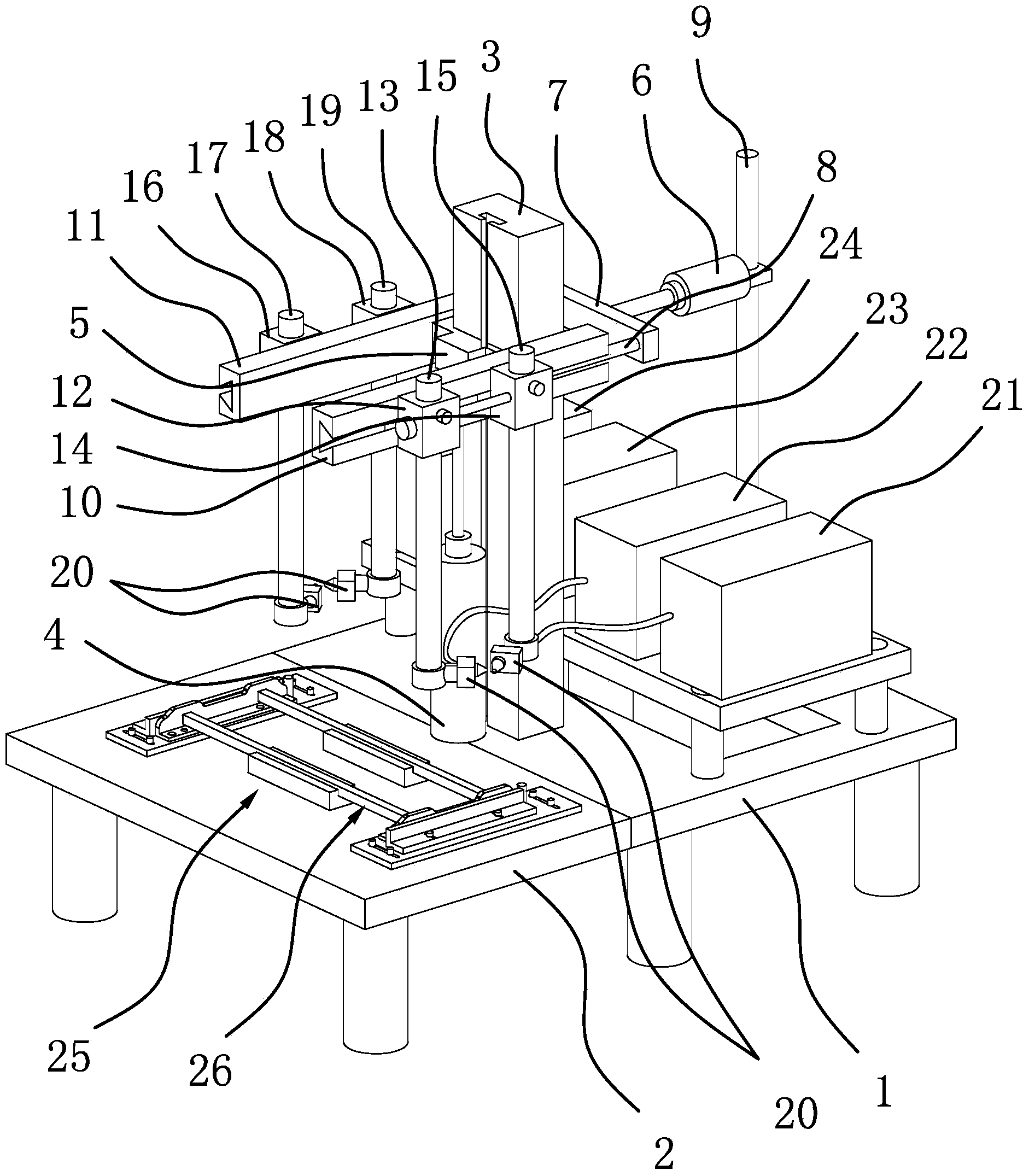

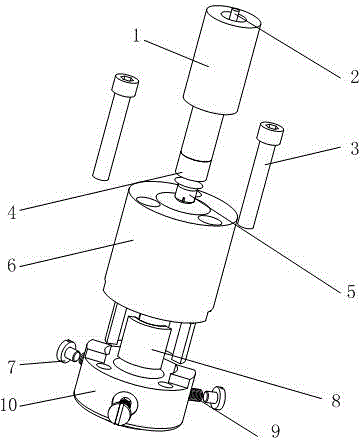

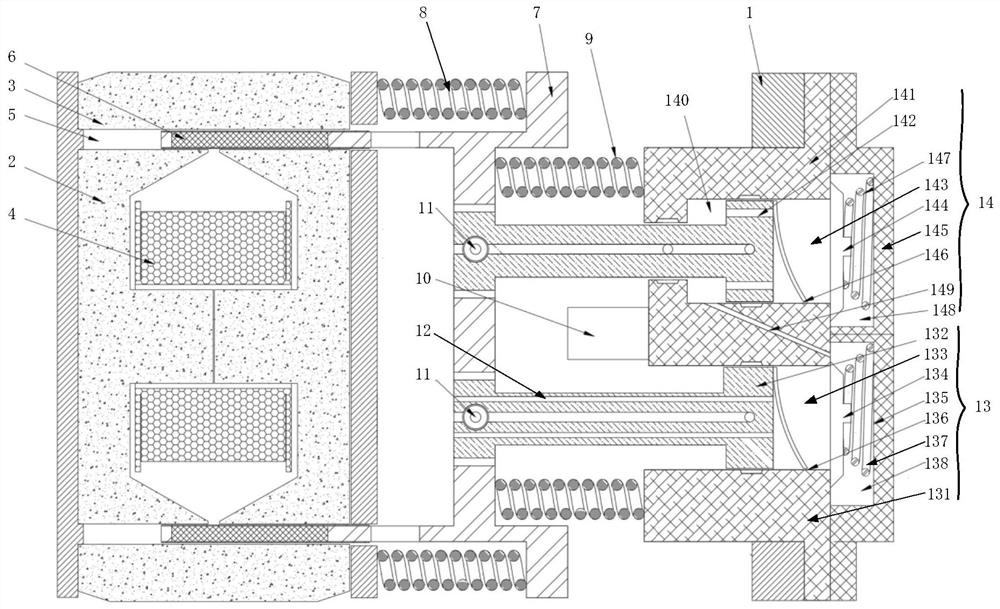

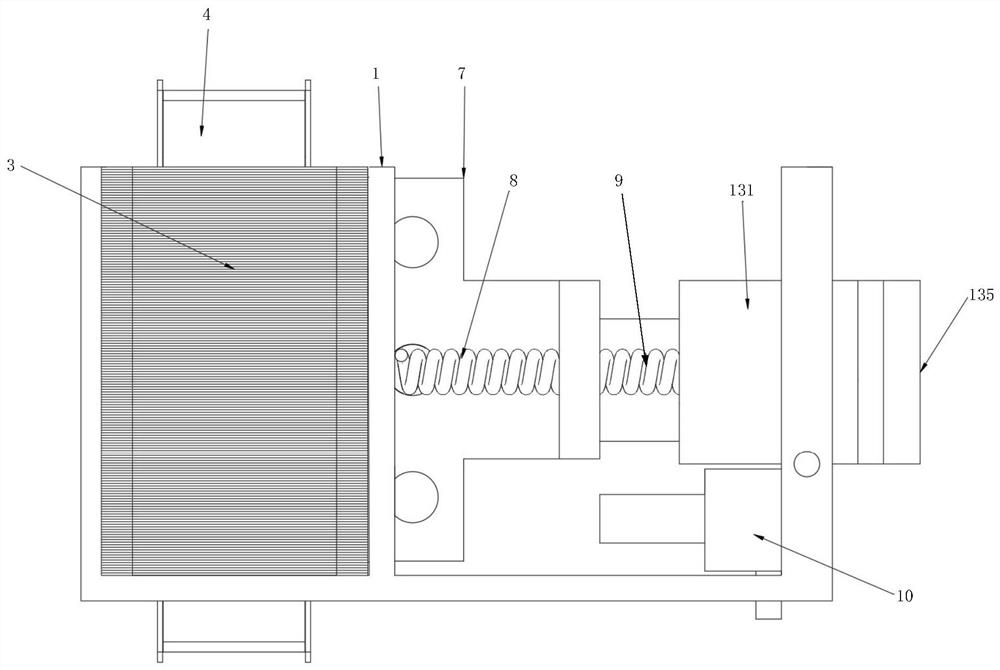

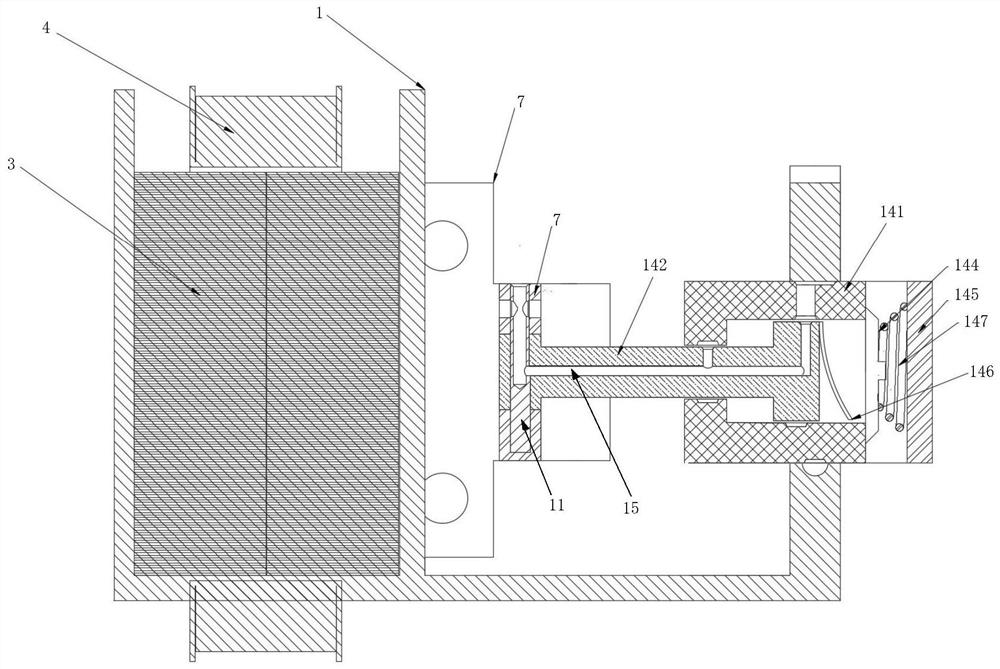

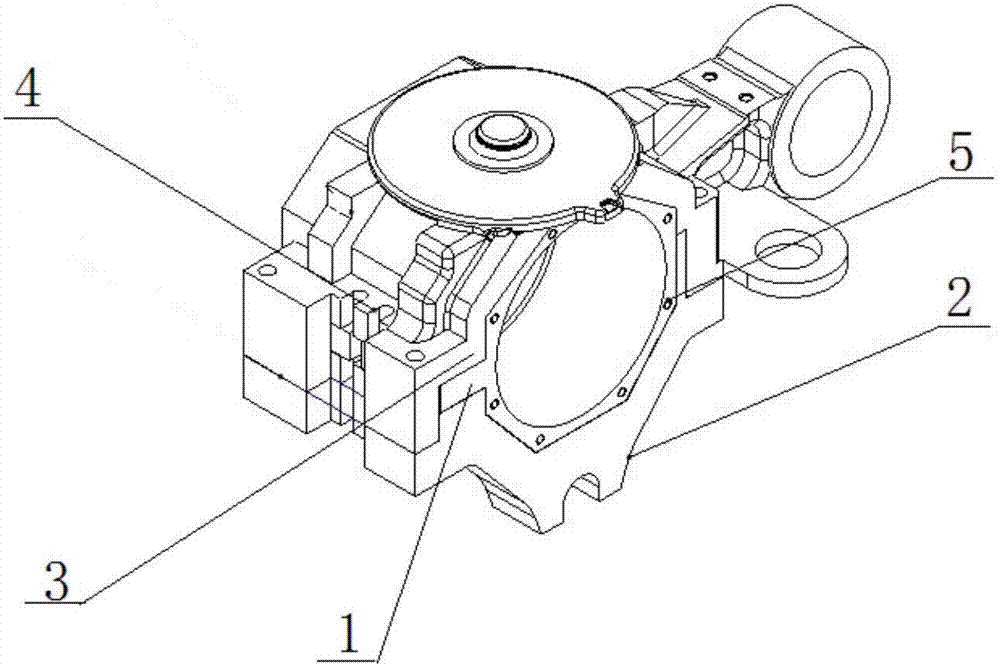

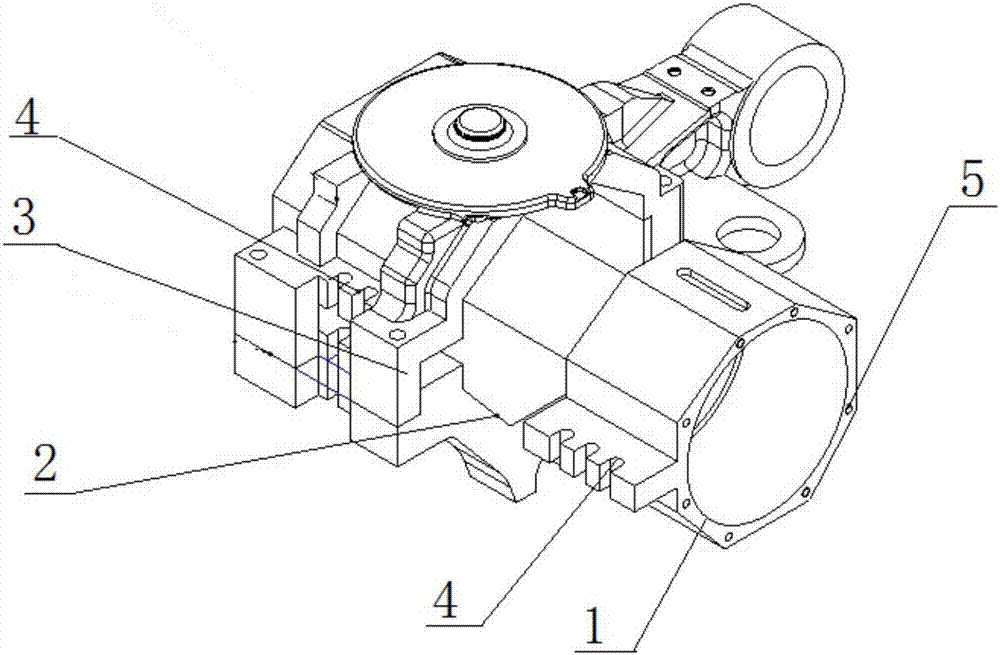

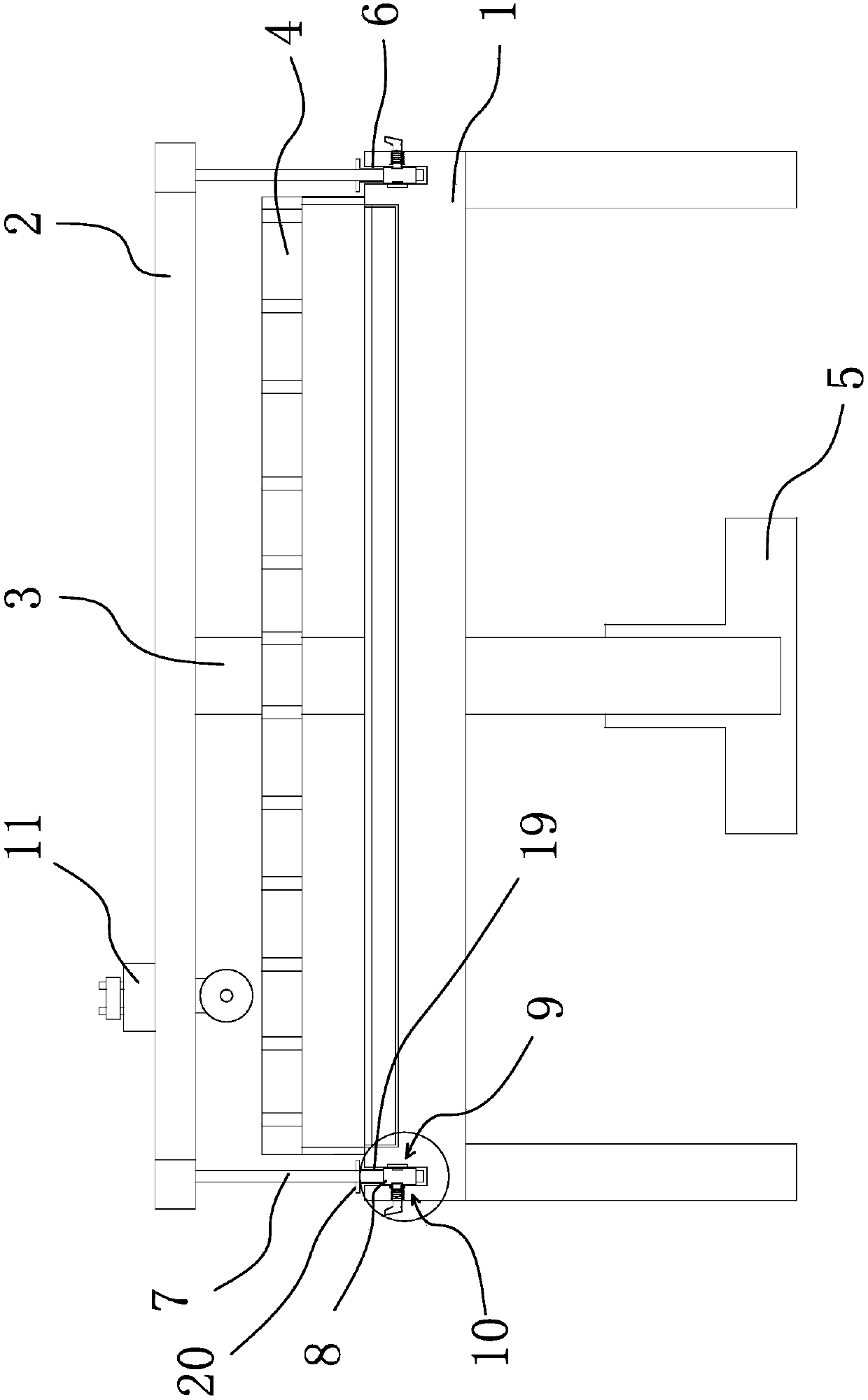

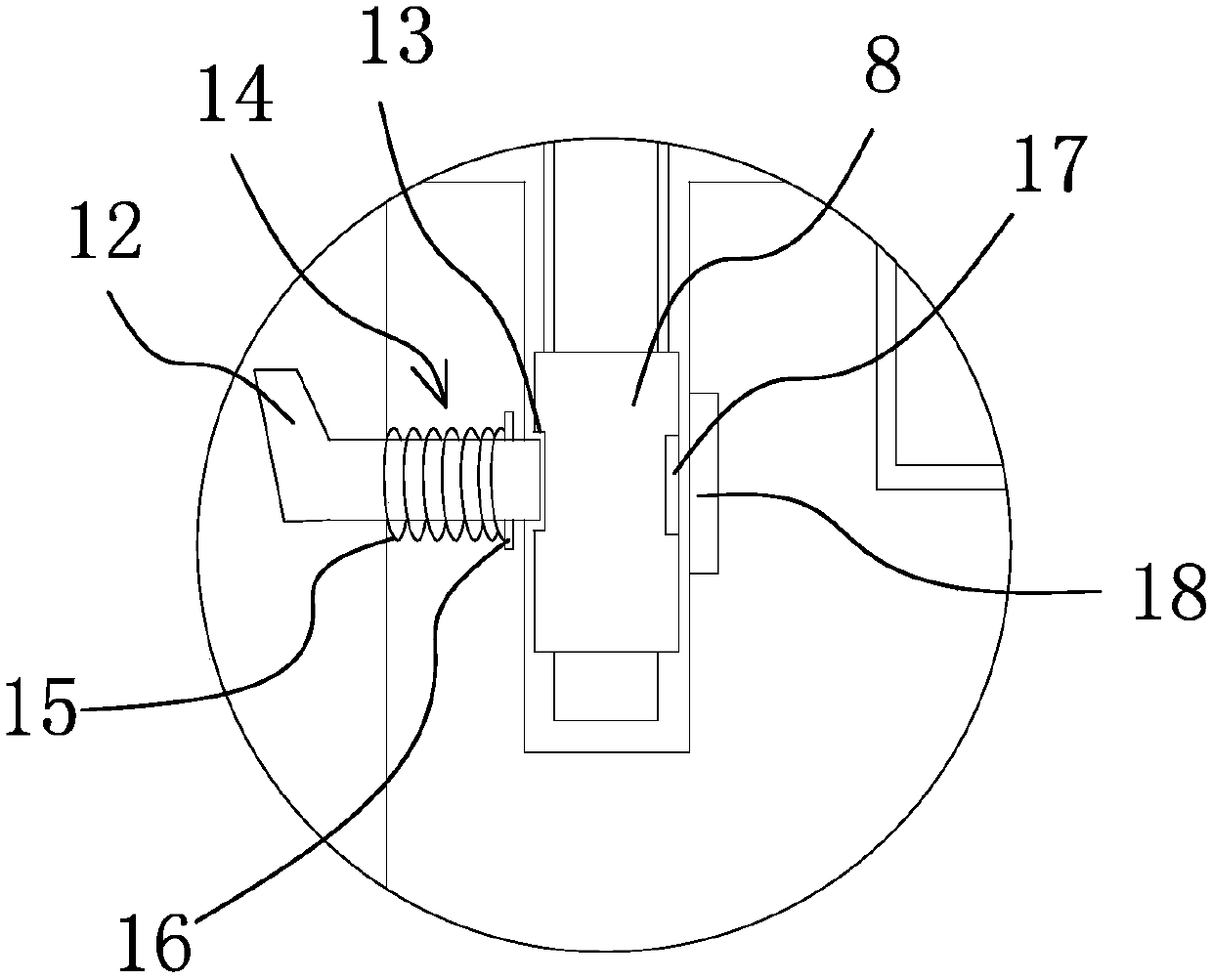

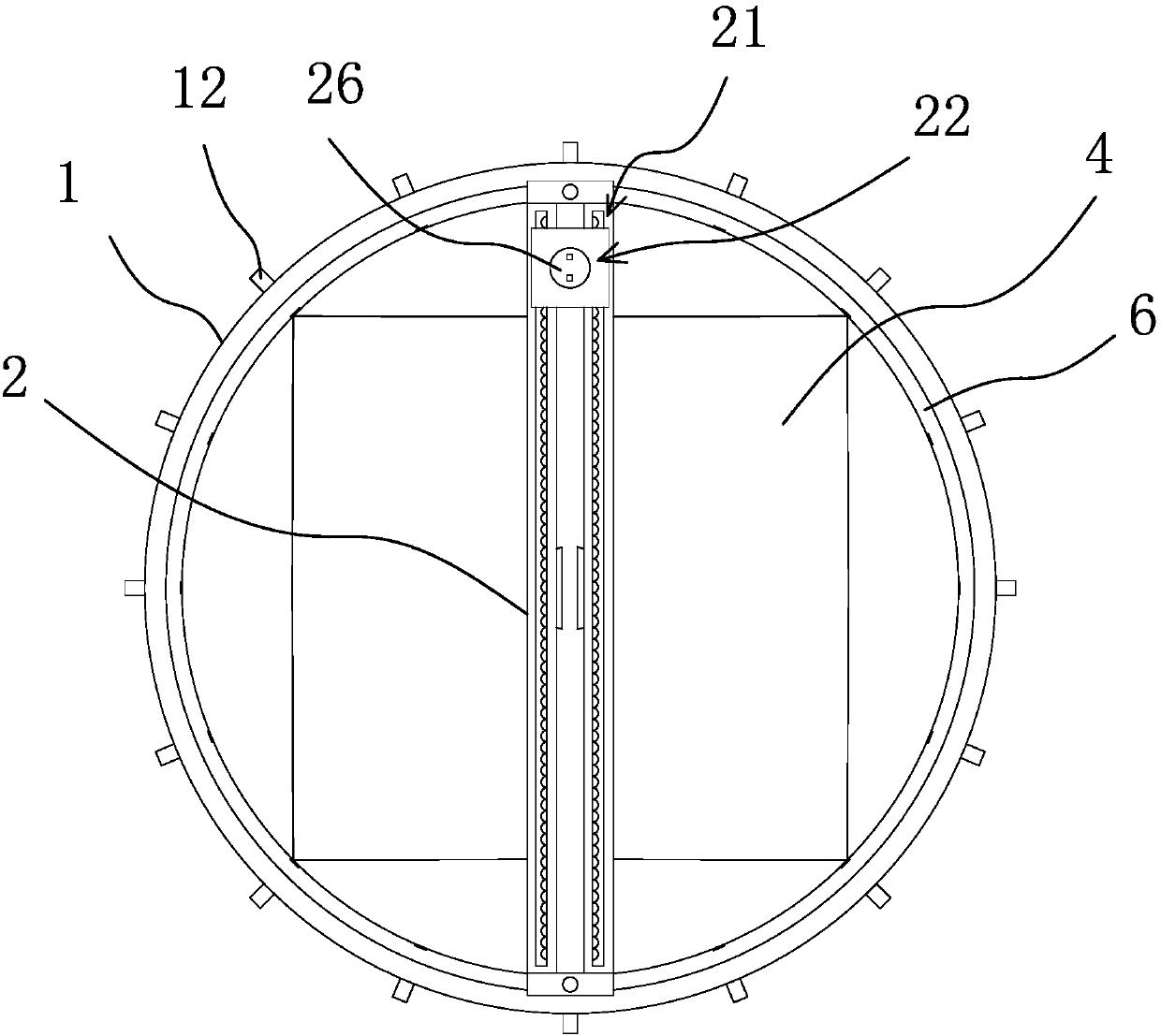

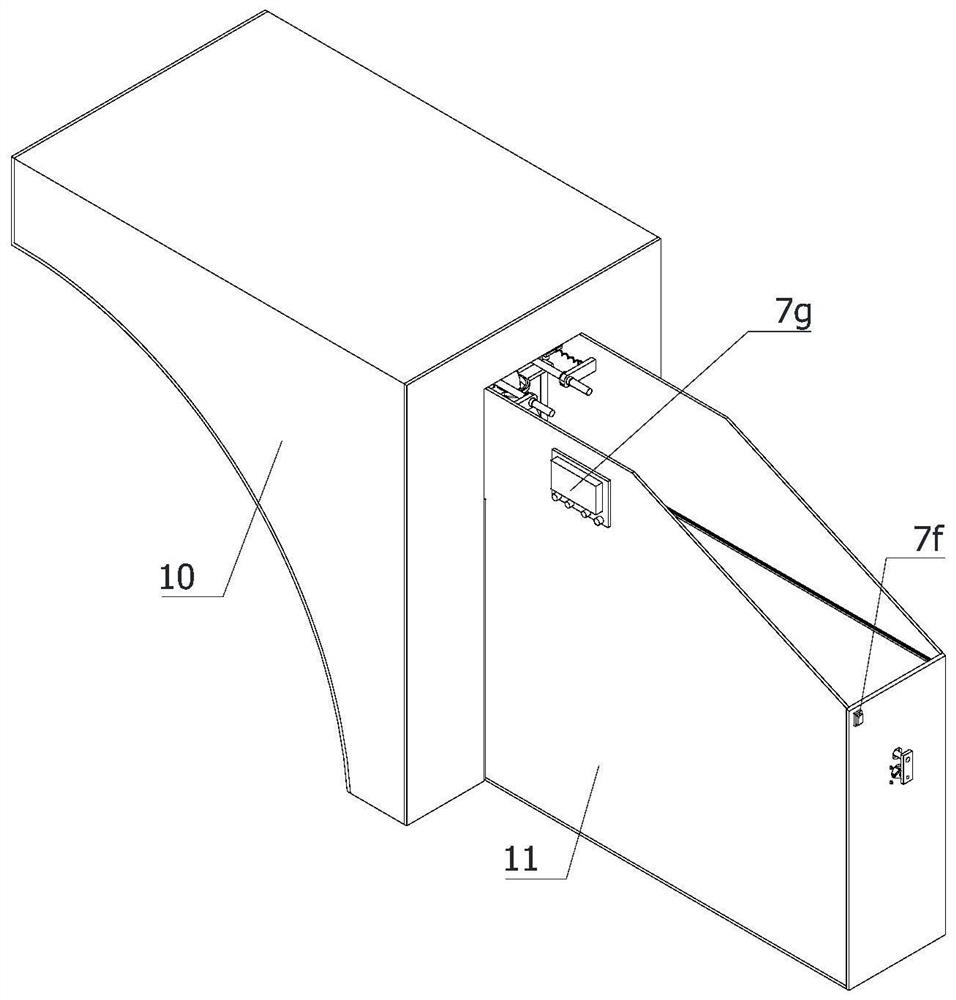

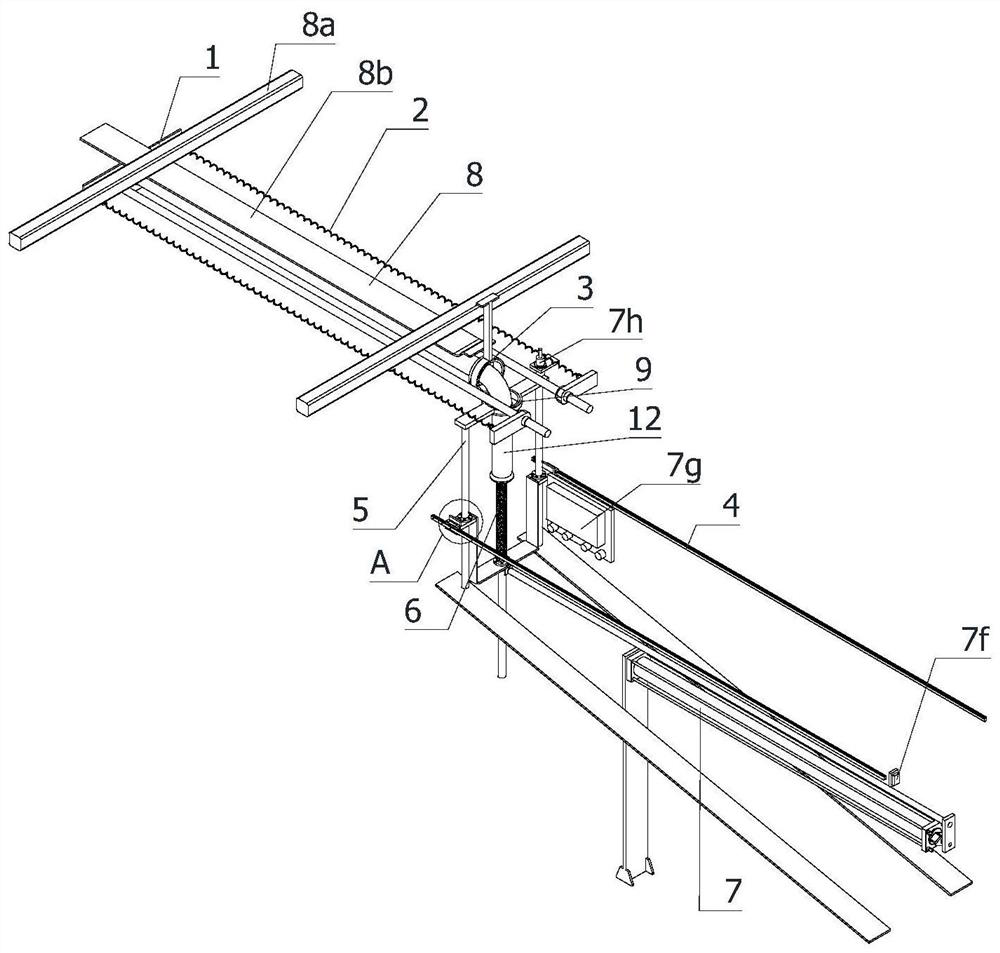

Magnetic pole installing device for surface-mounted permanent magnet motor

ActiveCN104993656ASimplify the pole assembly processImprove installation accuracyMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringElectrical and Electronics engineering

The invention provides a magnetic pole installing device for a surface-mounted permanent magnet motor. The magnetic pole installing device comprises a locating mechanism (10) locating and fixing a rotor core (5), an indexing mechanism (1) driving the rotor core (5) to rotate and setting the angle, a guide mechanism (6) holding magnetic poles (4) and aligning the magnetic poles (4) and magnetic pole grooves of the rotor core (5), and a power pushing mechanism (7) pushing the magnetic poles (4) to install the magnetic poles in the magnetic pole grooves. The indexing mechanism (1) and the rotor core (5) rotate in linkage. The magnetic pole installing device effectively solves such problems as great difficulty in surface-mounted permanent magnet motor magnetic pole installing and low surface-mounted permanent magnet motor magnetic pole installing accuracy.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

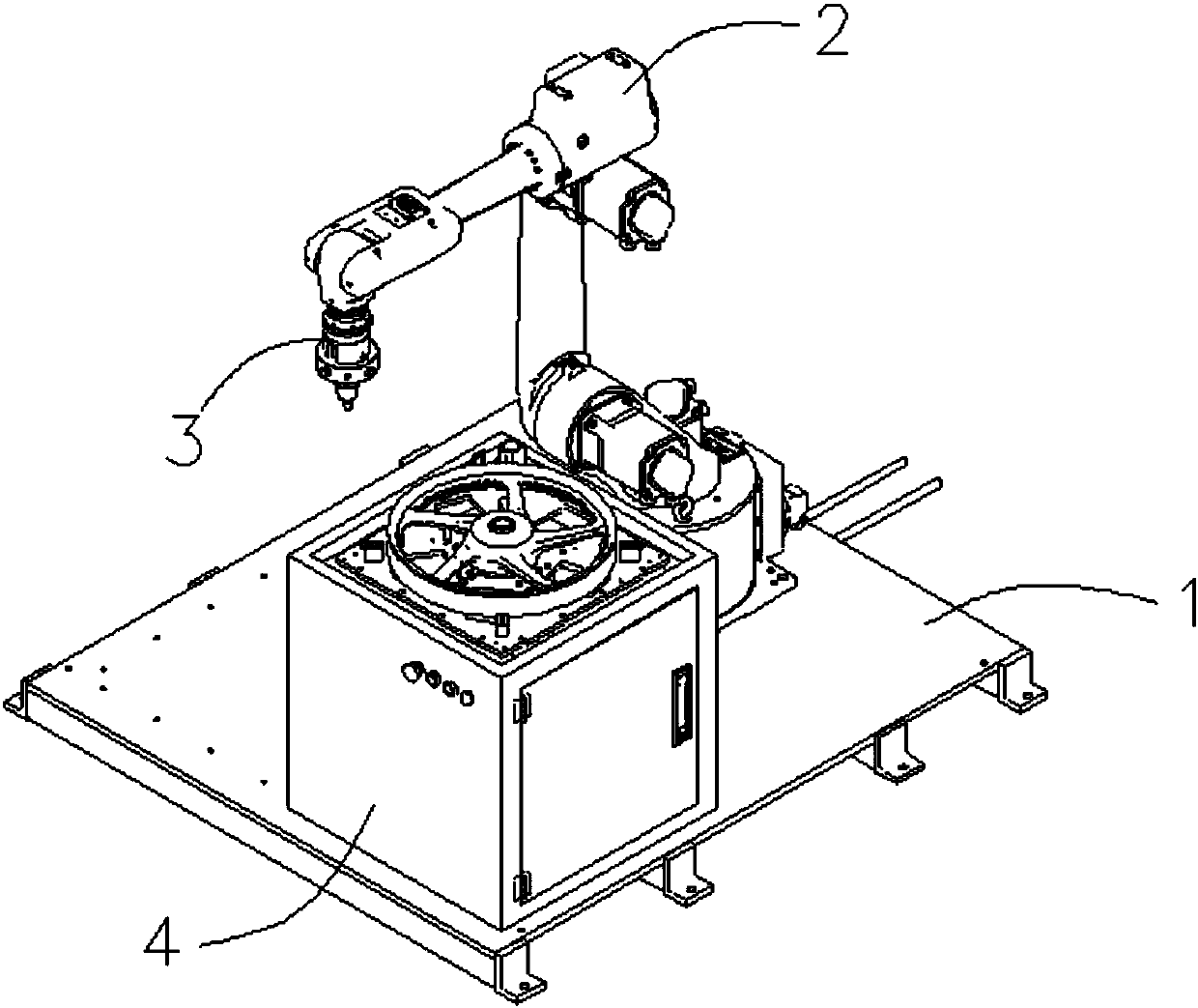

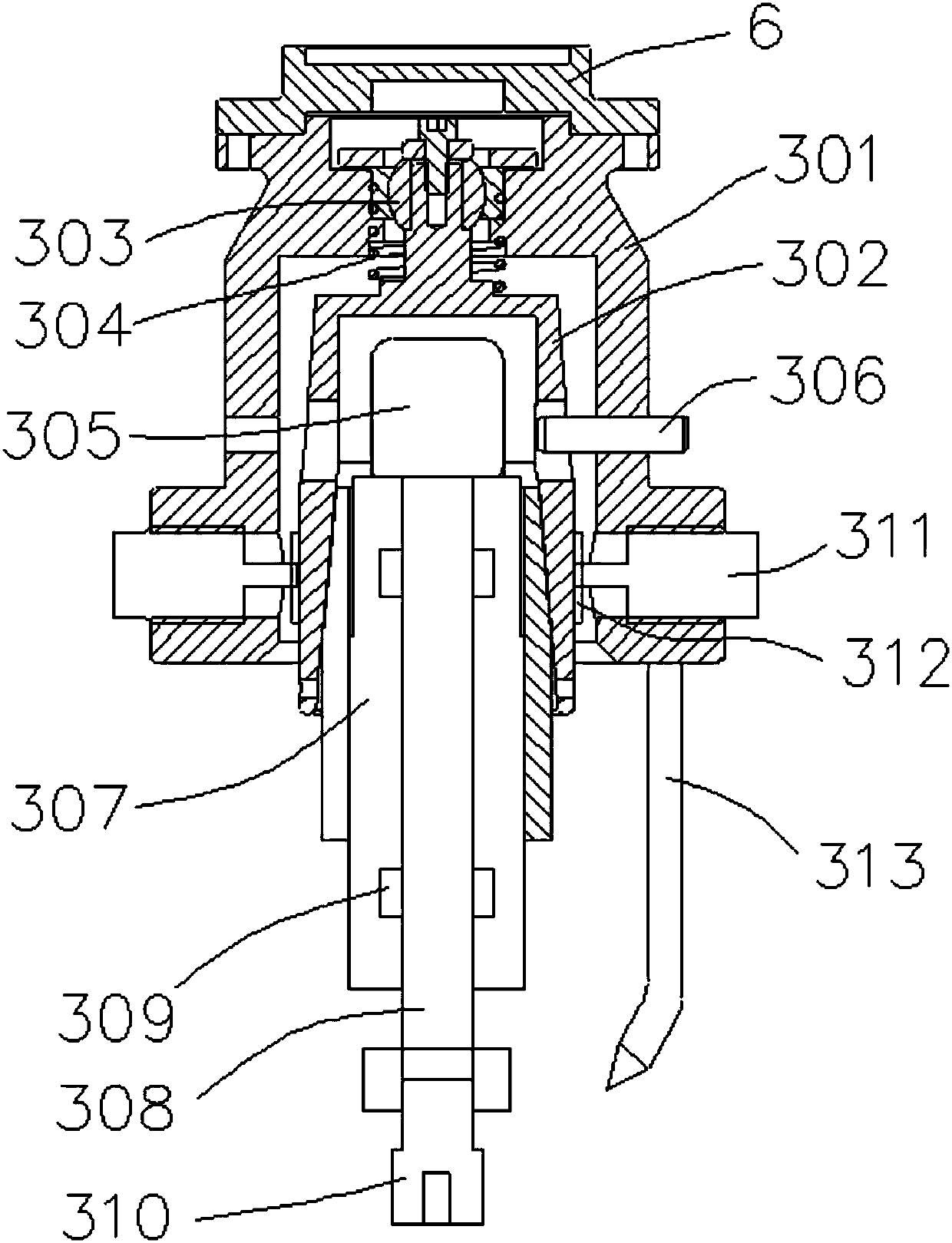

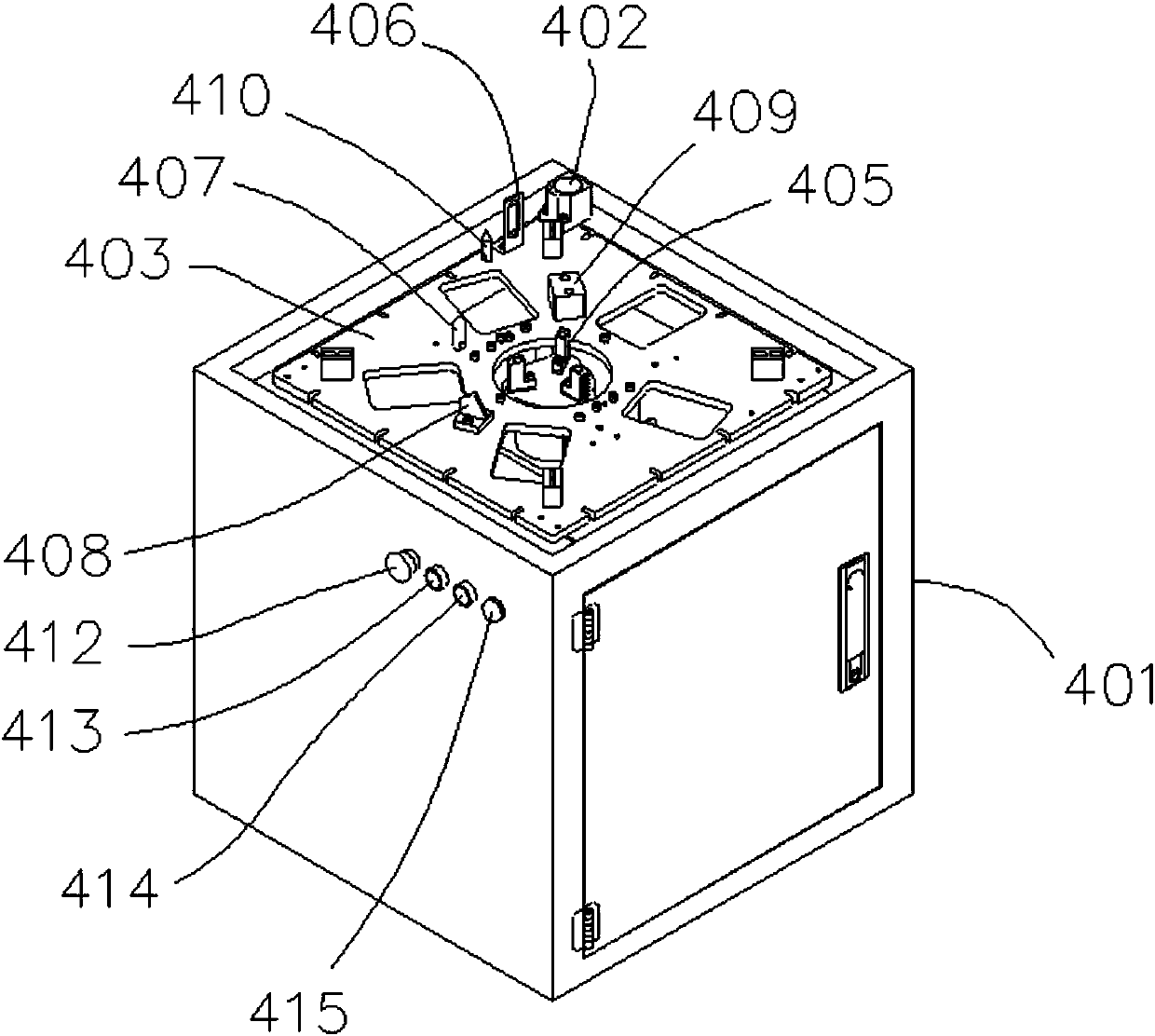

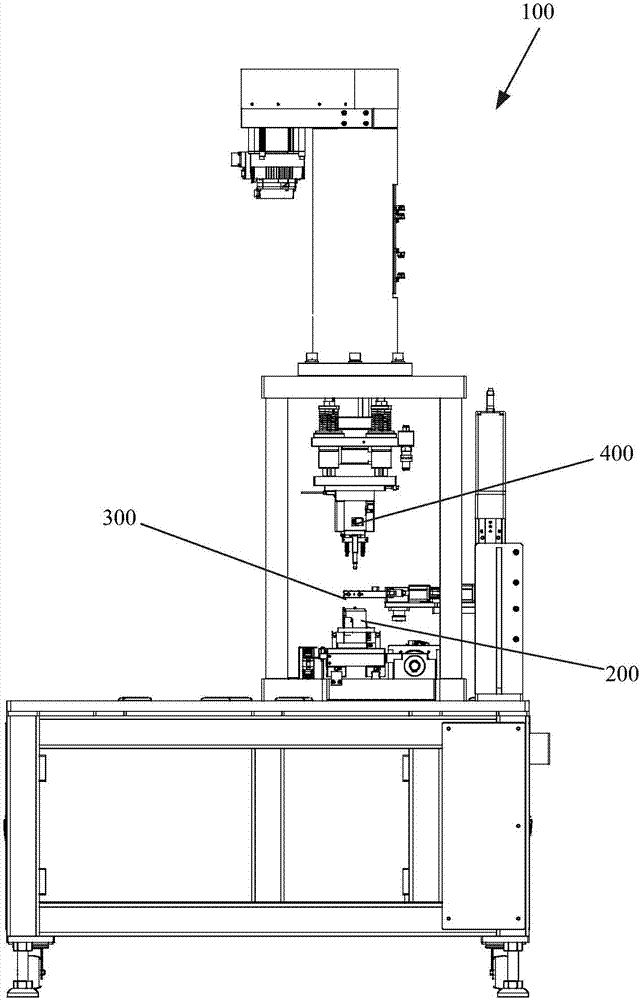

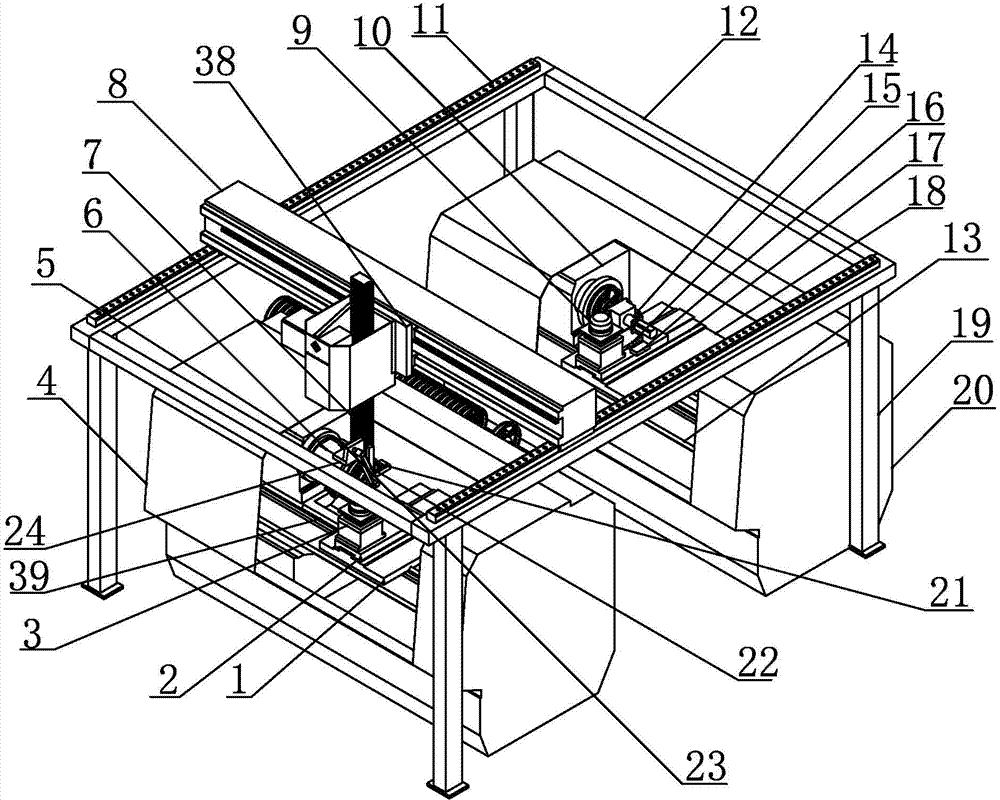

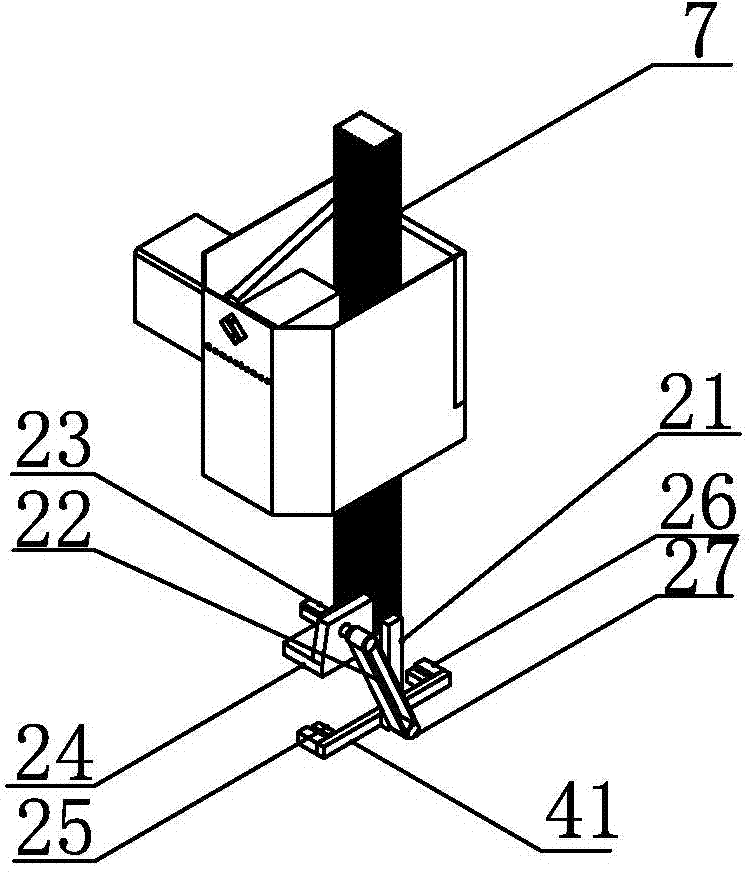

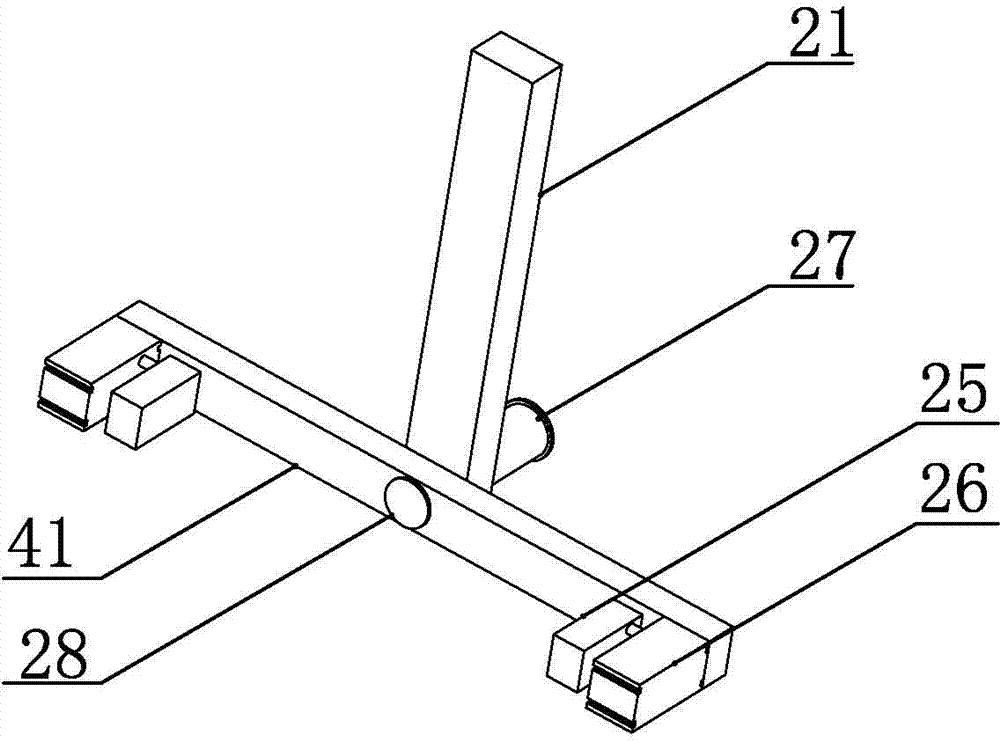

Multifunctional burr removing equipment

PendingCN107775023AImprove deburring efficiencyImprove transmission efficiencyAutomatic control devicesMeasurement/indication equipmentsControl engineeringVisual recognition

The invention relates to multifunctional burr removing equipment. The multifunctional burr removing equipment comprises a base, a robot, a floating burr removing device, a clamping device and a visualrecognition device, wherein the robot and the clamping device are both fixed at the upper end of the base; the floating burr removing device is vertically arranged at the tail end of the robot and connected with the tail end of the robot through a flange plate; the floating burr removing device is driven by the robot to move to the upper end of the clamping device and removes burrs of a workpiececlamped by the clamping device; the visual recognition device is connected with the floating burr removing device, and a signal output end of the visual recognition device is connected with a signalinput end of the robot through a line. Compared with the prior art, the multifunctional burr removing equipment can drive the floating burr removing device to precisely remove burrs on the workpiece according to recognition signals of the visual recognition device, and the burr removing efficiency is improved.

Owner:CHONQING HUASHU ROBOT CO LTD

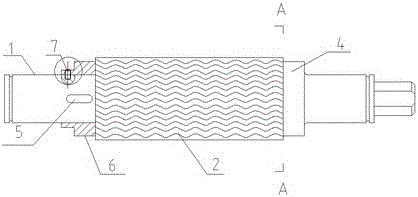

Combined type roller for rolling wave form corrugated composite boards

InactiveCN106734214ASolve deviationIncrease contact areaRollsMetal rolling arrangementsWave formComposite slab

The invention discloses a combined type roller for rolling wave form corrugated composite boards and belongs to the technical field of rollers. The combined type roller for rolling wave form corrugated composite board belts comprises a roller shaft, a roller shell, a spline, a flat key, a locking check ring and a screw. The combined type roller is structurally characterized in that an external spline is arranged on the roller shaft, an internal spline groove is formed in the roller shell, the roller shell is arranged on the roller shaft, the spline plays a role in positioning and is a rectangular spline, the outer surface of the roller shell is in a wave form corrugation shape, the metal composite board belts with wave form corrugation can be rapidly rolled, the contact area of a metallic matrix can be increased by using the wave form corrugation roller for making blanks, the combination strength of composite board interfaces can be enhanced, and the recombination rate of composite board interfaces can be increased; a step-shaped shaft shoulder is arranged at one end of the roller shaft and axially fixes the roller shell; and locking positioning, in the axial and radial directions of the roller shaft, of the other end of the roller shell is achieved through the cooperation of the flat key, the locking check ring and the screw. According to the combined type roller, the centring precision of the roller is high, the stability of centring is extremely high, axial roller shifting is prevented, the roller shell can be rapidly dismounted, and the assembling period of the combined type roller is shortened.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

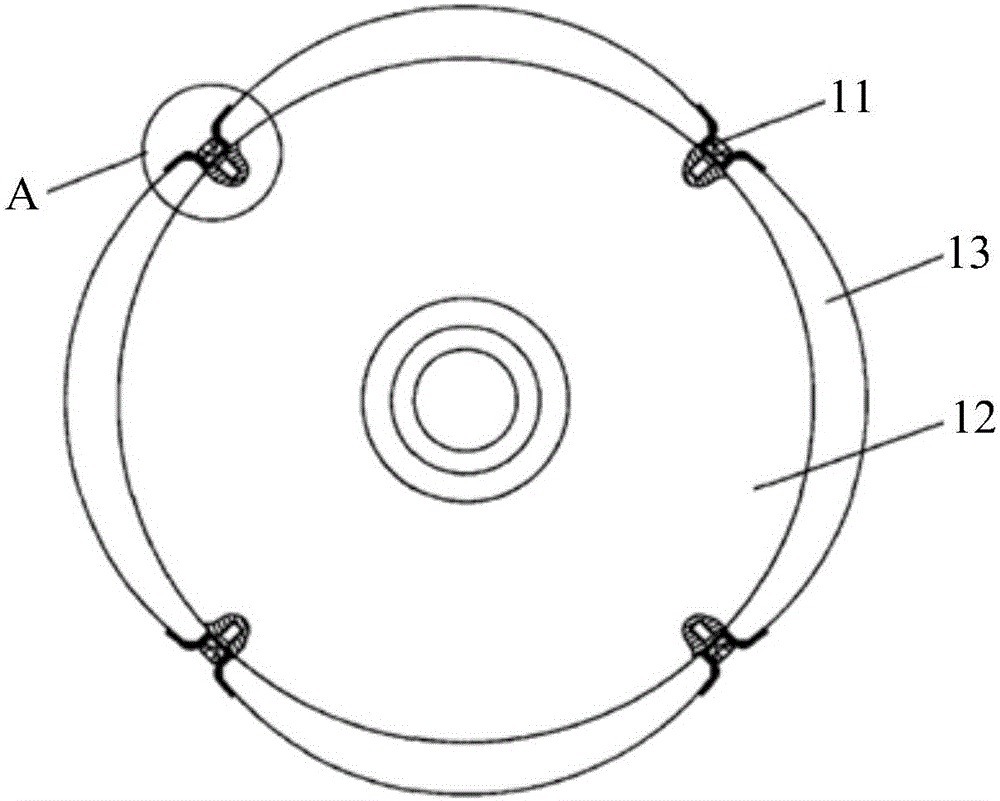

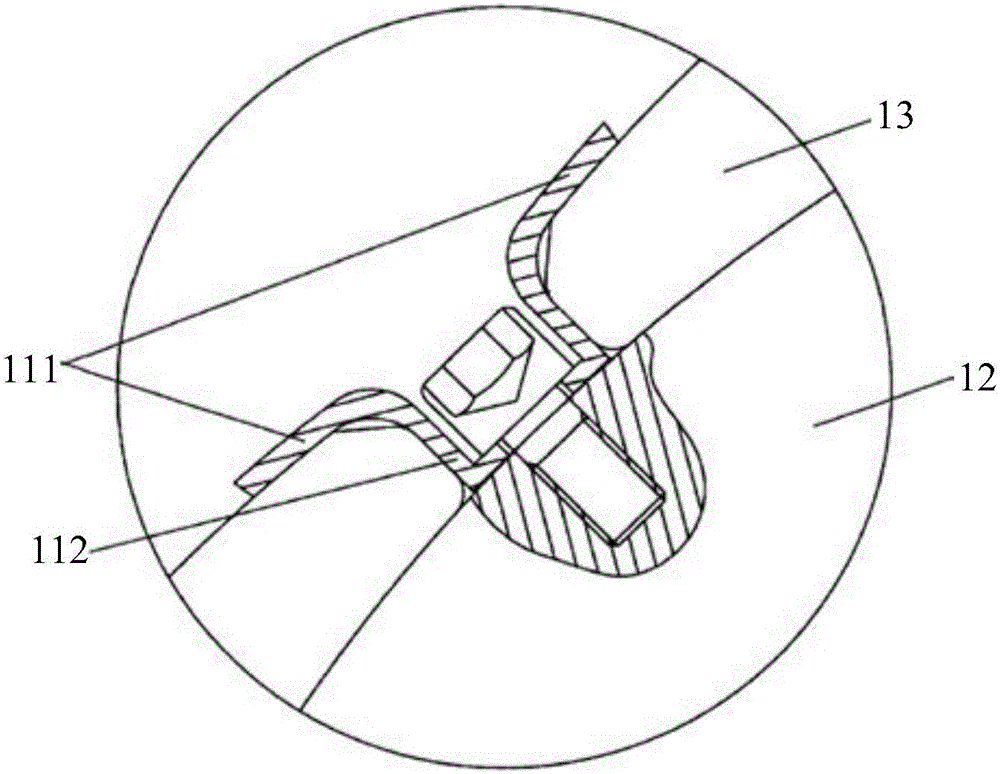

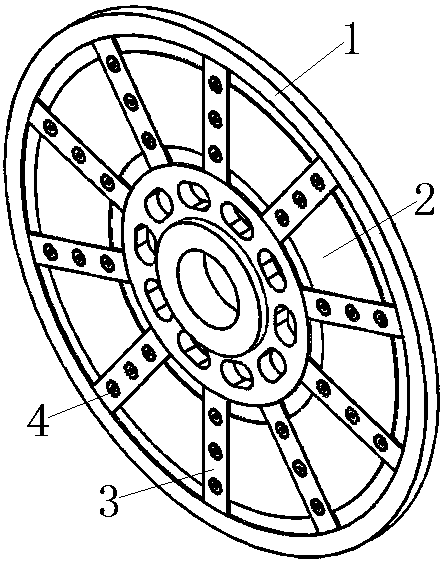

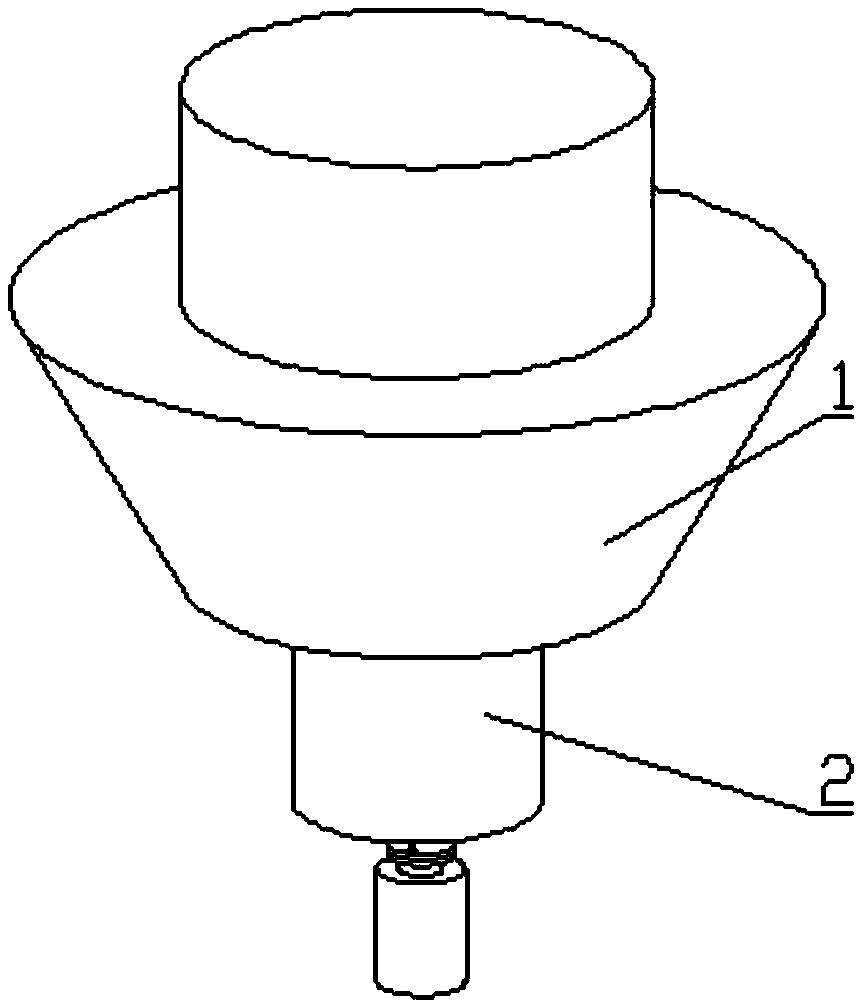

Rotor for disk motor, disk motor and vehicle

PendingCN109639003AAchieve circumferential positioningEasy assemblyMagnetic circuit rotating partsEngineeringFastener

The present invention relates to a rotor for a disk motor, the disk motor and a vehicle. The rotor for the disk motor comprises a rotor bracket, a plurality of magnetic steel grooves for mounting magnetic steels are circumferentially distributed on the rotor bracket, the magnetic steels are installed in the magnetic steel grooves, a pressing fixing member is arranged between two adjacent magneticsteels and has an overhanging pressing portion for pressing two adjacent magnetic steels, and the pressing fixing member is fixedly connected to the rotor bracket through a fastener. According to therotor for the disk motor, the pressing fixing member is arranged between the adjacent magnetic steels and has the overhanging pressing portion for pressing the two adjacent magnetic steels, the circumferential direction positioning of the magnetic steels is achieved by the magnetic steel grooves, the axial positioning of the magnetic steels is achieved by the magnetic steel grooves and overhangingpressing portions of pressing fixing members, the assembly method is simple, the matching surfaces of the magnetic steel grooves, the magnetic steels and the pressing fixing members are straight, theprocessing technology is simple, and the accuracy can be guaranteed.

Owner:SANMENXIA SUDA TRANSPORTATION ENERGY SAVING TECH

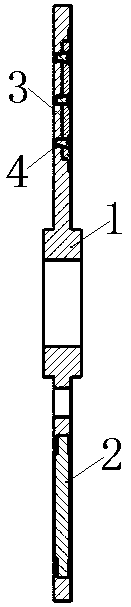

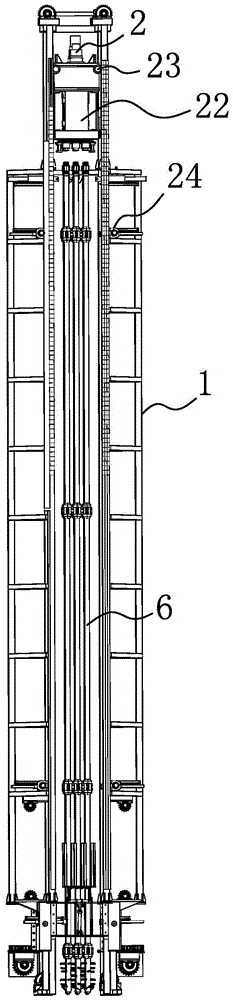

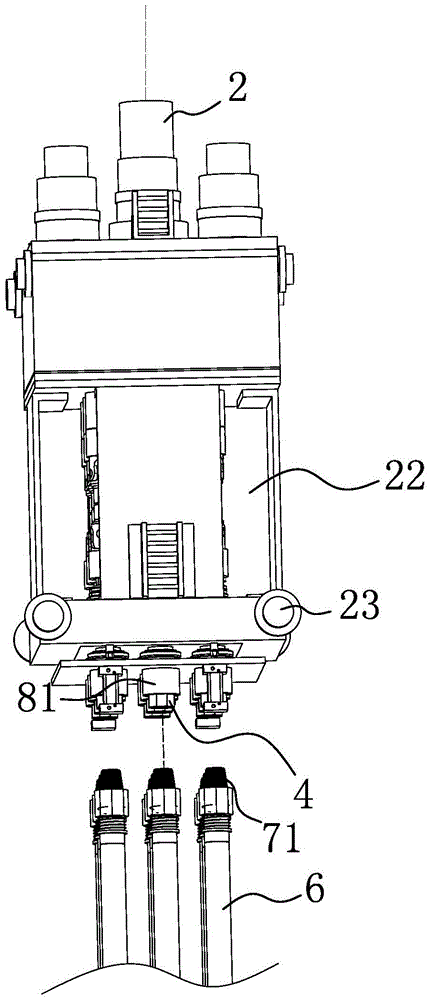

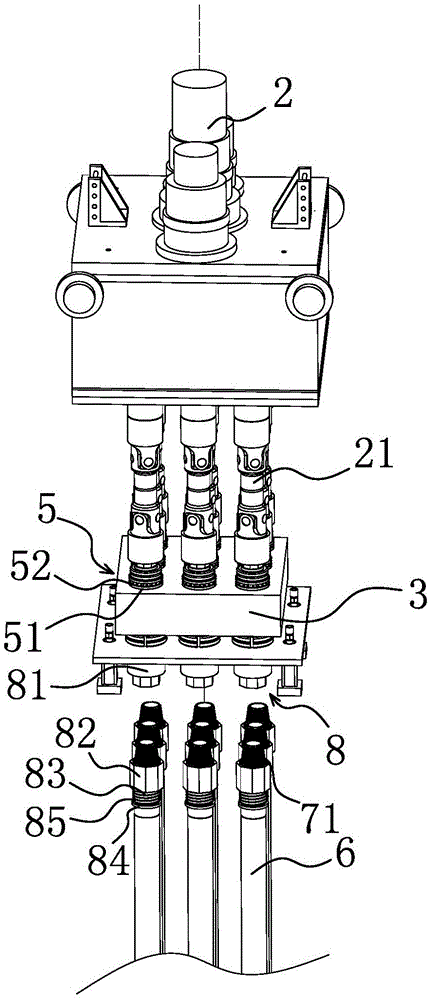

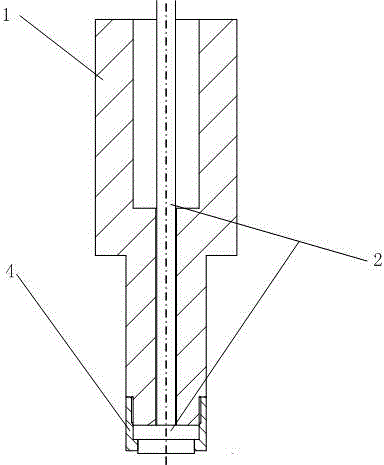

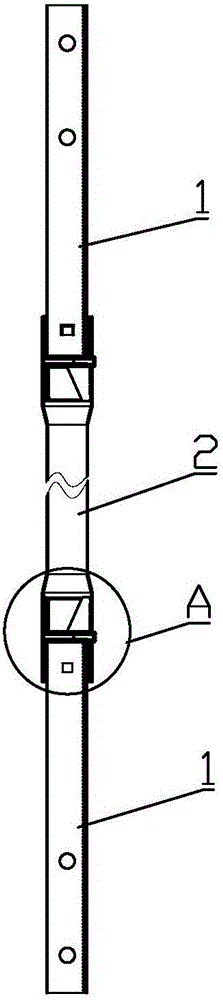

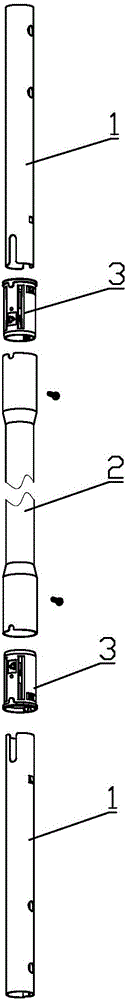

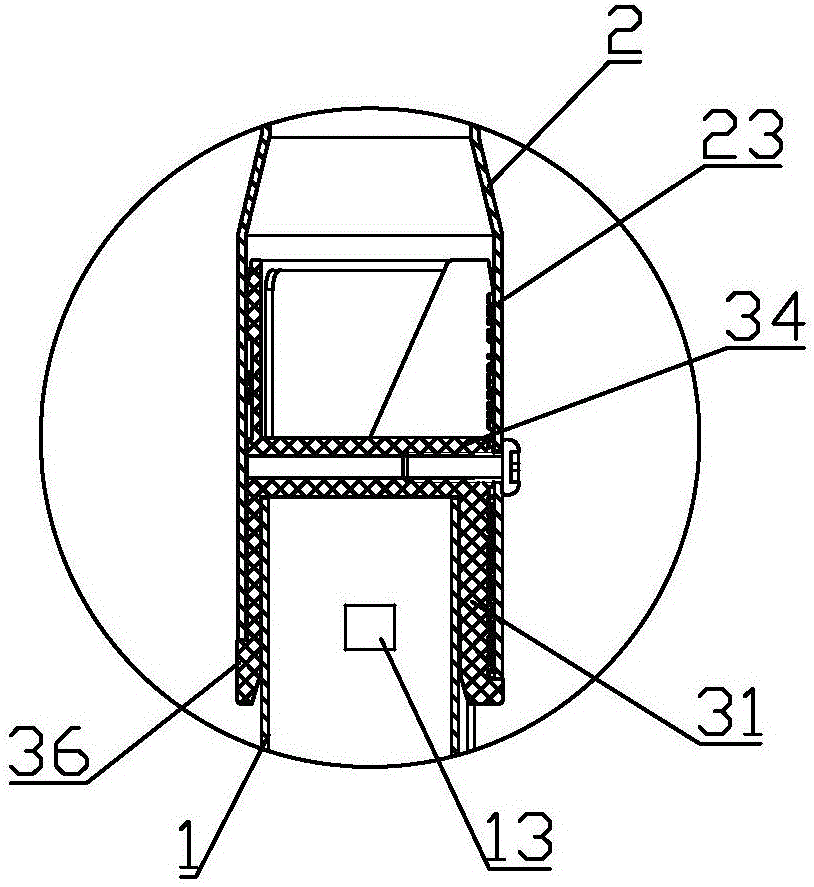

Drill stem dismounting and mounting device of pile driver

ActiveCN105544509AImprove connection strengthEasy to assemble and disassembleDrilling rodsDrilling casingsEngineeringUltimate tensile strength

The invention belongs to the technical field of construction equipment, and particularly relates to a drill stem dismounting and mounting device of a pile driver. By adopting the drill stem dismounting and mounting device, the problems that current drill stems of the pile driver are not convenient to dismount and mount and the like are solved. The drill stem dismounting and mounting device comprises a rack, wherein a grouting plate which is connected with a power head is movably arranged on the rack; a plurality of grouting plate connectors are arranged on the grouting plate in a penetration manner; the grouting plate connectors are separately connected with the grouting plate through a peripheral rotary connection structure; a plurality of drilling stem bodies which are in one-to-one correspondence with the grouting plate connectors are arranged below the grouting plate connectors; the drill stem bodies are connected with the grouting plate connectors through threaded connection structures; and peripheral positioning structures which can peripherally position the drill stem bodies and the grouting plate connectors are arranged between the drill stem bodies and the grouting plate connectors. The drill stem dismounting and mounting device has the advantages that the structure is simple and reasonable; the connection parts of the drill stems and a grouting mechanism are convenient to dismount and mount; the stability is good; the connection strength of the drill stems is high; the drill stems are not separated from the grouting plate easily during peripheral rotation; and peripheral positioning of the drill stems and the grouting plate connectors are realized through pressure plate drivers.

Owner:浙江兆弟技术有限公司

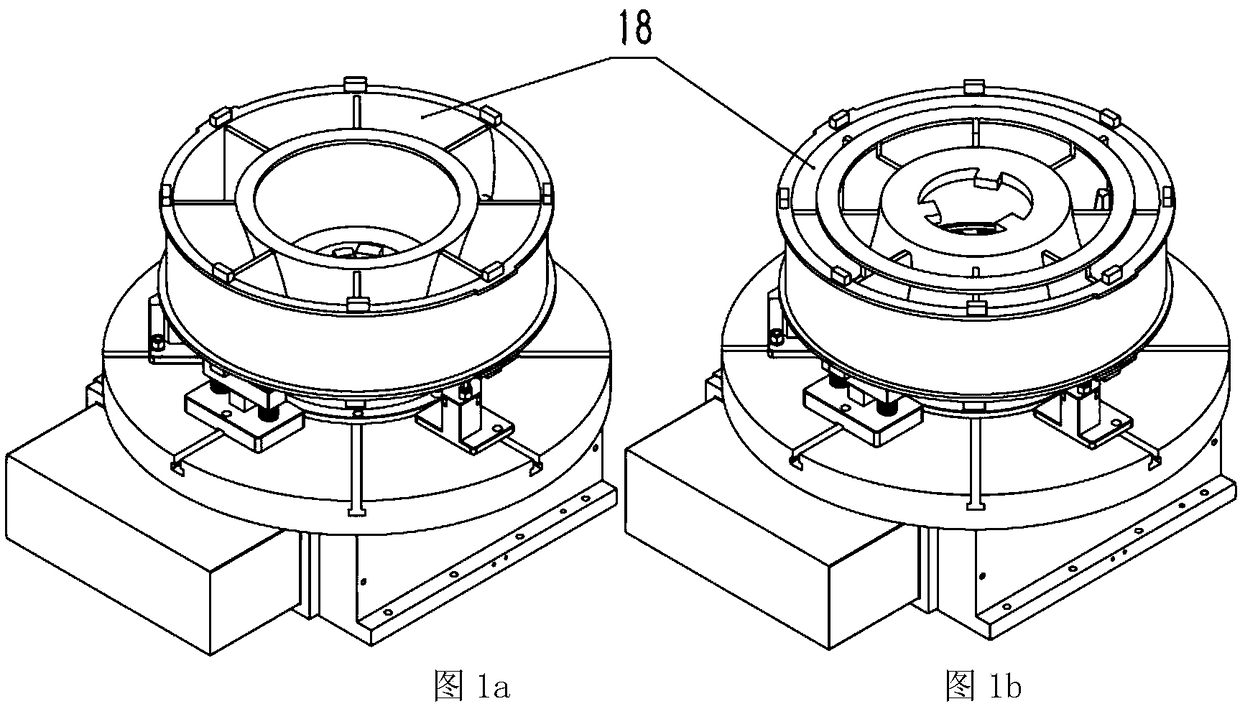

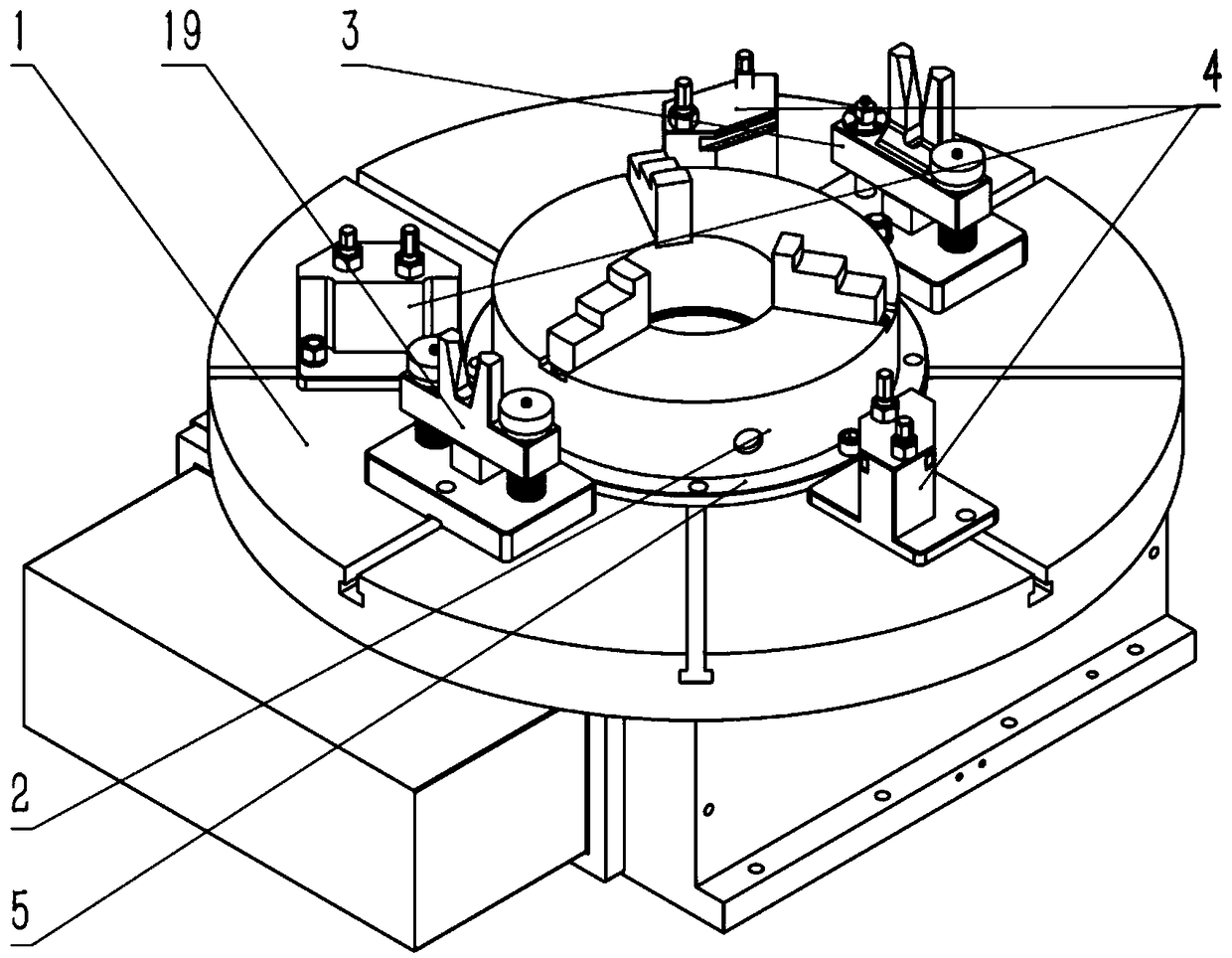

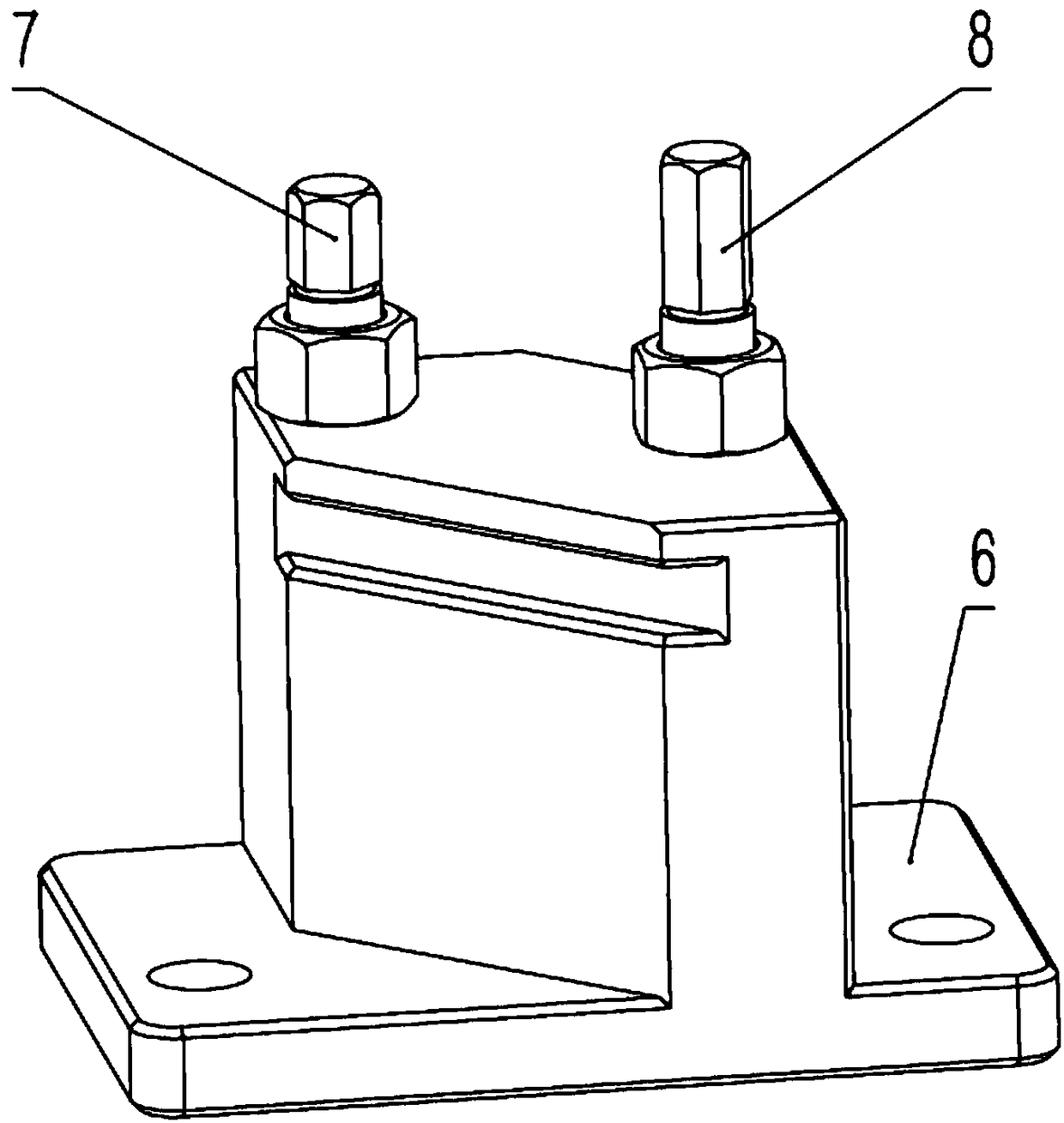

Positioning clamp used for titanium alloy ring-shaped casting and clamping method

ActiveCN109129186AAchieve circumferential positioningAchieving a centering effectGrinding work supportsRotational degrees of freedomTitanium alloy

The invention provides a positioning clamp used for a titanium alloy ring-shaped casting and a clamping method. The positioning clamp mainly comprises a rotating worktable, two floating V-shaped blockassemblies, three pin assemblies and one three-claw chuck. The titanium alloy ring-shaped casting is positioned through a clamp and is clamped to the surface of the rotating worktable. Three positioning pins are matched with the end face of the titanium alloy ring-shaped casting so as to limit the linear freedom degree of the titanium alloy ring-shaped casting in the height direction and two rotation freedom degrees. V-shaped blocks are matched with an elliptical structure on the titanium alloy ring-shaped casting to limit the circumferential rotation freedom degree of the titanium alloy ring-shaped casting. The three-claw chuck is matched with a circular inner hole of the titanium alloy ring-shaped casting to limit the linear freedom degree of the titanium alloy ring-shaped casting on the plane, and clamping is achieved. By means of the clamp, complete positioning of the titanium alloy ring-shaped casting is achieved, the clamp is suitable for front-face and back-face clamping of thetitanium alloy ring-shaped casting, and a servo motor arranged in a rotating worktable can be controlled to make the rotating worktable drive the clamp and the titanium alloy ring-shaped casting to rotate to the designated angle after clamping is completed.

Owner:WUHAN UNIV OF TECH

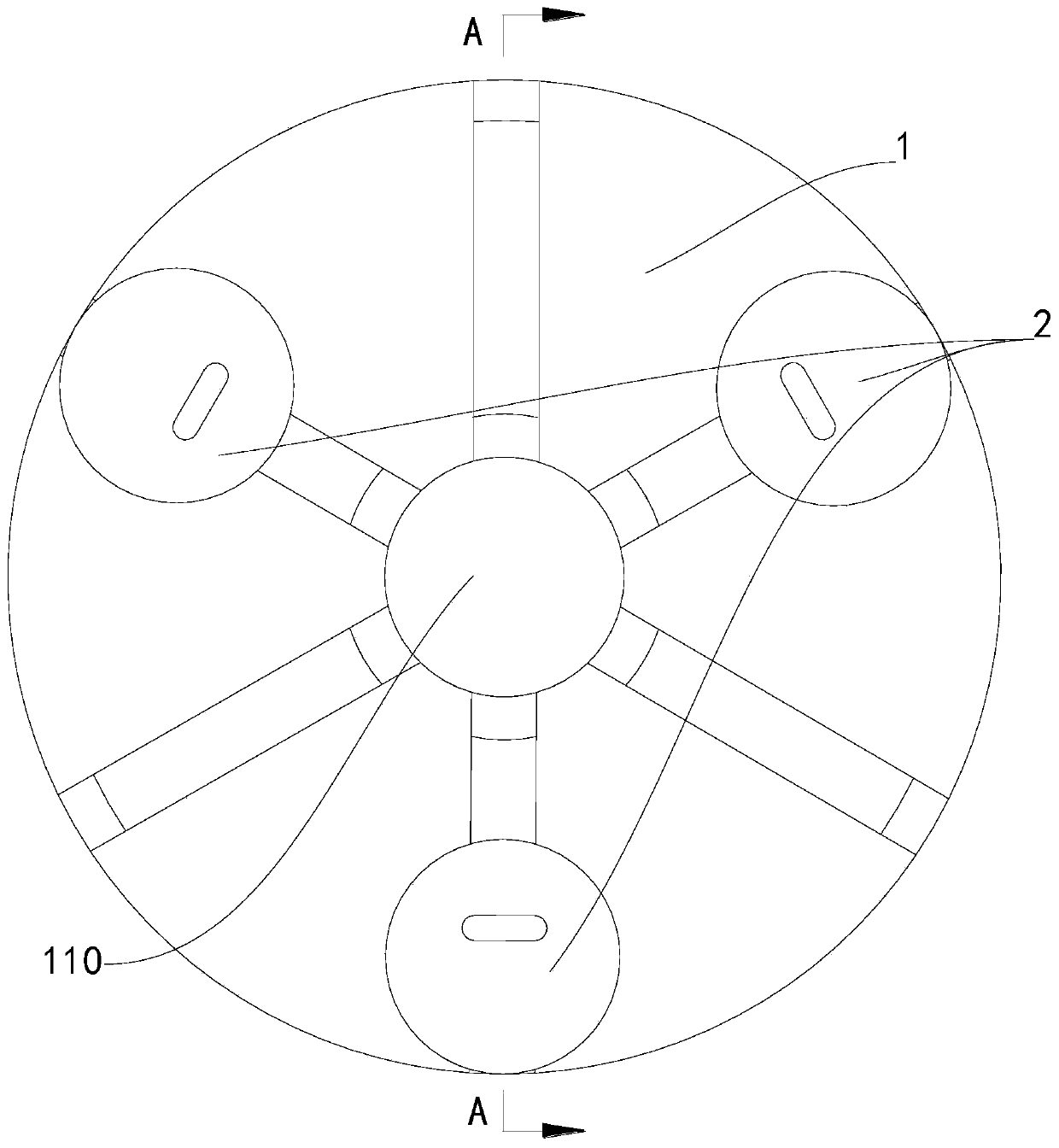

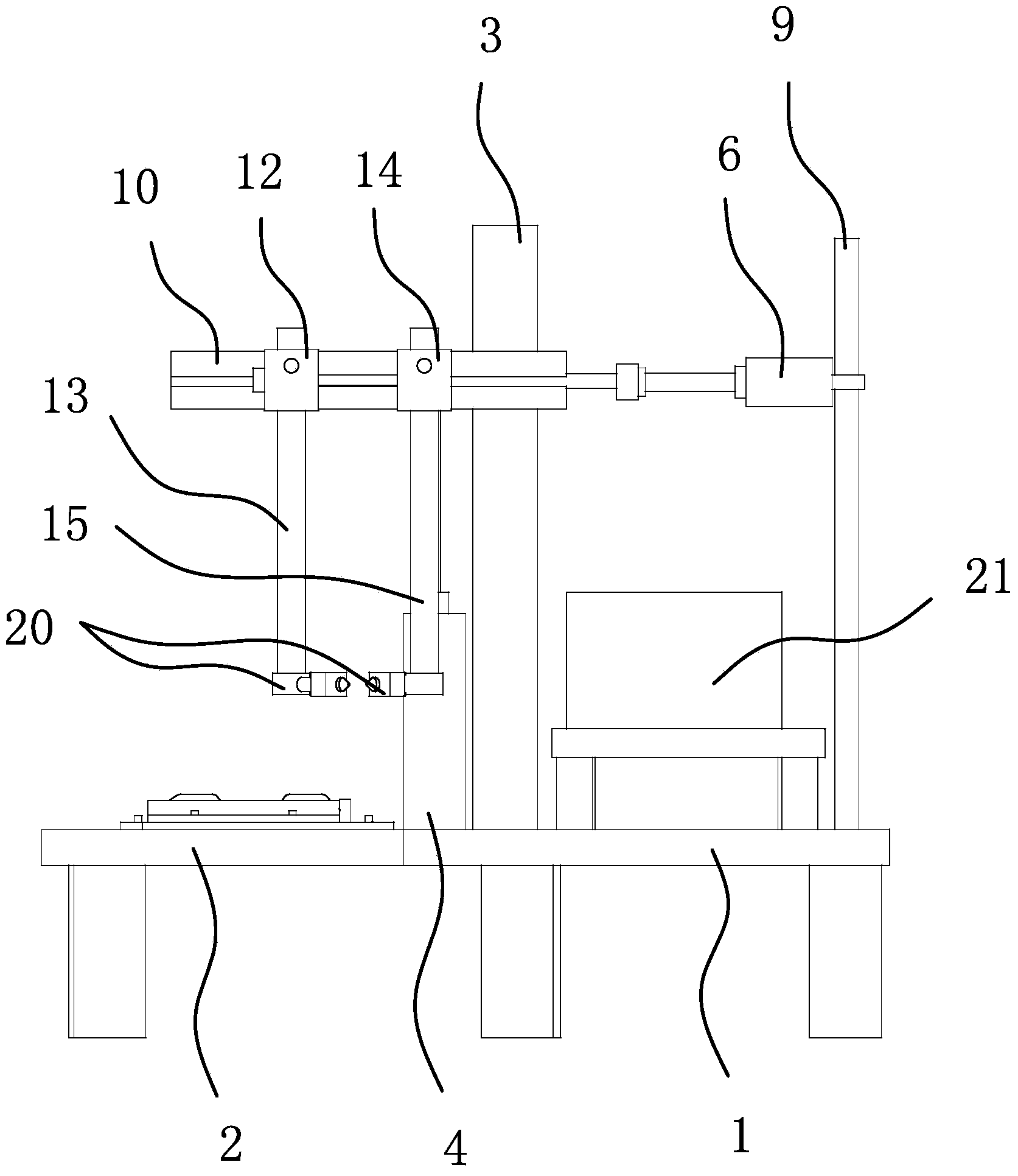

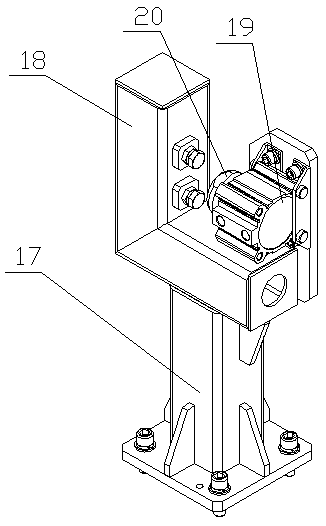

Auxiliary device for installation and positioning of claw poles

PendingCN110293493ANot easy to shakeAssembly accuracy is easy to guaranteeWork holdersManufacturing stator/rotor bodiesMechanical engineeringPositioning system

The invention relates to an auxiliary device for installation and positioning of claw poles. The auxiliary device comprises a base and a plurality of positioning assemblies, wherein an insertion holeis formed in the base, the plurality of positioning assemblies are arranged on the circumference with the insertion hole as a circle center, the positioning assemblies comprise positioning columns andpositioning plates, the positioning columns are arranged on the base, the positioning plates are arranged on the positioning columns, and positioning grooves matched with the tips of pawls of the claw poles are formed in the positioning plates. The auxiliary device has the beneficial effects that during use, a rotating shaft penetrates through the insertion hole, and then one claw pole is sleevedon the rotating shaft, the pawls are ensured to face upwards, the positioning columns are clamped among the pawls of the claw pole so as to enable the claw pole to be positioned in the circumferential direction, a magnetic field winding and a magnetic yoke are arranged on the rotating shaft, and finally the other claw pole is arranged on the rotating shaft, the pawls of the other claw pole facesdownwards, the tips of the pawls are clamped into the positioning grooves so as to enable the other claw pole to be positioned in the circumferential direction and not easy to shake; and in this way,the integral assembly accuracy is easy to guarantee during manual assembly.

Owner:武汉欣力瑞机电设备有限公司

Spatial butt-joint and positioning device

ActiveCN109625341ASimple structureReliable docking positioningCosmonautic vehiclesWork holdersTorsion springBiomedical engineering

The invention discloses a spatial butt-joint and positioning device. The spatial butt-joint and positioning device comprises a butt-joint device and a positioning device, the butt-joint device comprises a butt-joint device body, a positioning device body is provided with a butt-joint hole, and at least one clamping groove is formed in the inner wall of the butt-joint hole; the positioning device comprises the positioning device body, an unlocking device and at least clamping jaw, the positioning device body is hollow inside, at least one window is formed in the side face of the upper portion of the positioning device body, the top of each clamping jaw is installed in the corresponding window through a rotary shaft, and a torsion spring is arranged on each rotary shaft, endows the corresponding clamping jaw with the trend of turning outwards; the unlocking device comprises pull rods the number of which corresponds to that of the clamping jaws, the top of each pull rod is hinged to the middle or the lower portion of the inner side of the corresponding clamping jaw, the lower ends of the pull rods are hinged together to form hinging points, when the hinging points are pulled downwardsfrom the interior of the positioning device body through external force, the clamping jaws can be pulled to be retracted into the windows, and unlocking is completed. The spatial butt-joint and positioning device is high in butt-joint speed, stable and reliable, and through the cooperation of the clamping jaws and the clamping grooves, circumferential positioning is achieved.

Owner:WUHAN UNIV

Automatic welding machine with PLC

ActiveCN104708168AAccurate welding positionImprove welding qualityElectrode holder supportersEngineeringWelding

The invention provides an automatic welding machine with a PLC, and belongs to the technical field of machinery. The automatic welding machine solves the problem that in the prior art, the efficiency is low as a rocking chair iron support adopts manual welding. According to the automatic welding machine with the PLC, the rocking chair iron support comprises a first steel ribbon and a second steel ribbon arranged in parallel and a first installing seat and a second installing seat arranged in parallel; the welding machine comprises a rack, a working platform is arranged on the rack, a vertical column is vertically fixed to the working platform, a lifting and dropping block is arranged on the vertical column, and the lifting and dropping block is connected with a first driving mechanism; the working platform is further provided with a positioning device capable of fixing the first steel ribbon, the second steel ribbon, the first installing seat and the second installing seat, and the positioning device comprises a first positioning block and a second positioning block which can circumferentially position the first steel ribbon and the second steel ribbon and further comprises a first positioning ribbon and a second positioning ribbon which can axially position the first steel ribbon and the second steel ribbon. According to the automatic welding machine with the PLC, the automatic welding of the rocking chair iron support can be achieved, and the welding efficiency is high.

Owner:ZHEJIANG FEILI TECH CO LTD

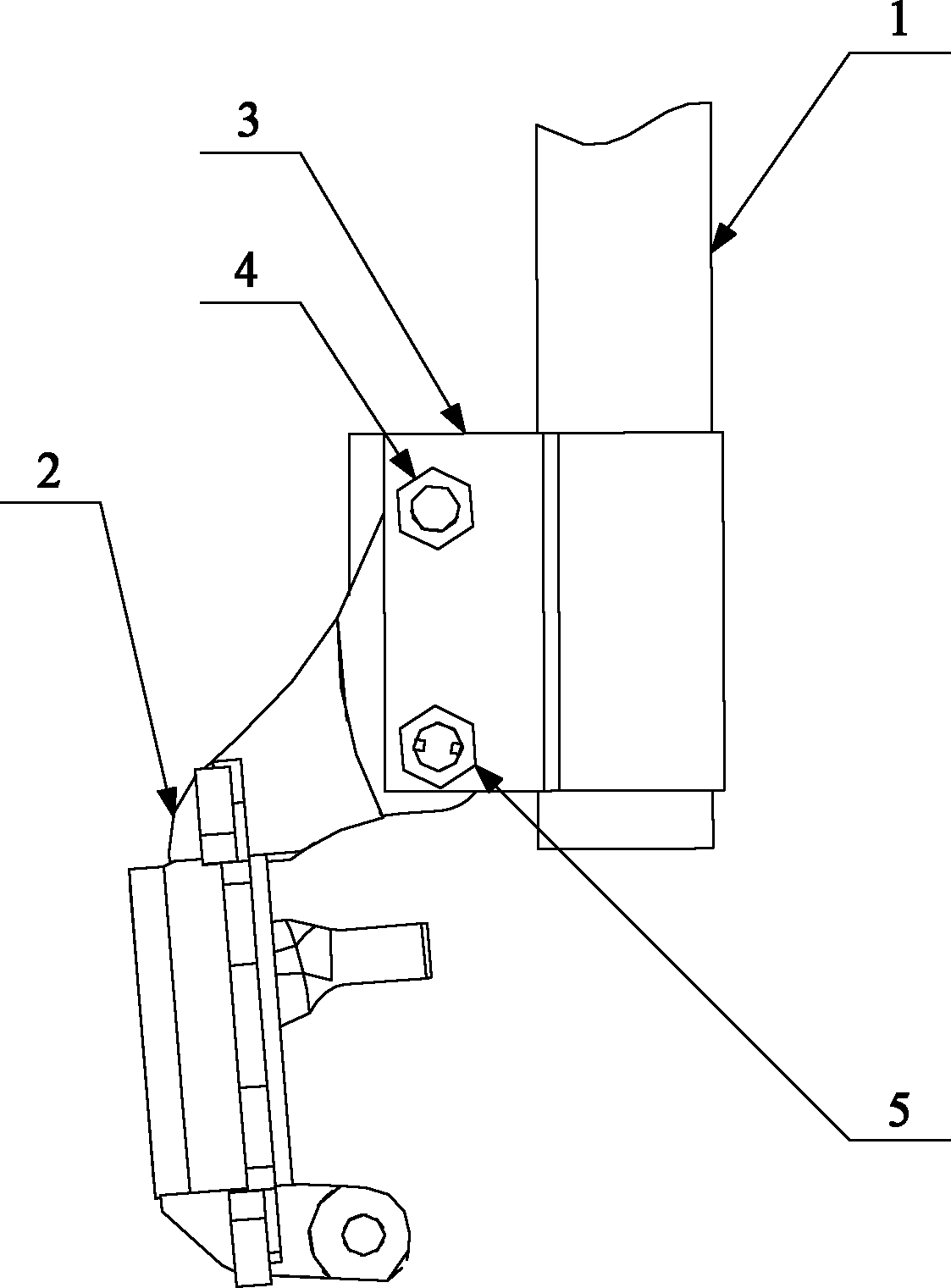

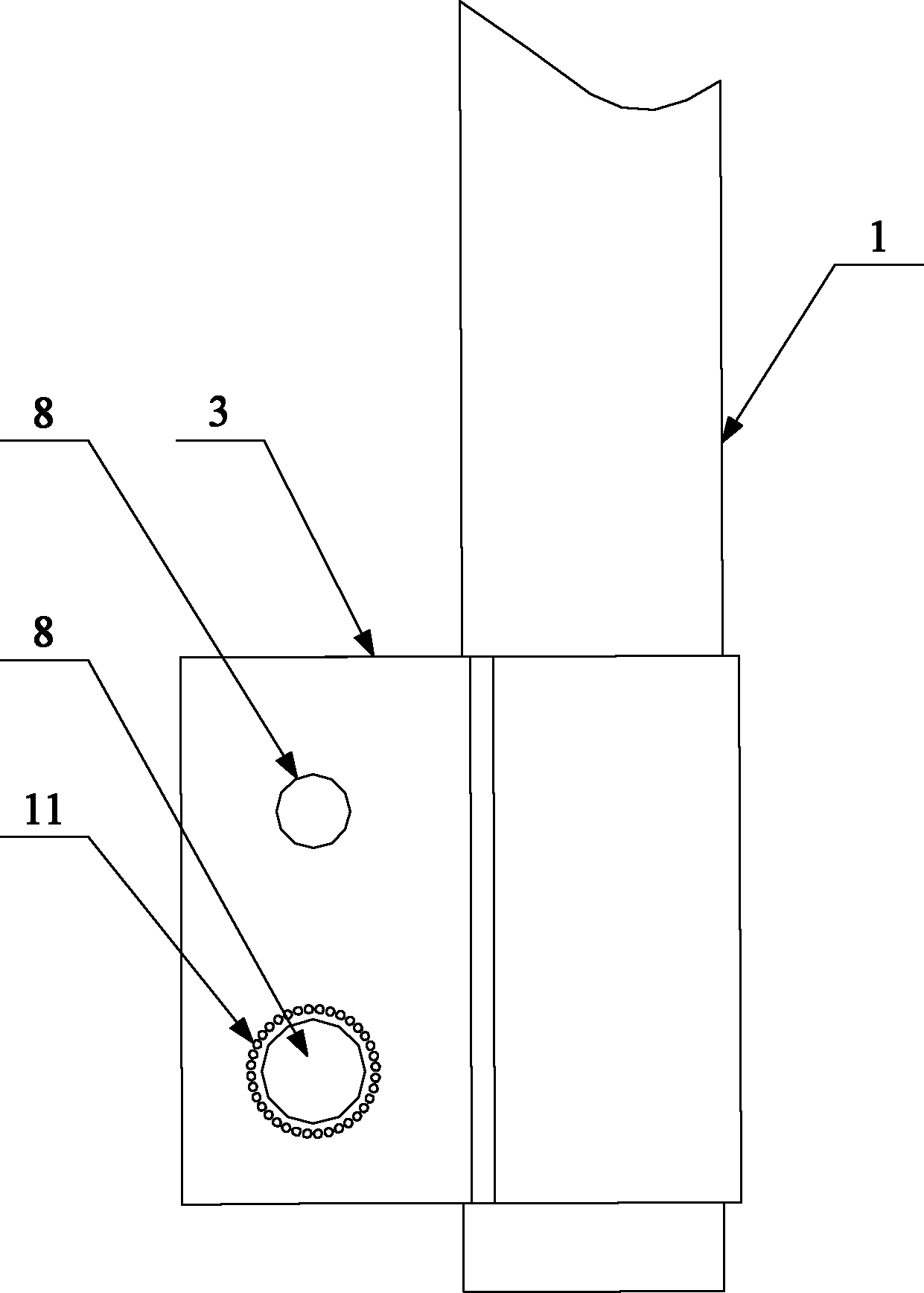

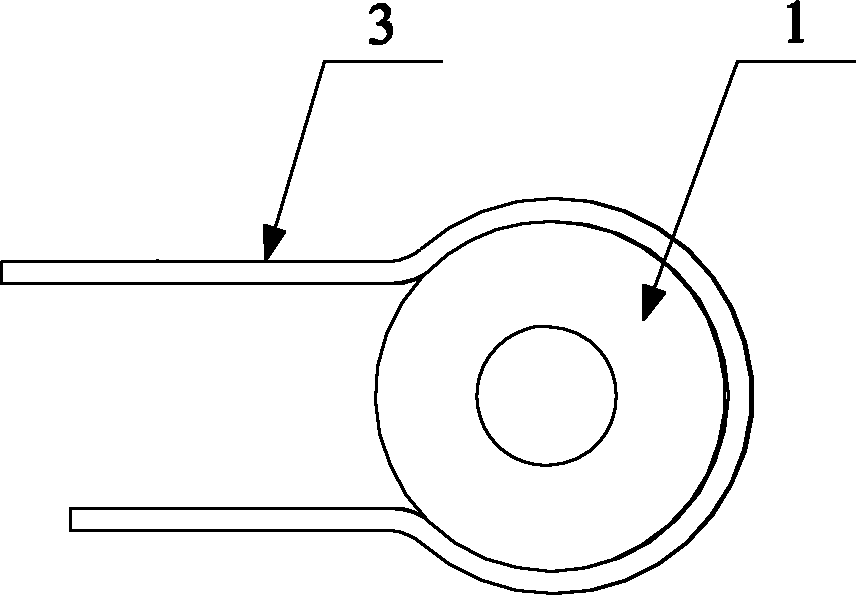

Macpherson suspension system

InactiveCN102490563AIncrease the scope of applicationAchieve circumferential positioningResilient suspensionsEngineeringContact position

The invention provides a Macpherson suspension system. The system comprises a shock absorber (1), a knuckle (2), a connecting piece (3) for connecting the shock absorber (1) and the knuckle (2), a bolt (4) arranged on the connecting piece (3), a groove bolt (5) and eccentric washers (7), wherein grooves (6) are formed at the thread positions of the groove bolt (5); a positioning device is arranged at the contact position of the groove bolt (5) and the connecting piece (3); and the eccentric washers (7) are arranged between the groove bolt (5) and connecting holes (8) of the connecting piece (3) and provided with bulges (9) protruded on the inner walls of the eccentric washers (7). The traditional Macpherson suspension system in which a kingpin inclination angle cannot be adjusted is improved into the Macpherson suspension system in which the kingpin inclination angle can be adjusted and changed, so that the application range and maintenance range of the Macpherson suspension system are expanded, and a larger free design space is provided for an automobile.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES +1

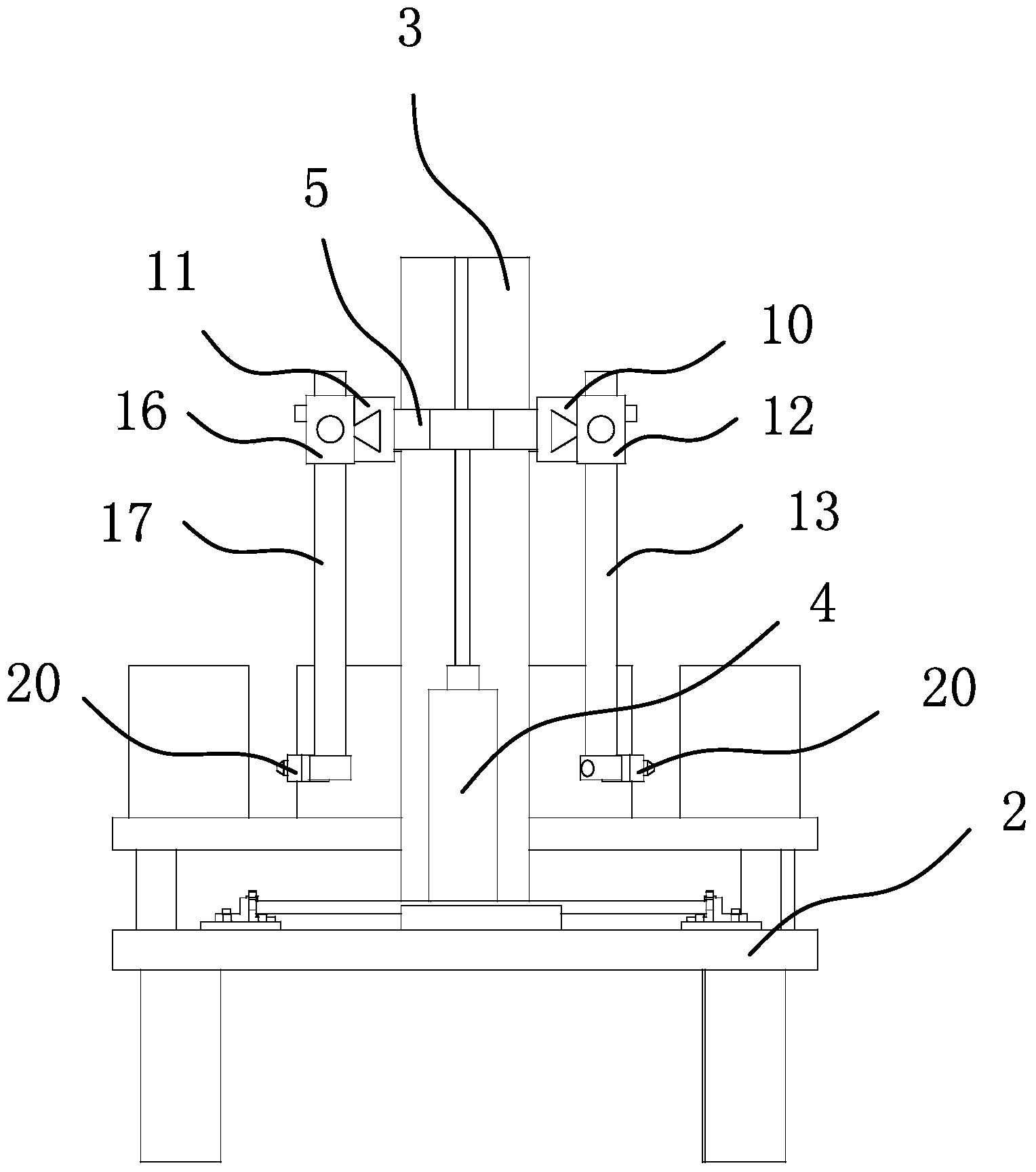

Automatic welding machine of rocking chair iron frame

ActiveCN103551771AAccurate welding positionImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesSteel barWelding

The invention provides an automatic welding machine of a rocking chair iron frame and belongs to the technical field of machinery. The automatic welding machine of the rocking chair iron frame solves the problem of low efficiency and the like due to the mode of manually welding the rocking chair iron frame in the prior art. According to the automatic welding machine of the rocking chair iron frame, the rocking chair iron frame comprises a steel bar I and a steel bar I which are parallel to each other, and a mounting seat I and a mounting seat II which are parallel to each other; the automatic welding machine comprises a machine frame on which a working platform is arranged, a stand column is vertically fixed onto the working platform and is provided with a lifting block with can be lift up and down along the stand column, and the lifting block is connected with a driving mechanism which can drive the lifting block to be lift up and down; the working platform is further provided with a positioning device which can fix the steel bar I, the steel bar II, the mounting seat I and the mounting seat II, the positioning device comprises a positioning block I and a positioning block I which can circumferentially position the steel bar I and the steel bar II respectively, and a positioning bar I and a positioning bar II which can axially position the steel bar I and the steel bar II respectively. The automatic welding machine of the rocking chair iron frame can achieve the automatic welding of the rocking chair iron frame and is high in welding efficiency.

Owner:ZHEJIANG FEILI TECH CO LTD

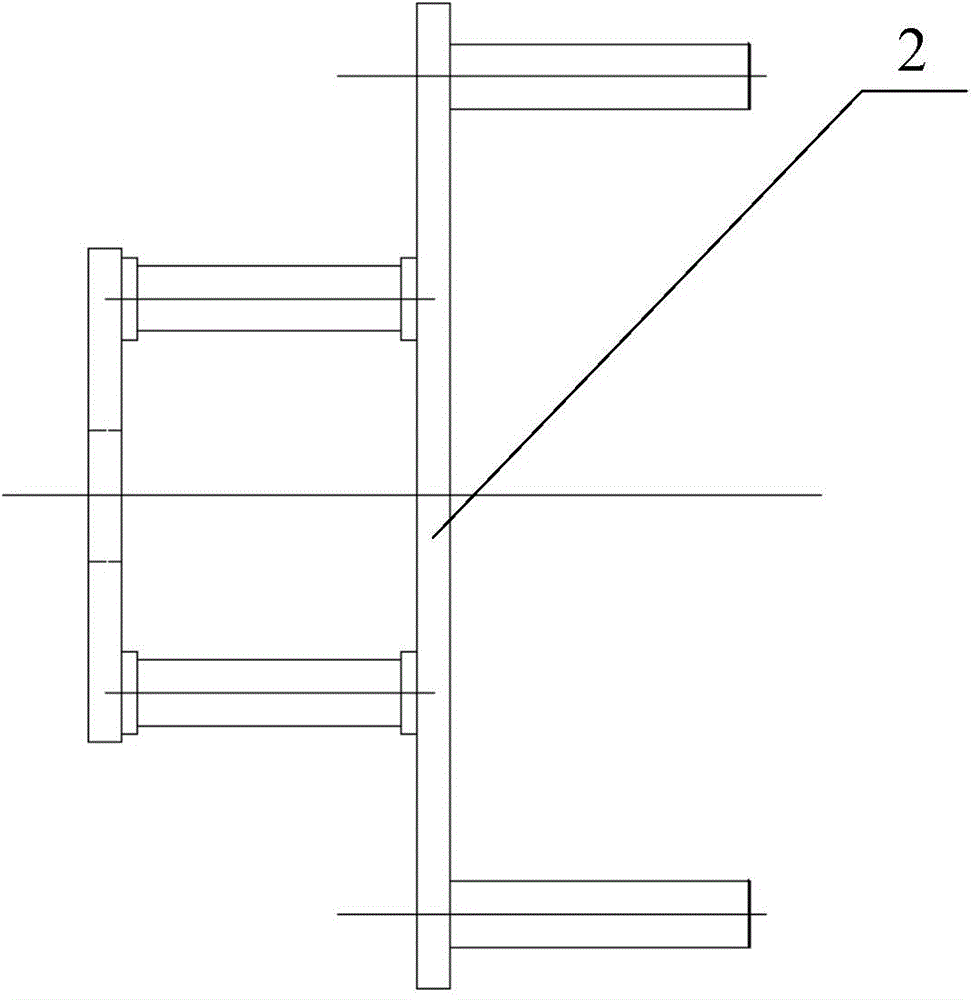

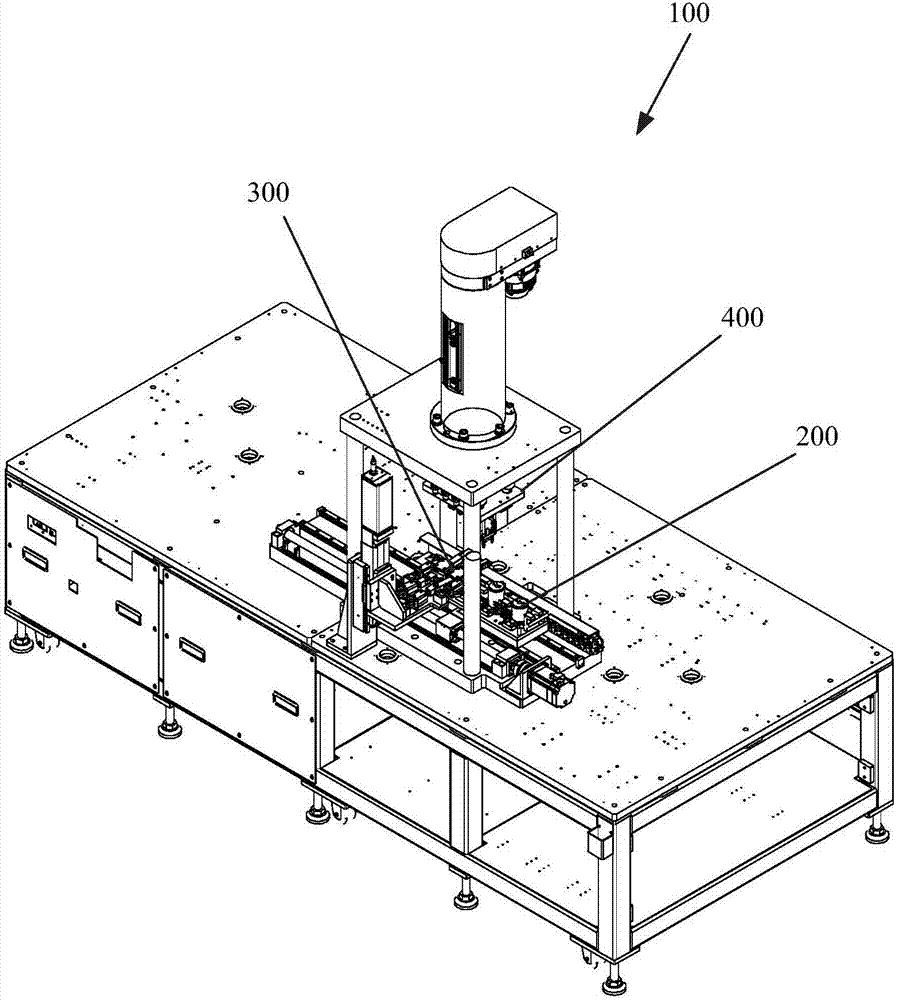

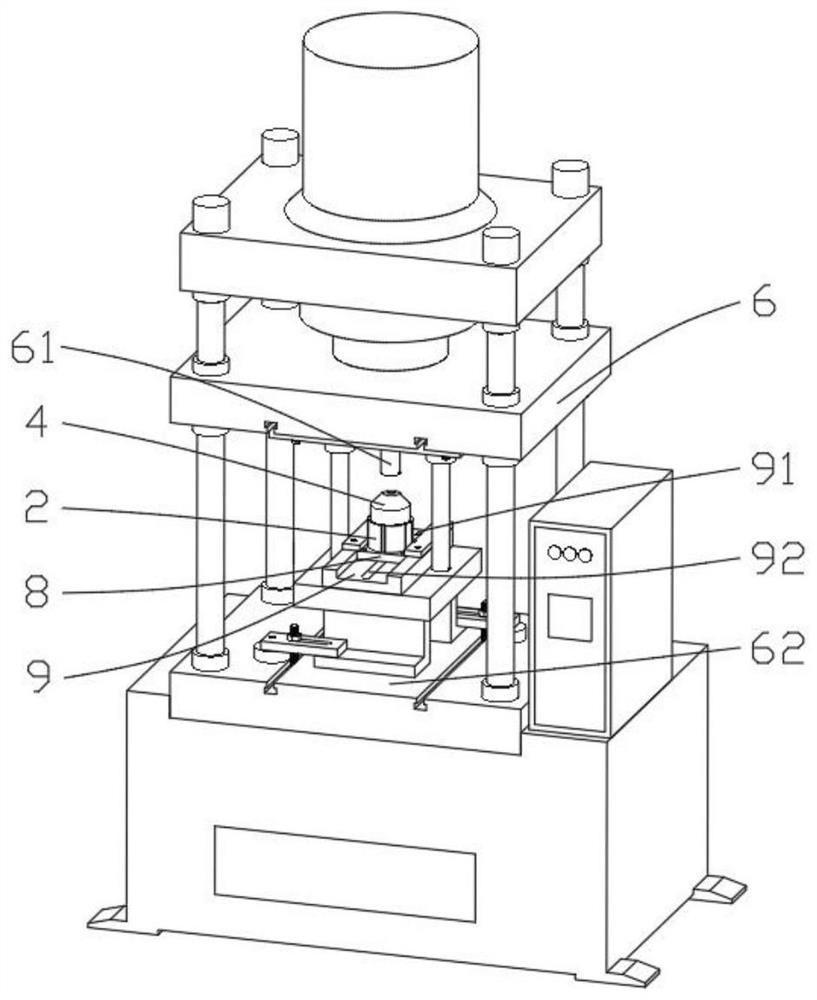

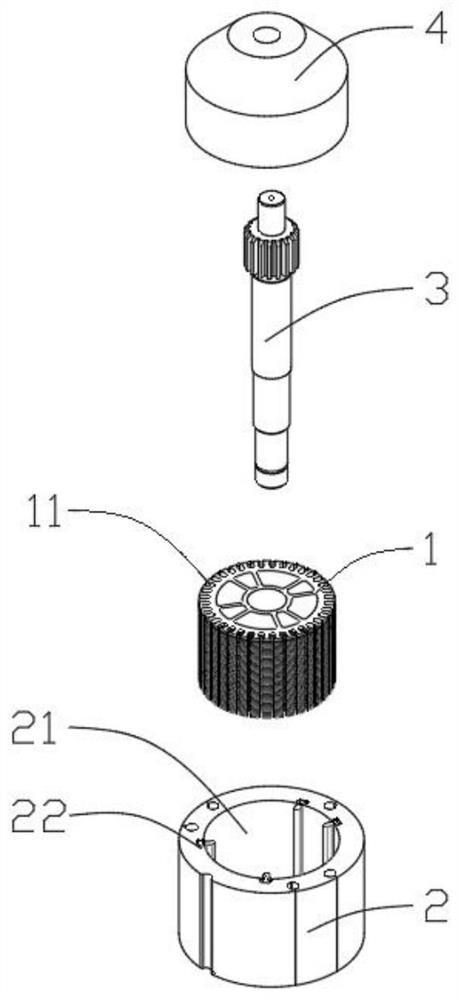

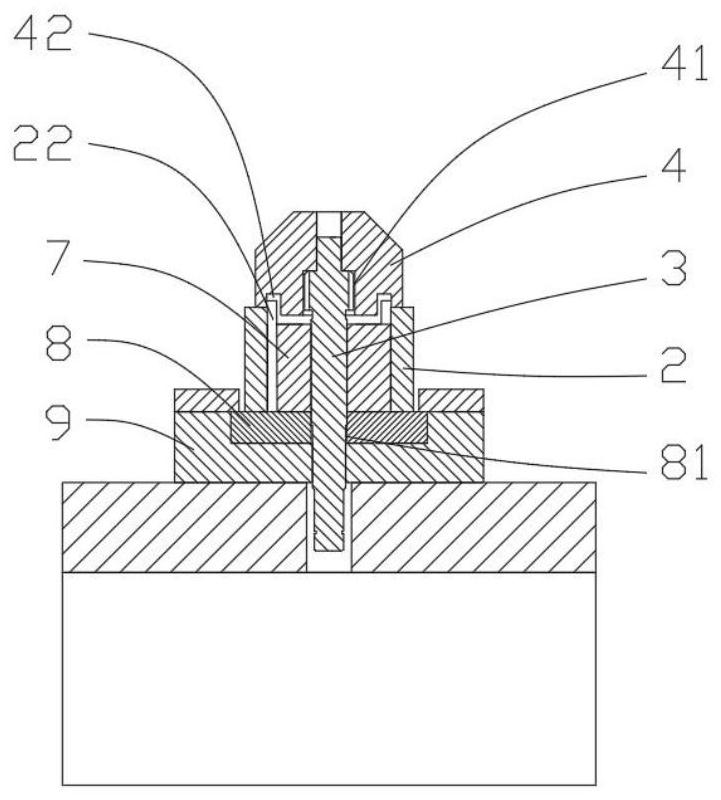

Automatic rotor iron core assembling device and motor manufacturing equipment having same

ActiveCN107070124AAchieve precise circumferential positioningLow rotational forceManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention relates to an automatic rotor iron core assembling device and motor manufacturing equipment having the same. The automatic rotor iron core assembling device comprises an insertion portion, a plurality of accommodating portions and a rotation portion; then insertion portion is used for inserting shafts into the center through holes of a plurality of rotor iron cores sequentially; the plurality of accommodating portions are use for accommodating rotor iron cores to be assembled; each of the accommodating portions is provided with a group of positioning protruding portions which extend out axially; each group of positioning protruding portions can be inserted into one group of circumferential positioning holes so as to circumferentially position a corresponding rotor iron core; the inner diameter of the circumferential positioning holes is larger than the outer diameter of the positioning protruding portions which are inserted into the circumferential positioning holes; the rotation portion is used for making the rotor iron cores arranged on the accommodating portions rotate with the center through holes of the rotor iron cores adopted as centers to positions where the outer peripheries of the positioning protruding portions abut against the inner peripheries of the positioning holes, and holding the rotor iron cores at the positions until the shafts are inserted into specified positions of the rotor iron cores; and the positions of each group of positioning protruding portions in the plurality of positioning protruding portions rotate to deviate by a specified angle relative to an adjacent group of positioning protruding portions.

Owner:尼得科智能装备(浙江)有限公司

Dissimilar metal rivet welding connecting device, notch rivet and control method

ActiveCN104475950APrevent deviationGuaranteed mechanical propertiesResistance electrode holdersRivetsEngineeringMechanical property

The invention discloses a dissimilar metal rivet welding connecting device, and belongs to the field of mechanical manufacturing. The dissimilar metal rivet welding connecting device comprises an impact electrode arranged from top to bottom, a guide mechanism, a spring pressure block mechanism, and a guide plate; the guide mechanism has a hollow structure; the impact electrode is connected with a power supply positive pole; the impact electrode is arranged in the guide mechanism and can slide along the guide mechanism from top to bottom; the spring pressure block mechanism is mounted below an inner hole of the guide mechanism and used for supporting a rivet; the guide plate is connected with a power supply negative pole; and the surfaces of an impact guide rod, the guide mechanism and the spring pressure block mechanism are coated with insulating layer. By the dissimilar metal rivet welding connecting device, stamping force of a notch rivet penetrating through a material and the deformation of a joint can be effectively reduce, the rivet welding contact area between the rivet and dissimilar metal can be increased, the rivet welding stability of the dissimilar metal can be improved, cracks of the rivet can be avoided, mechanical properties of the material can be ensured, and the stability of the connection is enhanced. The invention also discloses a notch rivet and a rivet welding control method which are used for the dissimilar metal rivet welding connecting device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

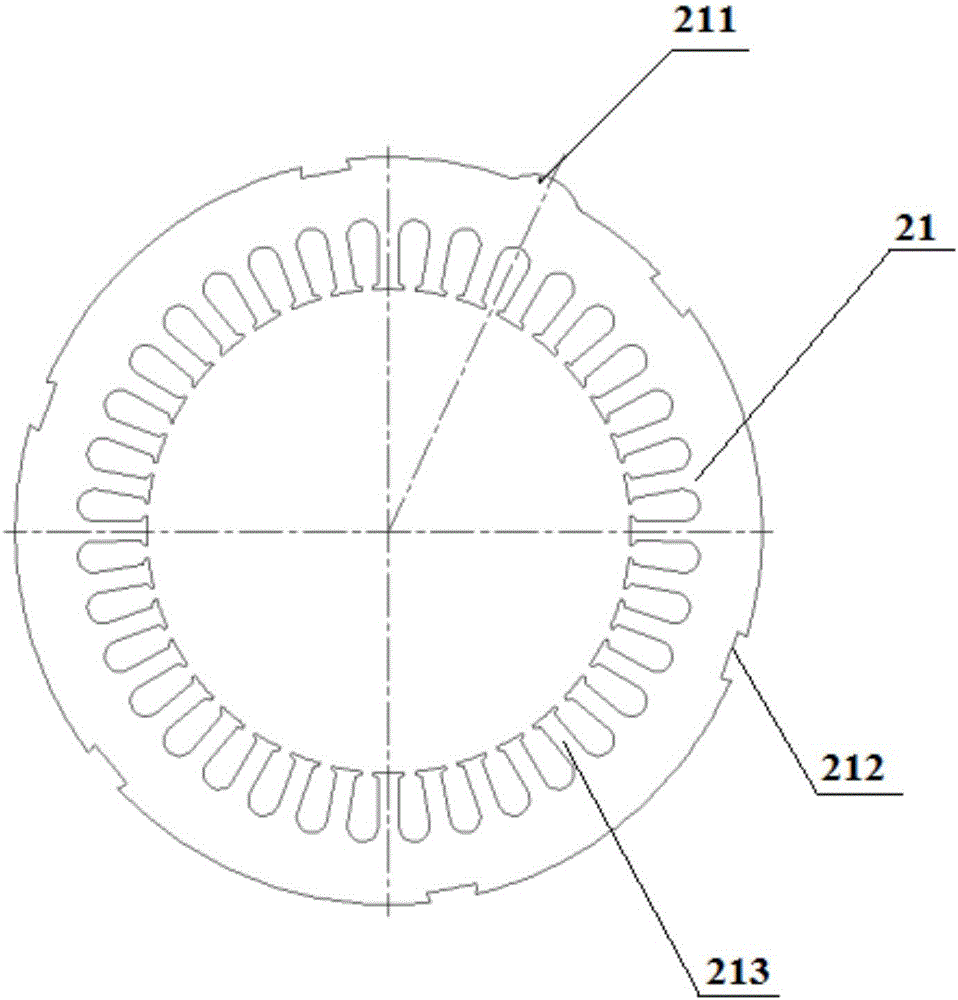

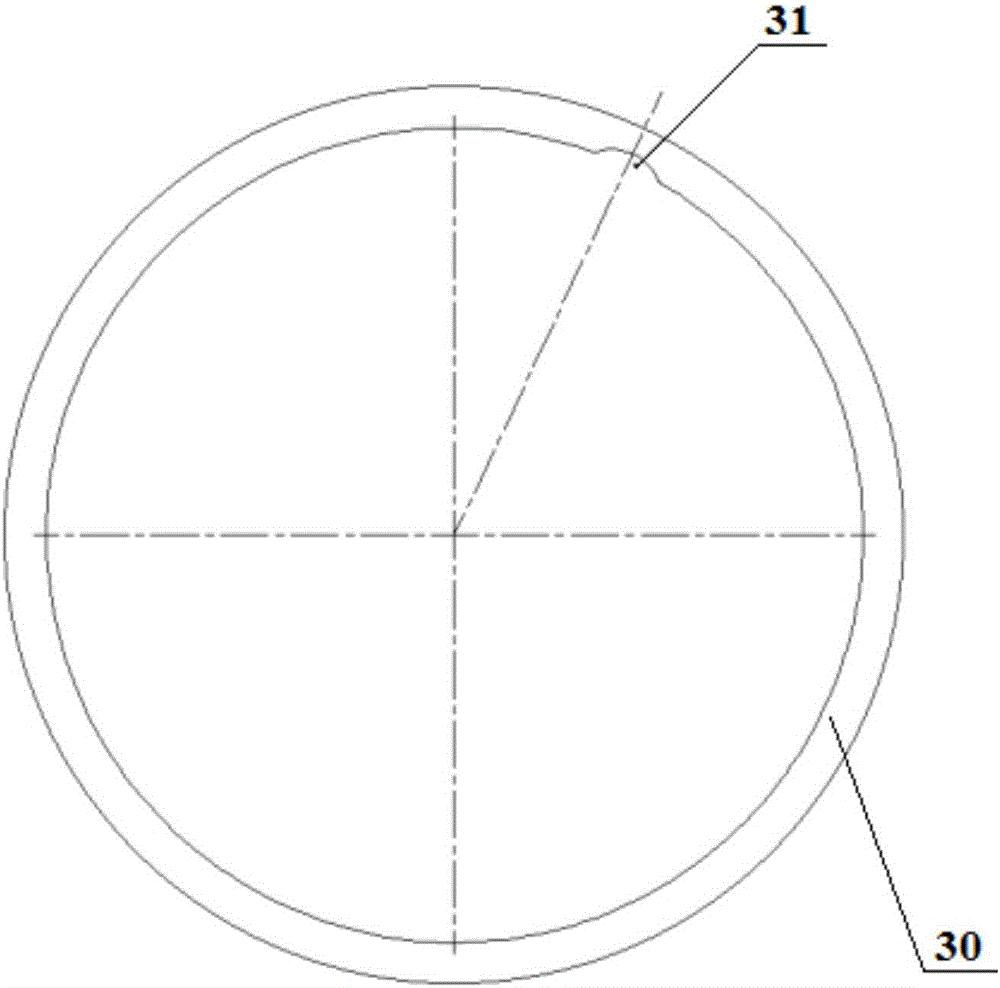

Motor stator and engine base positioning structure and fault diagnosis method thereof

InactiveCN106357036AAchieve circumferential positioningPlay a role in error preventionMagnetic circuit stationary partsSupports/enclosures/casingsPunchingDiagnosis methods

The invention discloses a motor stator and engine base positioning structure and a fault diagnosis method thereof. The motor stator and engine base positioning structure comprises a rotor, a stator punching plates and an engine base; positioning protrusions are arranged on the outer circumference of the stator punching plates and are used for positioning; positioning grooves arranged in the engine base are capable of being mutually matched with the positioning protrusions, and circumferential positioning with the stator is achieved; the shape of the positioning protrusions and the positioning grooves is one of semicircular shape, trapezoid shape and rectangular shape. A protrusion structure is arranged on the outer circumference of the stator punching plates, the stator punching plates are pressed in an overlaying manner to form the stator with the positioning protrusions, the stator is matched with the positioning grooves in the inner wall of the engine base, and circumferential positioning of the stator is achieved; noise reduction signals are decomposed by adopting an EMD decomposition method, the neighboring signals are combined by adopting a CMF method, and the vibrating signals which are more smooth, stable and complete can be acquired; motor fault diagnosis is performed through a wavelet packet decomposition and BP neural network method, motor fault can be detected timely and accurately, and loss brought by the motor fault is prevented.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

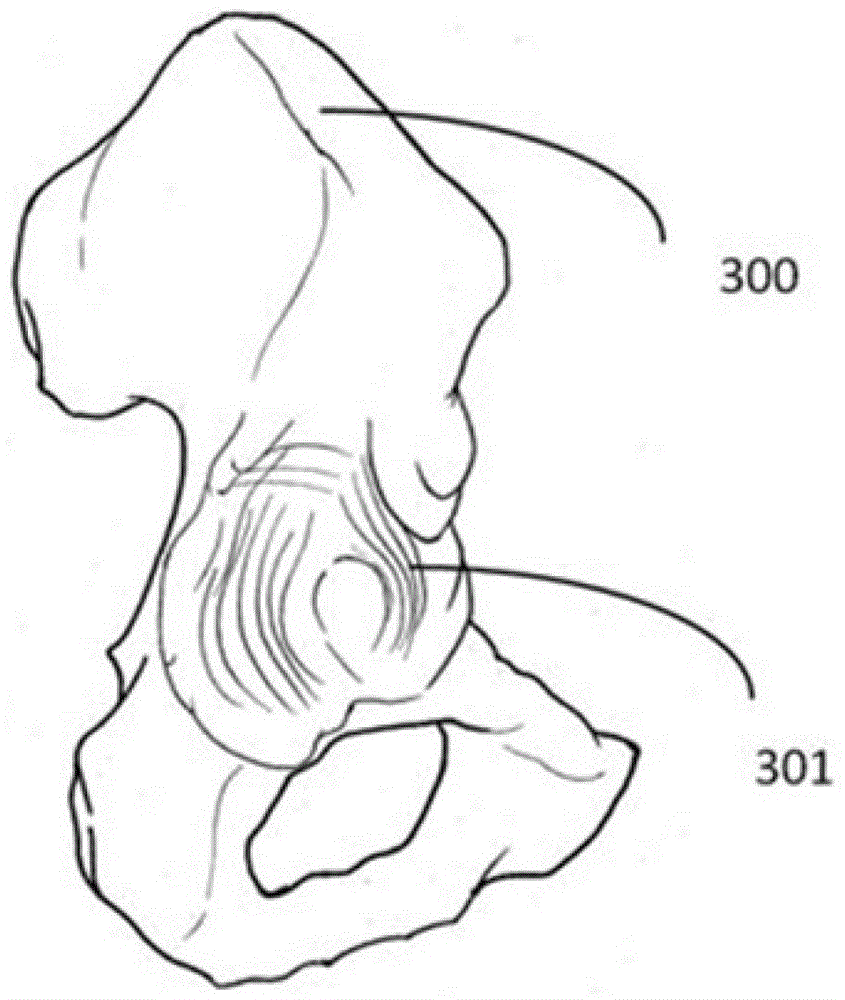

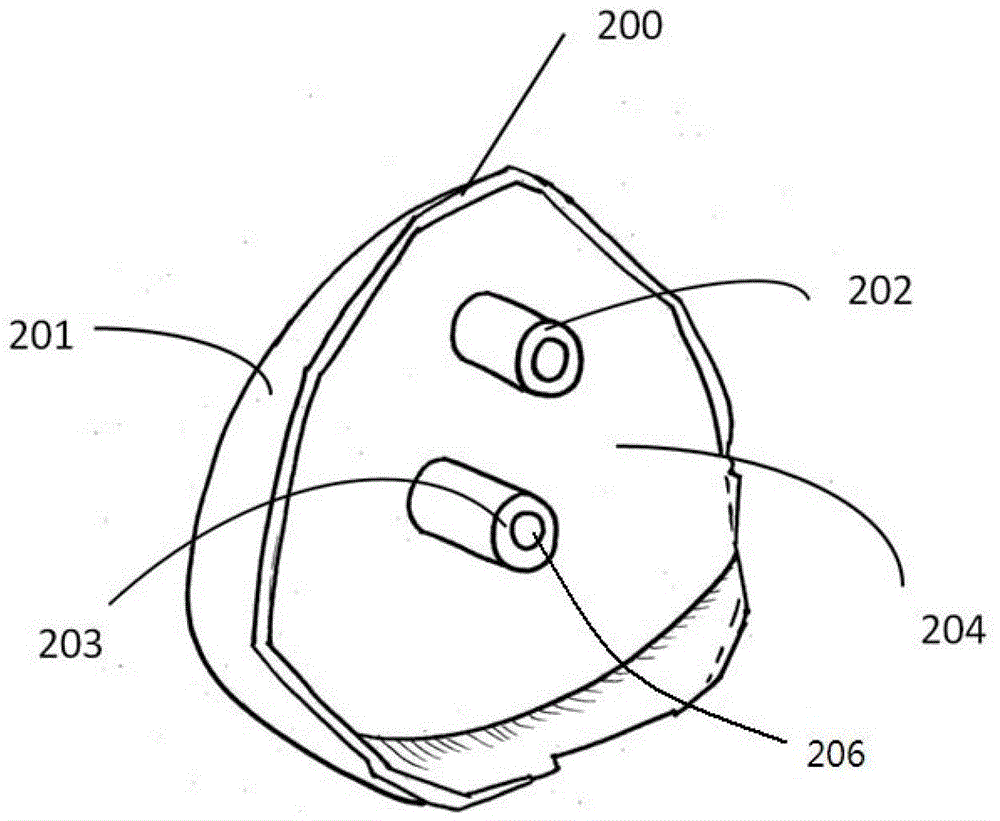

Customized positioning device for hip joint surgery and supporting prosthesis based on medical images

ActiveCN104337572BHigh precisionEfficient resectionJoint implantsAcetabular cupsAcetabular boneAcetabulum prosthesis

Owner:SHANGHAI XINJIAN MEDICAL TECH

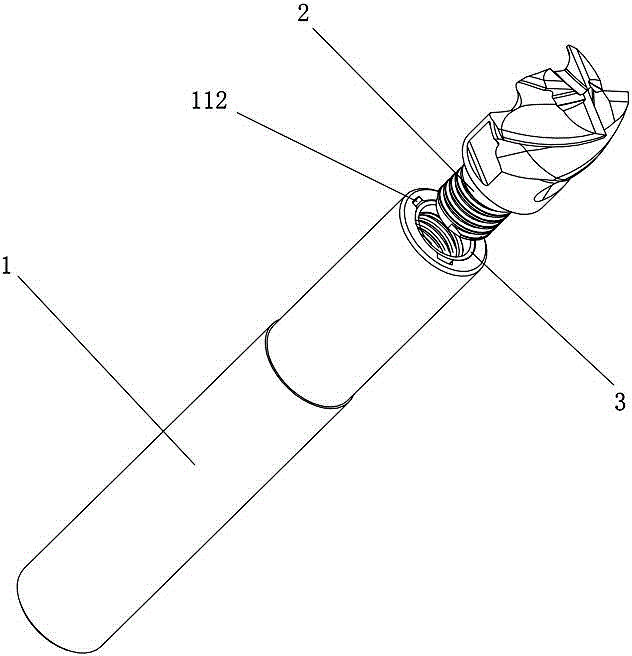

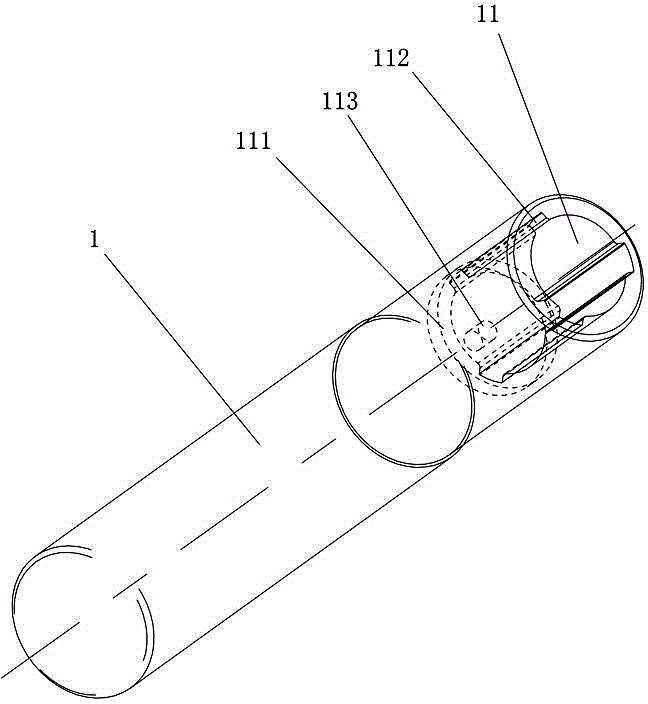

Rotational cutting tool capable of assembling and disassembling

ActiveCN104400104ALarge locking forcePrecise positioningMilling cuttersEngineeringMechanical engineering

The invention discloses a rotational cutting tool capable of assembling and disassembling. The rotational cutting tool comprises a clamping component, a cutting component and an embedded connecting component, wherein the clamping component comprises a clamping head and a clamping handle, an axial recess is formed in the end face of the clamping head and is used for mounting the embedded connection component, the embedded connection component is arranged in the axial recess, the cutting component is arranged on the embedded connection component, at least one bulge part is arranged on an external wall curved surface of the embedded connection component, a revolving slot is formed in the side wall of the bottom of the axial recess, axial grooves are formed in the side wall of the axial recess, the number of the axial grooves is equal to the number of the at least one bulge part, the at least one bulge part can pass through the axial grooves and is mounted in the revolving slot, an axially protruded locating shaft is arranged at the center of the bottom of the embedded connecting component, a locating hole is formed in the bottom of the axial recess and is not concentric with the axial recess, and the locating shaft is arranged in the locating hole. The rotational cutting tool capable of assembling and disassembling has the advantages of high convenience in assembly and disassembly and reliability in location.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

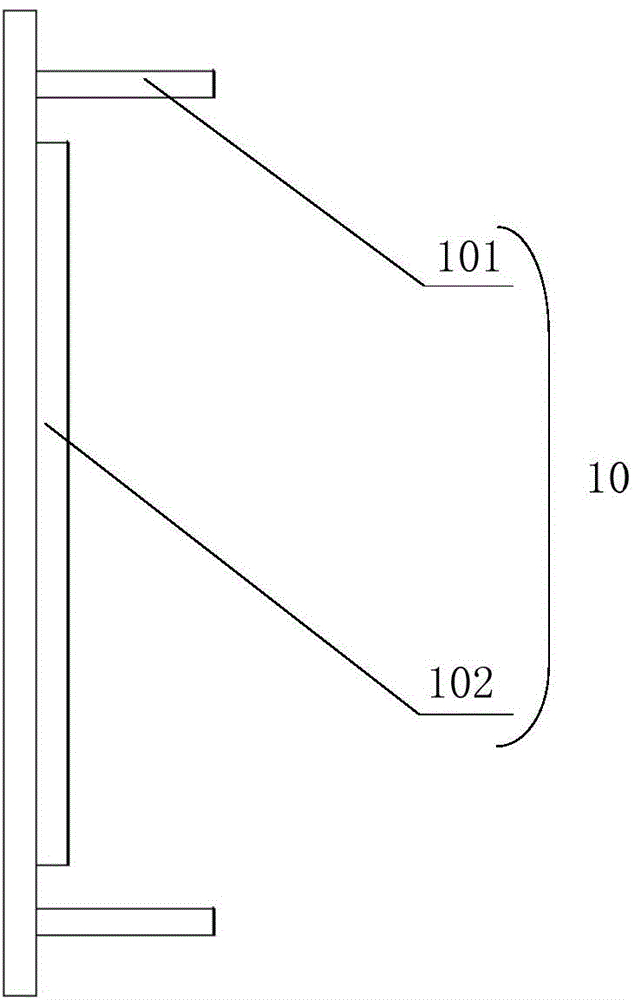

Rotor iron core stacking die

PendingCN113270984AFlat surfaceTightly boundManufacturing stator/rotor bodiesEngineeringStructural engineering

The invention relates to the technical field of rotor iron core production, and discloses a rotor iron core stacking die which comprises an iron core punching sheet positioning seat, a rotor shaft pressing seat and an iron core punching sheet pressing seat. The rotor shaft pressing seat and the iron core punching sheet pressing seat are located above the iron core punching sheet positioning seat. According to the invention, the laminated rotor iron core punching sheets are circumferentially positioned through the iron core punching sheet positioning seat, the positions of the winding grooves of the rotor iron core punching sheets are ensured to be in one-to-one correspondence, the subsequent off-line operation is facilitated, and the rotor shaft pressing seat and the iron core punching sheet pressing seat axially press the rotor shaft and the rotor iron core punching sheets respectively, so that the rotor iron core punching sheets are tightly connected with the rotor shaft, all layers of rotor iron core punching sheets are tightly attached, it is guaranteed that the size of the stacked rotor iron core is matched with the set size, and meanwhile after stacking, the surface of each rotor iron core punching sheet is smooth, the stacking process is simple, the efficiency is high, the size precision is high, and the quality is good.

Owner:湖北信友汽车零部件有限公司

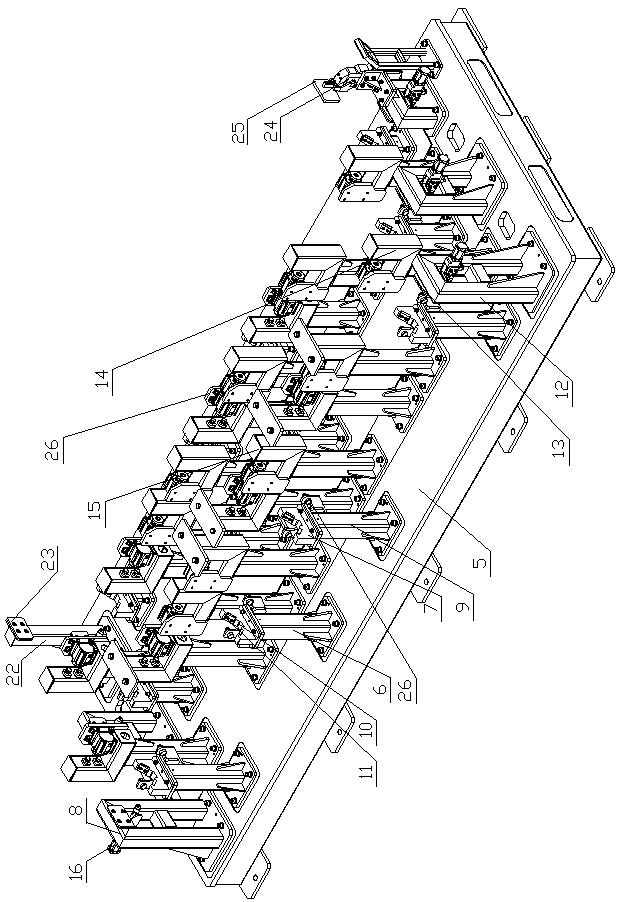

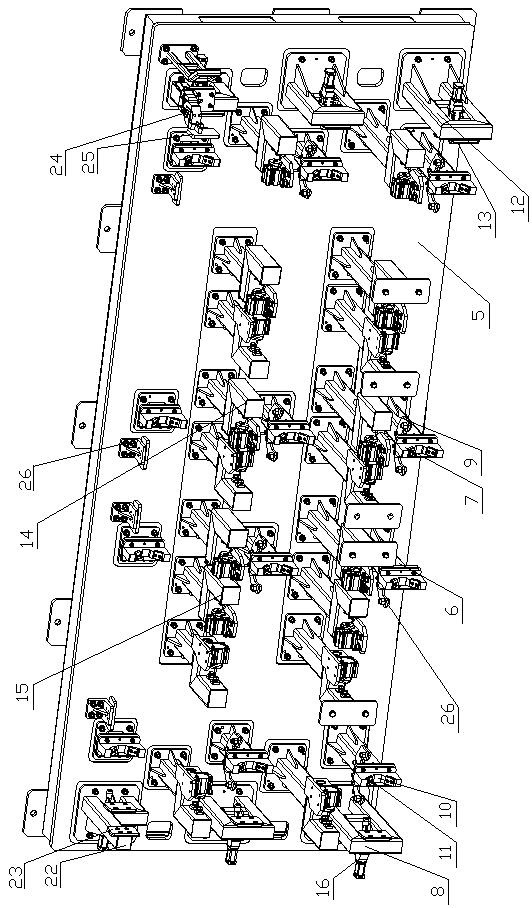

Automatic bicycle hub machining system

InactiveCN104759701AAchieve axial positioningAchieve circumferential positioningMachining systemMechanical engineering

The invention relates to a machining system used for machining hubs, and aims at providing an automatic bicycle hub machining system which is high in machining accuracy, simple in structure and high in working efficiency. The automatic bicycle hub machining system comprises guide rails, a sliding beam is installed on the guide rails, and a transfer robot is installed on the sliding beam; a first plane machining device and a second plane machining device are arranged below the sliding beam; the first plane machining device comprises a first spindle box and a first sliding rail, a positioning shaft and a positioning pin are arranged on the first spindle box, and a first cutter set and a screw assembling and disassembling mechanism are installed arranged above the first sliding rail; the second plane machining device comprises a second spindle box and a second sliding rail, a clamp body is arranged on the second spindle box, and a second cutter set is installed above the second sliding rail; a feeding device is arranged between the first plane machining device and the second plane machining device, and a transfer device is arranged in front of the feeding device.

Owner:CONSCI TIANJIN SCI & TECH CO LTD

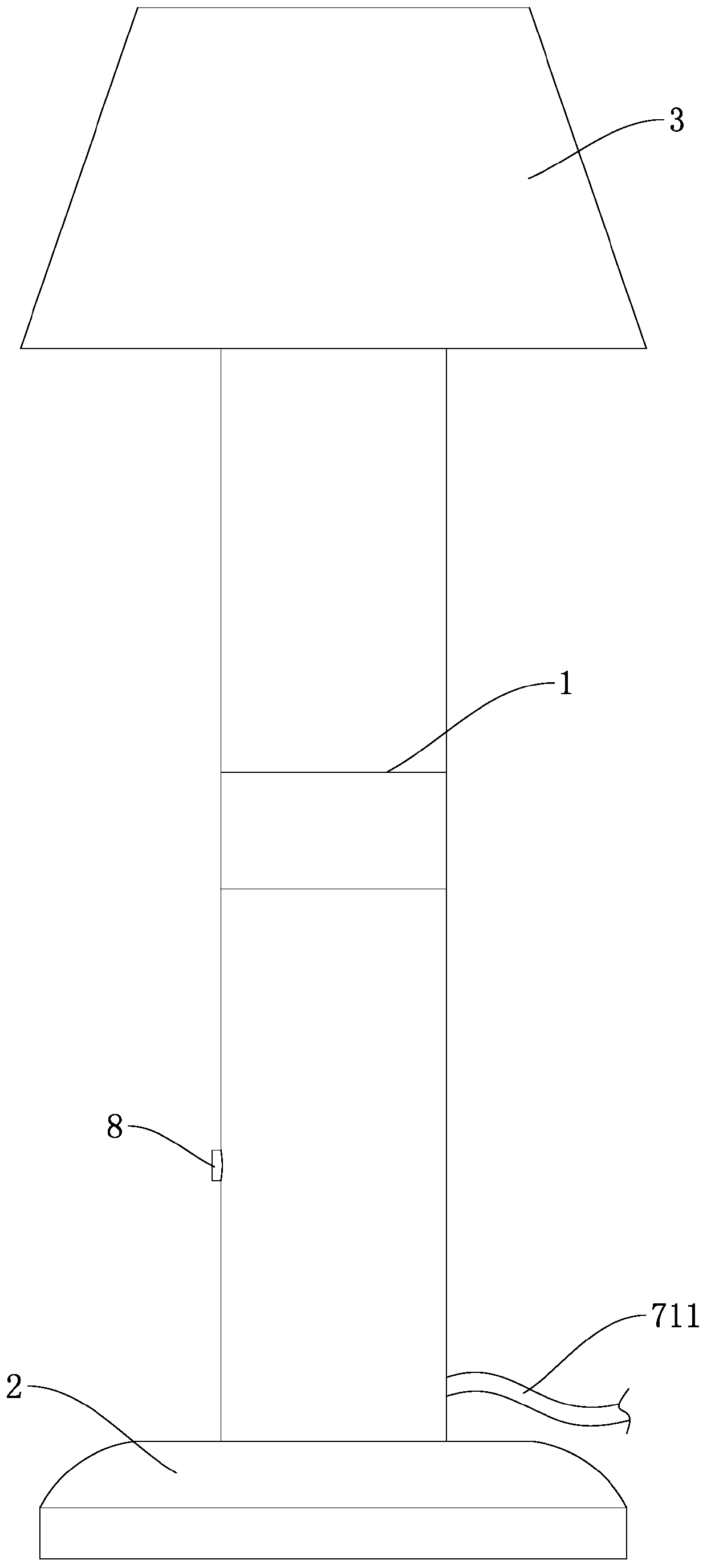

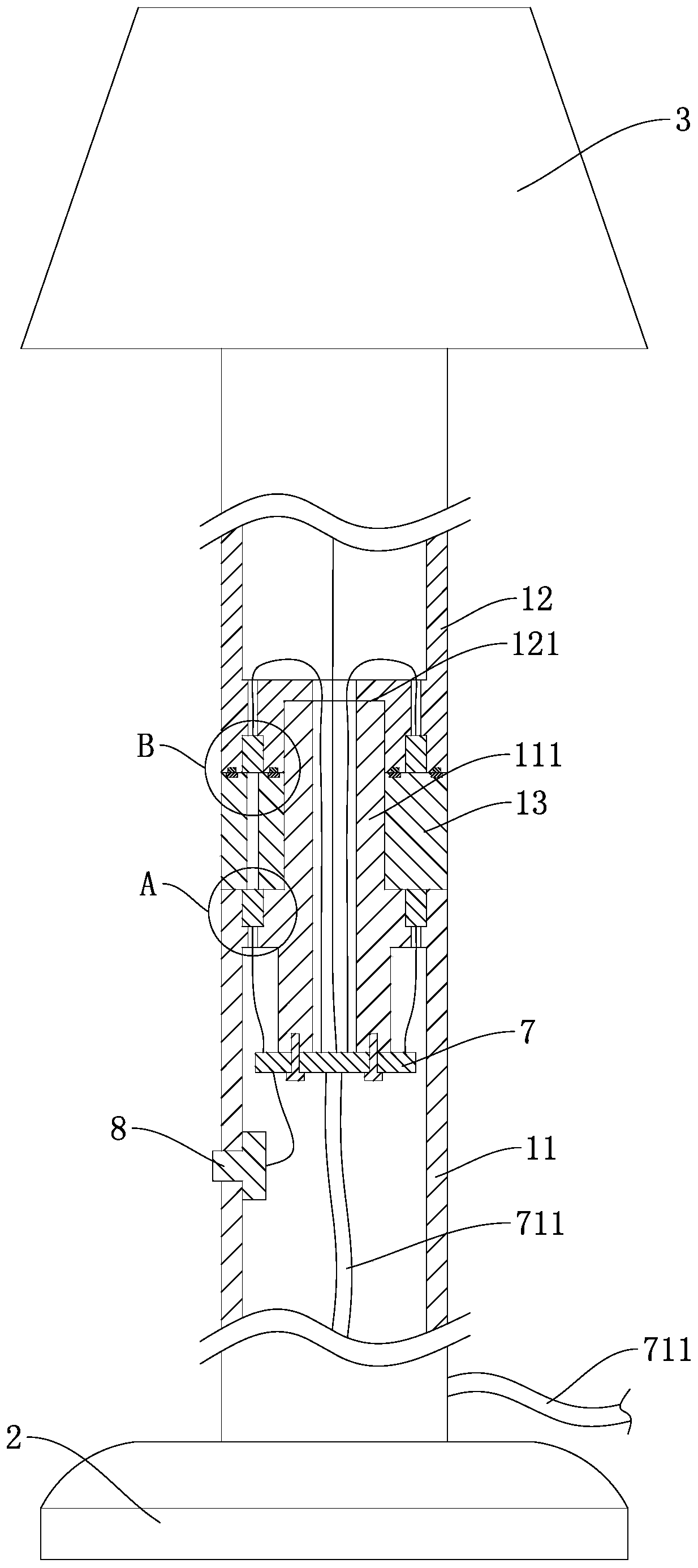

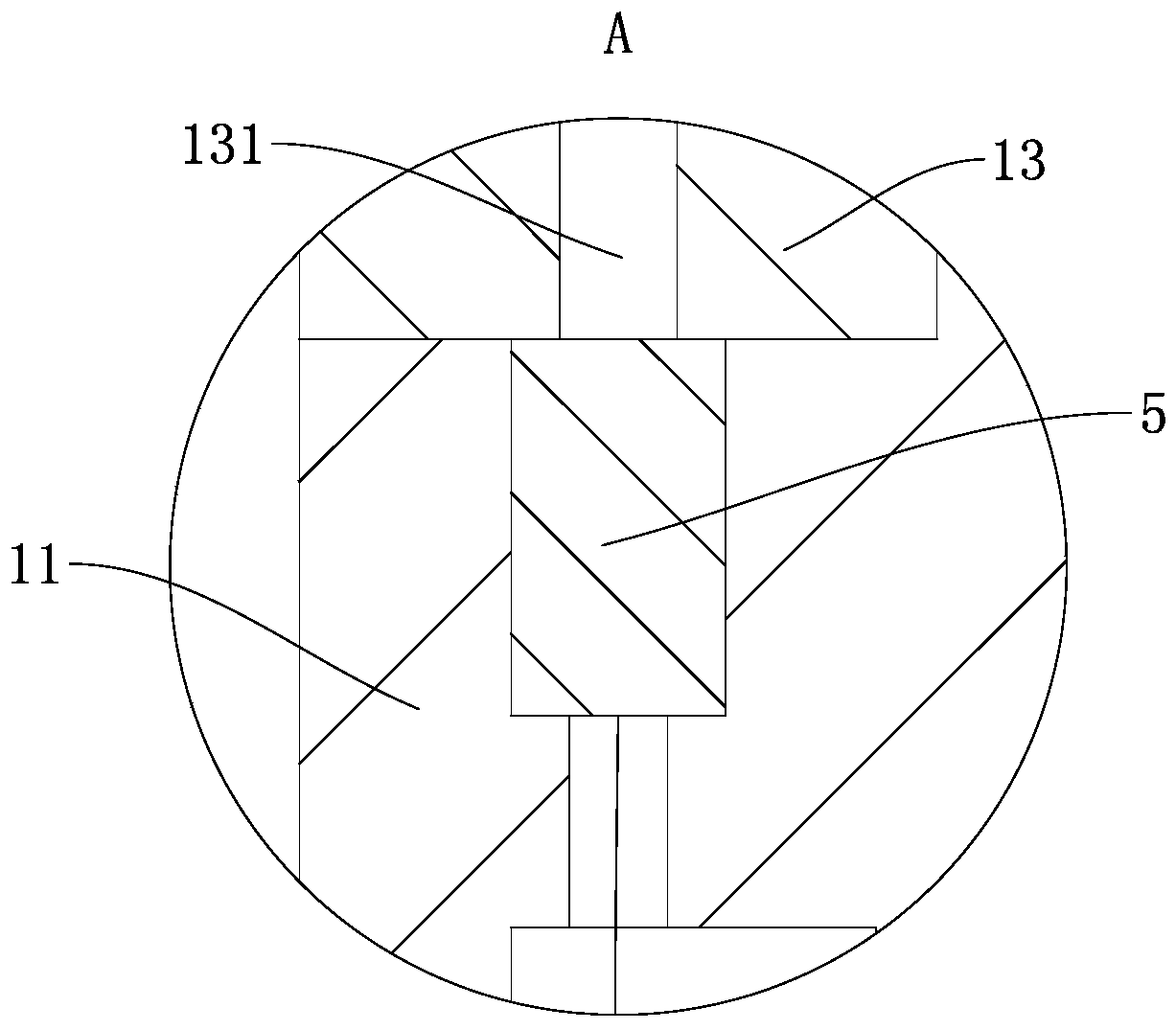

Table lamp with intelligent dimming function and control method thereof

InactiveCN110657365ABrightness adjustableColor temperature adjustableElectrical apparatusLighting support devicesEngineeringControl theory

The invention discloses a table lamp with an intelligent dimming function and a control method thereof. The table lamp with the intelligent dimming function comprises a lamp pole, a base and a lampshade; a lamp holder is further fixed to the upper end of the lamp pole, an LED bulb is installed on the lamp holder, the lamp pole comprises a first pole body, a second pole body and a rotating sleeve,an annular pipe body is integrally formed on the upper end face of the first pole body, the rotating sleeve is arranged outside the annular pipe body in a sleeving mode, a threaded groove is formed inthe lower end face of the second pole body, and the upper end of the annular pipe body is screwed into the threaded groove; a plurality of infrared transmitting tubes which are uniformly distributedin the circumferential direction are embedded in the upper end surface of an annular step, a plurality of infrared receiving tubes which are evenly distributed in the circumferential direction are embedded in the lower end face of the second pole body, a through hole is formed in the rotating sleeve, a circuit board is fixed in the first pole body, and a power supply module, a control module and alight and color modulation driving module are installed on the circuit board; and the table lamp with the intelligent dimming function and the control method thereof in the invention have the advantages of being convenient in brightness and color temperature regulation and high in intelligent degree.

Owner:沈惠萍

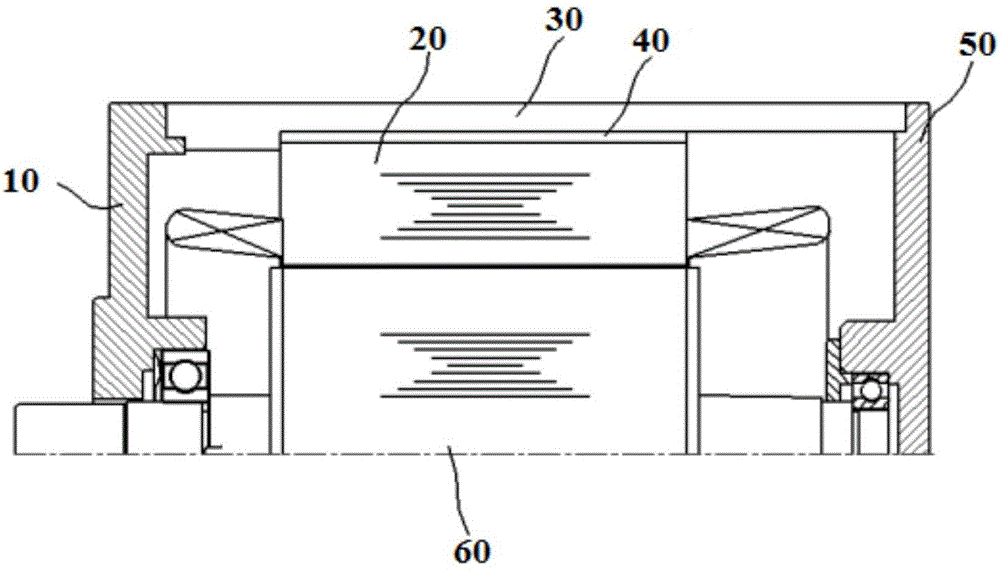

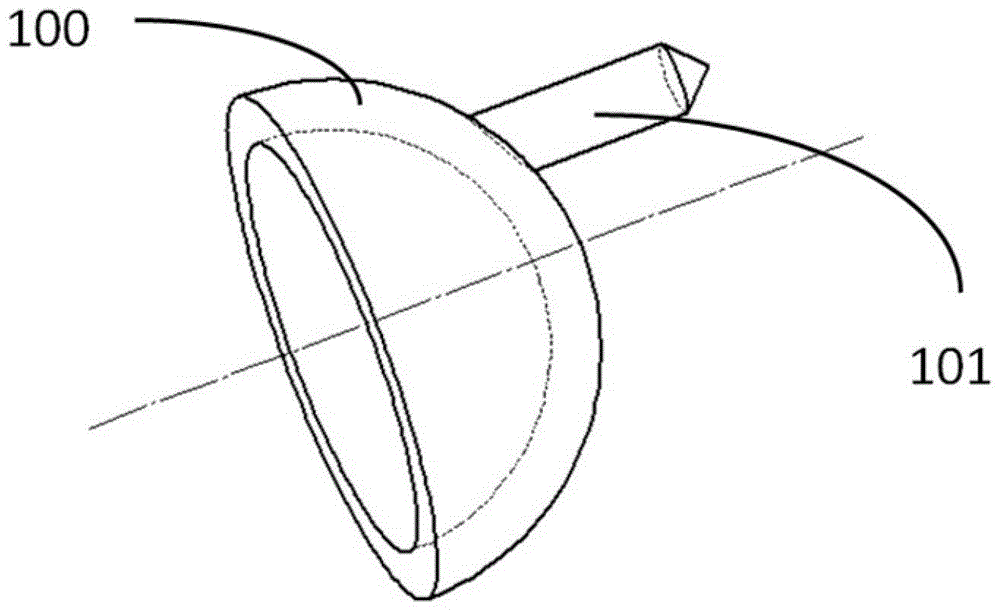

Square linear compressor

PendingCN113374668AAvoid stickingAchieve circumferential positioningReciprocating/oscillating/vibrating magnetic circuit partsPositive displacement pump componentsExhaust valveReciprocating motion

The invention relates to the technical field of linear compressors, and discloses a square linear compressor. The square linear compressor comprises a compressor base, a square linear oscillation motor and a plurality of air cylinder piston assemblies; the square linear oscillation motor comprises a stator component and a rotor component, the stator component is fixedly connected to the compressor base, and one end of the rotor component is inserted into an air gap formed by the stator component; each air cylinder piston assembly comprises a piston and an air cylinder, the air cylinders are fixedly connected to the compressor base, and the tail ends of the pistons are flexibly connected to the other end of the rotor component; the front ends of the pistons are installed in the air cylinders in a reciprocating motion mode, a compression cavity is defined by the front end wall face of each piston and the corresponding air cylinder, and an air suction valve is installed on the front end wall face of each piston; and at least one piston is provided with an air suction hole, and a compression cavity of at least one air cylinder is provided with an exhaust valve. According to the square linear compressor, the multiple air cylinder piston assemblies are flexibly connected to the rotor component, circumferential positioning of the square rotor component is achieved, circumferential rotation of the rotor component of the square linear motor can be prevented, and rotor jamming is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Special clamp suitable for assembling and welding of multiple specifications of vertical plates and multiple round pipes

PendingCN107695595AFacilitate automatic weldingImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesCoaxial lineWelding

The invention discloses a special clamp suitable for assembling and welding multiple specifications of vertical plates and multiple round pipes and relates to the field of tool clamps. The special clamp comprises a supporting platform. Multiple supporting pipe assemblies are arranged on the supporting platform in parallel in a spaced manner. The supporting pipe assemblies are used for supporting first round pipes. The supporting platform is provided with multiple columns of vertical plate positioning assemblies at intervals, and round holes coaxially arranged are formed between vertical plates. Second round pipes penetrate in the round holes of the vertical plates. End portion limiting seats used for positioning one ends of the second round pipes are arranged at the positions, located at one ends of the second round pipes, on the supporting platform, and end portion limiting air cylinders used for positioning the other ends of the second round pipes are arranged at the positions, located at the other ends of the second round pipes, of the supporting platform. By means of the special clamp, multiple specifications of vertical plates and multiple round pipes can be assembled and clamped into a whole, automatic welding of a welding robot is facilitated, the product quality and work efficiency are effectively improved, the production cost is reduced, and scale production is betterachieved.

Owner:HAIAN JIAORUI ROBOT TECH

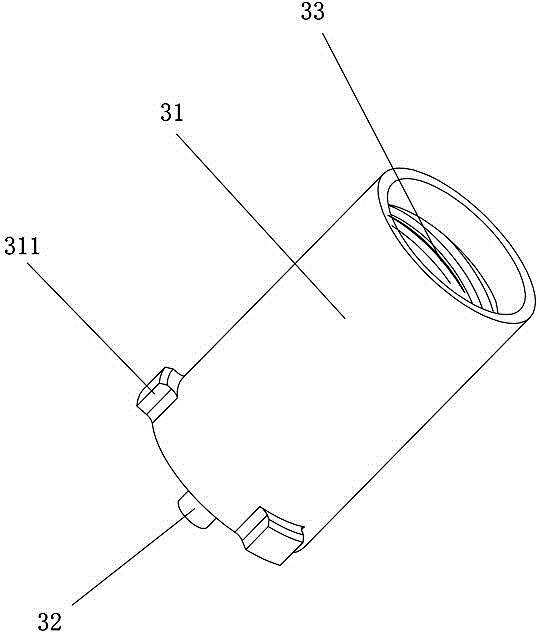

Grass trimmer

The invention discloses a grass trimmer according to which the problem that a connecting rod is large in occupied space and unfavorable for transportation and packaging is solved. According to the technical scheme for solving the problem, the grass trimmer mainly comprises a machine body, a connecting rod and a handle. The machine body and the handle are connected with the two ends of the connecting rod respectively, and the connecting rod comprises a first connecting pipe, a second connecting pipe and a pipe sleeve. The end of the first connecting pipe is arranged at one end of the pipe sleeve in a sleeved mode, the pipe sleeve is in clamped connection with the first connecting pipe, and the other end of the pipe sleeve extends into the second connecting pipe and is in threaded connection with the second connecting pipe. The connecting rod not only facilitates users' dismantling and installation, but also enables the joint of the first connecting pipe and the second connecting pipe to be good in strength and rigidity, and relative vibration between the first connecting pipe and the second connecting pipe is avoided.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

High speed train set axle box device used for accurate-wide track gauge transformation

InactiveCN107878497AAchieve axial slidingAchieve circumferential positioningAxle-boxesDifferent width rail tracksBogieLocking mechanism

Disclosed is a high speed train set axle box device used for accurate-wide track gauge transformation. The high speed train set axle box device includes an axle box rotating arm beam and a rotating arm hoop and is characterized in that a cavity formed by the axle box rotating arm beam and the rotating arm hoop is internally provided with an axle box body in a gap fit mode; the sections of the axlebox body, the axle box rotating arm beam and the rotating arm hoop are corresponding polygonal sections, and the side surfaces of the axle box body, the axle box rotating arm beam and the rotating arm hoop are provided with mounting interfaces of a locking mechanism; and the bottom of the rotating arm hoop is used as a mounting seat of a bearing mechanism, and the axle box rotating arm beam and the rotating arm hoop are provided with mounting interfaces composed of axle ends. According to the high speed train set axle box device, through three body axle boxes of the axle box body, the axle box rotating arm beam and the rotating arm hoop all with the polygonal sections, the axle box body can slide in the inner cavity formed by the axle box rotating arm beam and the rotating arm hoop in theaxial direction, circumferential positioning is achieved, because the side surfaces of the three-body axle boxes are provided with the mounting interfaces of the locking mechanism, the bottom of therotating arm hoop is provided with a mounting interface of the bearing mechanism, the axle box rotating arm beam and the rotating arm hoop are provided with the mounting interfaces composed of the axle ends, a track transformation process is achieved smoothly, increase of human and material cost due to replacing of bogies during cross-border intermodal transportation is reduced, and the operationefficiency is improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Tool adjusting assembly of multi-shaped sheet cutting device

InactiveCN107598256AAchieve circumferential positioningImprove stabilityShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention provides a tool adjusting assembly of a multi-shape sheet cutting device. The tool adjusting assembly of the multi-shaped sheet cutting device solves the technical problems in the priorart and comprises a table body, wherein a knife rest is erected on the table body, and a rectangular cutting table is erected between the knife rest and the table body; a rotating rod is fixedly connected to the bottom side of the middle of the knife rest, and the rotating rod sequentially penetrates through the cutting table and the table body to be connected with a rotating seat arranged below the table body; annular positioning grooves are formed in the table body; positioning column bodies extending downwards are arranged at the two ends of the knife rest respectively, sleeve bodies capable of vertically ascending and descending along the positioning column bodies are arranged on the positioning column bodies in a sleeving mode, and rotating positioning structures are arranged betweenthe sleeve bodies and the annular positioning grooves; rotating locking structures are arranged on the circumferential side parts of the table body; and a knife bed is connected with the knife rest ina sliding mode. The tool adjusting assembly has the advantages that the knife rest is stable and the cutting line is smooth.

Owner:吴阳涛

A shaft-mounted braking device for variable-gauge wheel sets

ActiveCN108407845BRealize the braking effectAchieve circumferential positioningSelf-applying brakesControl theoryVehicle brake

The invention relates to the technical field of rail vehicle braking and discloses an axle-mounted brake device for a gauge-changeable wheel set. The axle-mounted brake device for the gauge-changeablewheel set comprises a transitional sleeve, a locating mechanism and a plurality of axle-mounted brake discs; the plurality of axle-mounted brake discs are fixed on the transitional sleeve at intervals; the transitional sleeve is connected with an axle of the gauge-changeable wheel set through a spline in a matched manner; and the locating mechanism is used for connecting the transitional sleeve with the axle so as to axially locate the transitional sleeve relative to the axle. According to the axle-mounted brake device for the gauge-changeable wheel set, by improving the connection modes between the axle-mounted brake discs and the axle, the relative positions of a brake clamp and the axle-mounted brake discs can be kept invariable during changing the gauge so that braking effects at different gauges are realized.

Owner:CRRC QINGDAO SIFANG CO LTD

Self-adaptive sand-blasting polishing device for aluminium alloy bend pipe

InactiveCN111975651AEqual grinding forceEqual distanceBlast gunsAbrasive machine appurtenancesSand blastingWork time

The invention relates to the field of aluminium alloy bend pipe polishing, in particular to a self-adaptive sand-blasting polishing device for an aluminium alloy bend pipe. The device comprises a centering fixture mechanism, a guiding sliding mechanism, a horizontal ring-shaped sand-blasting pipe, a horizontal guiding rail, a lifting mechanism, a centering base, a one-way pushing mechanism, a pressing rail, a vertical ring-shaped sand-blasting pipe, a containing box body, and a pushing box body. The self-adaptive sand-blasting polishing device for the aluminium alloy bend pipe realizes the automatic clamping of the aluminium alloy bend pipe, ensures the equal distance between the outer wall of the aluminum alloy bend pipe and the inner side of the horizontal ring-shaped sand-blasting pipe,and ensures that the brightness of the external wall of the aluminum alloy bend pipe is basically the same after polishing, so that the device can polish all aluminum alloy bent pipes with differentheights, and polish both sides of the aluminum alloy bent pipe simultaneously, so as to improve the working efficiency of the device and reduce the working time of a worker.

Owner:孔霄

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com