Reversible wedge-type overrunning clutch with grooves in inner ring

An overrunning clutch and wedge-type technology, which is applied in the direction of clutches, one-way clutches, mechanical equipment, etc., can solve the problems that cannot meet the requirements of mechanical equipment, general products do not have a suitable structure, and are inconvenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation method, Structure, characteristic and effect thereof are as follows in detail.

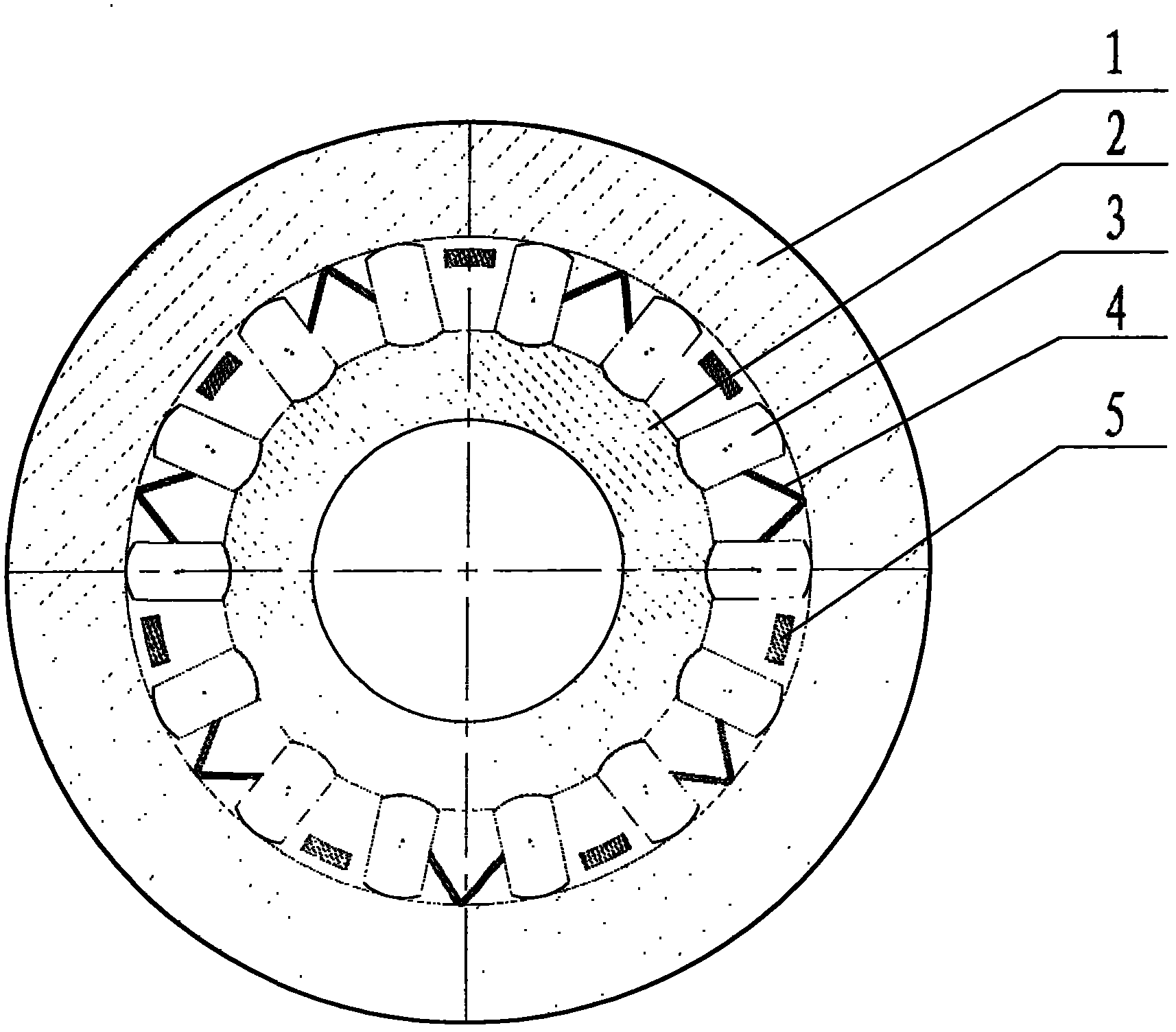

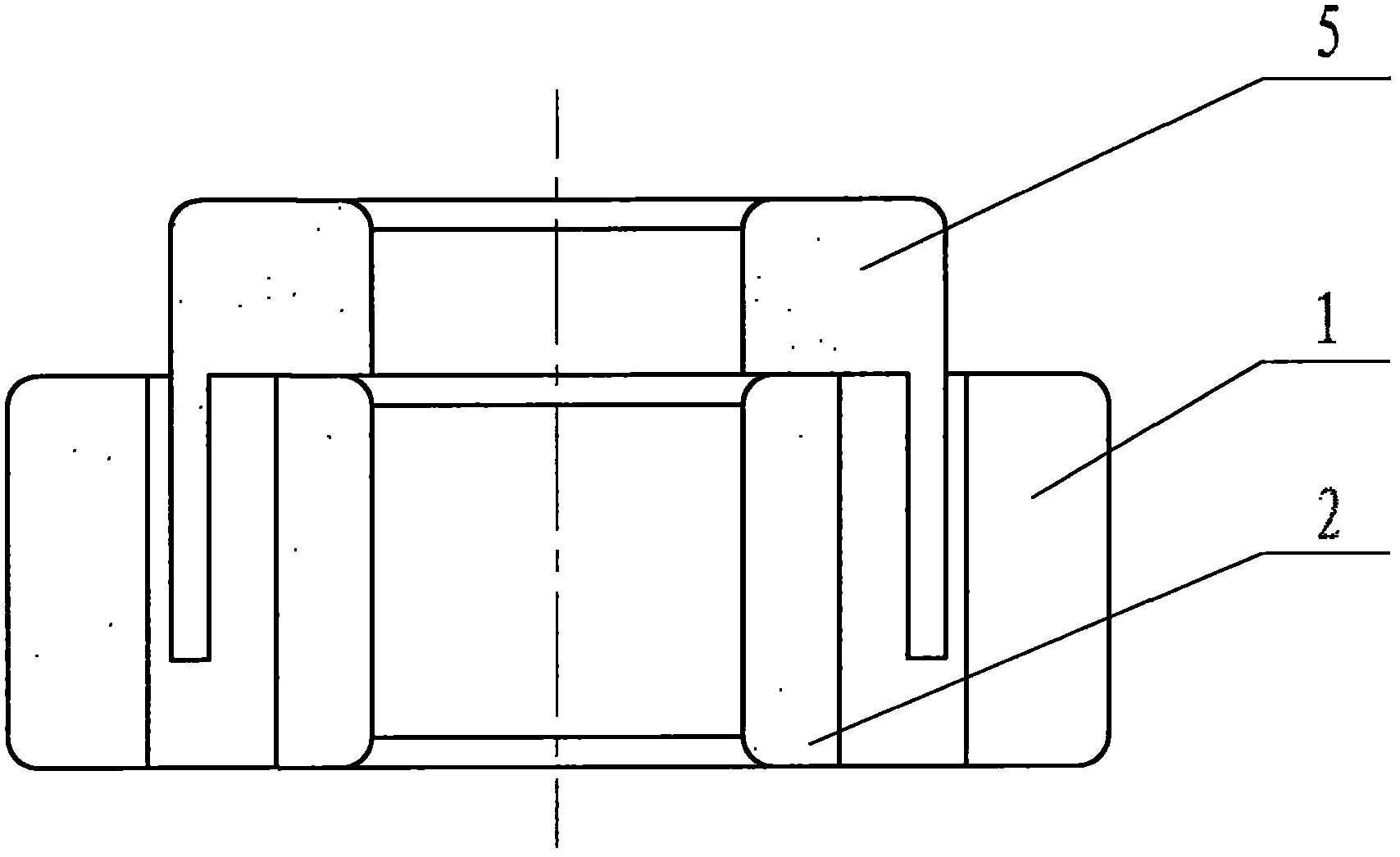

[0016] see figure 1 and figure 2 the law, figure 1 It is a structural schematic diagram of the reversible sprag type overrunning clutch with grooves on the inner ring of the present invention, figure 2 for figure 1 cutaway view. The reversible sprag type overrunning clutch with grooved inner ring includes an outer ring 1, an inner ring 2, a plurality of sprags 3, a spring 4 and a shift fork 5. In the present invention, the spring 4 is a tension spring, a compression spring or a leaf spring.

[0017] In one embodiment of the present invention, the inner ring 2 is provided with arc-shaped grooves distributed along the circumferential direction. Between the outer ring 1 and the inner ring 2, a spring 4 is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com