Rotational cutting tool capable of assembling and disassembling

A technology of rotating cutters and slewing grooves, which is applied in the direction of milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problems of low coupling force of matching parts, brittle cracks of hard alloy rods, low processing efficiency, etc., and achieve stable and reliable positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

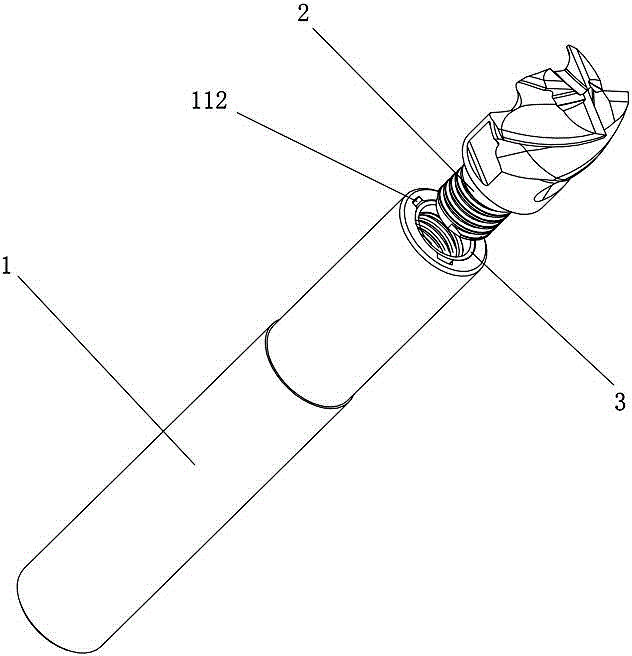

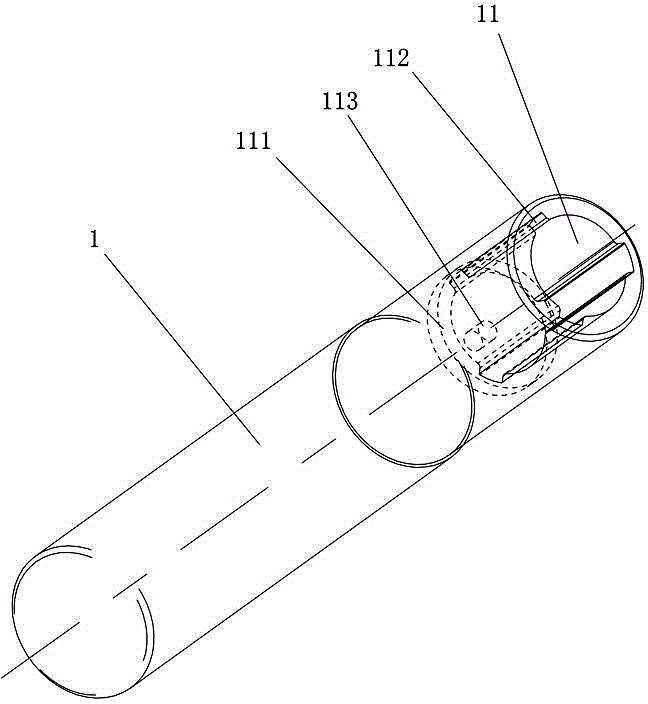

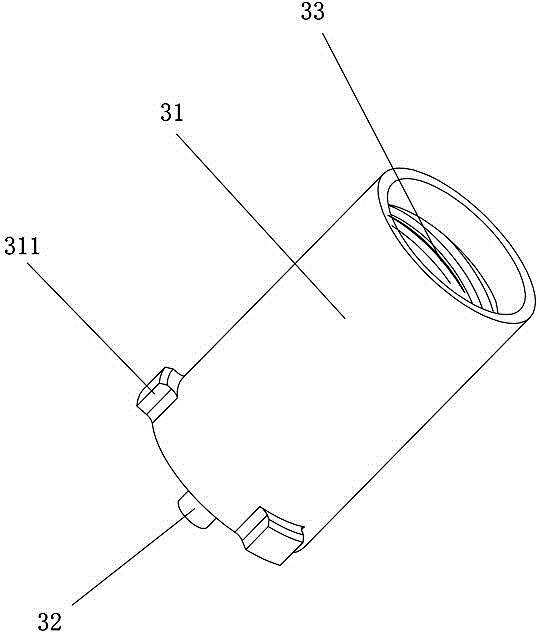

[0031] Figure 1 to Figure 5 The first embodiment of the detachable rotary tool of the present invention is shown, the detachable rotary tool of this embodiment includes a clamping part 1, a cutting part 2 and an embedded connecting piece 3, and the clamping part 1 includes a clamping head and The handle is clamped, and the end surface of the clamping head is provided with an axial recess 11 for installing the inserting connector 3, and the inserting connector 3 is installed in the axial recess 11, and the cutting part 2 is installed on the insert On the connector 3, at least one protrusion 311 is provided on the curved surface 31 of the outer wall of the connector 3, and a rotary groove 111 is opened on the bottom side wall of the axial recess 11, and on the side wall of the axial recess 11 There are axial grooves 112 which have the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com