Auxiliary device for installation and positioning of claw poles

A technology for installation, positioning and auxiliary devices, which is applied in the direction of electromechanical devices, workpiece clamping devices, manufacturing stator/rotor bodies, etc., can solve problems such as difficult to ensure assembly accuracy, and achieve good stability, not easy to shake, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

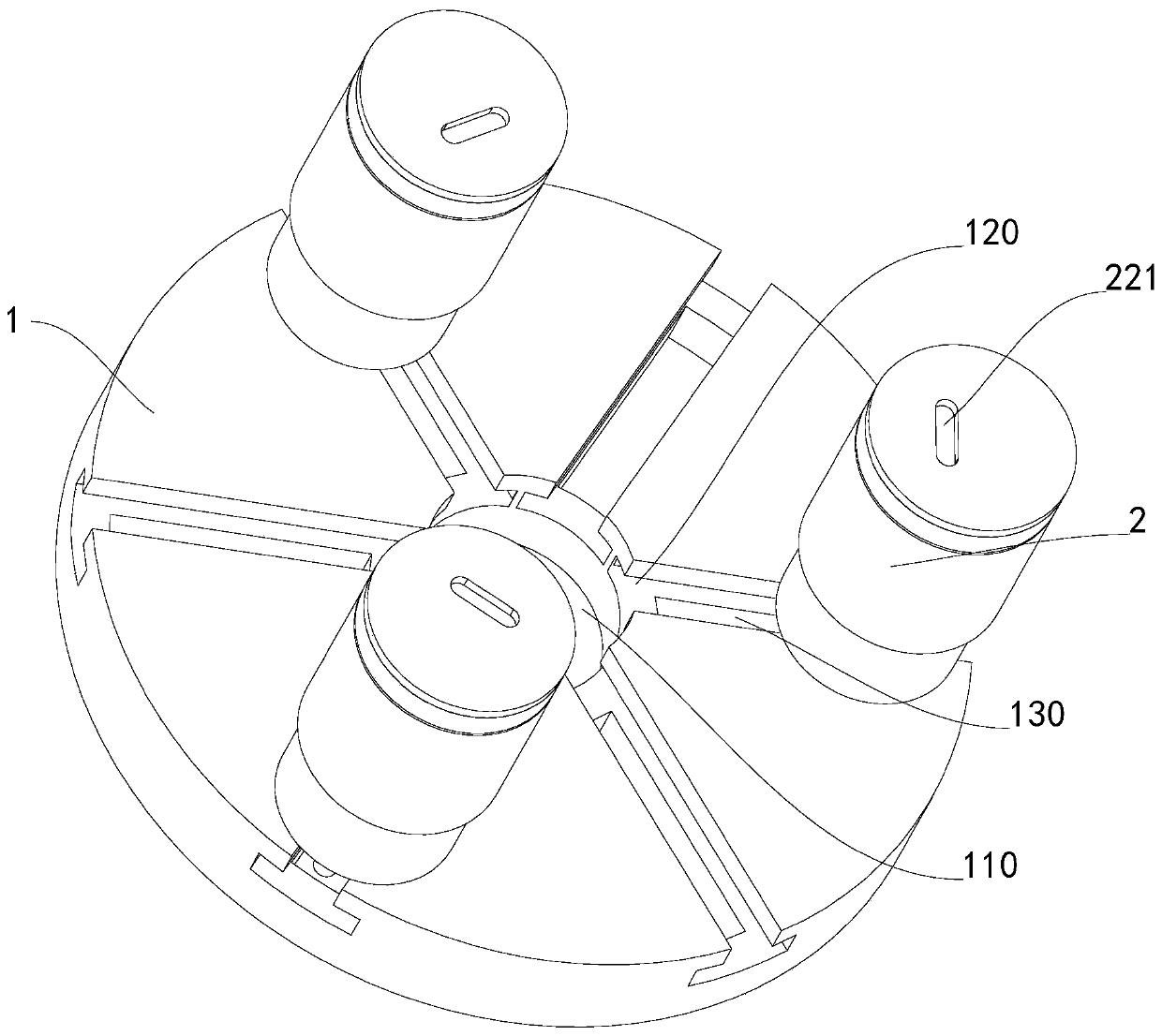

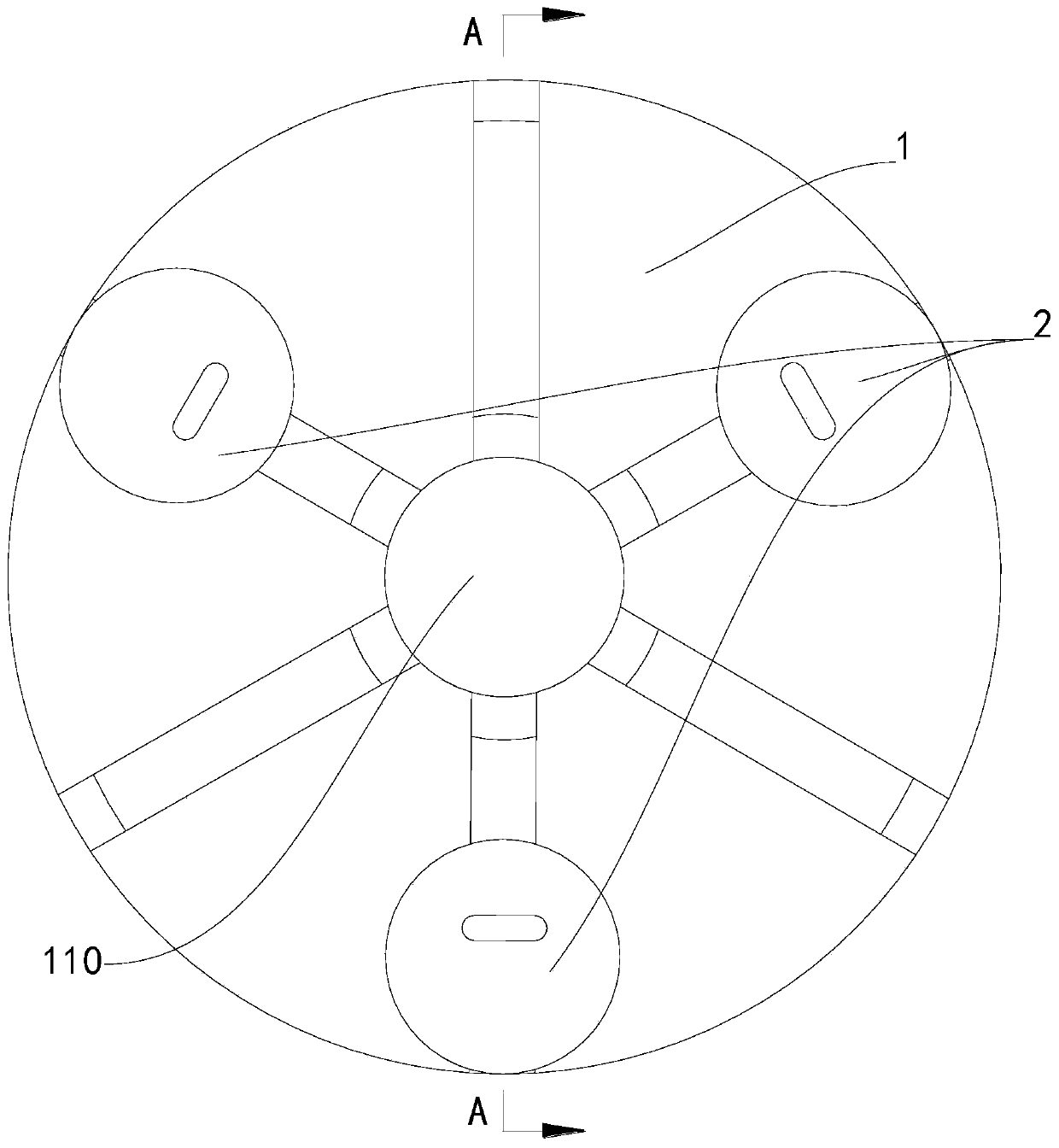

[0029] Such as figure 1 , figure 2 , image 3 As shown, a claw pole installation and positioning auxiliary device includes a base 1 and a positioning assembly 2, the base 1 is provided with a socket 110, and a plurality of positioning assemblies 2 are arranged on the circumference with the socket 110 as the center of the circle, and multiple positioning The angular distribution of the assembly 2 matches the angular distribution of the ratchets of the claw poles to be installed. The socket 110 is mainly used to allow the shaft 3 of the two claw poles to be installed to pass through. The inner diameter of the socket 110 is preferably equal to the outer diameter of the rotary shaft 3 The number of positioning components 2 is determined according to the number of pawls to be installed with claw poles. For example, when a claw pole containing six pawls needs to be positioned, the number of positioning components 2 can be three or six, as Taking three as an example, at this time,...

Embodiment 2

[0032] This embodiment is a further improvement made on the basis of Embodiment 1, specifically as follows:

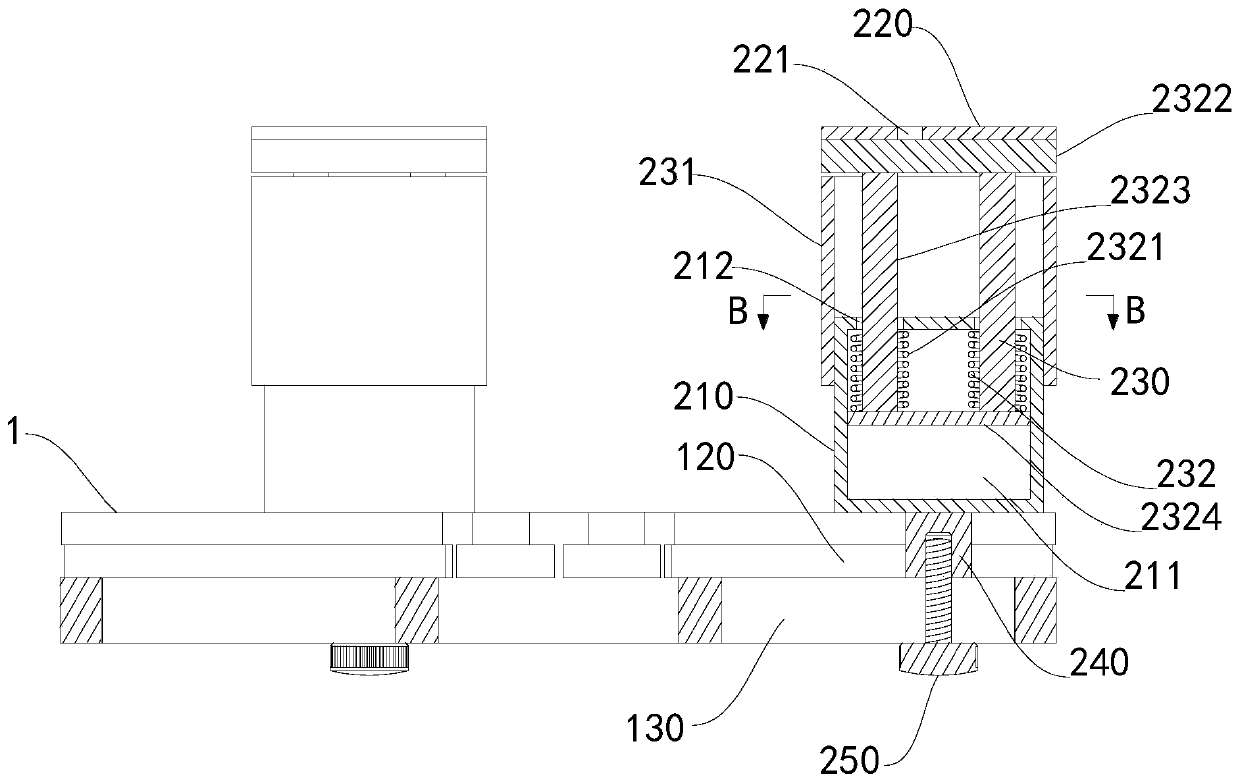

[0033] In the embodiment, the positioning assembly 2 also includes a linear lifting mechanism 230, the linear lifting mechanism 230 is arranged on the positioning column 210, the positioning plate 220 is arranged on the linear lifting mechanism 230, and the linear lifting mechanism 230 can drive the positioning plate 220 to move up and down. Move, thereby changing the distance between the positioning plate 220 and the positioning column 210, so that the claw pole installation and positioning auxiliary device can meet the assembly of various claw poles with different heights.

[0034] The linear lifting mechanism 230 includes a positioning sleeve 231 and a rotation stopper 232. The inner wall surface of the positioning sleeve 231 is provided with internal threads, and the outer circumferential surface of the positioning column 210 is provided with external threads. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com