Patents

Literature

31results about How to "Assembly accuracy is easy to guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

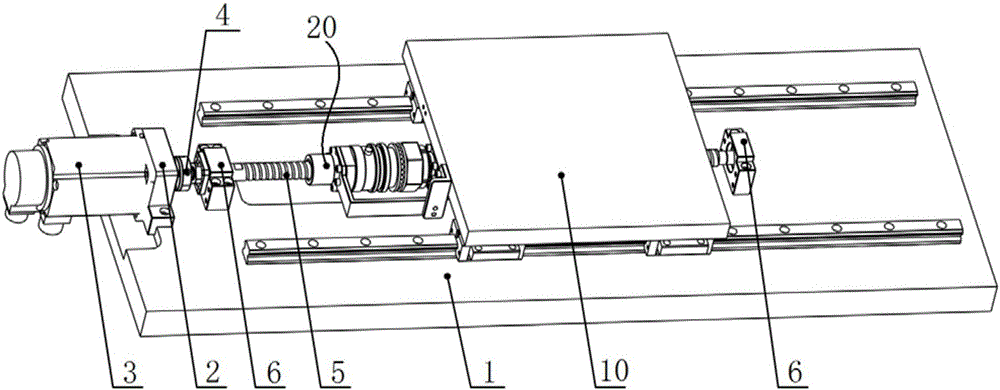

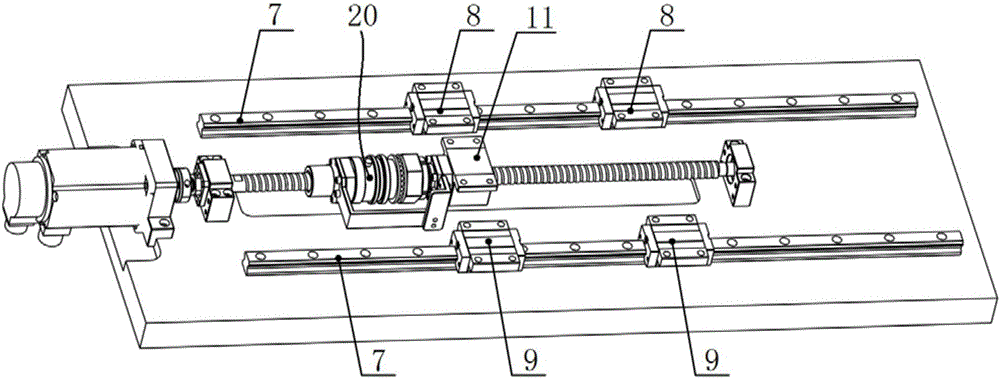

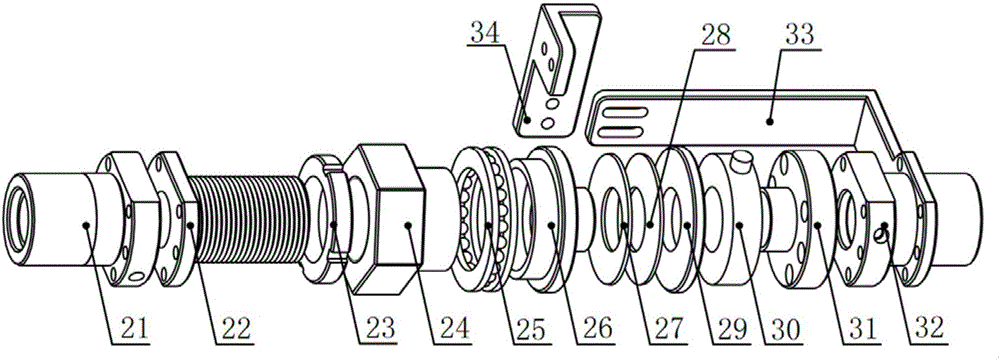

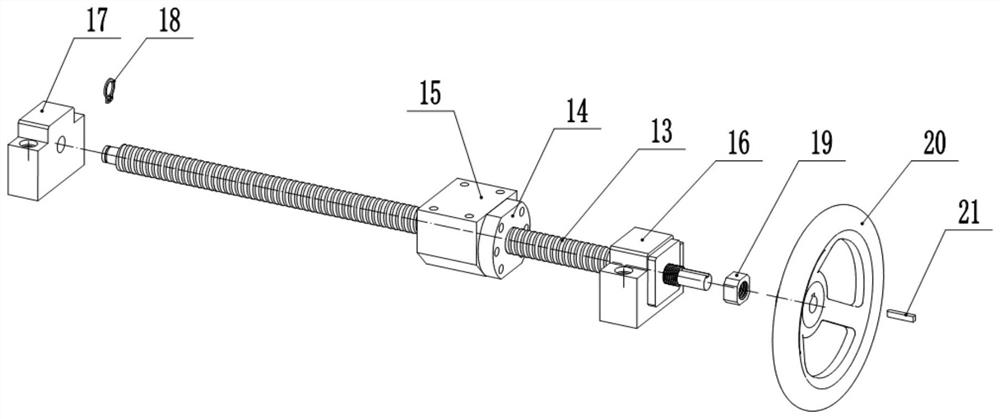

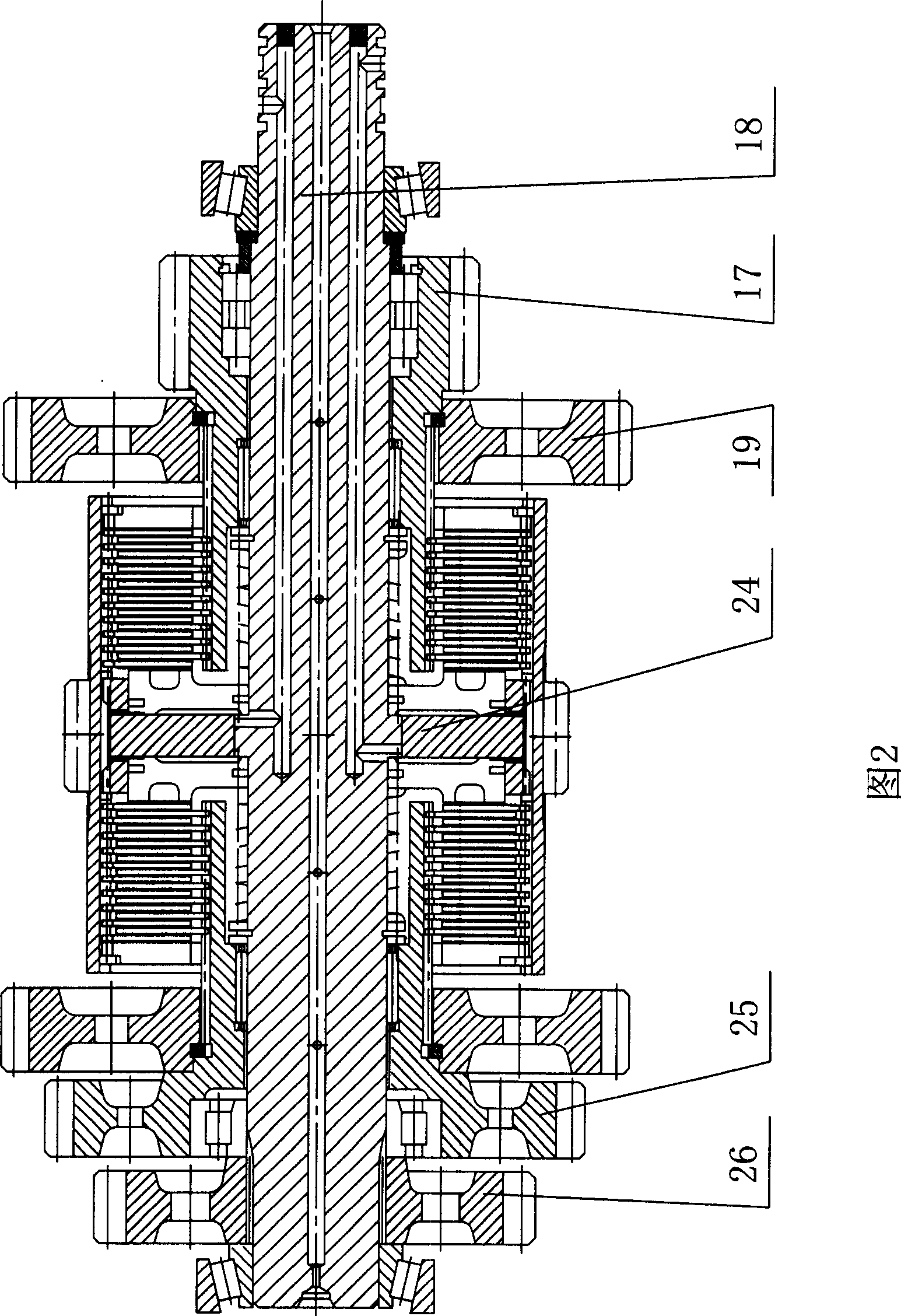

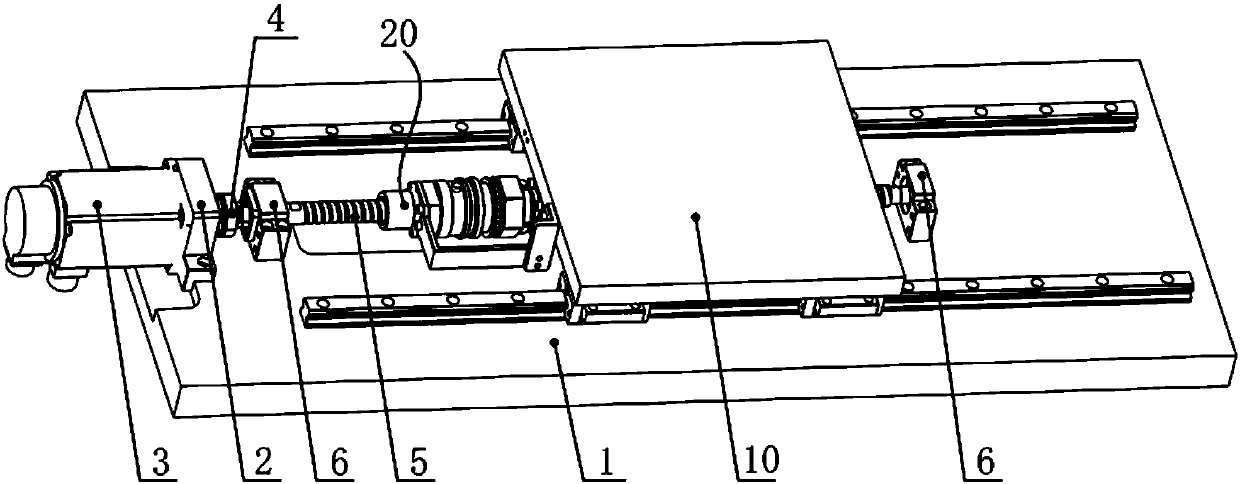

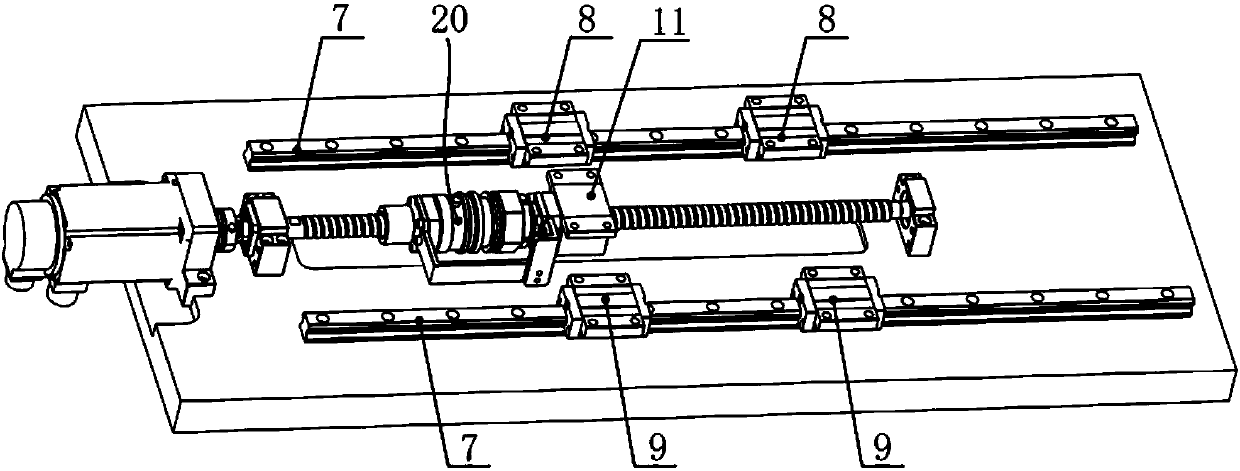

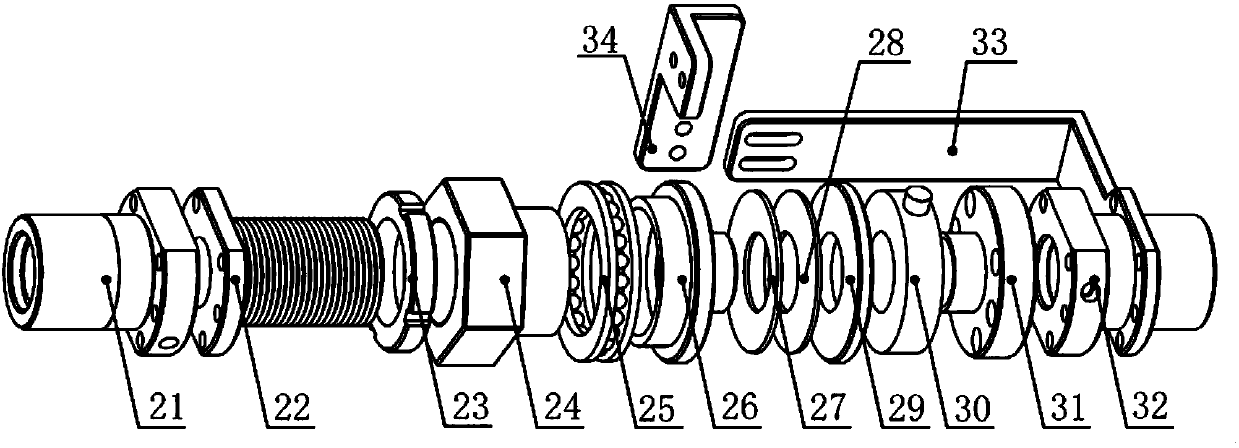

Double-nut ball screw pair pre-tightening force adjusting and measuring device and linear feeding system

InactiveCN105965307ALittle effect on stiffnessEvenly distributedMeasurement/indication equipmentsFeeding apparatusBall screwThrust bearing

The invention relates to a double-nut ball screw pair pre-tightening force adjusting and measuring device and a linear feeding system. The double-nut ball screw pair pre-tightening force adjusting and measuring device comprises a main screw nut, a nut sleeve, a locking nut, a pre-tightening nut, a thrust bearing, a front disc spring fixing plate, a first disc spring, a second disc spring, a rear disc spring fixing plate, an annular pressure sensor, a sensor fixing plate, an auxiliary screw nut, an auxiliary nut connecting plate and a worktable connecting plate; one end of the nut sleeve is in fastened connection with the main screw nut; the locking nut and the pre-tightening nut are connected to the nut sleeve by threads; the thrust bearing clings to the pre-tightening nut; the front disc spring fixing plate clings to the thrust bearing; the excircle side of the first disc spring clings to the front disc spring fixing plate; the inner hole of the second disc spring clings to the inner hole of the first disc spring; the rear disc spring fixing plate clings to the excircle side of the second disc spring; and the annular pressure sensor clings to the rear disc spring fixing plate, the sensor fixing plate clings to the annular pressure sensor, and the other side of the sensor fixing plate is in fastened connection with the auxiliary screw nut.

Owner:TSINGHUA UNIV

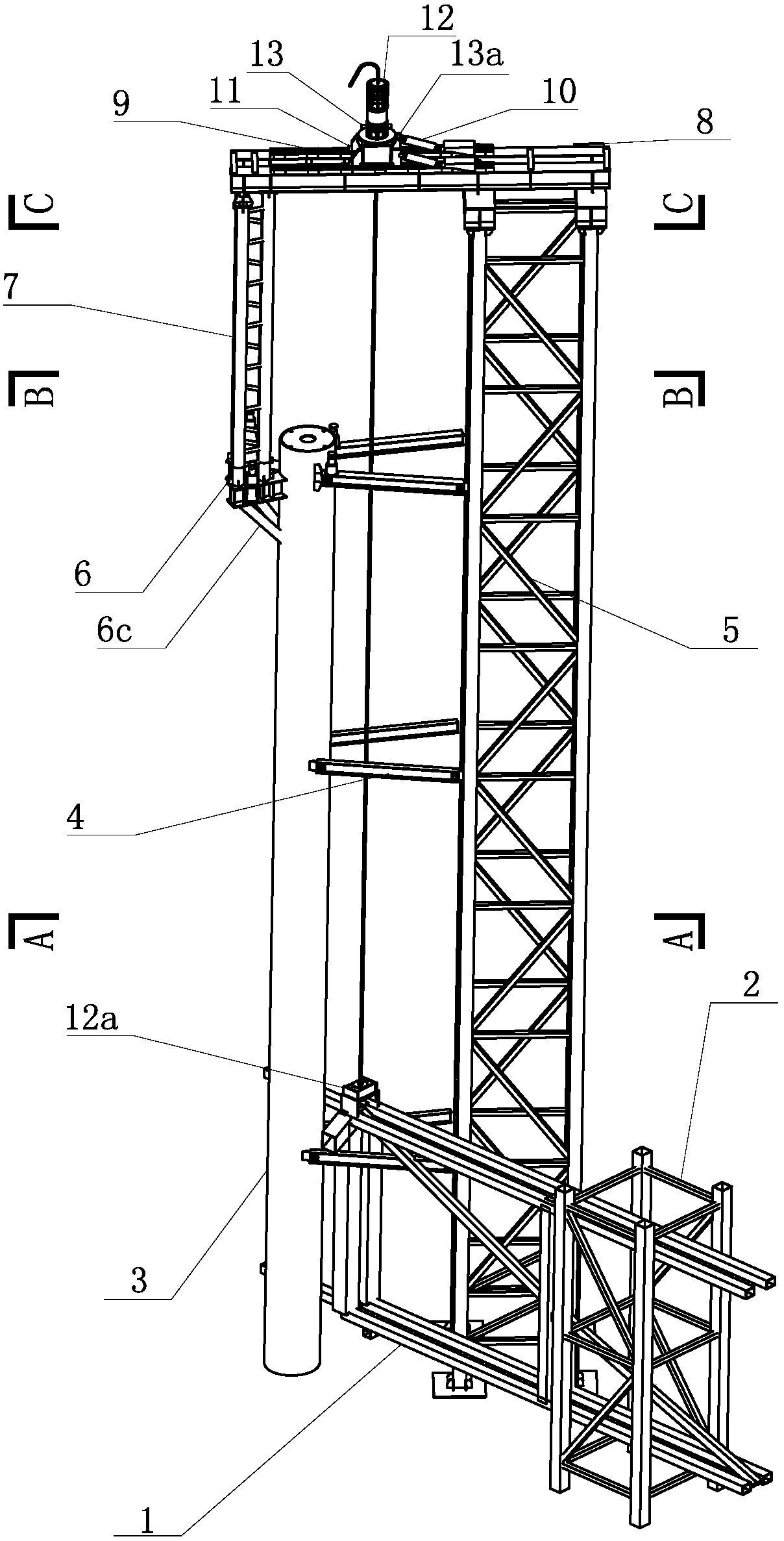

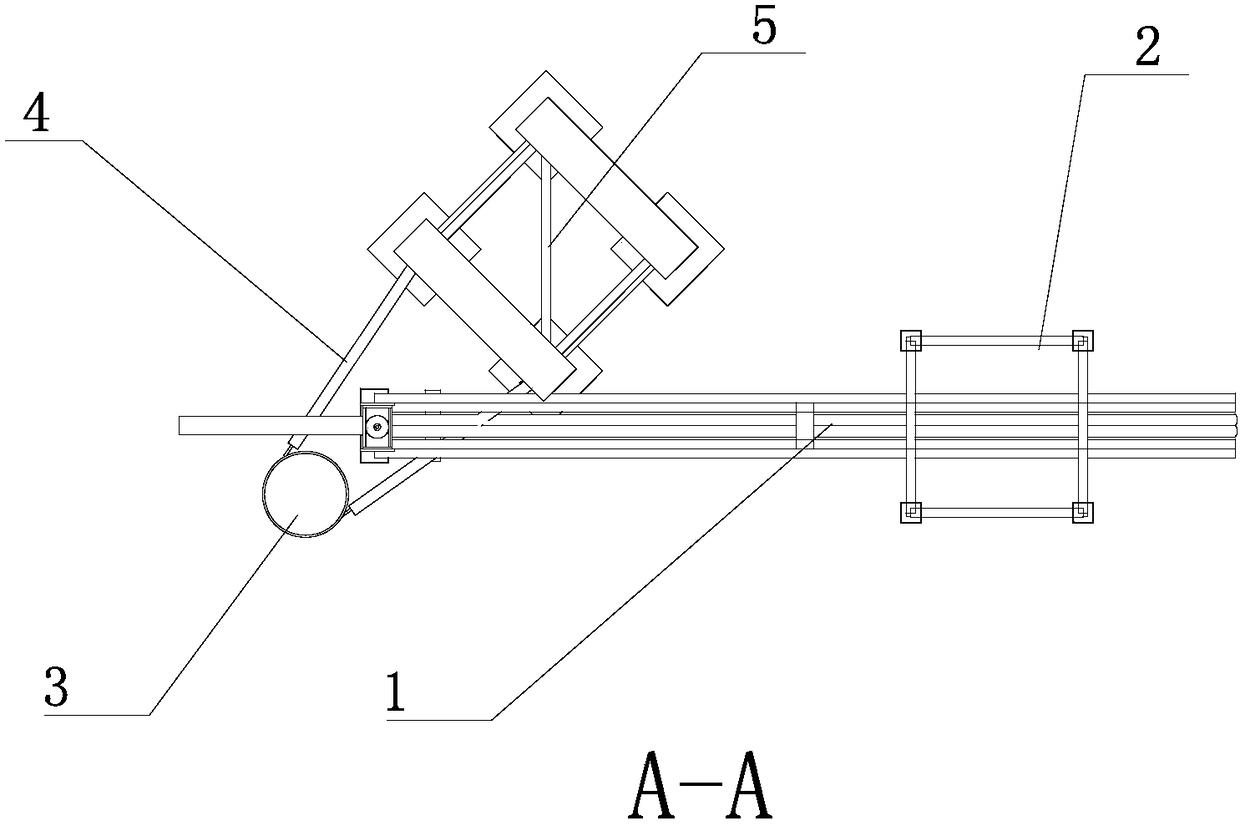

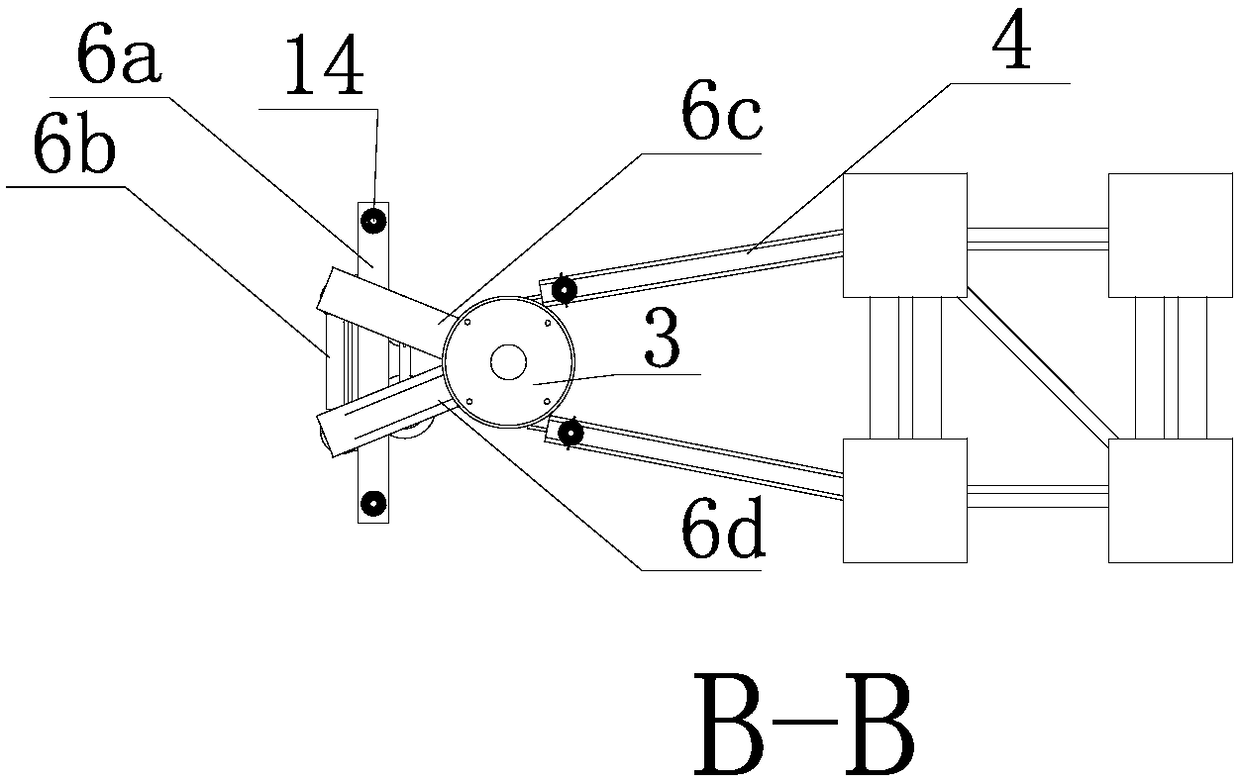

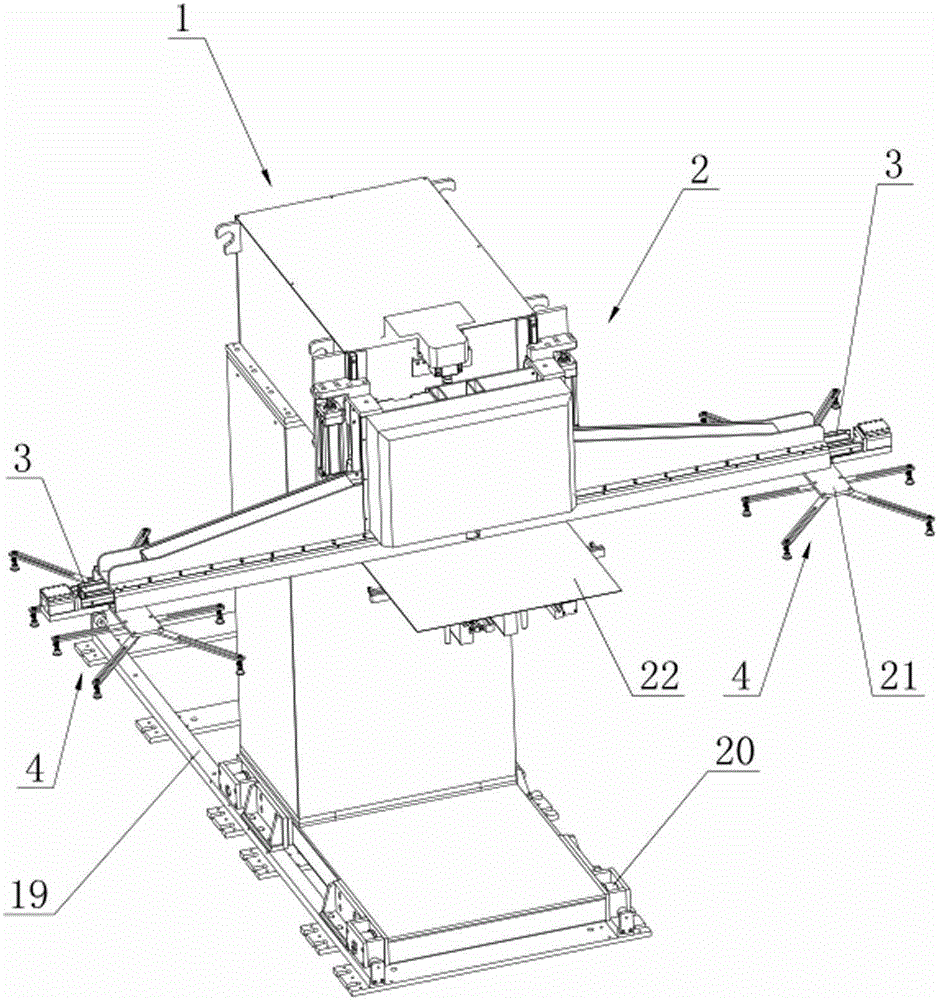

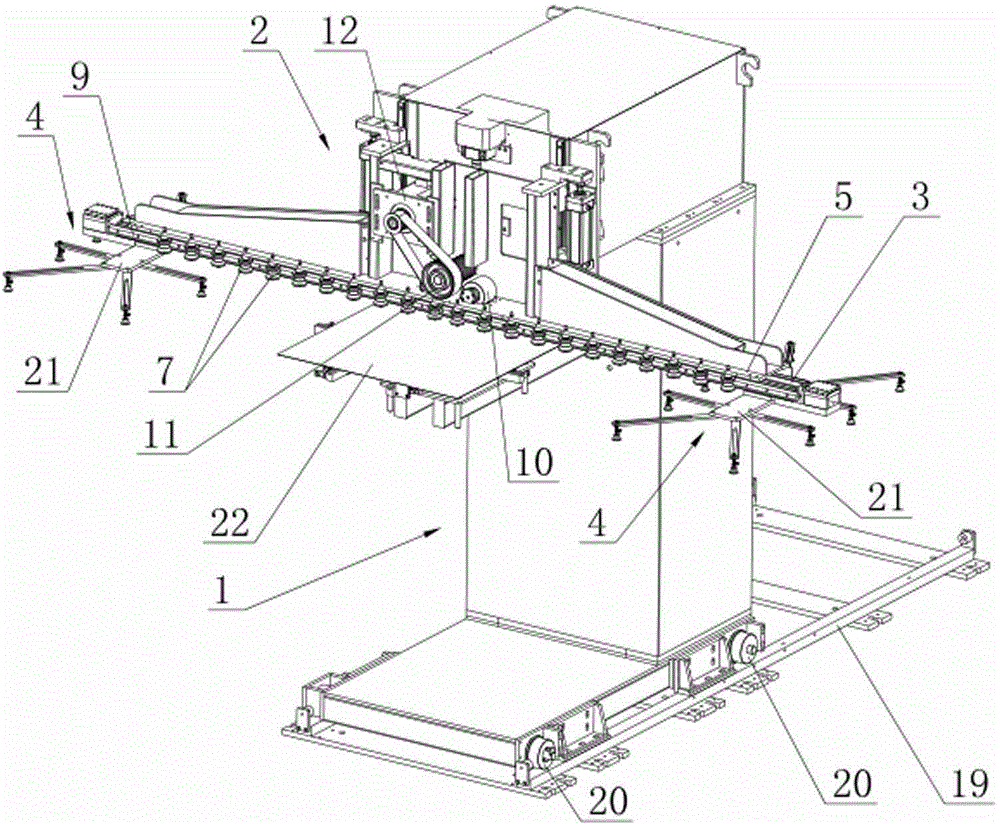

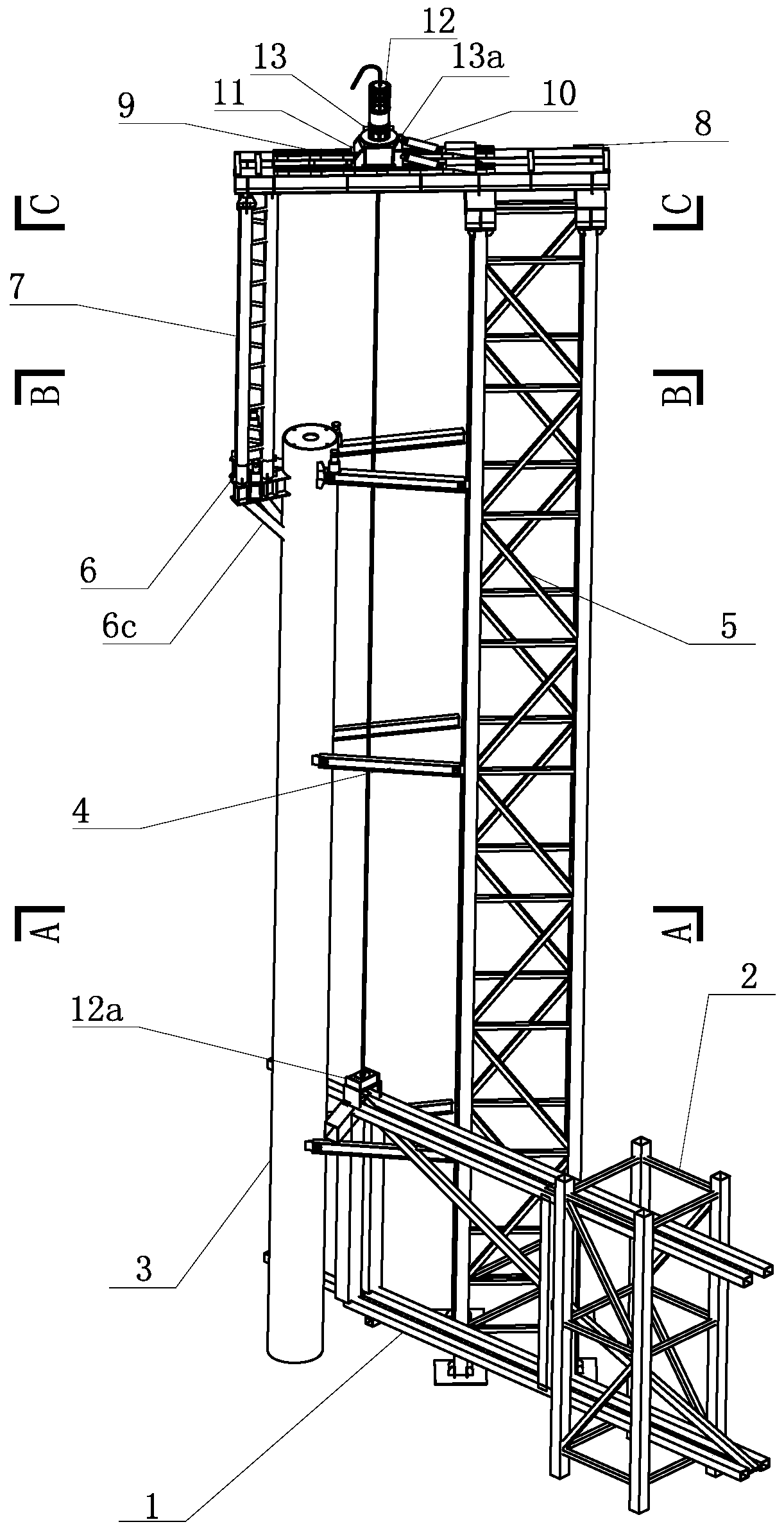

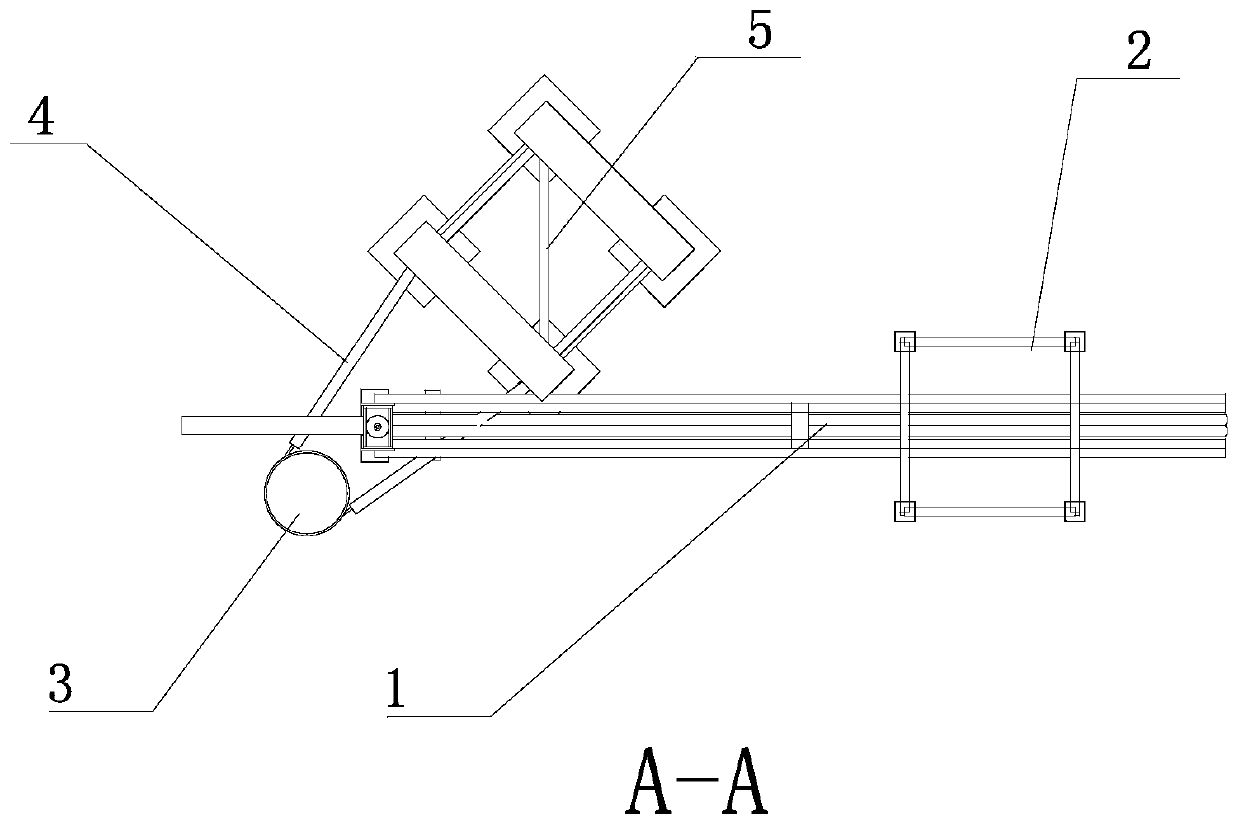

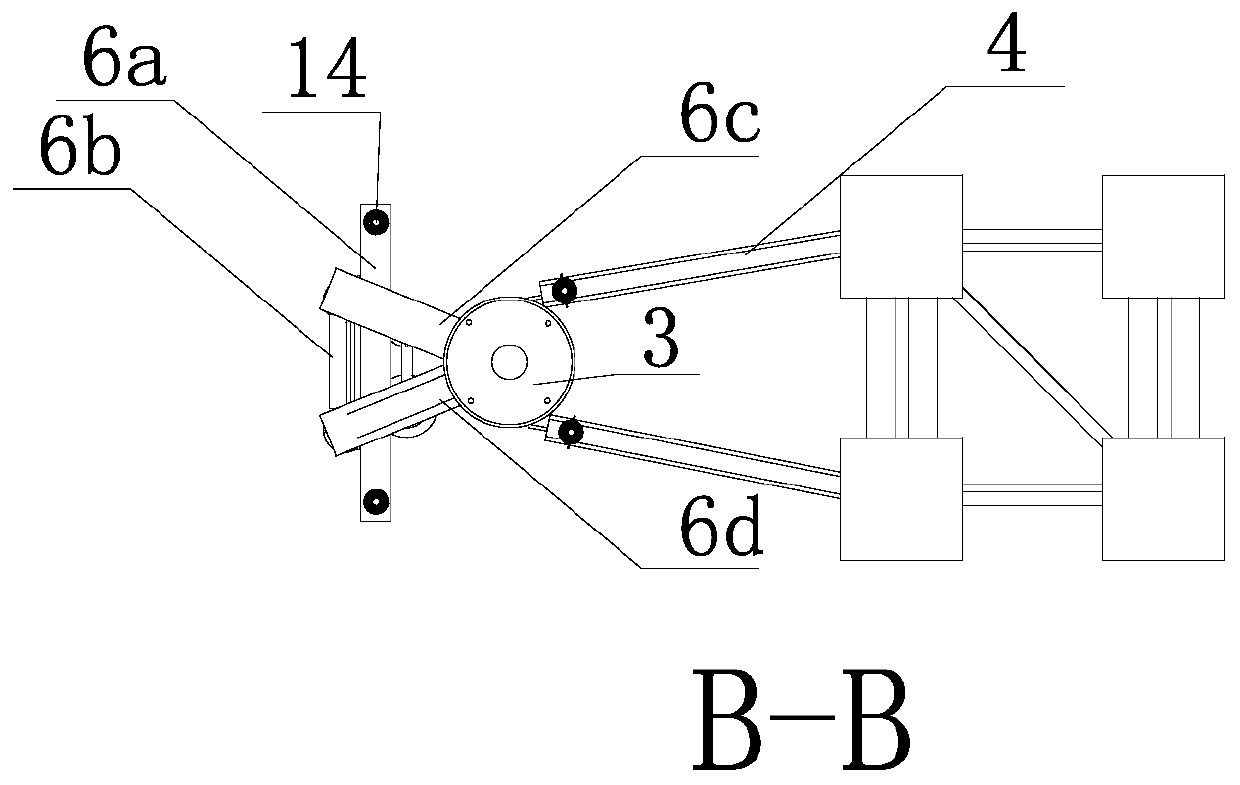

Offset lifting slip device and method

The invention belongs to the field of steel structure construction, and particularly relates to an offset lifting slip device and method. A lifting supporting frame is arranged on a structure main body steel column; an assembled jig frame is erected on a floor, and main body roof trusses are assembled into an overall structure; the overall roof trusses are lifted to be arranged below a load-bearing track beam; hydraulic jacking and pushing driving equipment is connected with a lifting load-bearing beam through a pin shaft, the hydraulic jacking and pushing driving equipment is started, and thelifting load-bearing beam is jacked and pushed to slip to a calculated elevation on the load-bearing track beam; and four jacks are used on the structure main body steel column for jacking lower chords of the roof trusses, a lifter equipment device is shut down, all the jacks unload the main body roof trusses in place in synchronous and in-step modes, and the main body roof trusses and the structure main body steel column are fixedly connected, so that construction is completed. According to the offset lifting slip device and method, working at heights is reduced, safety is improved, the efficiency is high, and the cost of measures is saved.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

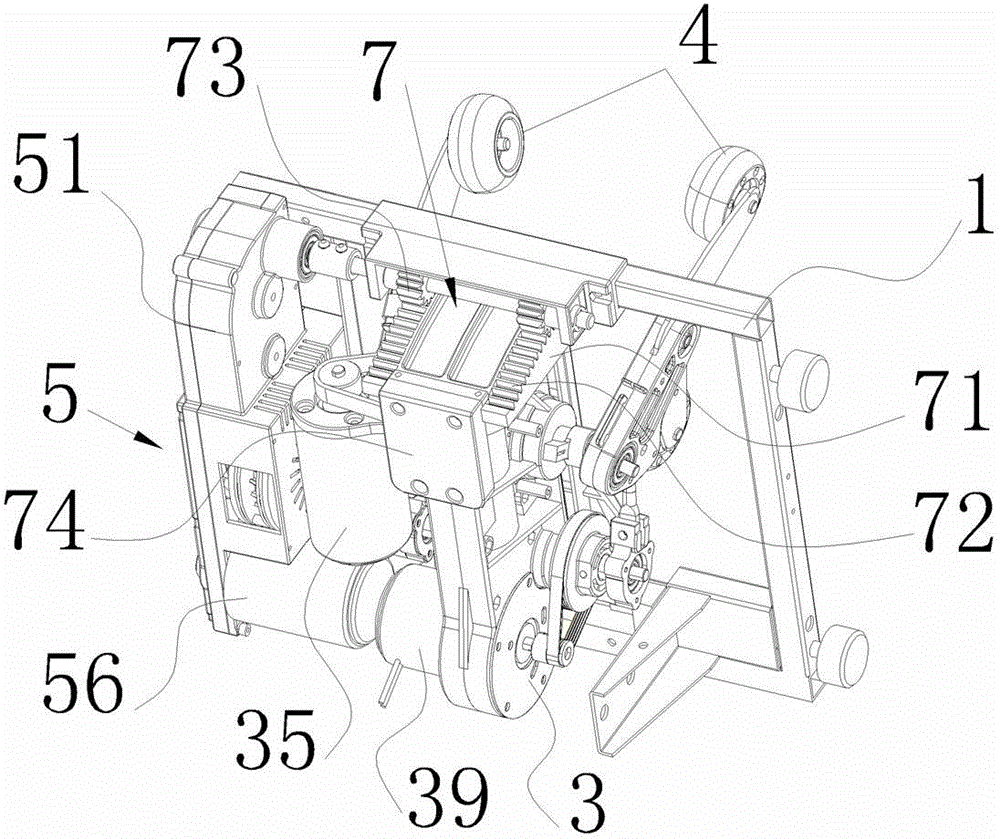

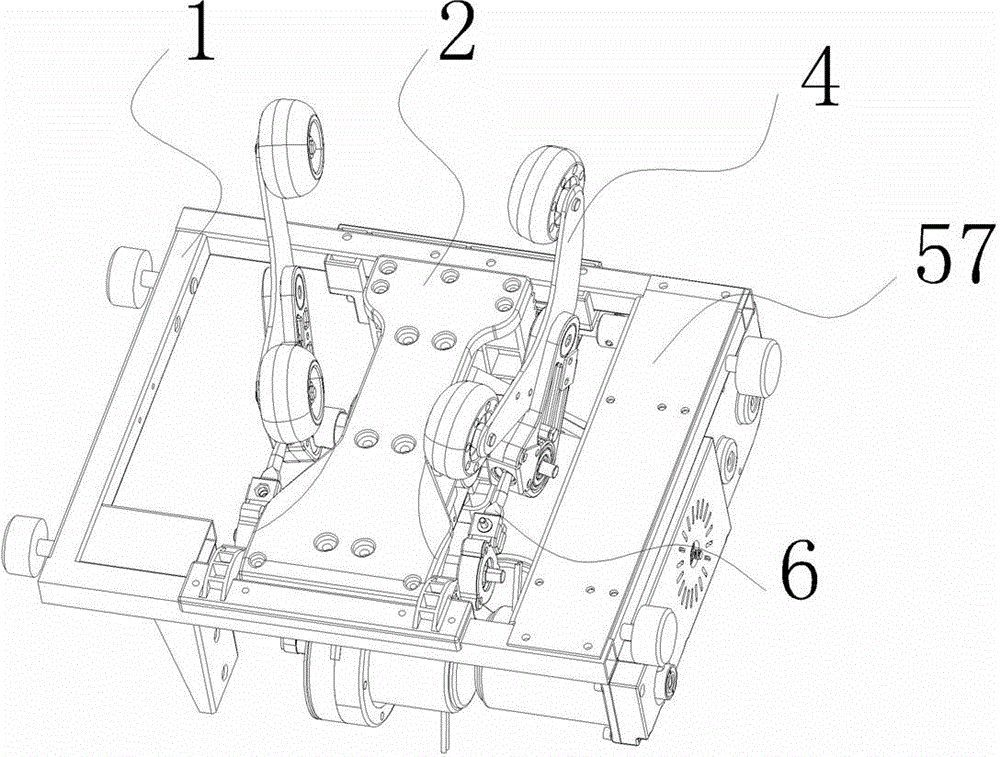

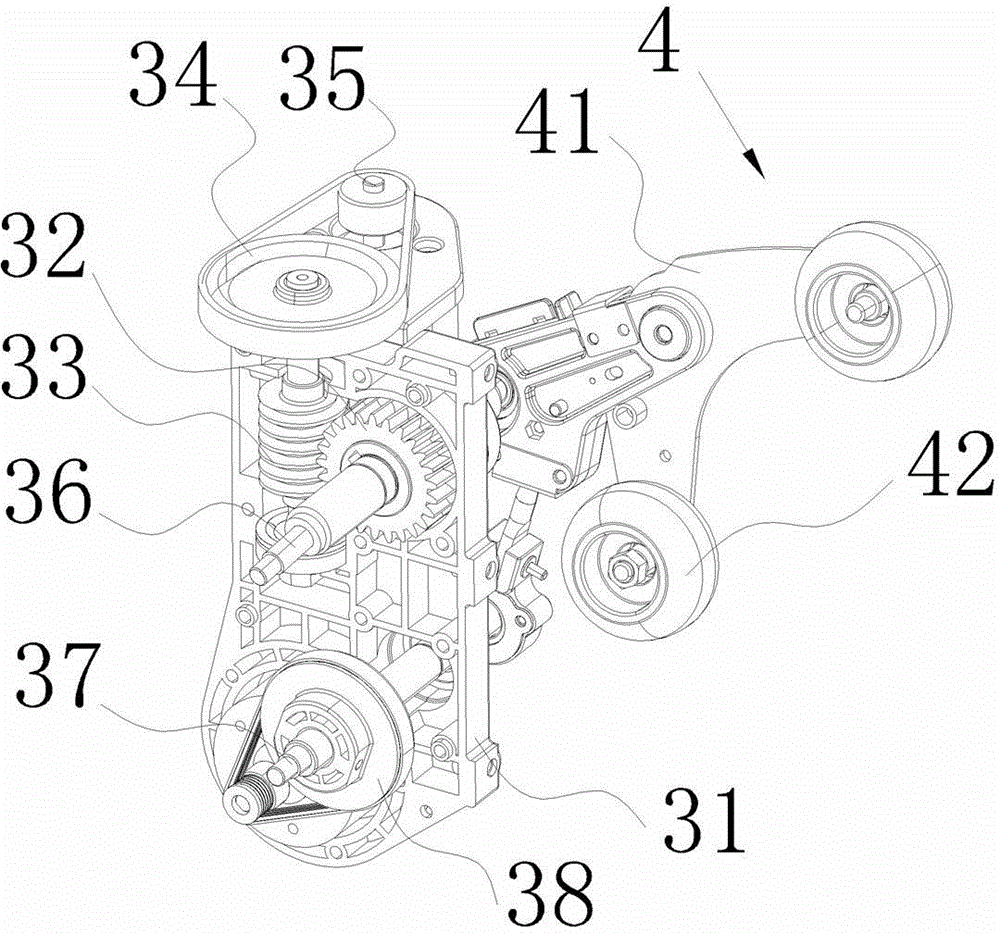

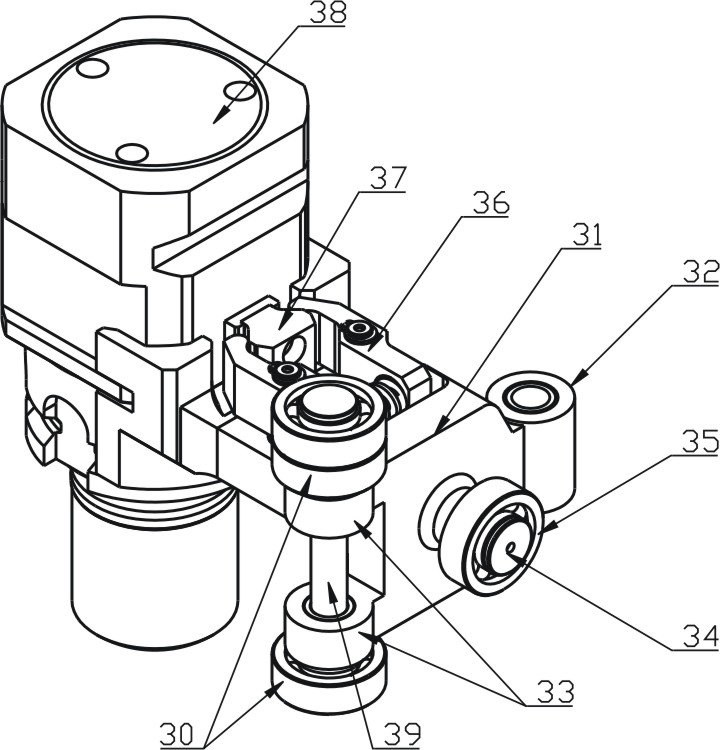

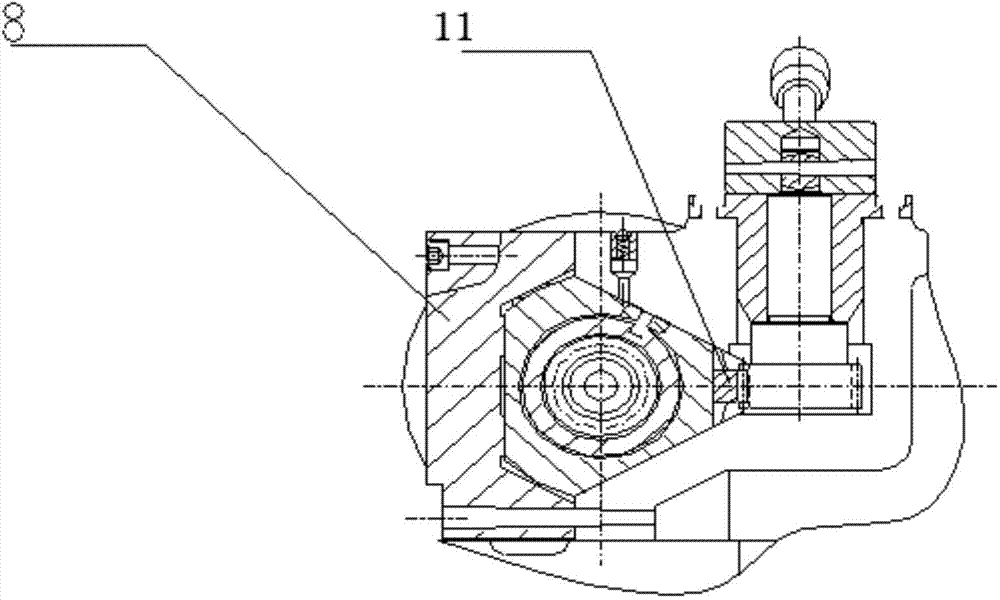

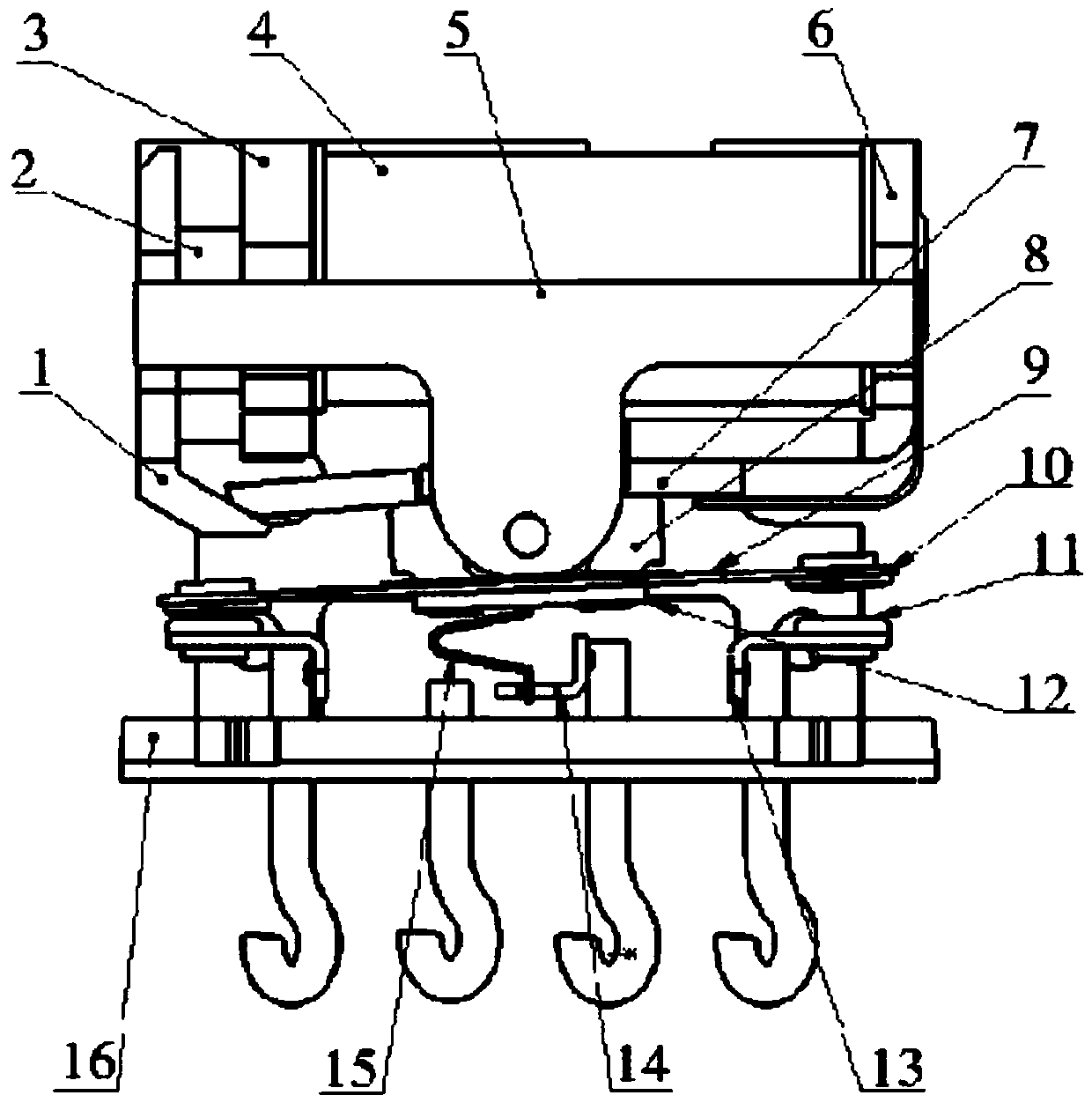

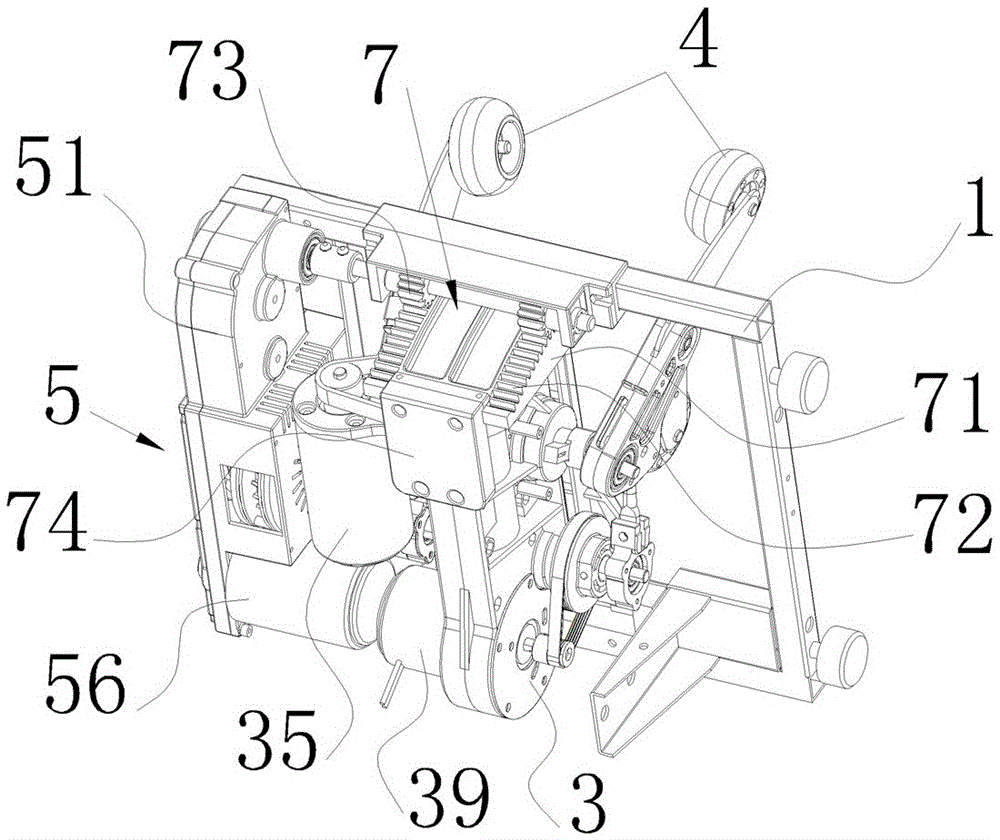

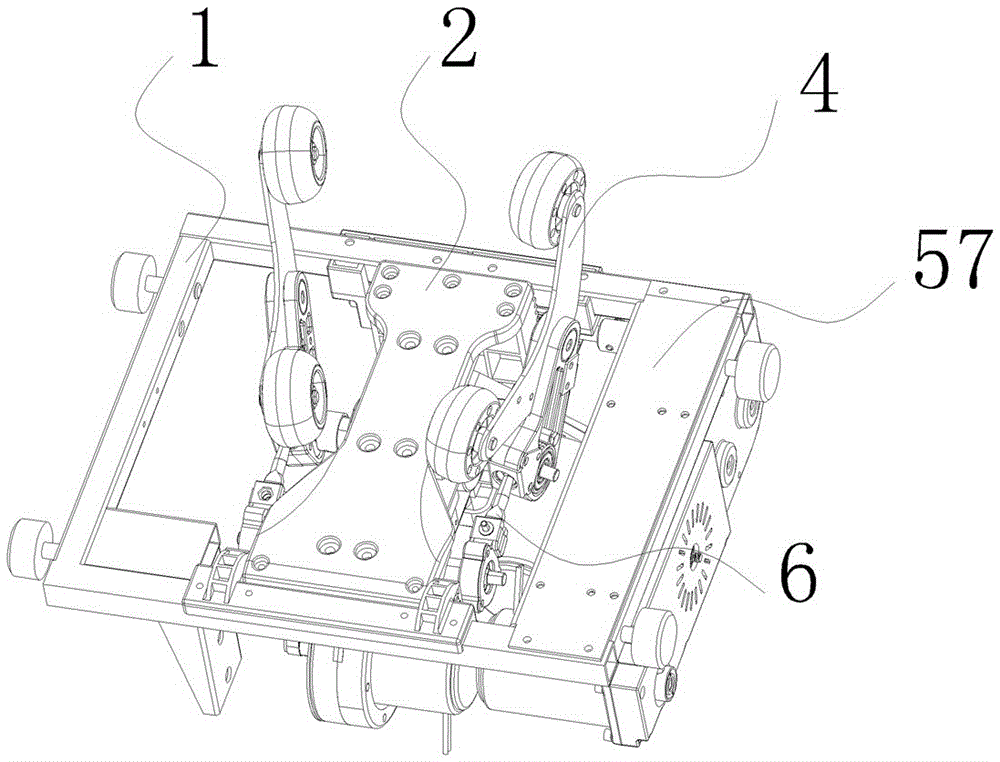

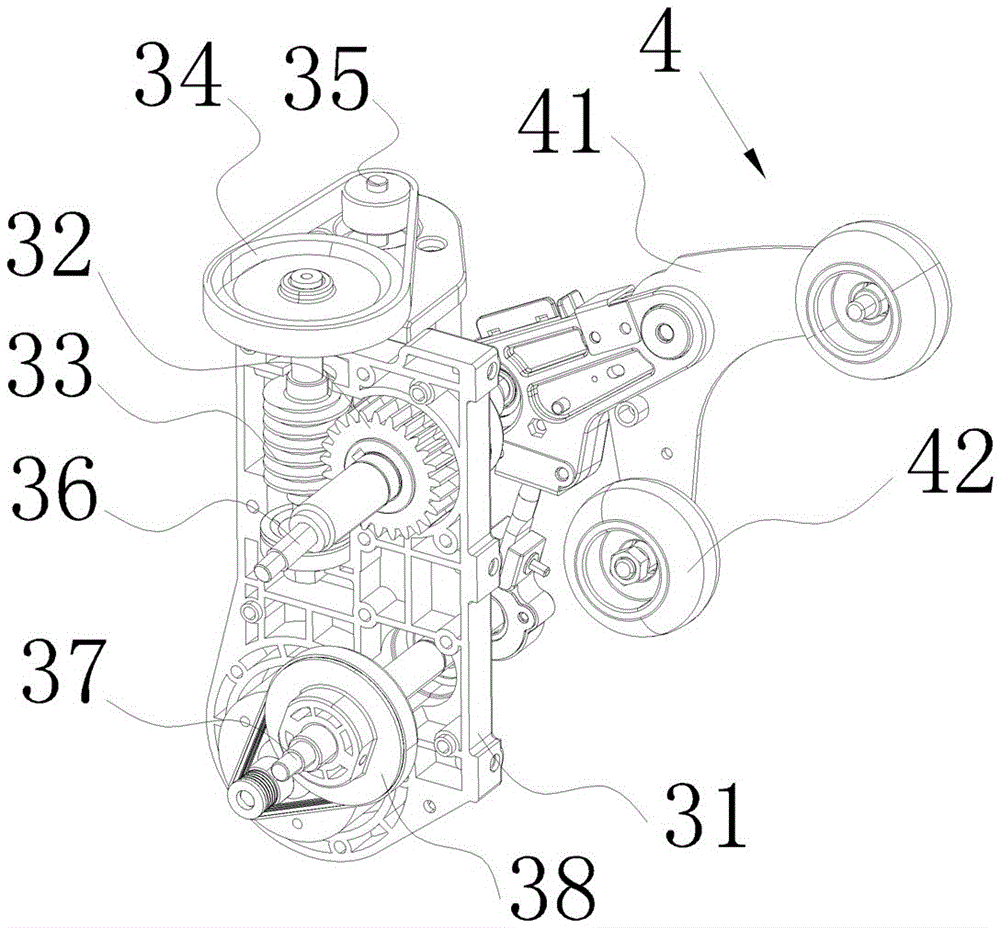

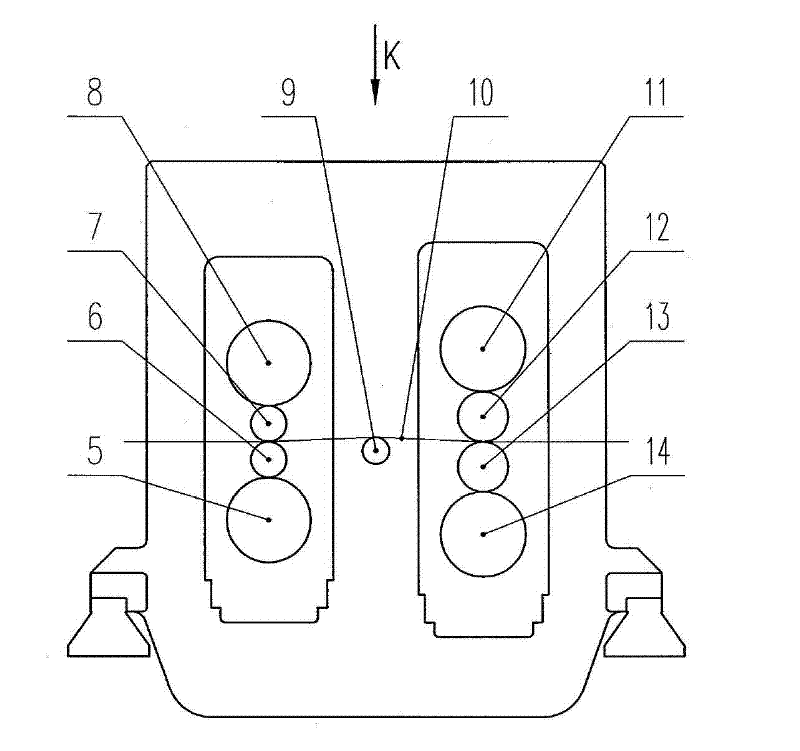

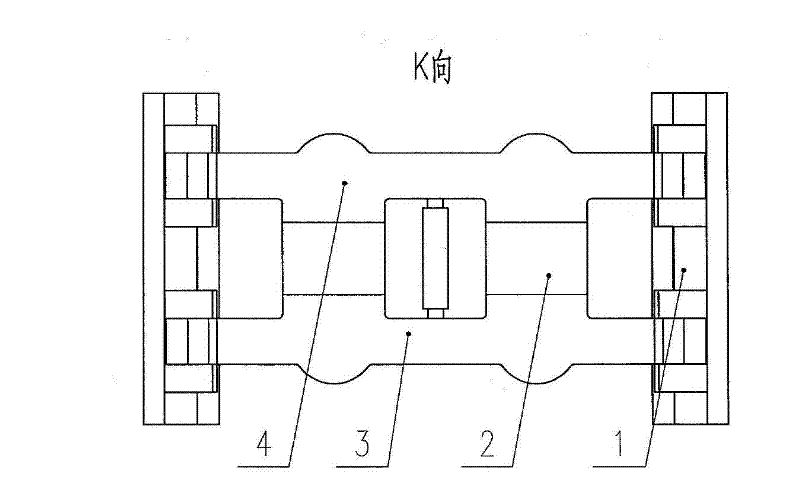

Magnetic 3D (Three-Dimensional) mechanism structure for massage chairs

ActiveCN104546399AImprove massage efficiencyImprove stabilityVibration massageSuction-kneading massageEngineeringPhysical therapy

The invention discloses a massage chair structure, and provides a magnetic 3D (Three-Dimensional) mechanism structure for massage chairs, which is compact in structure, simple in assembly and high in assembly precision, can selectively perform kneading-type and beating-type massage the back of the human body according to operating requirement and can automatically regulate massage force, and the invention solves the technical problems existing in the prior art that products are structurally complex and large in size, are highly difficult to assemble and repair, cannot ensure assembly precision, and affect the normal use of massage chairs. The magnetic 3D mechanism structure comprises a square mechanism frame which is longitudinally and slidably connected to the back of a massage chair, wherein the lower border of the mechanism frame is rotatably connected to one end of a mechanism fixing plate, the mechanism fixing plate is provided with a first gear set, the first gear set is connected with a massage roller group and can drive the massage roller group to perform reciprocating kneading-type or beating-type operation, the other end of the mechanism fixing plate is provided with a rack mechanism capable of driving the mechanism fixing plate to rotate, the rack mechanism is connected with a second gear set, and the second gear set can automatically adjust the mechanism fixing plate to swing back and forth relative to the mechanism frame according to the resistance value of the massage roller group.

Owner:NINGBO OSUN HEALTH CARE TECH

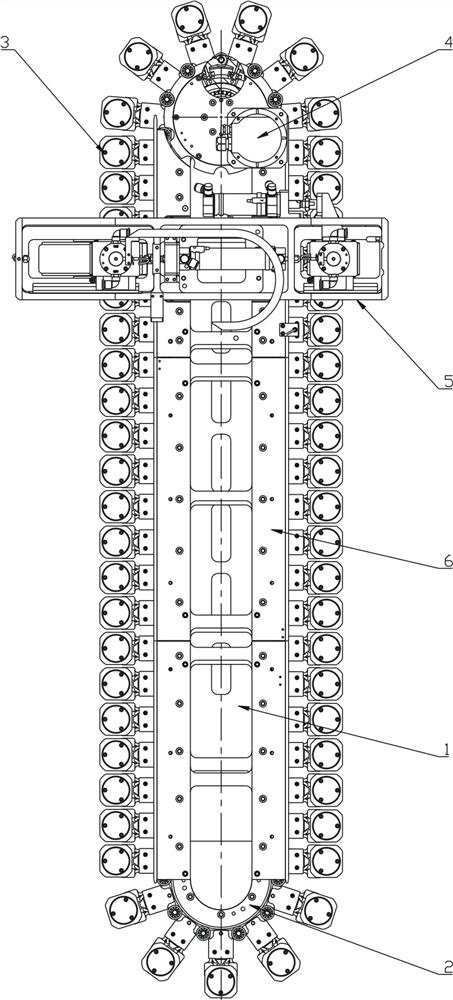

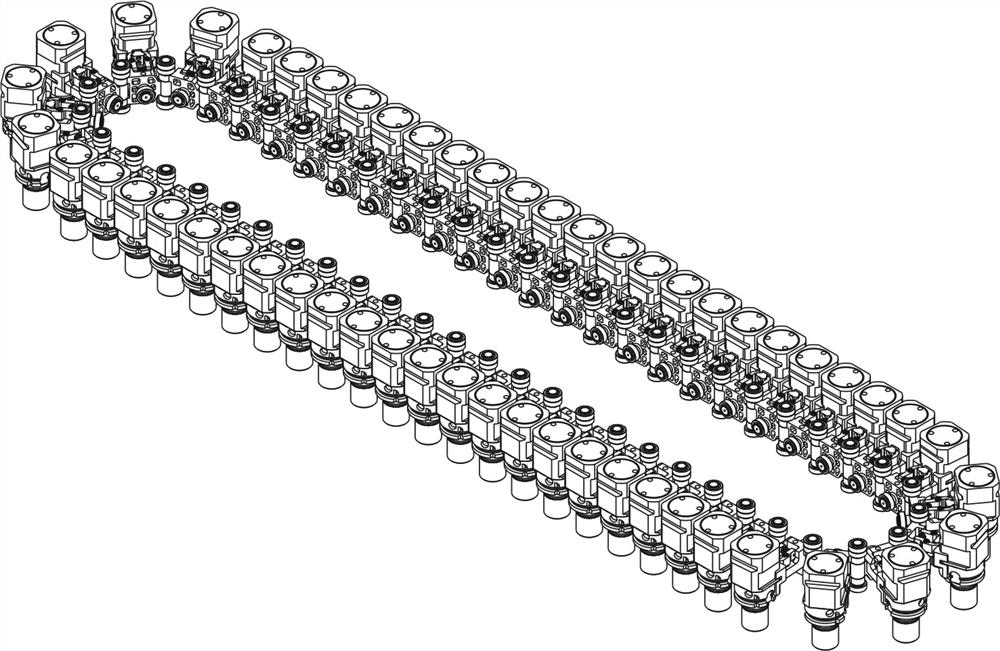

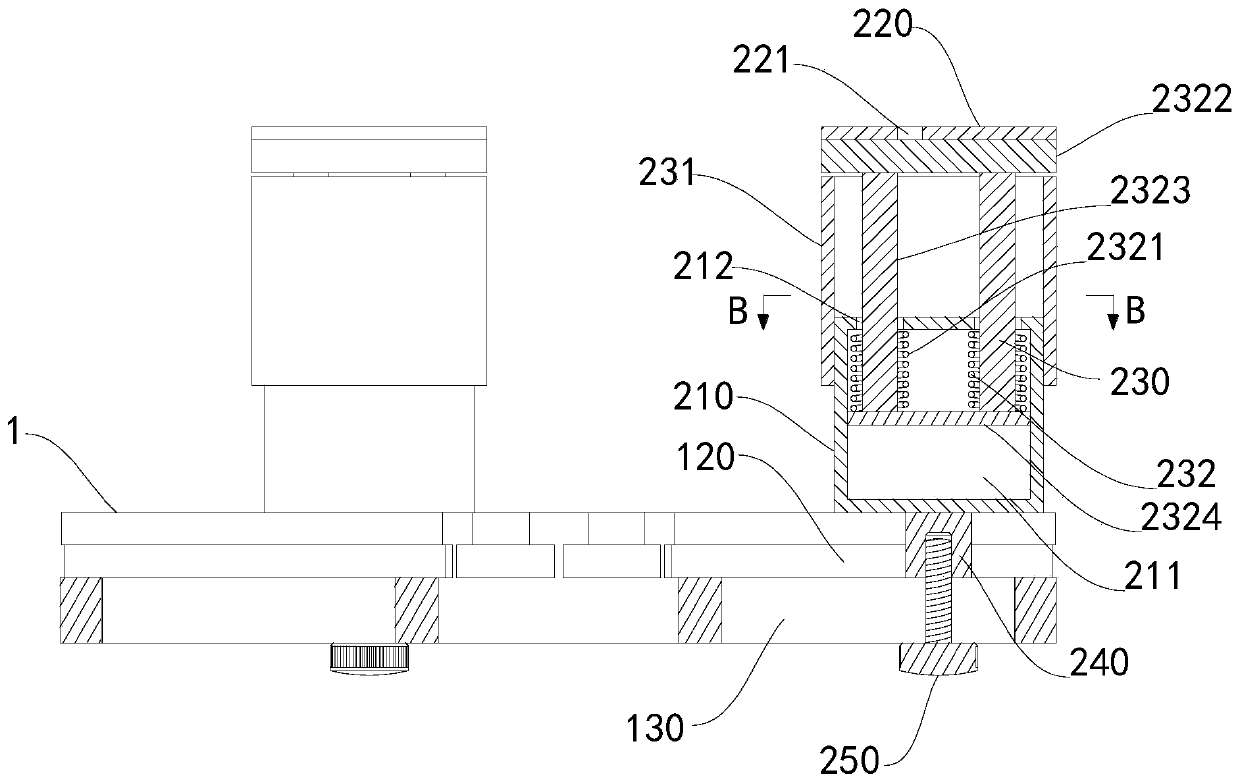

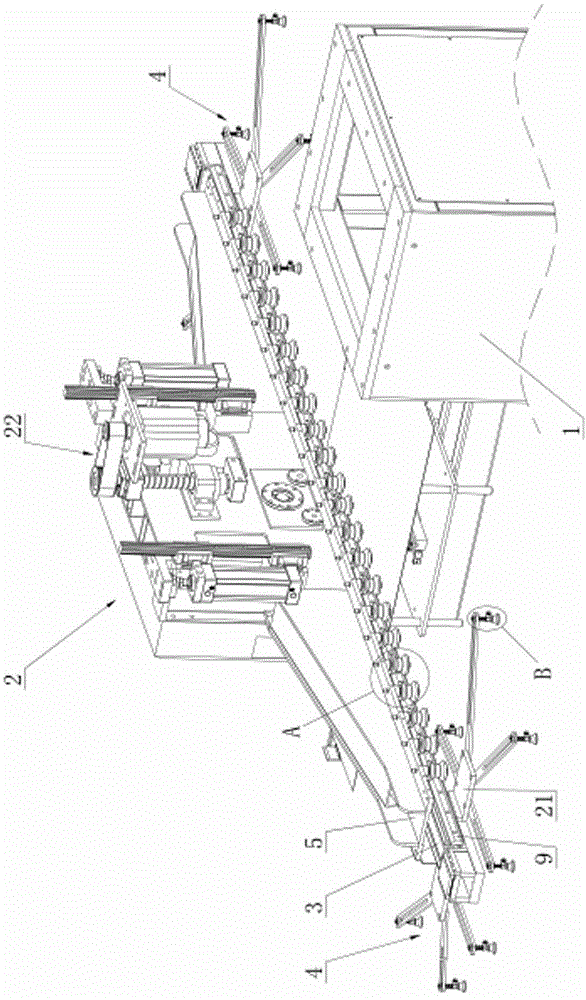

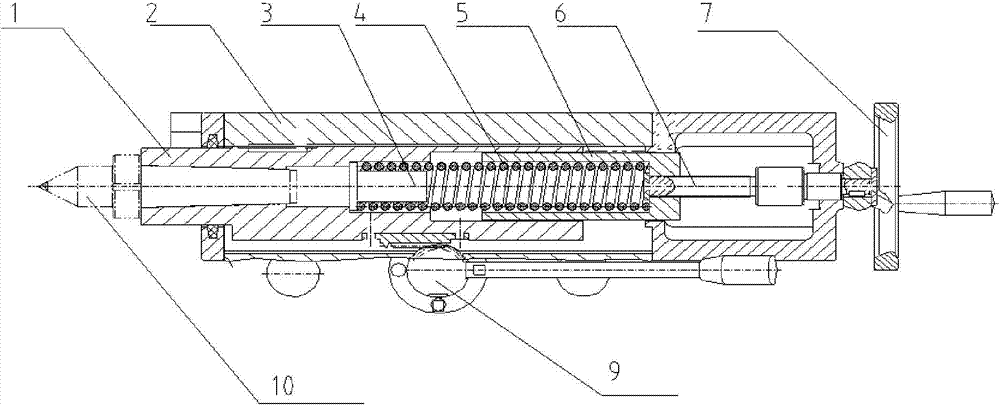

Knife pouch push-out type chain type tool magazine

PendingCN111843578AHigh precisionIncrease line speedPositioning apparatusMetal-working holdersChain typeChain link

The invention relates to a knife pouch push-out type chain type tool magazine, and aims to provide a chain type tool magazine structure which is simple in structure, small in structural space, high inmotion precision, high in tool changing speed, stable in operation, small in vibration, long in service life, low in use cost, convenient to adjust and flexible in application. The knife pouch push-out type chain type tool magazine comprises a base, an annular guide rail, a chain mechanism, a chain driving unit and a knife pouch push-out device. The base is connected with a machine tool, the annular guide rail is arranged on the base, and the chain mechanism comprising a plurality of knife pouches is arranged on the annular guide rail and can rotate along the annular guide rail under the action of the chain driving unit. The knife pouch push-out device is erected above the chain mechanism and installed on the base through a push-out installation plate, and the knife pouches can be pushedout of the chain mechanism to conduct automatic tool changing or manual tool installing.

Owner:北京精雕精密机械制造有限公司

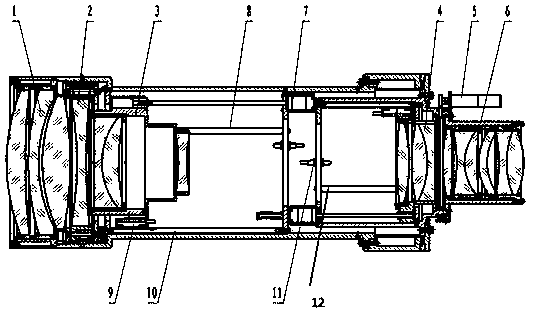

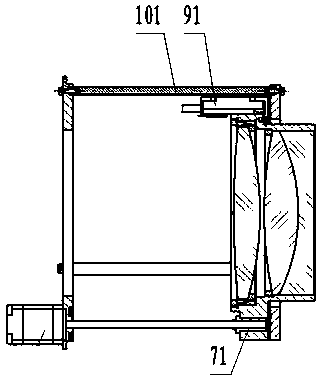

Digital cam continuous zooming system

The invention relates to a digital cam continuous zooming system which comprises a fixing frame, a focusing assembly, a compensation assembly, a times changing assembly, a first guide rod and a second guide rod, wherein the focusing assembly and the compensation assembly are arranged at the two ends of the fixing frame respectively, the times changing assembly is arranged between the focusing assembly and the compensation assembly, the first guide rod is used for the times changing assembly to do reciprocating rectilinear motion, and the second guide rod is used for the compensation assembly to do reciprocating rectilinear motion; a front mirror assembly is arranged at one end of the focusing assembly, a dimming assembly and a rear mirror assembly are sequentially arranged at one end of the compensation assembly, and a precision screw rod output linear motor providing a power source for the first guide rod and the second guide rod is arranged between the times changing assembly and the compensation assembly. The digital cam continuous zooming system is low in cost, high in precision, small in size and adjustable.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

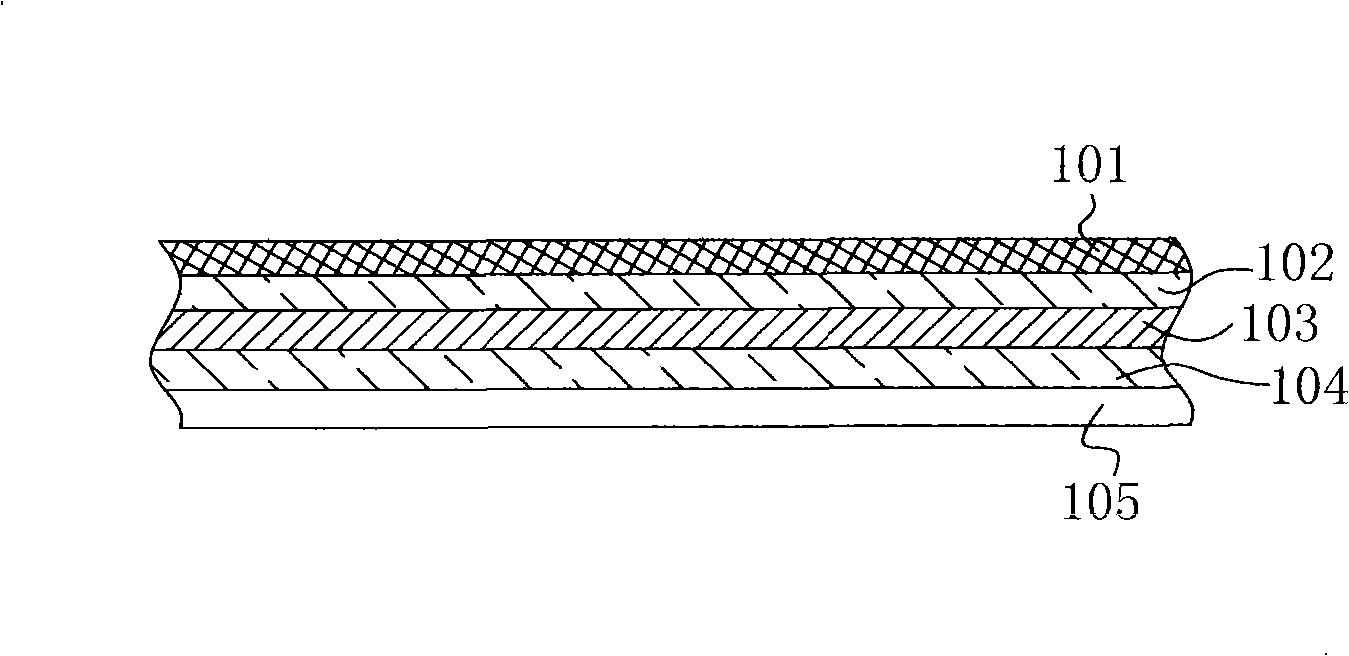

Electromagnetic wave shielding material

InactiveCN101513782AGuaranteed assembly accuracyAssembly accuracy is easy to guaranteeMetal layered productsEngineeringMobile phone

The present invention relates to an electromagnetic wave shielding material which is suitable for electronic products of computer, video game console, mobile phone, etc. The electromagnetic wave shielding material comprises conductive cloth. The electromagnetic wave shielding material is characterized in that the electromagnetic wave shielding material also comprises insulating cloth, a release material layer and two adhesive layers. The electromagnetic wave shielding material is sequentially composed of the release material layer, a first adhesive layer, conductive cloth, a second adhesive layer and insulating cloth from the inner part to the outer part. The two adhesive layers bond the release material layer, the conductive cloth and the insulating cloth. The external surface of insulating cloth can be coated or printed with colors or patterns. The insulating requirement is satisfied when the recognizing requirement or decorating requirement is satisfied. The electromagnetic wave shielding material provided by the invention has the advantages of single-surface or double-surface insulation, easy insurance of assembling precision and easy use.

Owner:DONGGUAN WANFENG NANOMETER MATERIALS

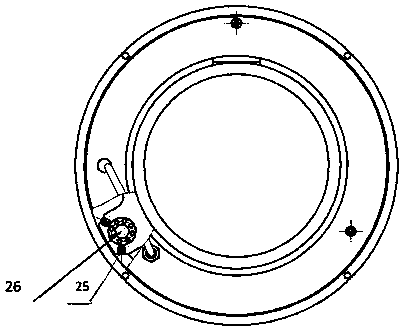

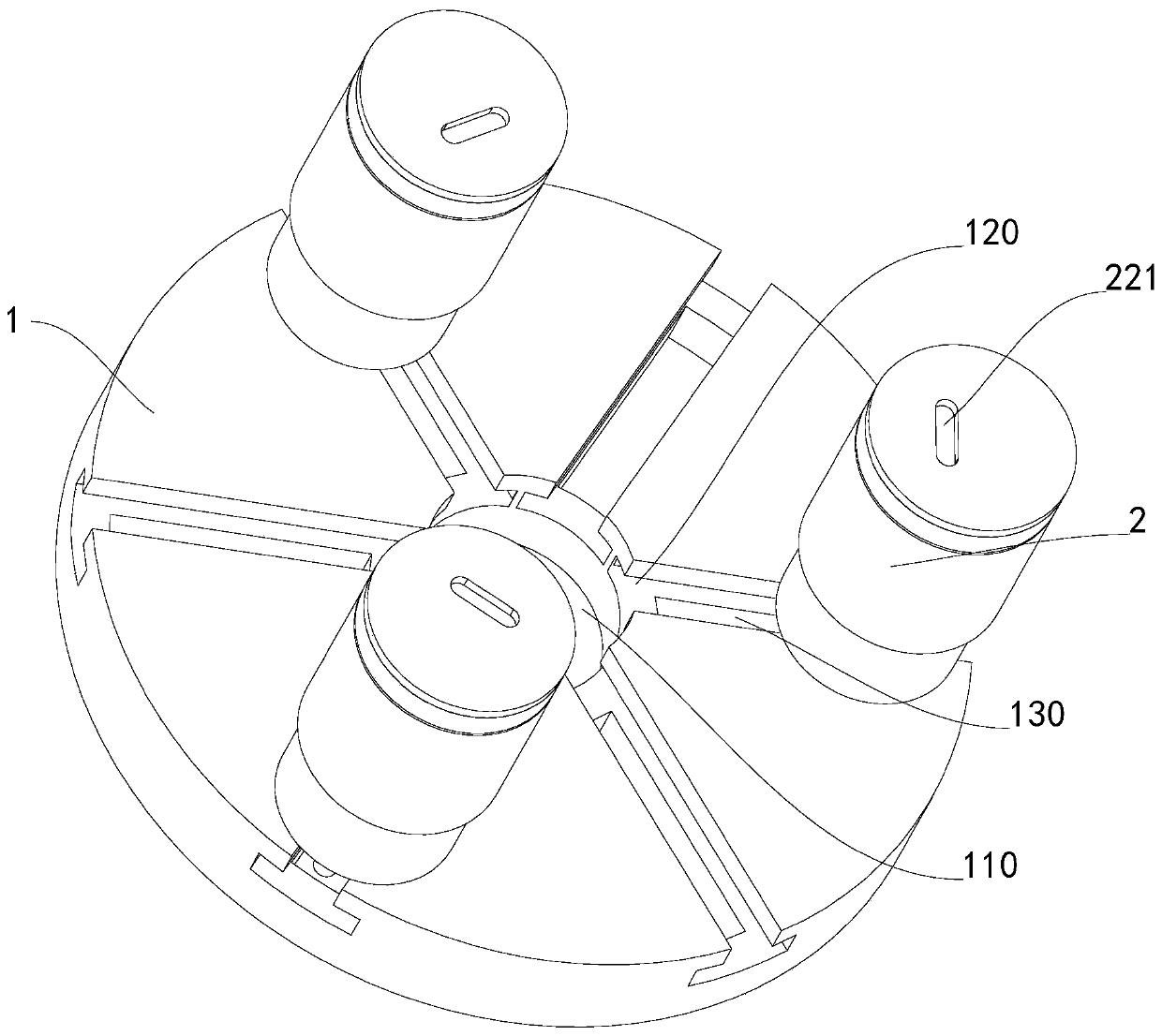

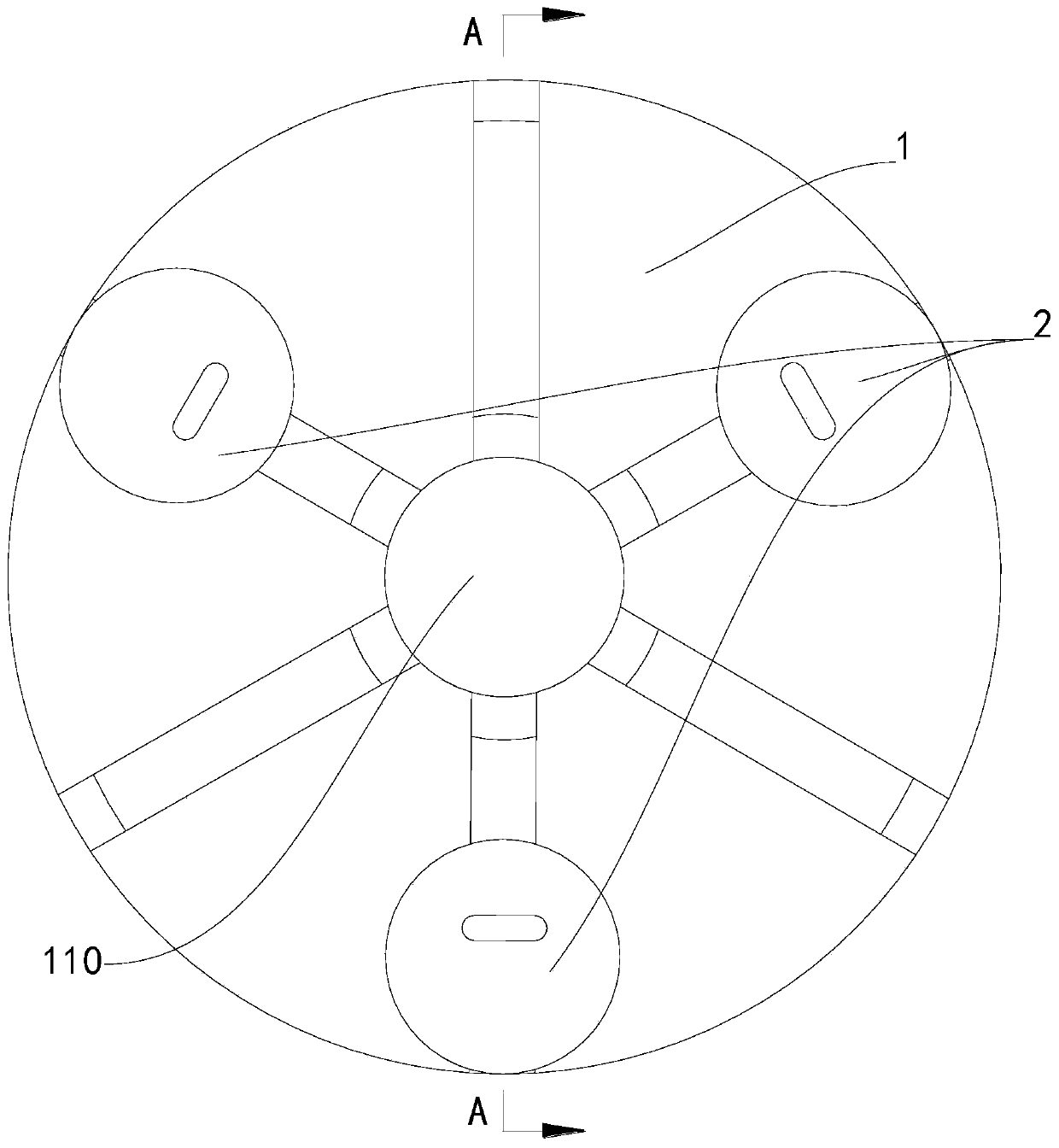

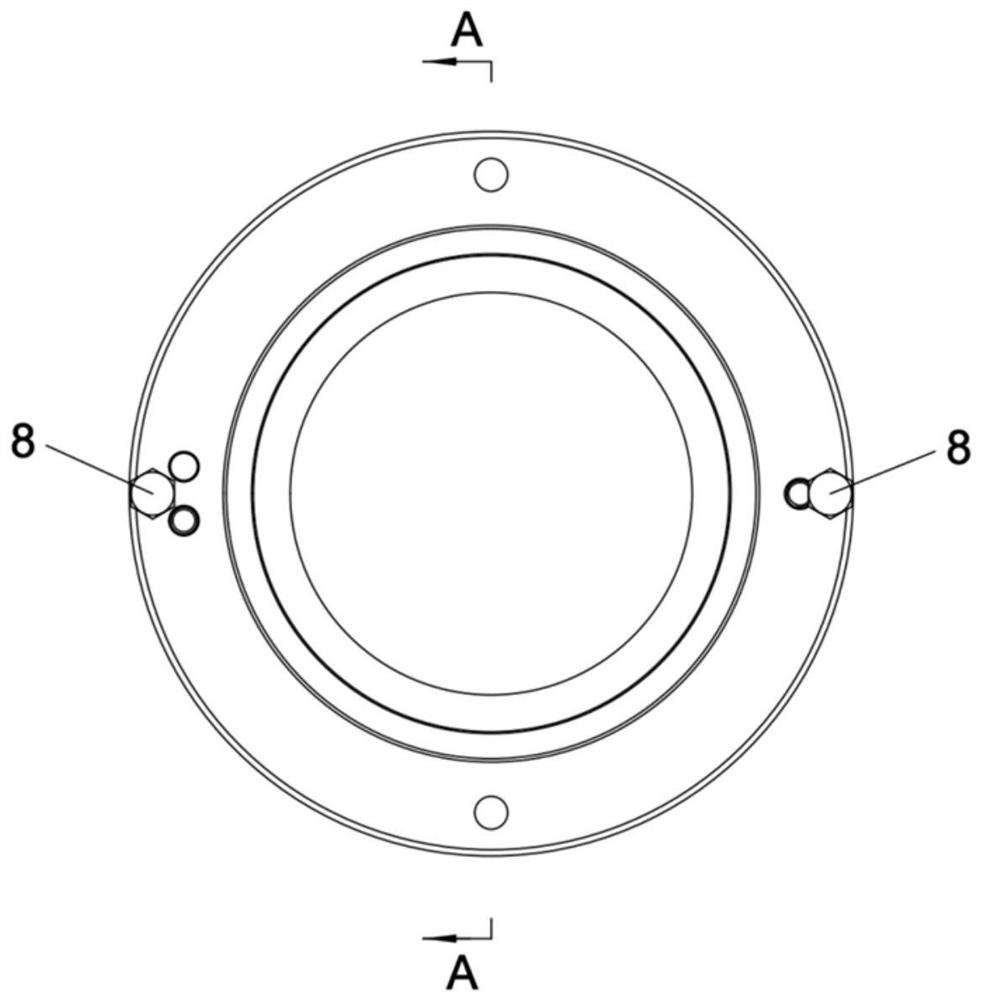

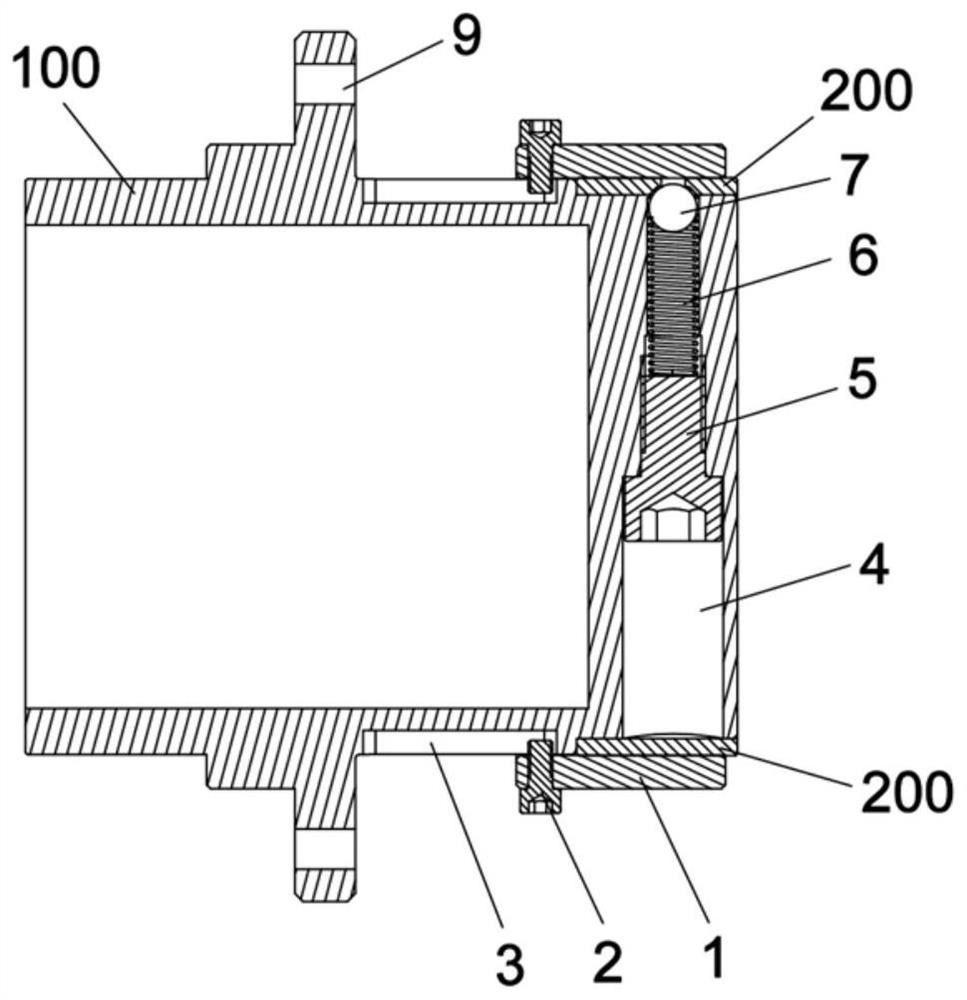

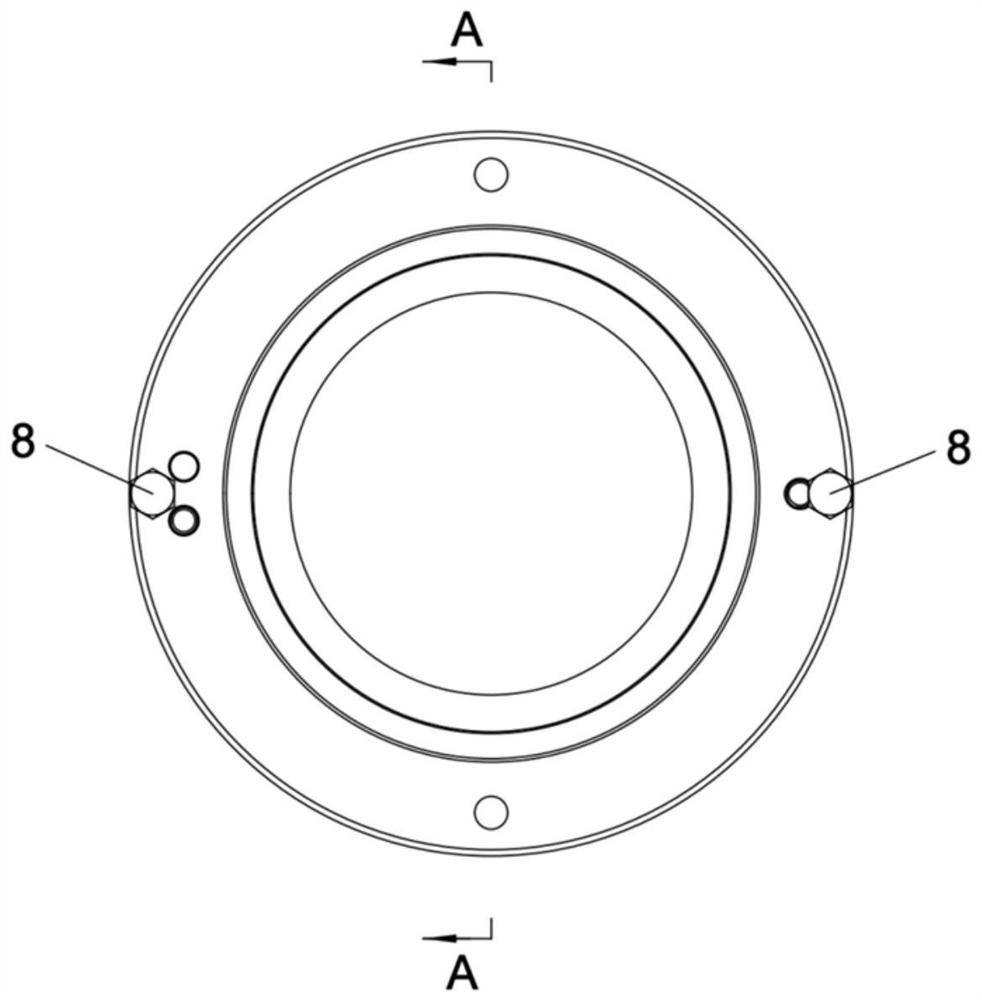

Auxiliary device for installation and positioning of claw poles

PendingCN110293493ANot easy to shakeAssembly accuracy is easy to guaranteeWork holdersManufacturing stator/rotor bodiesMechanical engineeringPositioning system

The invention relates to an auxiliary device for installation and positioning of claw poles. The auxiliary device comprises a base and a plurality of positioning assemblies, wherein an insertion holeis formed in the base, the plurality of positioning assemblies are arranged on the circumference with the insertion hole as a circle center, the positioning assemblies comprise positioning columns andpositioning plates, the positioning columns are arranged on the base, the positioning plates are arranged on the positioning columns, and positioning grooves matched with the tips of pawls of the claw poles are formed in the positioning plates. The auxiliary device has the beneficial effects that during use, a rotating shaft penetrates through the insertion hole, and then one claw pole is sleevedon the rotating shaft, the pawls are ensured to face upwards, the positioning columns are clamped among the pawls of the claw pole so as to enable the claw pole to be positioned in the circumferential direction, a magnetic field winding and a magnetic yoke are arranged on the rotating shaft, and finally the other claw pole is arranged on the rotating shaft, the pawls of the other claw pole facesdownwards, the tips of the pawls are clamped into the positioning grooves so as to enable the other claw pole to be positioned in the circumferential direction and not easy to shake; and in this way,the integral assembly accuracy is easy to guarantee during manual assembly.

Owner:武汉欣力瑞机电设备有限公司

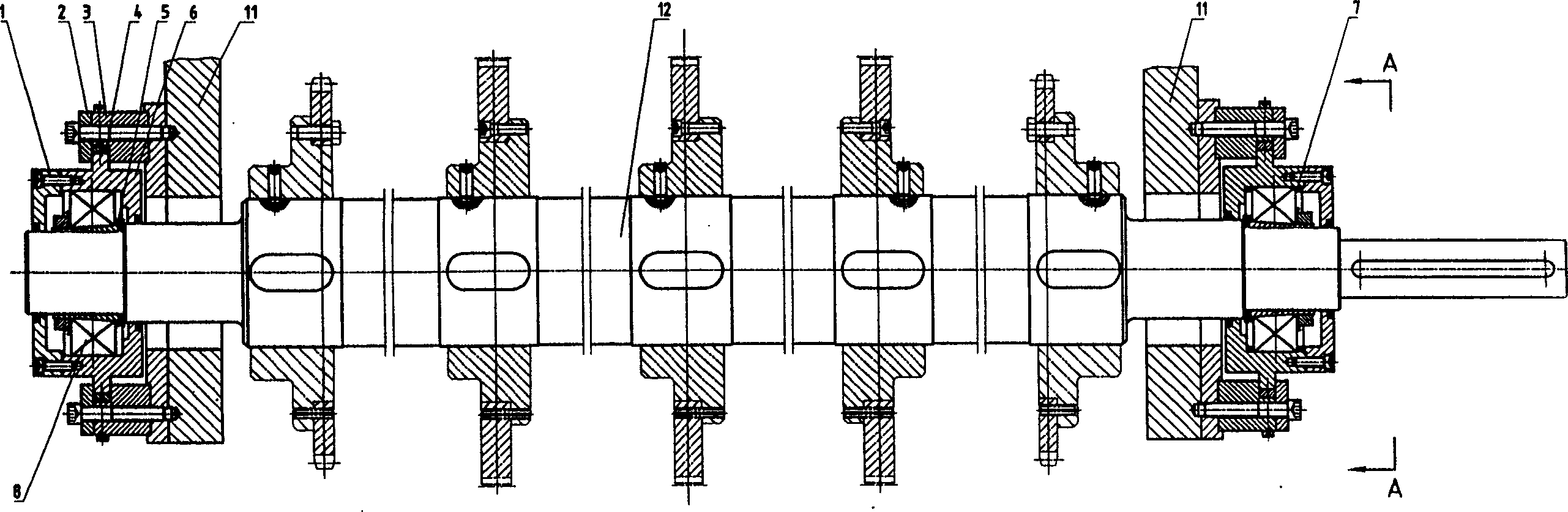

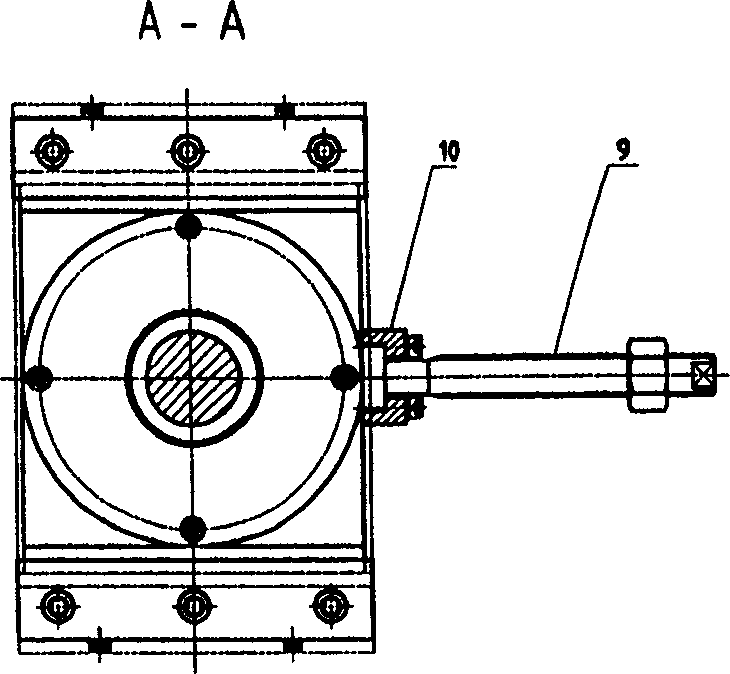

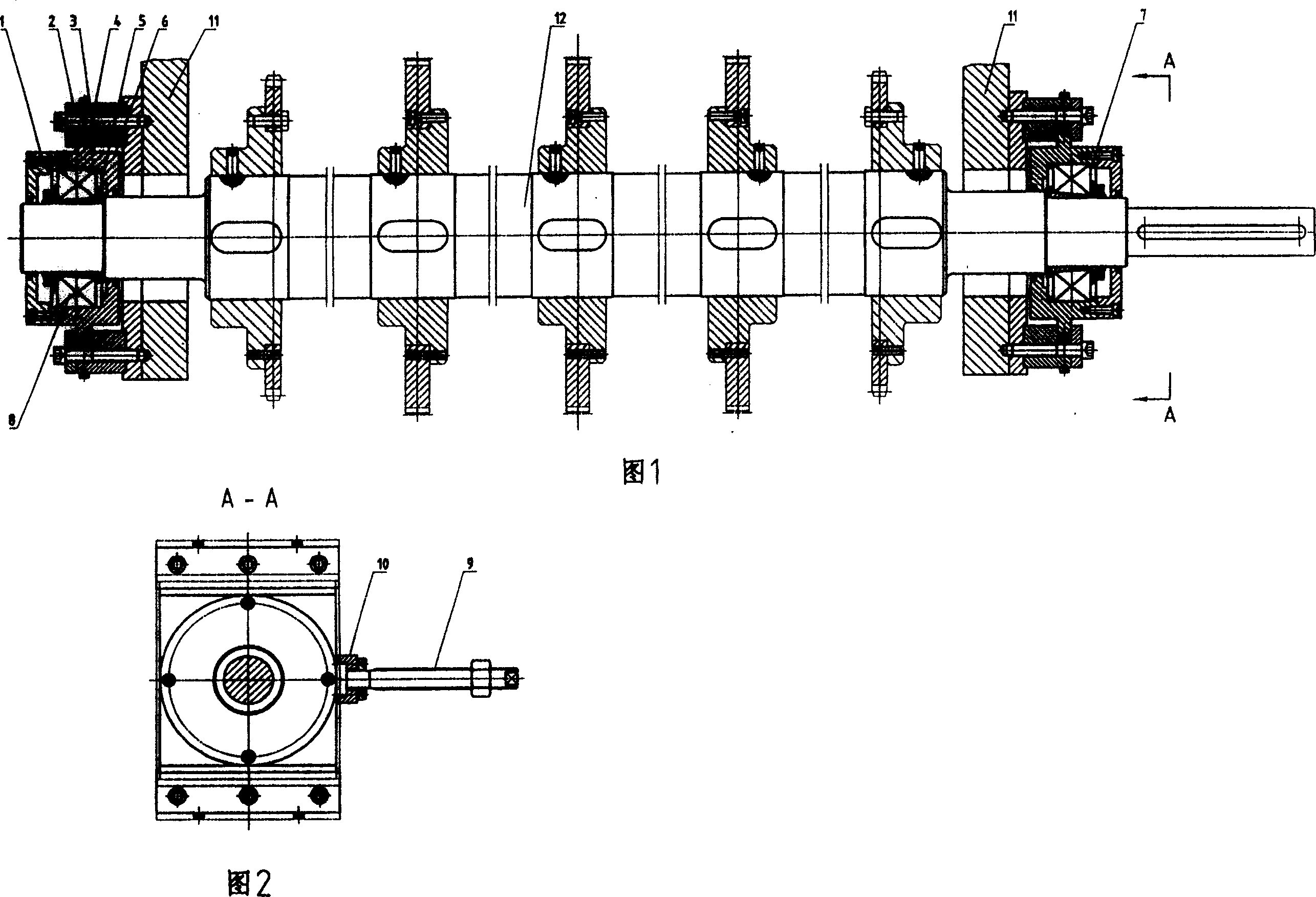

Feed shaft bearing block structure of flat pressing continuous press

InactiveCN1799797AEasy to lubricateExtended service lifeWood working apparatusDomestic articlesBlock structureMechanical engineering

The invention relates to a bearing block of feeding bearing of wood-based panel flat impression continuous compressor and relative fixing method. Present bearing blocks of feeding bearings are all fixed on the support of feeding head and the temperature inside the support reaches 170Deg. C to affect the service life and the maintenance. The inventive structure comprises a bearing cap, a compression board, a board, a backing block, an inner positioning ring, a bearing block, an outer positioning ring, a bearing, a screw and a connection board. Wherein, each element is fixed via six long bolts on the outer side surfaces of feeding head support, and via adjusting the screws on its two sides, the bearing block can be driven to right position of guide rail groove to adjust the vertical property between feeding axes and the working direction and the tension of chain blanket. The invention has the advantages that the bearing block is mounted on the outer side of feeding head support whose temperature is lower, to apply the mount, regulation, and maintenance of bearing block with prolonged service life.

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

Automated device for long-distance conveying

InactiveCN104438929ASimplify the assembly processReduce manufacturing costMetal-working feeding devicesPositioning devicesMetal formingIdler-wheel

The invention relates to the technical field of metal forming machining equipment, in particular to an automated device for long-distance conveying. A lifting mechanism is movably provided with telescopic movable beams and a transverse sliding device, mechanical grippers are installed on the telescopic movable beams, a fixing plate is installed at the lower portion of the lifting mechanism, two rows of idler wheel shafts are fixed to the fixing plate, the idler wheel shafts are provided with rotatable transition wheels, annular grooves are formed in the wheel surfaces of the transition wheels, sliding rails are installed on the two sides of each telescopic movable beam, and the sliding rails are embedded into the annular grooves. Due to the fact that the fixing plate is provided with only two rows of idler wheel shafts and the transition wheels, the assembly procedures of transfer equipment are simplified, and the production cost of the transfer equipment is reduced; the structure is fixed due to the fact that the sliding rails correspond to the annular grooves of the transition wheels.

Owner:DONGGUAN JINGTIAN AUTOMATION EQUIP

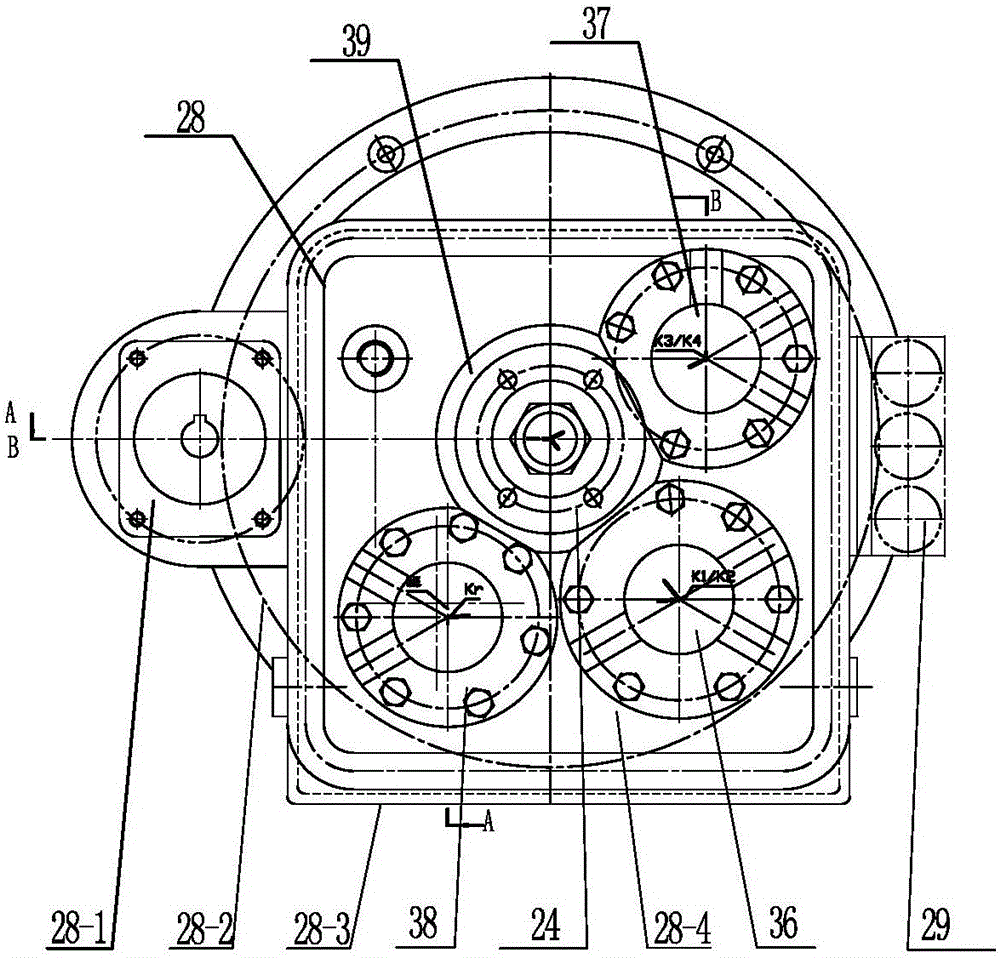

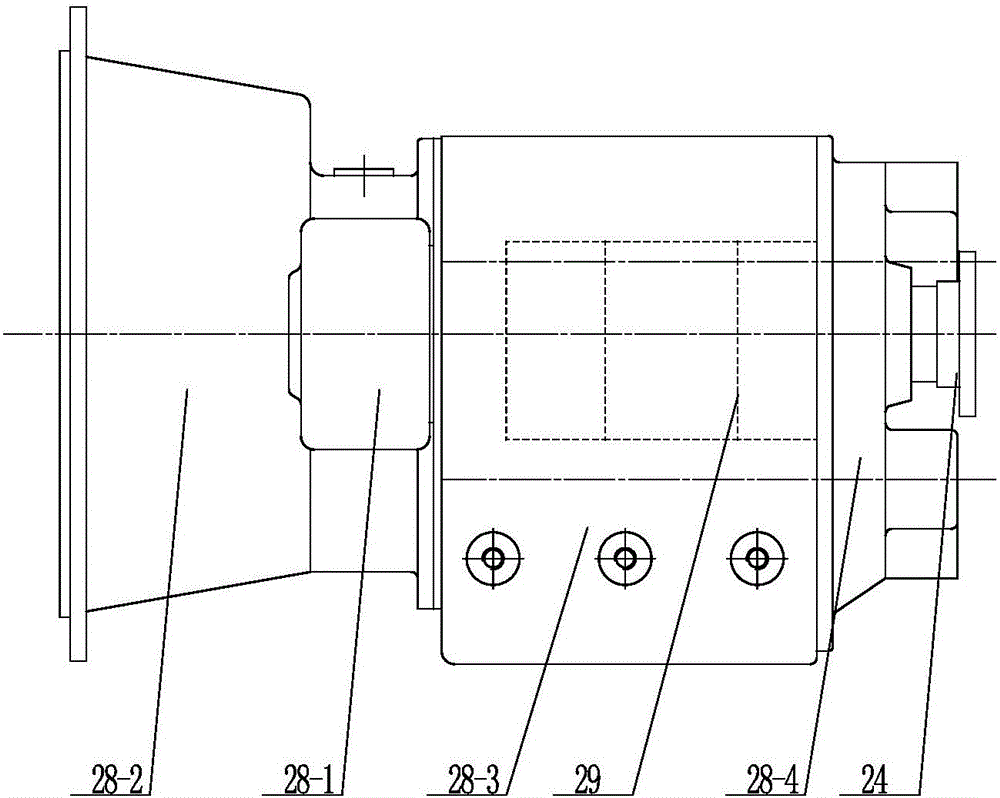

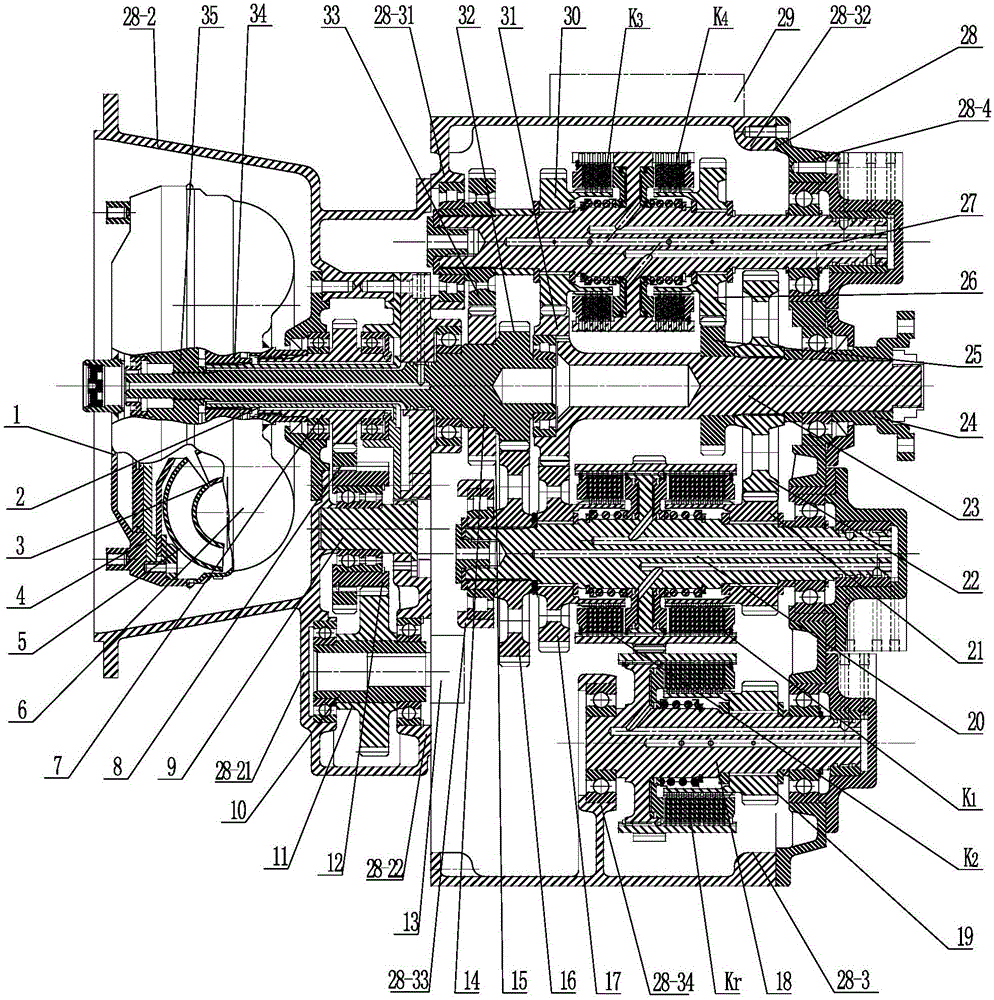

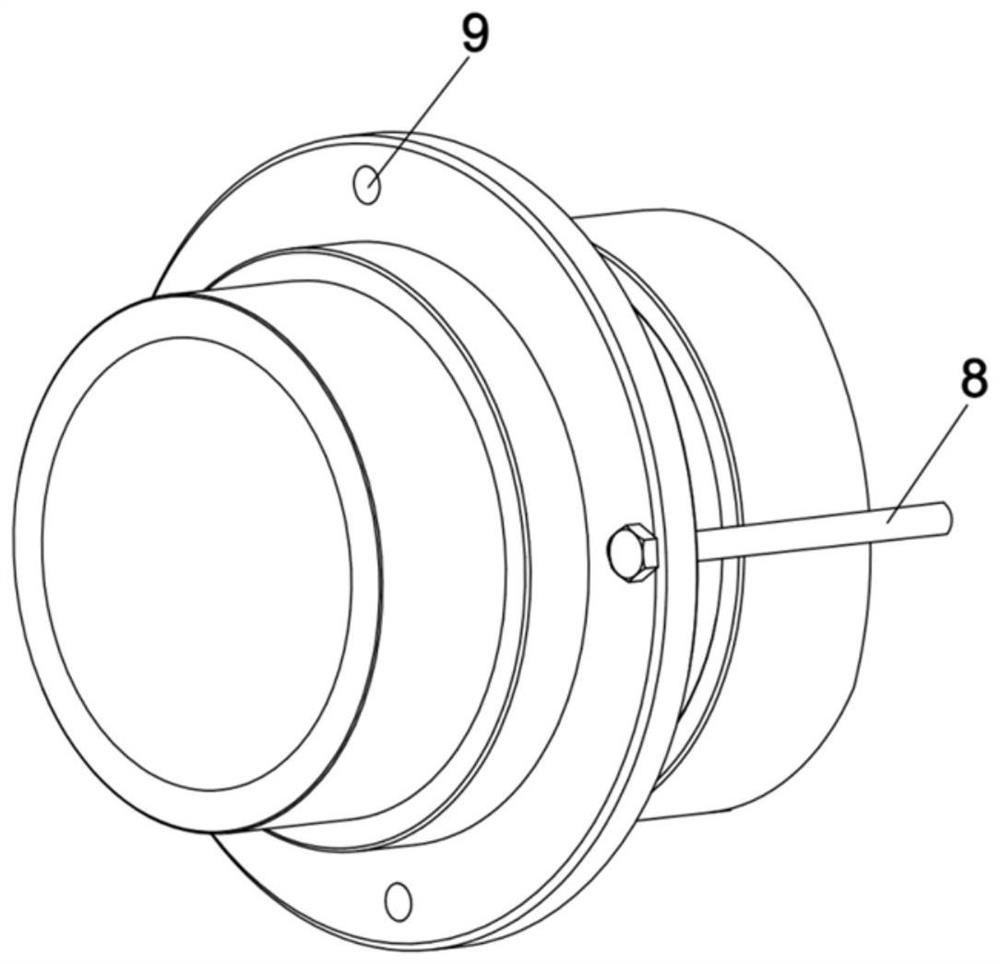

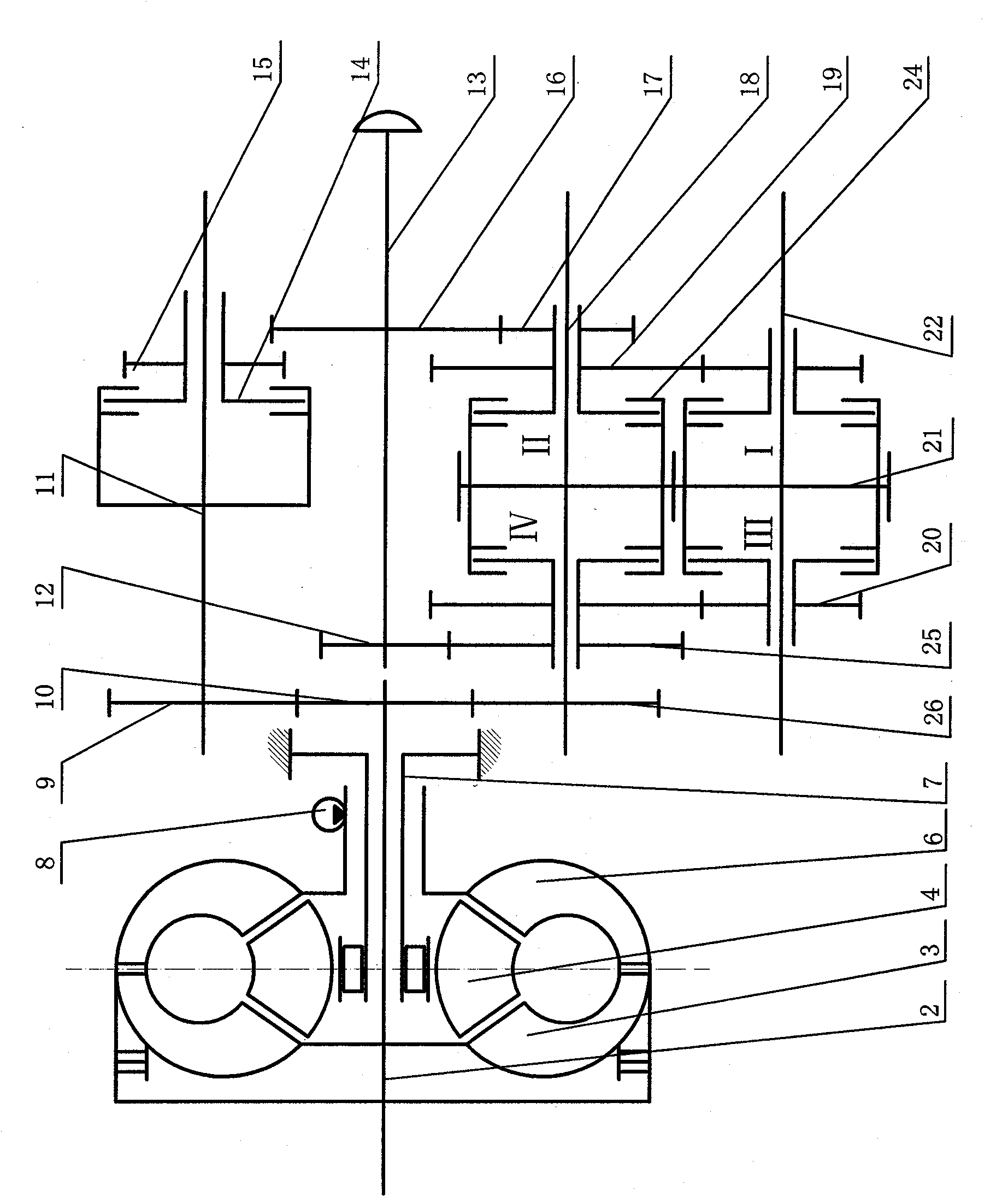

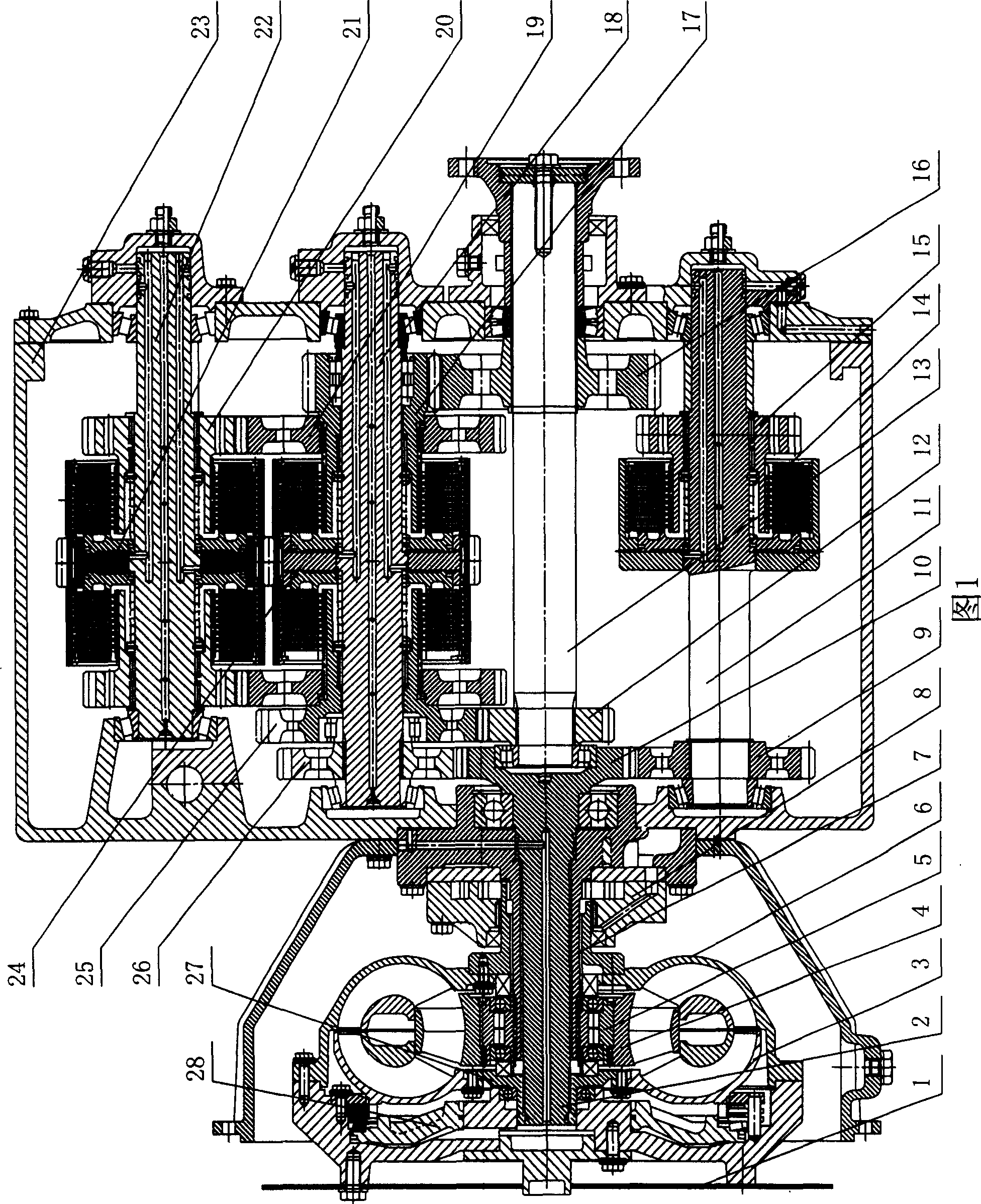

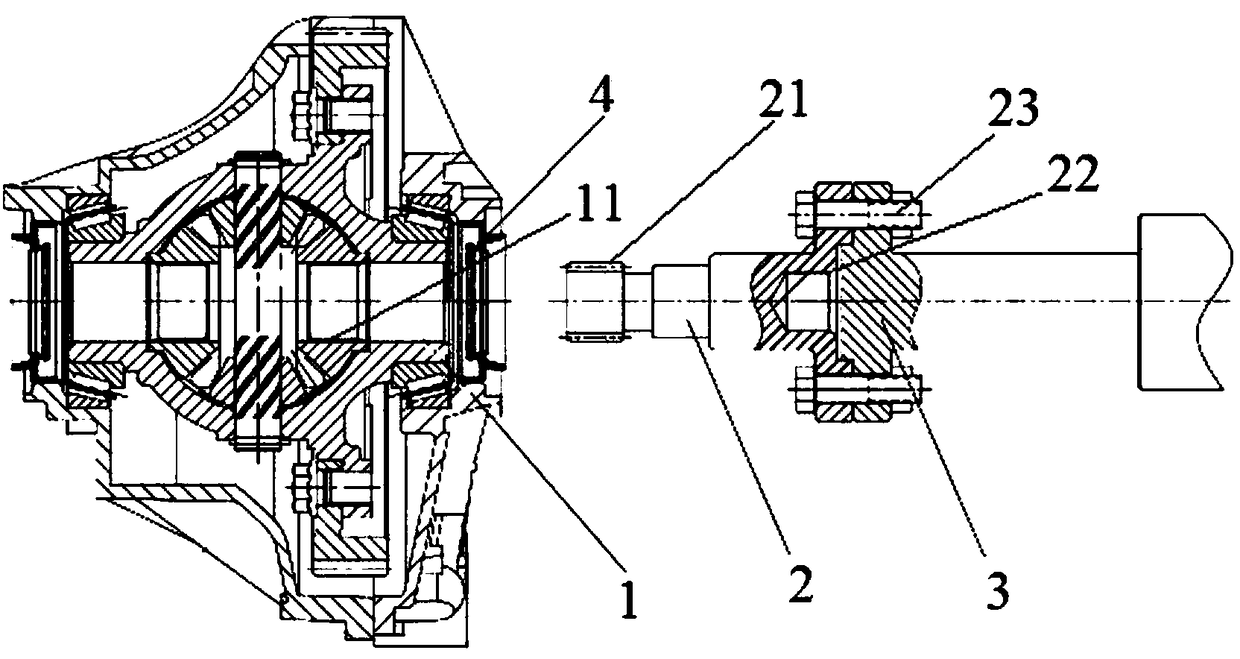

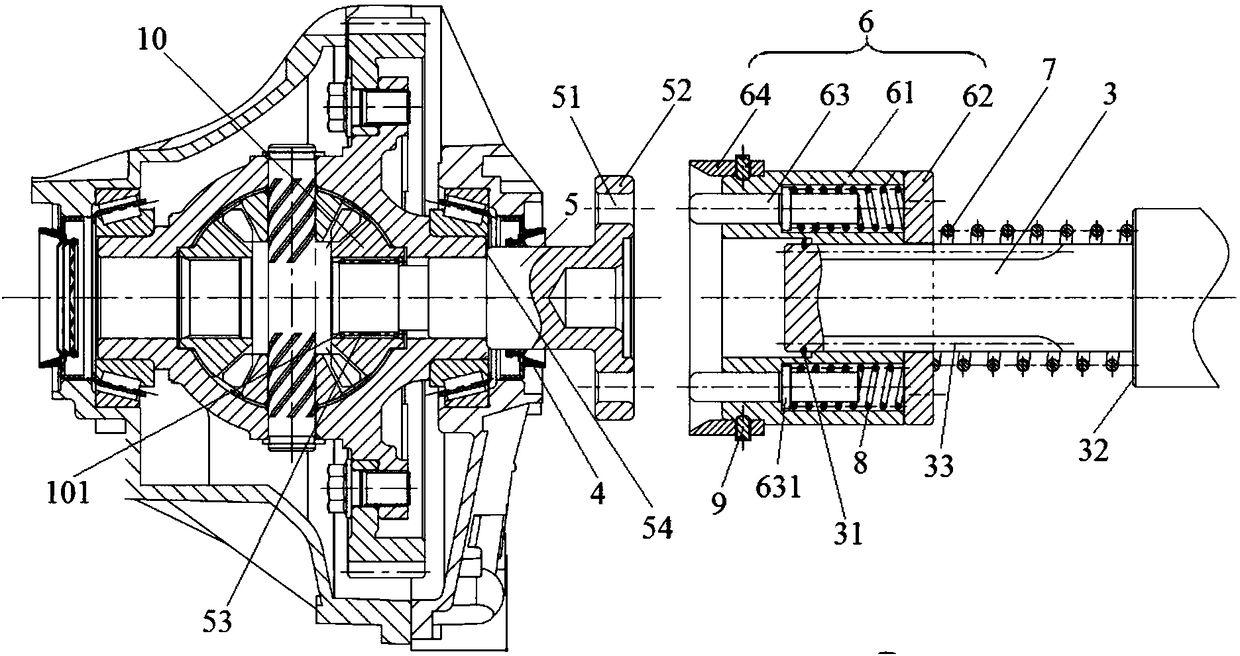

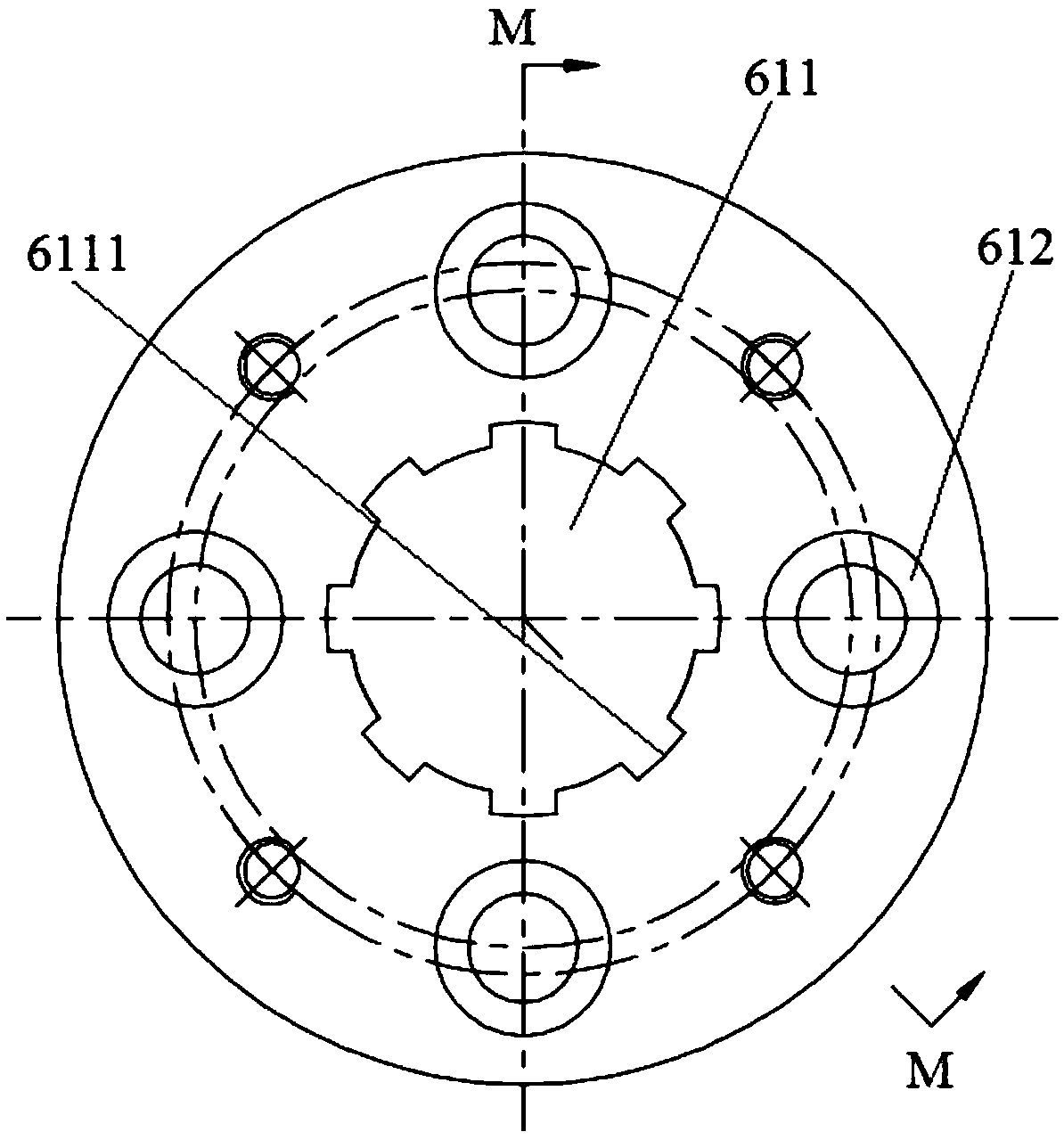

Hydrodynamic transmission for light vehicle

PendingCN106678326AMeet different working conditionsAdjustable speed ratioFluid gearingsGearing detailsPower take-offClutch

The invention relates to a hydrodynamic transmission for a light vehicle. An oil pump driving sleeve and a supporting shaft are installed on a box body; an oil pump arranged in the box body is connected with the oil pump driving sleeve; a power take-off window is formed in the position, at the horizontal part of an input shaft, of the box body; a connection gear arranged on a guide wheel base in a sleeving mode is engaged with an oil pump connection gear arranged on the pump driving sleeve through two power takeoff gears on the supporting shaft; a first shaft and a second shaft are each provided with a wet clutch and a corresponding driving gear; driven gears installed on the first shaft and the second shaft are engaged with two input gears of the input shaft correspondingly; all driving gears on the first shaft and the second shaft are engaged with an output shaft gear, a high-gear output gear and a low-gear output gear on an output shaft correspondingly; and a reverse-gear clutch Kr and a reverse-gear driving gear on a reverse-gear shaft are engaged with the wet clutch on the first shaft and the low-gear output gear correspondingly, and are matched with a lockup clutch, so that output with six forward gears and one reverse gear is achieved. The hydrodynamic transmission is ingenious and compact in structure and flexible in operation, has the multiple gears, and can adapt to different working conditions of the light vehicle.

Owner:邓亚民

Engine bearing bush mounting and dismounting tool

ActiveCN112975338APrevent radial deformationPrevent radial displacementMetal working apparatusEngineeringMechanical engineering

The invention discloses an engine bearing bush mounting and dismounting tool, and belongs to the field of engine assembly. The engine bearing bush mounting and dismounting tool comprises a tool body. The two ends of the tool body are a dismounting end and a mounting end respectively, and the mounting end sequentially comprises a guide journal and a bearing bush matching journal in the direction away from the dismounting end. The diameter of the guide journal is larger than that of the bearing bush matching journal, the bearing bush matching journal is used for sleeving two half bushes of a bearing bush, and a step surface between the guide journal and the bearing bush matching journal is a bearing bush thrust surface. A guide ring can be hooped on the peripheries of the two half bushes and can provide radial limiting for the bearing bush in the mounting process, so that the two half bushes are prevented from radial deformation or radial displacement. In addition, the guide ring can axially move along the guide journal in the press-fitting process so as to play an axial limiting role in mounting of the bearing bush and determine the press-in amount of the bearing bush pressed into a bearing seat. The engine bearing bush mounting and dismounting tool is simple in structure and low in manufacturing cost, and the assembly precision is easy to guarantee.

Owner:FAW JIEFANG AUTOMOTIVE CO

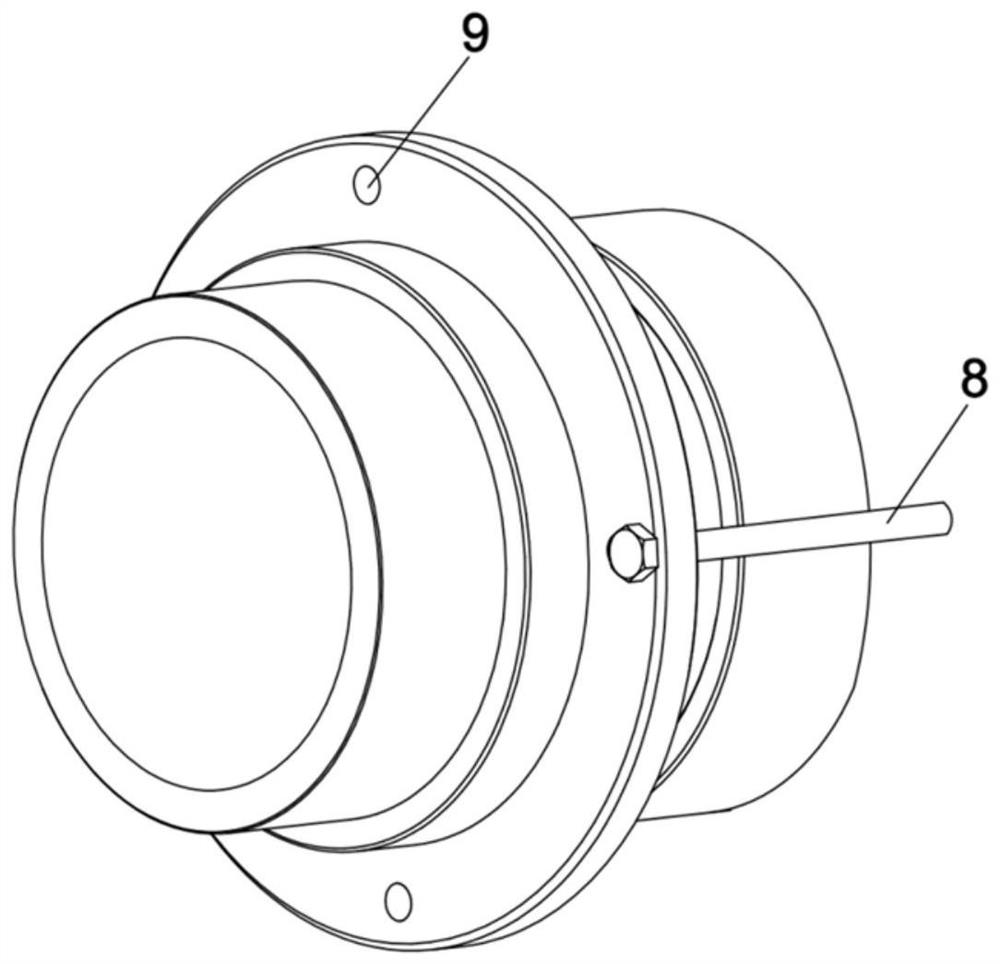

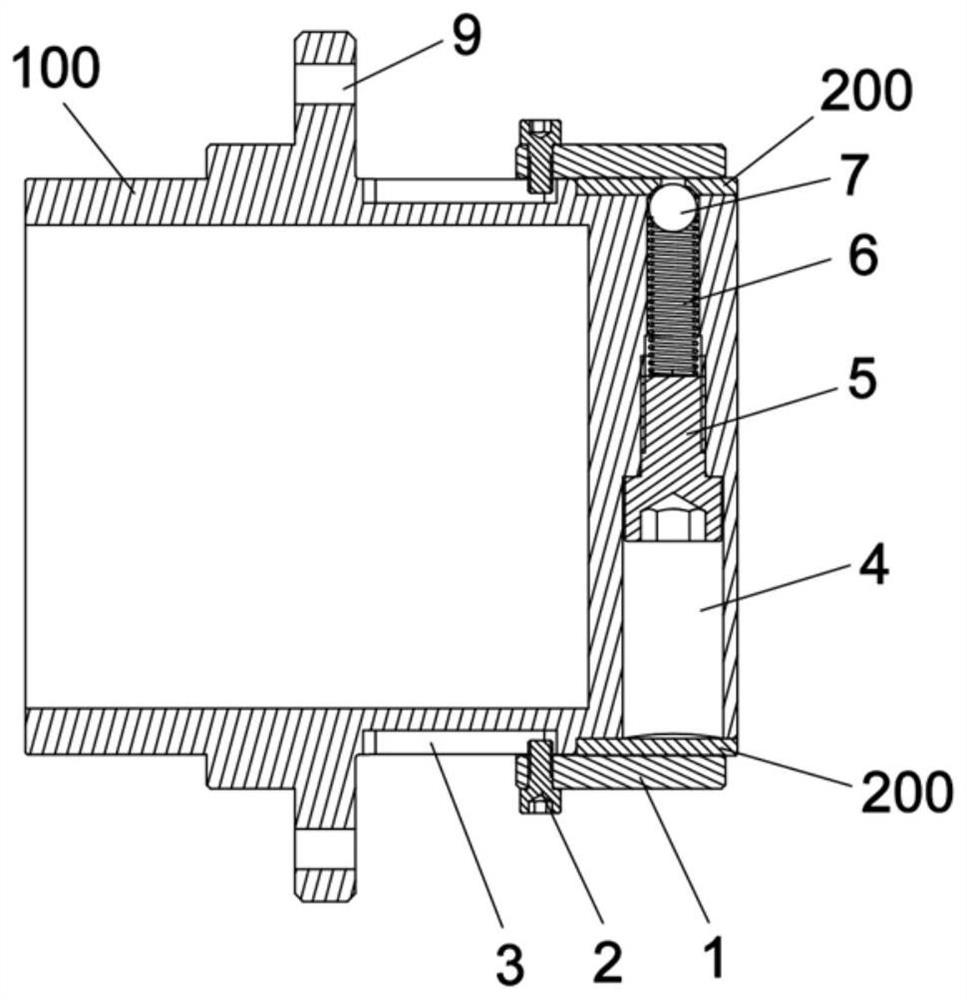

Novel main shaft reciprocating support structure of sliding bearing type fiberglass drawing equipment

InactiveCN104712664ASimple structureSimplify the assembly processEngine sealsEngine lubricationGlass fiberMechanical engineering

The invention relates to a novel main shaft reciprocating support structure of sliding bearing type fiberglass drawing equipment. The novel main shaft reciprocating support structure comprises an assembling type rolling wheel, wherein the assembling type rolling wheel comprises a rotary table and a shaft core cylinder detachably connected with the rotary table, and the interior of the rotary table and the interior of one end of the shaft core cylinder are respectively provided with one sliding bearing; the main shaft is supported by the two sliding bearings, a first dustproof mechanism is arranged between the rotary table and the sliding bearing arranged in the rotary table, and a second dustproof mechanism is arranged between the shaft core cylinder and the sliding bearing arranged in the shaft core cylinder. The main shaft reciprocating support structure has the advantages of being simple in structure, low in cost, simple in assembly technology, easy for assurance of assembly accuracy, good in whole rigidity, relatively low in reciprocating resistance and the like.

Owner:泰安佳成机电科技有限公司

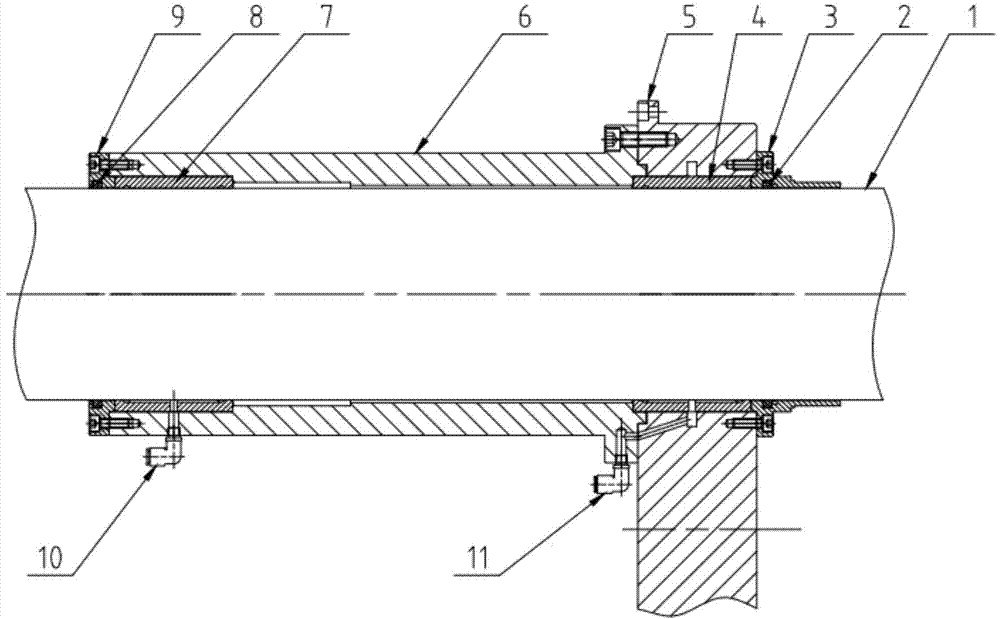

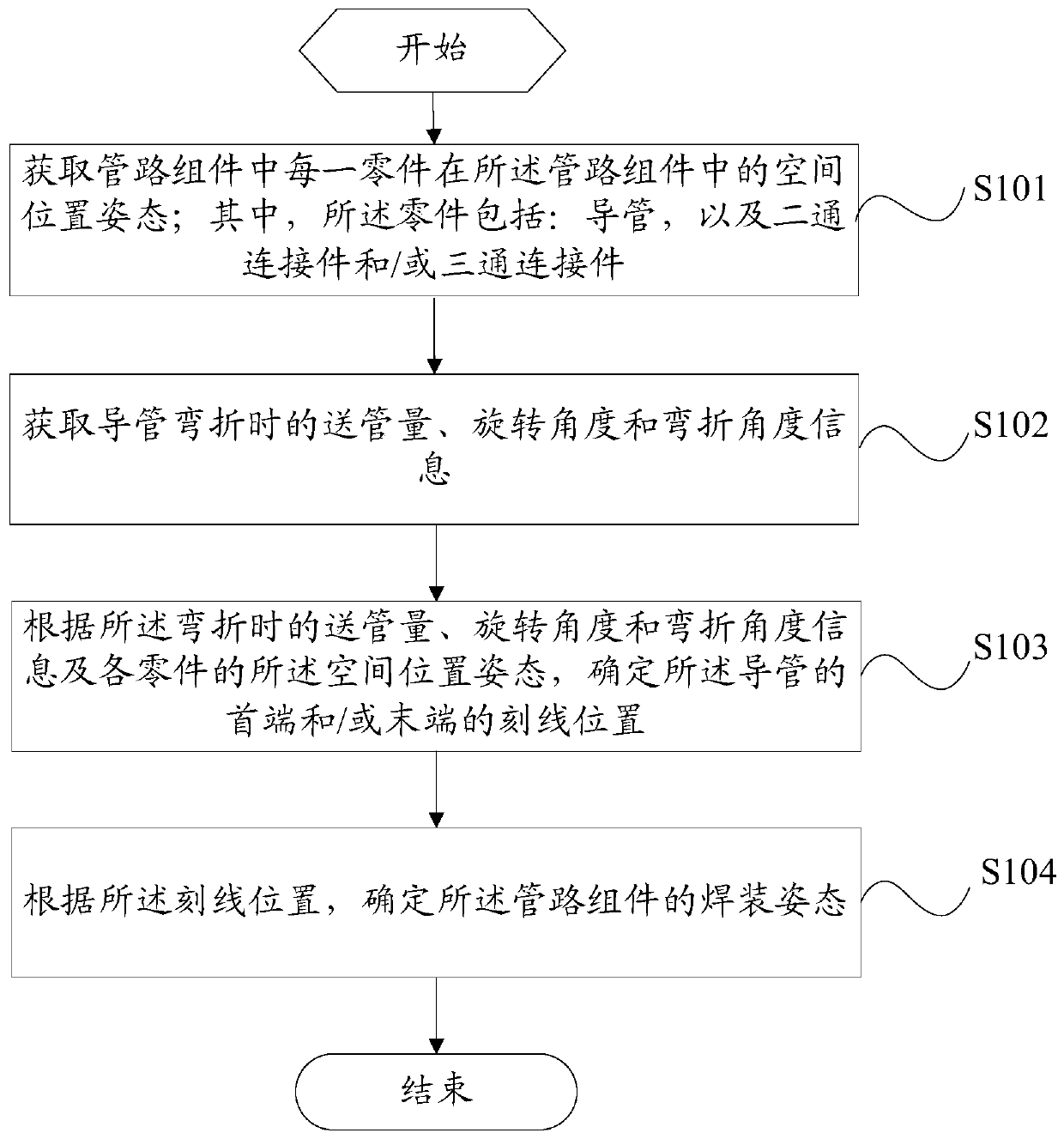

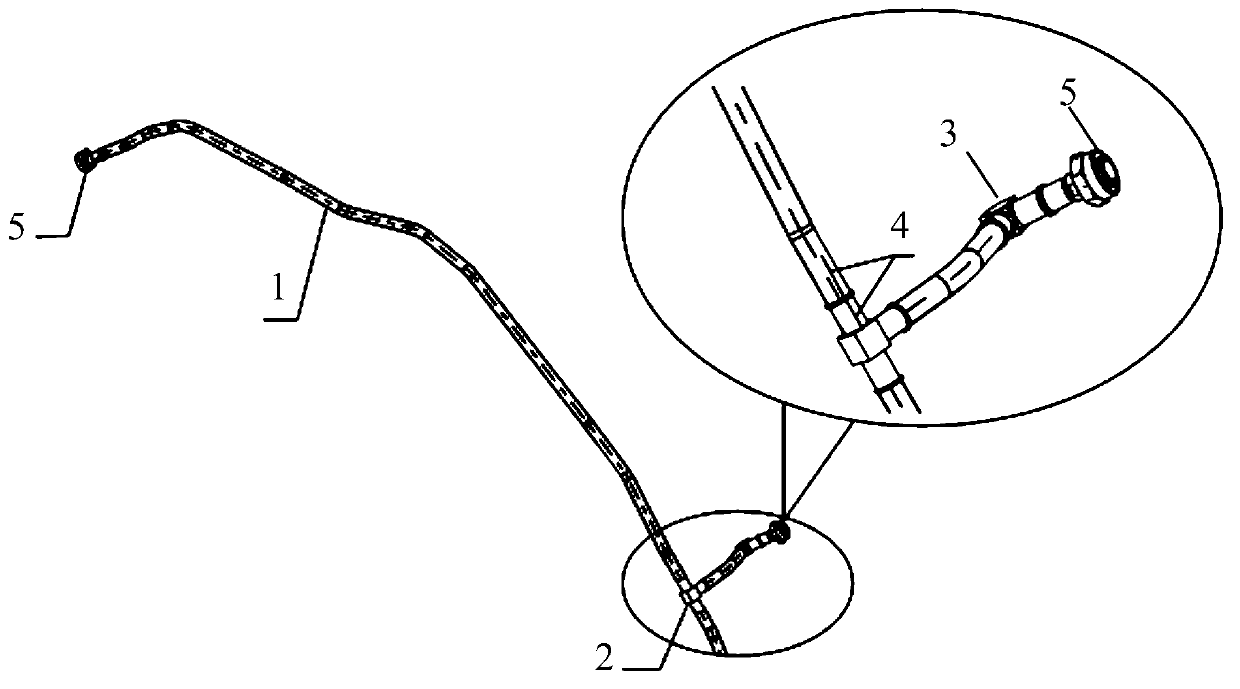

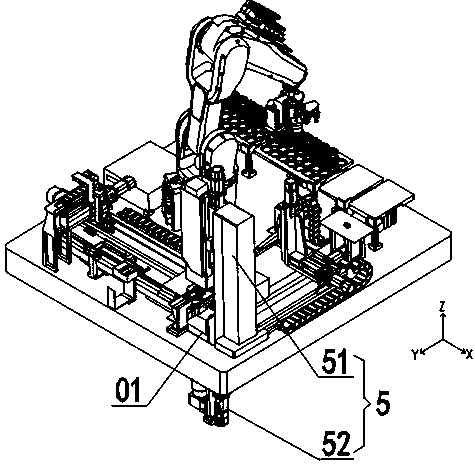

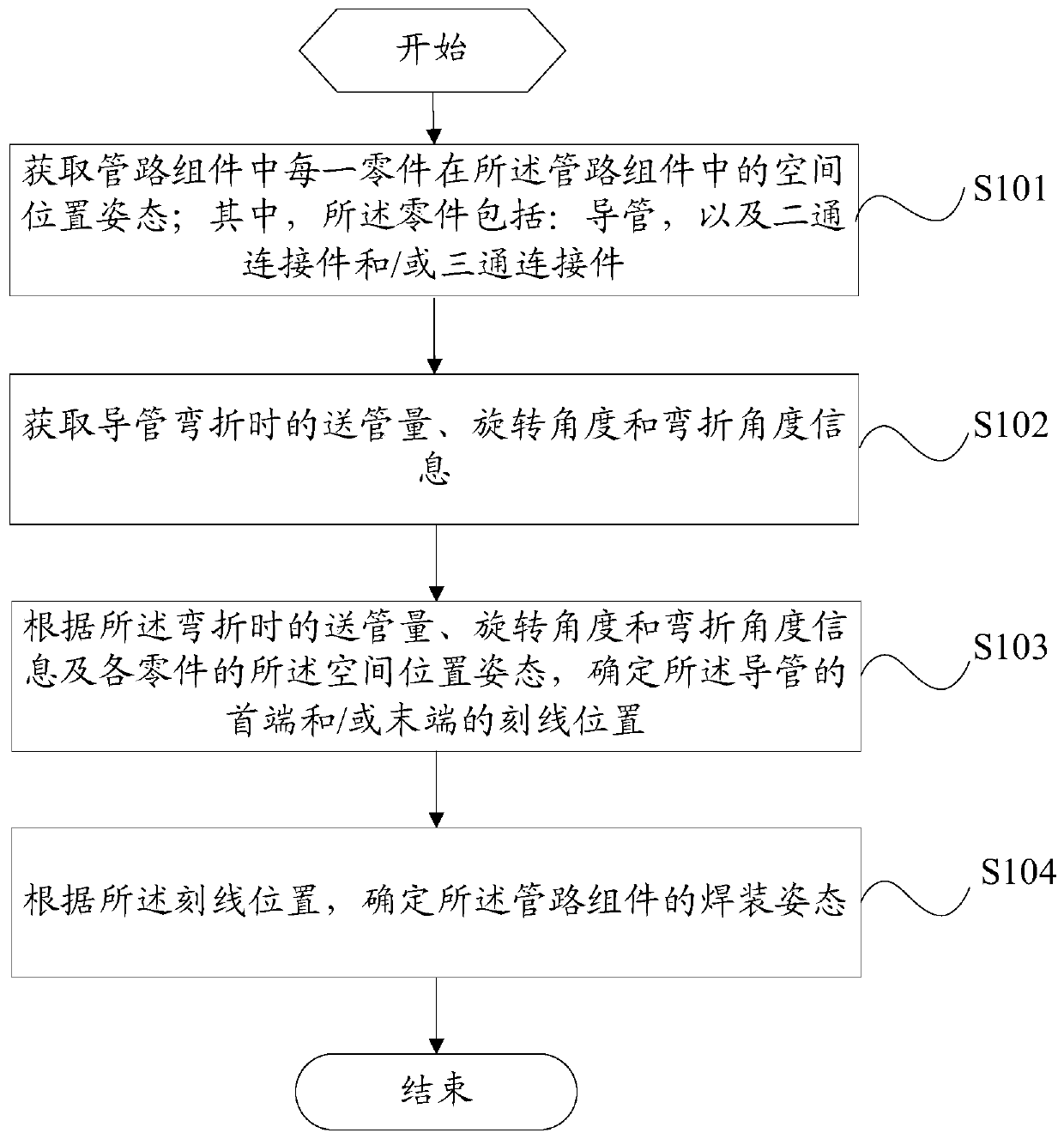

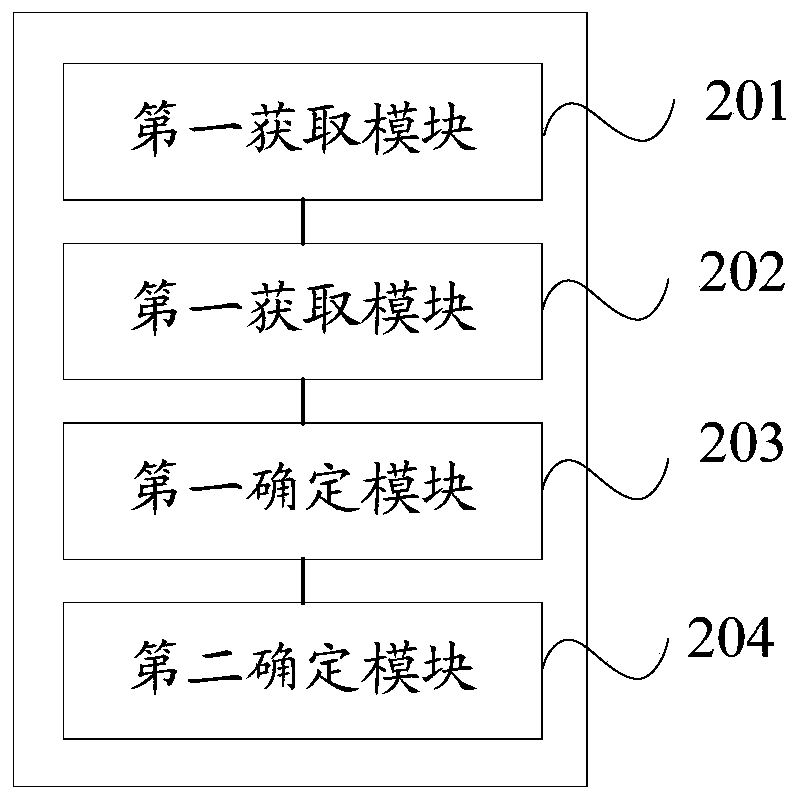

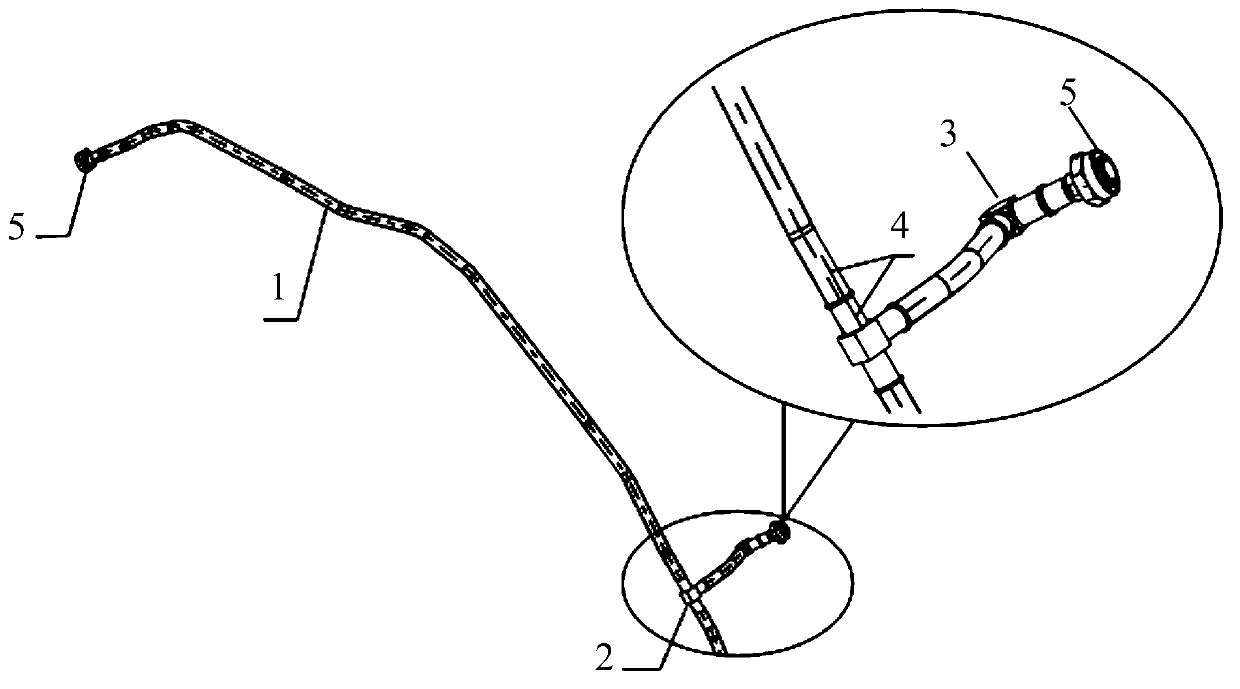

Method and device for determining welding posture of pipeline assembly and upper computer

ActiveCN109693058AImprove welding efficiencyGuaranteed posture relationshipWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a method and device for determining a welding posture of a pipeline assembly and an upper computer, and relates to the technical field of pipeline assembling. The method for determining the welding posture of the pipeline assembly comprises the following steps that the spatial position posture of each part in the pipeline assembly in the pipeline assembly is acquired, wherein the parts comprise guide pipes, two-way connecting parts and / or three-way connecting parts; the information of the pipe feeding amount, the rotation angle and the bending angle are acquired when theguide pipes are bent; the scribing positions of the head ends and / or the tail ends of the guide pipes are determined according to the information of the pipe feeding amount, the rotation angle and the bending angle during bending and the spatial position posture of each part; and according to the scribing positions, the welding posture of the pipeline assembly is determined. According to the scheme of the method and device for determining the welding posture of the pipeline assembly and the upper computer, the step of building a combined clamp in the welding process of a complex pipeline assembly is omitted, the manual operation amount is reduced, and the welding efficiency of the complex pipeline assembly is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

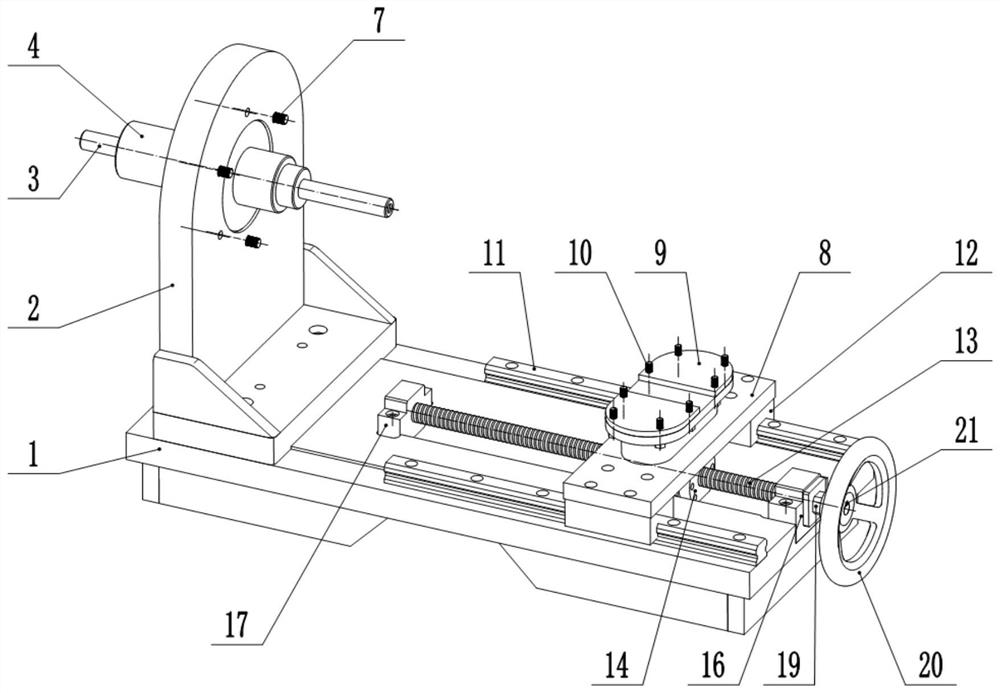

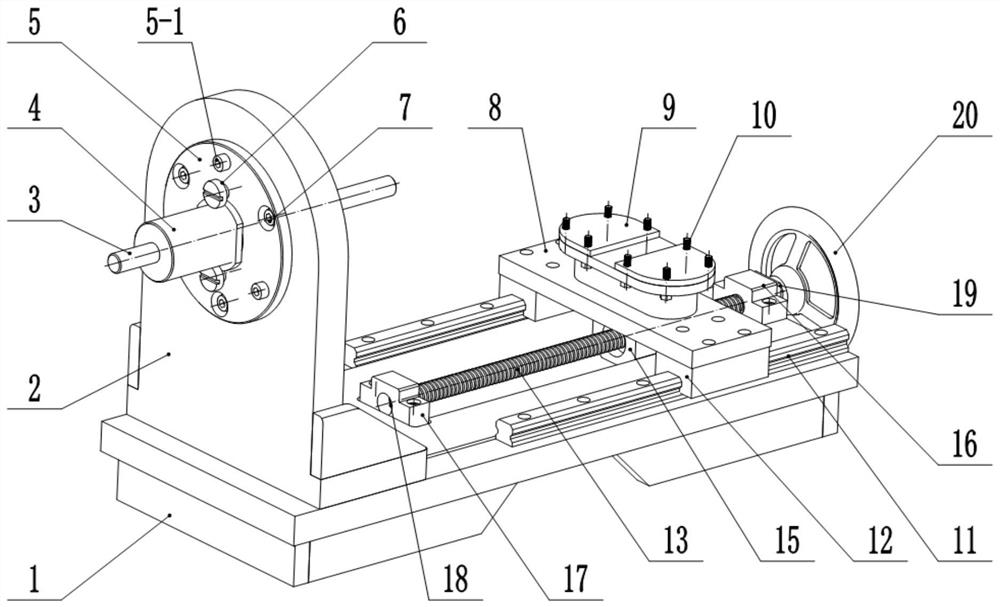

Stator and rotor horizontal assembling device and assembling method of turbine power generation equipment

ActiveCN114337137ANo contactNo collisionManufacturing stator/rotor bodiesBall screwControl engineering

The invention discloses a horizontal stator and rotor assembling device and method for turbine power generation equipment, and belongs to the technical field of turbine power generation equipment assembling. The problem that the assembling technology in the prior art is not suitable for coaxial assembling of the stator and the rotor of the turbine power generation equipment is solved. According to the technical scheme, a casing bent plate support is used for installing a stator and casing combination and fixed to the left end of a platform base, a linear guide rail is installed on the right side of the platform base, and a sliding block is assembled on the linear guide rail; the turbine shell sliding bracket is used for installing a rotor and turbine semi-finished product assembly and fixed to the sliding block, the lead screw nut is fixedly installed on the sliding bracket through the lead screw nut base, the ball screw and the lead screw nut are installed in a threaded fit mode, and the hand wheel is used for rotating the ball screw to drive the sliding bracket to move horizontally along the linear guide rail. According to the tool, it is ensured that stator and rotor assemblies of the turbine power generation device are accurate in positioning, reliable in clamping and convenient to assemble, it is effectively ensured that the stator and the rotor do not make adsorption contact or collide in the assembling process, and the assembling quality and efficiency are effectively improved.

Owner:航天科工哈尔滨风华有限公司

Special-shaped-surface modular grinder tailstock center sleeve support structure and using method thereof

ActiveCN103465160BImprove radial stiffnessReduce precisionGrinding carriagesGrinding bedsEngineeringHeavy load

The invention provides a special-shaped-surface modular grinder tailstock center sleeve support structure comprising a triangular center sleeve, a special-shaped surface shell, an adjusting press plate, a pressure spring, a spring pretightening nut, a guide sleeve, an adjusting screw, a rotating hand wheel, a clamping adjusting gear and the like. The tailstock center sleeve of a grinder is mounted in a special-shaped surface support. The invention further provides a corresponding method. By using the special-shaped surface support for replacing a traditional cylindrical support structure, the special-shaped-surface modular grinder tailstock center sleeve support structure has the advantages of high radial stiffness of the center sleeve, suitability for large-sized heavy-load mechanisms, proneness to guaranteeing assembly accuracy, easiness in adjustment after wear of the support and the like.

Owner:SHANGHAI JIAOTONG UNIV

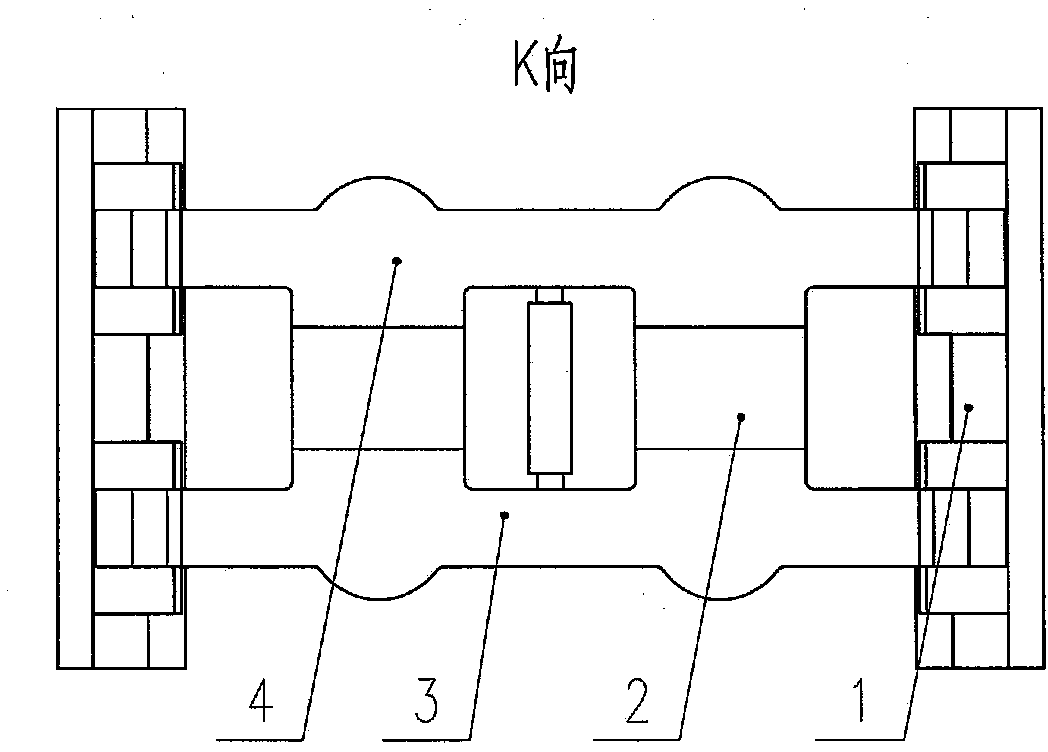

Automobile ordinary geartrain hydraulic speed transmission

The invention relates to automobile dead axle train hydrodynamic drive transmission. It is formed by hydrodynamic torque converter and transmission. The former includes dynamic force coupling, locking clutch, runner, impeller, oil pump, idler pulley seat, and input shaft. The latter includes driving shaft, each driving gear, output shaft, gear shift sleeve, and reverse shaft and gear. It has the advantages reasonable structure and convenient installation.

Owner:江苏润五特汽车智能传动科技股份有限公司

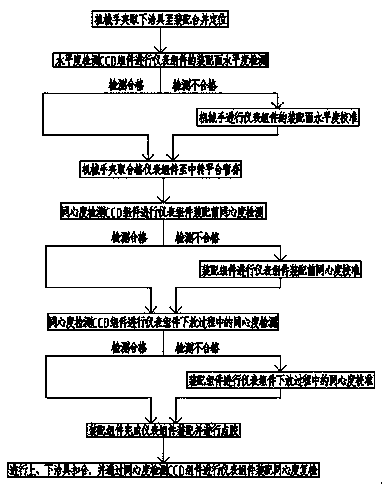

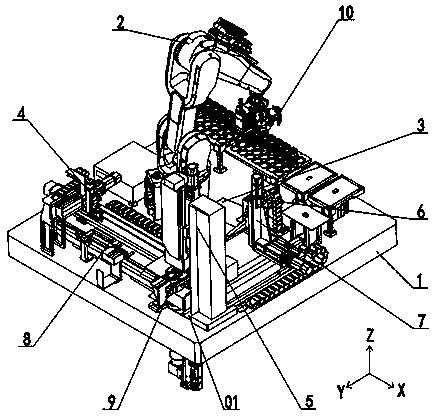

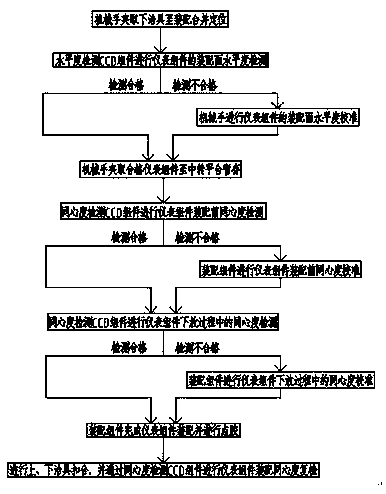

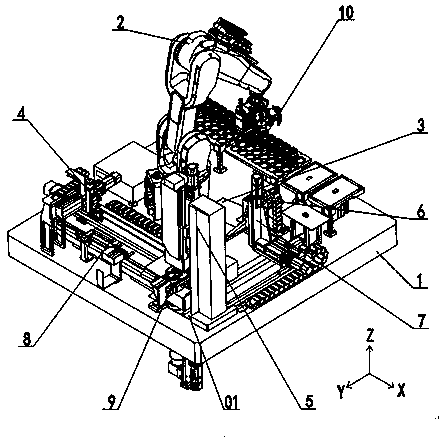

An assembly method for the assembly accuracy of instrument components based on image detection

ActiveCN108994601BImprove assembly accuracyGuaranteed assembly accuracyAssembly machinesMetal working apparatusSoftware engineeringImage detection

Owner:CHENGDU JIANGYE OPTOELECTRONICS TECH

Method, device and host computer for determining welding attitude of pipeline components

ActiveCN109693058BImprove welding efficiencyGuaranteed posture relationshipWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

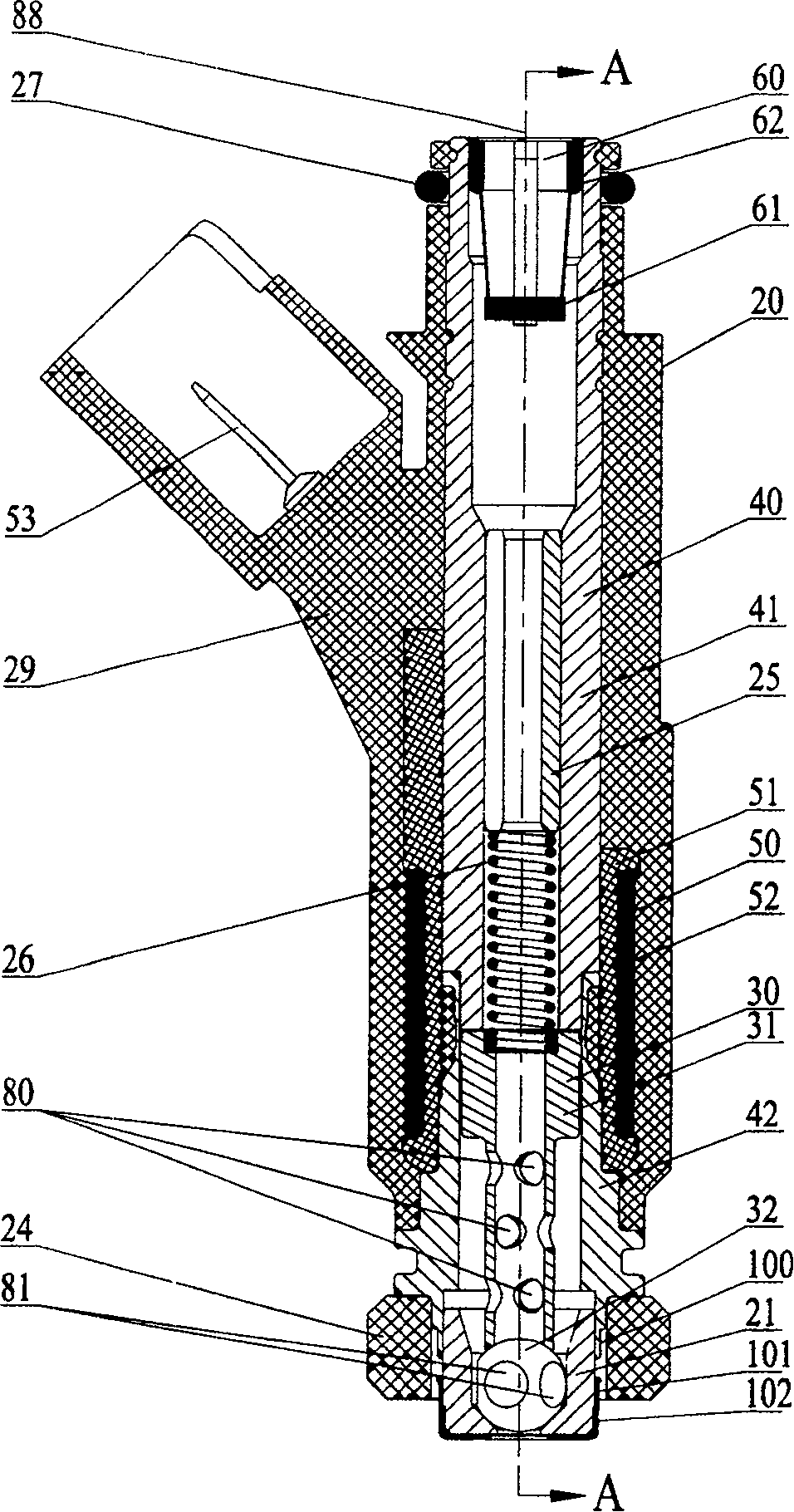

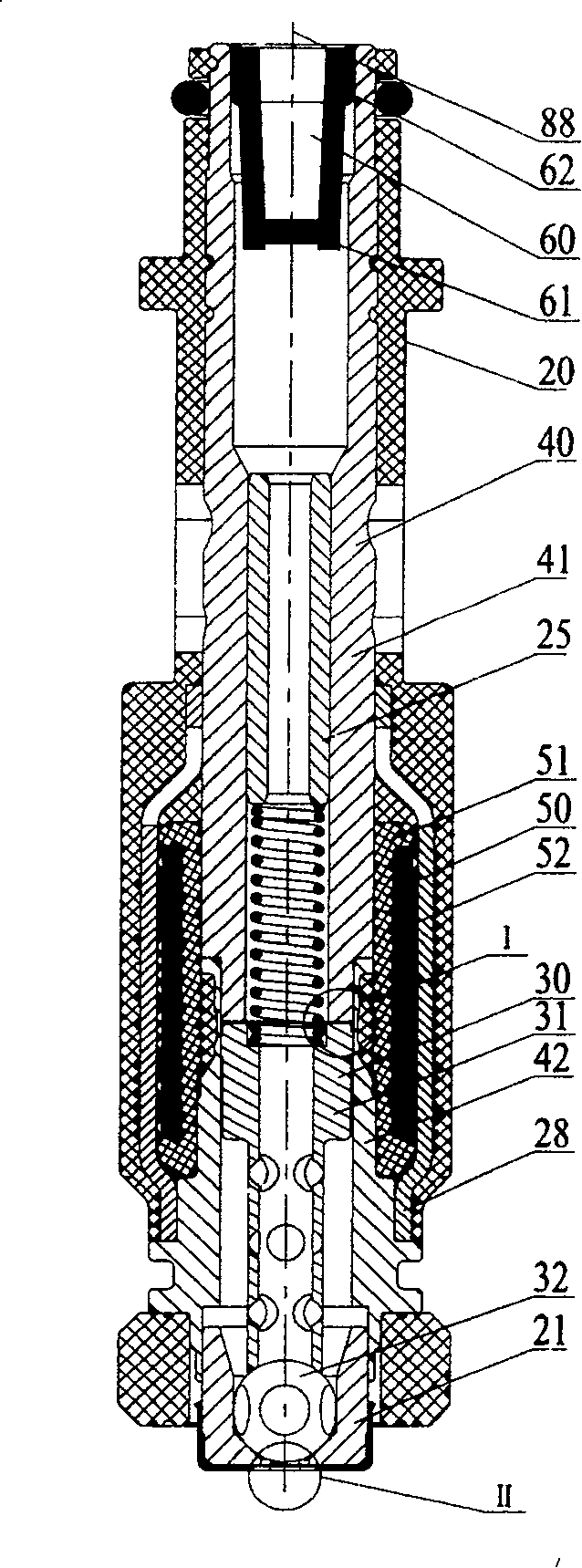

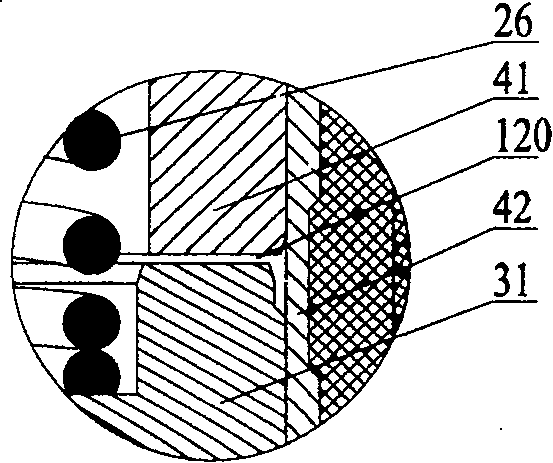

Fuel oil injector

ActiveCN100404847CHigh flux densityReduce manufacturing costFuel injection apparatusMachines/enginesEngineeringVolumetric Mass Density

There is disclosed an improved structure of a fuel injector, in which by removing the middle magnet resistor from the valve assembly and switching over to cutting the lower valve body producing the magnetic gap into a circular cylindrical surface or being finished into a thin-wall ring, a circular wall groove is formed to reduce the wall thickness and increase the magnetic resistance, so as to increase the magnetic flux density between the iron core and the bicyclic flat surface of the upper valve body. Because of removing the intermediate adapter, the iron core is welded with the ball valve directly.

Owner:BYD CO LTD

A device and method for offset lifting and sliding

ActiveCN108179816BReduce dosageIncrease reaction forceBuilding constructionsEngineeringSteel columns

The invention belongs to the field of steel structure construction, and particularly relates to an offset lifting slip device and method. A lifting supporting frame is arranged on a structure main body steel column; an assembled jig frame is erected on a floor, and main body roof trusses are assembled into an overall structure; the overall roof trusses are lifted to be arranged below a load-bearing track beam; hydraulic jacking and pushing driving equipment is connected with a lifting load-bearing beam through a pin shaft, the hydraulic jacking and pushing driving equipment is started, and thelifting load-bearing beam is jacked and pushed to slip to a calculated elevation on the load-bearing track beam; and four jacks are used on the structure main body steel column for jacking lower chords of the roof trusses, a lifter equipment device is shut down, all the jacks unload the main body roof trusses in place in synchronous and in-step modes, and the main body roof trusses and the structure main body steel column are fixedly connected, so that construction is completed. According to the offset lifting slip device and method, working at heights is reduced, safety is improved, the efficiency is high, and the cost of measures is saved.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Image-detection-based assembling method capable of guaranteeing instrument assembly assembling precision

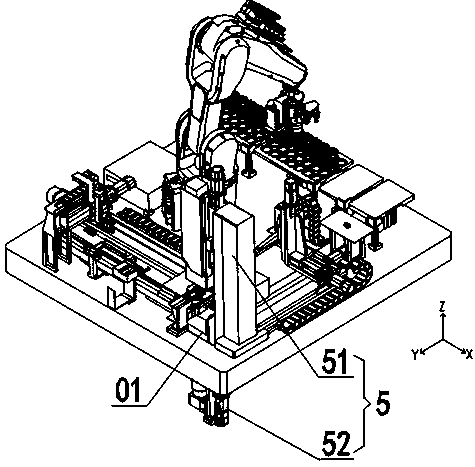

ActiveCN108994601AImprove assembly accuracyGuaranteed assembly accuracyAssembly machinesMetal working apparatusImage detectionAutomation

The invention discloses an image-detection-based assembling method capable of guaranteeing instrument assembly assembling precision. The assembling method is used for assembling instrument assembliesby using an instrument assembly assembling precision control device on the basis of image detection. The assembling method the comprises the following steps that step A, a lower jig is clamped to an assembling table for positioning and fixing; step B, the instrument assemblies are clamped to a levelness detection CCD assembly for assembly surface levelness detection and calibration as well as temporary storage; step C, an assembling assembly sucks the instrument assemblies to a position above the assembling table, a concentricity detection CCD assembly is used for performing concentricity detection and calibration of the instrument assemblies before assembling and during the lowering process, and then glue dispensing is carried out in sequence; step D, an upper jig and the lower jig are buckled and combined, and then the concentricity detection CCD assembly is used for performing assembling concentricity re-inspection of the instrument assemblies. The assembling method has the beneficial effects that the assembling precision is higher, the assembling precision is easy to guarantee, the relative positions of the instrument assemblies can be adjusted in real time, the assembling costis low, the assembling efficiency is high, the automation degree is high, and the assembling time is short.

Owner:CHENGDU JIANGYE OPTOELECTRONICS TECH

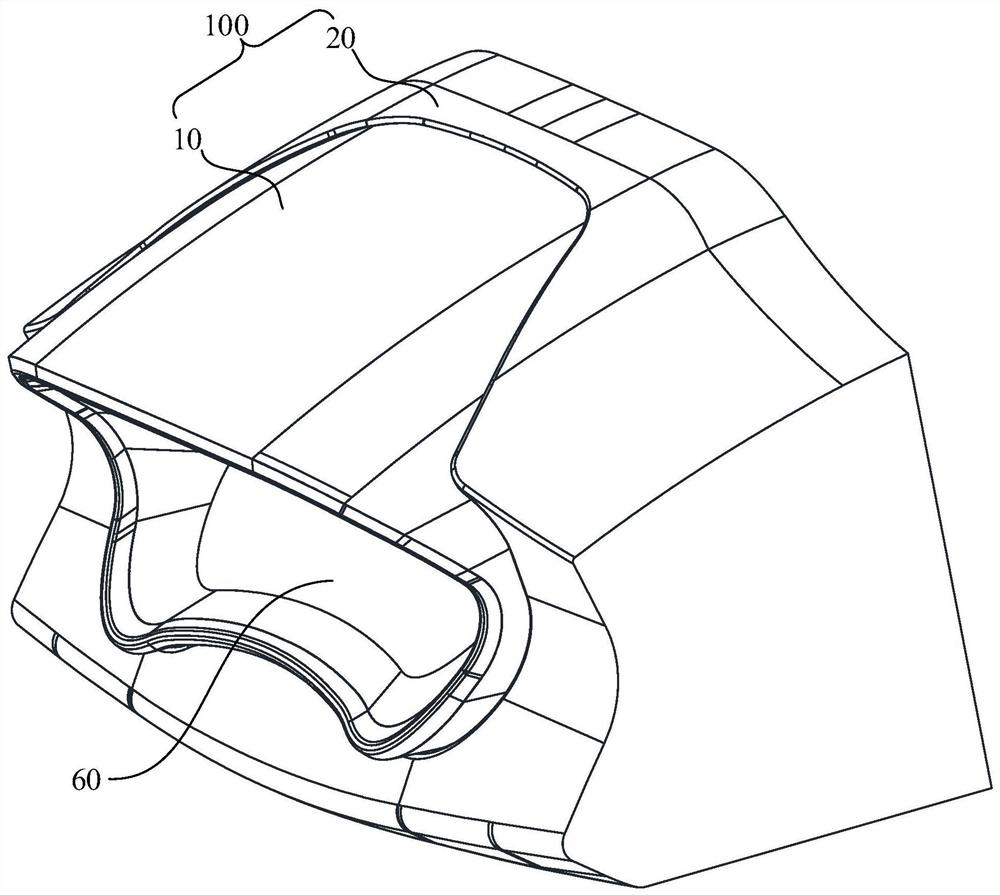

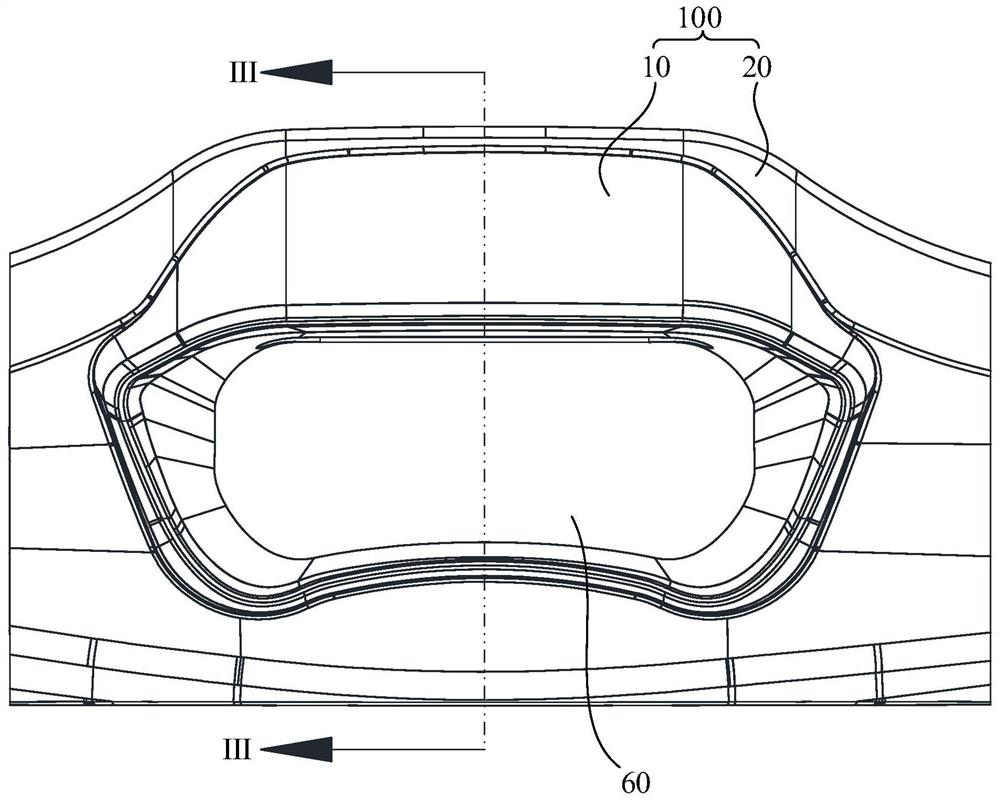

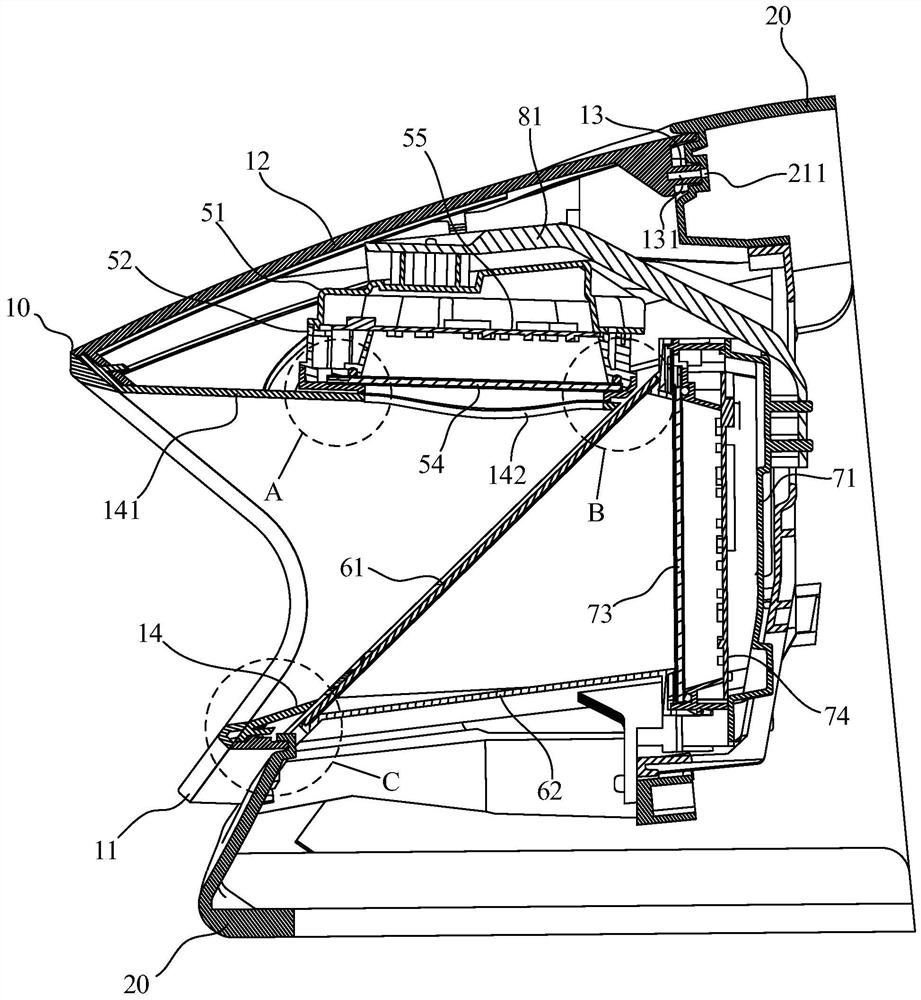

Automobile instrument panel

ActiveCN113752830AWill not affect the 3D display effect3D display effect is easy to guaranteeDashboard fitting arrangementsInstrument arrangementsDashboardLight guide

The invention discloses an automobile instrument panel which comprises an outer cover and a displayer assembly arranged in the outer cover. The outer cover comprises a light shield and a rear shell, and the rear shell is provided with a front installation opening; the light shield comprises an opening part, a light shielding part and a light guide cylinder; a top wall opposite to the light shielding part is formed at the top of the light guide cylinder, and a window is formed in the top wall; the displayer assembly comprises an upper screen assembly, a reflecting mirror assembly and a rear screen assembly which are fixedly arranged with one another, the reflecting mirror assembly comprises a half reflecting mirror, the half reflecting mirror is obliquely arranged forwards from top to bottom, the rear screen assembly is arranged behind the half reflecting mirror, and the upper screen assembly is arranged above the half reflecting mirror; the upper screen assembly is arranged between the top wall of the light guide cylinder and the light shielding part, is in non-contact with the light shielding cover and is fixedly connected with the rear shell; and the reflecting mirror assembly and the outer cover are arranged in a non-contact mode. The internal parts of the displayer assembly of the automobile instrument panel are mutually fixed, and the whole displayer assembly is only fixedly connected with the rear shell in a suspended mode so that the assembly quality and the 3D display effect are easier to guarantee.

Owner:HEILONGJIANG TIANYOUWEI ELECTRONICS CO LTD

Microminiature balance-force type sealed DC electromagnetic relay

InactiveCN107845543AReduce ablationReduce wearElectromagnetic relay detailsNon-polarised relaysEngineeringRelay

The invention discloses a microminature balance-force type sealed DC electromagnetic relay. A conductive piece is fixed on a pedestal, the lower end of a connecting card is installed in an installation hole of the conductive piece, and the upper end of the connecting card is installed on a bottom surface of a pressure piece. A movable contact spring is installed in an installation hole of an insulating block, and a movable contact is fixedly installed at the right end of the movable contact spring. A transition piece is installed on the pedestal, and a static contact is fixedly installed on the transition piece. The insulating block is installed on a shaft frame through a rotating shaft, and an armature is installed in an installation groove on the shaft frame. A first yoke is installed onthe shaft frame, and a magnetic steel is installed on the shaft frame. A second yoke is installed on the shaft frame, and a third yoke is installed on the shaft frame, and is close to the right sidesurface of the shaft frame. A coil is installed on the shaft frame, and is located between the second yoke and the third yoke. The electromagnetic relay is simple in structure, is good in manufacturability, is high in operability, guarantees the assembly precision easily, can improve the assembly efficiency, and achieves the batch production.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH

Double-nut ball screw pair preload adjustment and measurement device and linear feed system

InactiveCN105965307BLittle effect on stiffnessEvenly distributedMeasurement/indication equipmentsFeeding apparatusMeasurement deviceBall screw

The invention relates to a double-nut ball screw pair pre-tightening force adjusting and measuring device and a linear feeding system. The double-nut ball screw pair pre-tightening force adjusting and measuring device comprises a main screw nut, a nut sleeve, a locking nut, a pre-tightening nut, a thrust bearing, a front disc spring fixing plate, a first disc spring, a second disc spring, a rear disc spring fixing plate, an annular pressure sensor, a sensor fixing plate, an auxiliary screw nut, an auxiliary nut connecting plate and a worktable connecting plate; one end of the nut sleeve is in fastened connection with the main screw nut; the locking nut and the pre-tightening nut are connected to the nut sleeve by threads; the thrust bearing clings to the pre-tightening nut; the front disc spring fixing plate clings to the thrust bearing; the excircle side of the first disc spring clings to the front disc spring fixing plate; the inner hole of the second disc spring clings to the inner hole of the first disc spring; the rear disc spring fixing plate clings to the excircle side of the second disc spring; and the annular pressure sensor clings to the rear disc spring fixing plate, the sensor fixing plate clings to the annular pressure sensor, and the other side of the sensor fixing plate is in fastened connection with the auxiliary screw nut.

Owner:TSINGHUA UNIV

Magnetic 3D movement structure of massage chair

ActiveCN104546399BImprove massage efficiencyImprove stabilityVibration massageSuction-kneading massageLower borderMassage

The invention discloses a massage chair structure, and provides a magnetic 3D (Three-Dimensional) mechanism structure for massage chairs, which is compact in structure, simple in assembly and high in assembly precision, can selectively perform kneading-type and beating-type massage the back of the human body according to operating requirement and can automatically regulate massage force, and the invention solves the technical problems existing in the prior art that products are structurally complex and large in size, are highly difficult to assemble and repair, cannot ensure assembly precision, and affect the normal use of massage chairs. The magnetic 3D mechanism structure comprises a square mechanism frame which is longitudinally and slidably connected to the back of a massage chair, wherein the lower border of the mechanism frame is rotatably connected to one end of a mechanism fixing plate, the mechanism fixing plate is provided with a first gear set, the first gear set is connected with a massage roller group and can drive the massage roller group to perform reciprocating kneading-type or beating-type operation, the other end of the mechanism fixing plate is provided with a rack mechanism capable of driving the mechanism fixing plate to rotate, the rack mechanism is connected with a second gear set, and the second gear set can automatically adjust the mechanism fixing plate to swing back and forth relative to the mechanism frame according to the resistance value of the massage roller group.

Owner:NINGBO OSUN HEALTH CARE TECH

An engine bearing bush installation and removal tool

ActiveCN112975338BPrevent radial deformationPrevent radial displacementMetal working apparatusEngineeringMechanical engineering

The invention discloses an engine bearing bush mounting and dismounting tooling, belonging to the field of engine assembly. The engine bearing bush mounting and dismounting tooling comprises a tooling body, two ends of which are respectively a dismounting end and an mounting end, and the mounting end includes guides in a direction away from the dismounting end in turn. The journal and the bearing bush are matched with the journal, and the diameter of the guide journal is larger than that of the bearing bush and the journal. On the thrust surface of the bearing bush, the guide ring can be hooped on the outer circumference of the two half-tiles, which can provide radial limit to the bearing bush during the installation process to prevent radial deformation or radial displacement of the two half-tiles, and the guide ring can During the press-fitting process, it moves axially along the guide journal to play an axial limit on the installation of the bearing bush and determine the pressing amount of the bearing bush into the bearing seat. The engine bearing bush installation and disassembly tooling structure is simple, the manufacturing cost is low, and the assembly accuracy is easy to ensure.

Owner:FAW JIEFANG AUTOMOTIVE CO

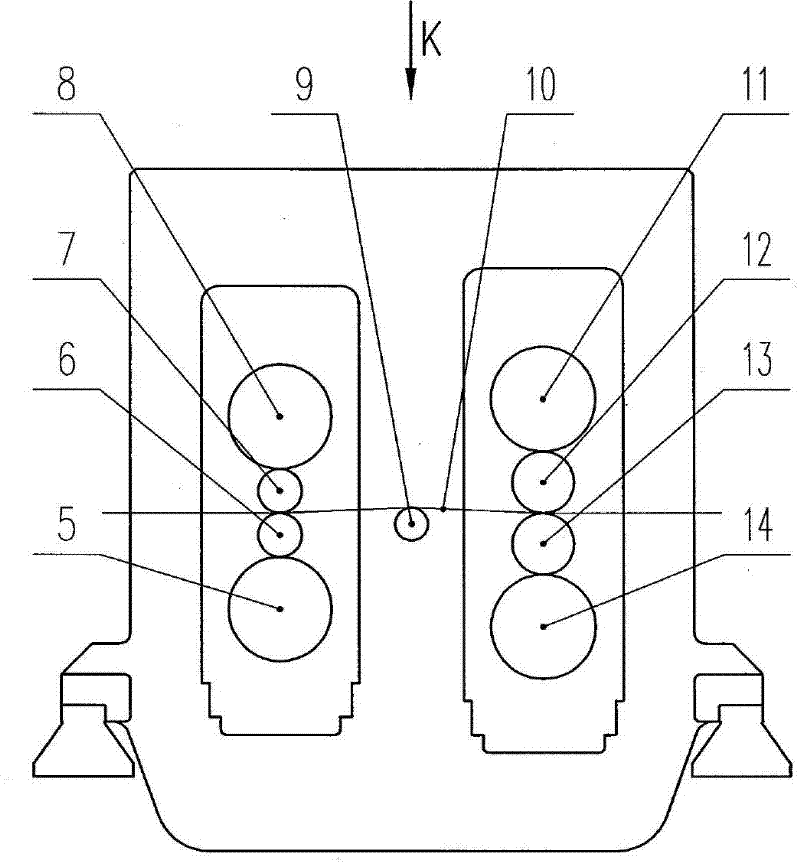

Double four-roll temper mill

InactiveCN102652959AIncrease production capacitySmall footprintMetal rolling arrangementsPulp and paper industryStrip steel

The invention comprises a double four-roll temper mill, comprising two rail supports, four breams, an operation side rack, a transmission side rack, a No.1 four-roll roller system, a tension measuring roller and a No.2 four-roll roller system. The two rail supports are fixed on a workshop foundation, and the operation side rack and the transmission side rack are fixed and supported on the rail supports. The operation side rack and the transmission side rack are both integrated steel casting pieces with double windows, and are connected into a whole through the four beams. The No.1 four-roll roller system and the No.2 four-roll roller system are respectively installed in corresponding rack windows. The tension measuring roller is arranged between the No.1 four-roll roller system and the No.2 four-roll roller system and is supported on the racks for detecting tension in the rollers. Secondary cold rolling and temper rolling of band steel can be implemented through the No.1 four-roll roller system, the tension measuring roller and the No.2 four-roll roller system. The double four-roller temper mill has the significant characteristics of compact structure, easy assurance in integral assembly precision, short band through time, high unit efficiency, high pass percent and the like.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Feed shaft bearing block structure of flat pressing continuous press

InactiveCN100348394CReduce widthReduce installation difficultyWood working apparatusDomestic articlesEngineeringBlock structure

The invention relates to a bearing block of feeding bearing of wood-based panel flat impression continuous compressor and relative fixing method. Present bearing blocks of feeding bearings are all fixed on the support of feeding head and the temperature inside the support reaches 170Deg. C to affect the service life and the maintenance. The inventive structure comprises a bearing cap, a compression board, a board, a backing block, an inner positioning ring, a bearing block, an outer positioning ring, a bearing, a screw and a connection board. Wherein, each element is fixed via six long bolts on the outer side surfaces of feeding head support, and via adjusting the screws on its two sides, the bearing block can be driven to right position of guide rail groove to adjust the vertical property between feeding axes and the working direction and the tension of chain blanket. The invention has the advantages that the bearing block is mounted on the outer side of feeding head support whose temperature is lower, to apply the mount, regulation, and maintenance of bearing block with prolonged service life.

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

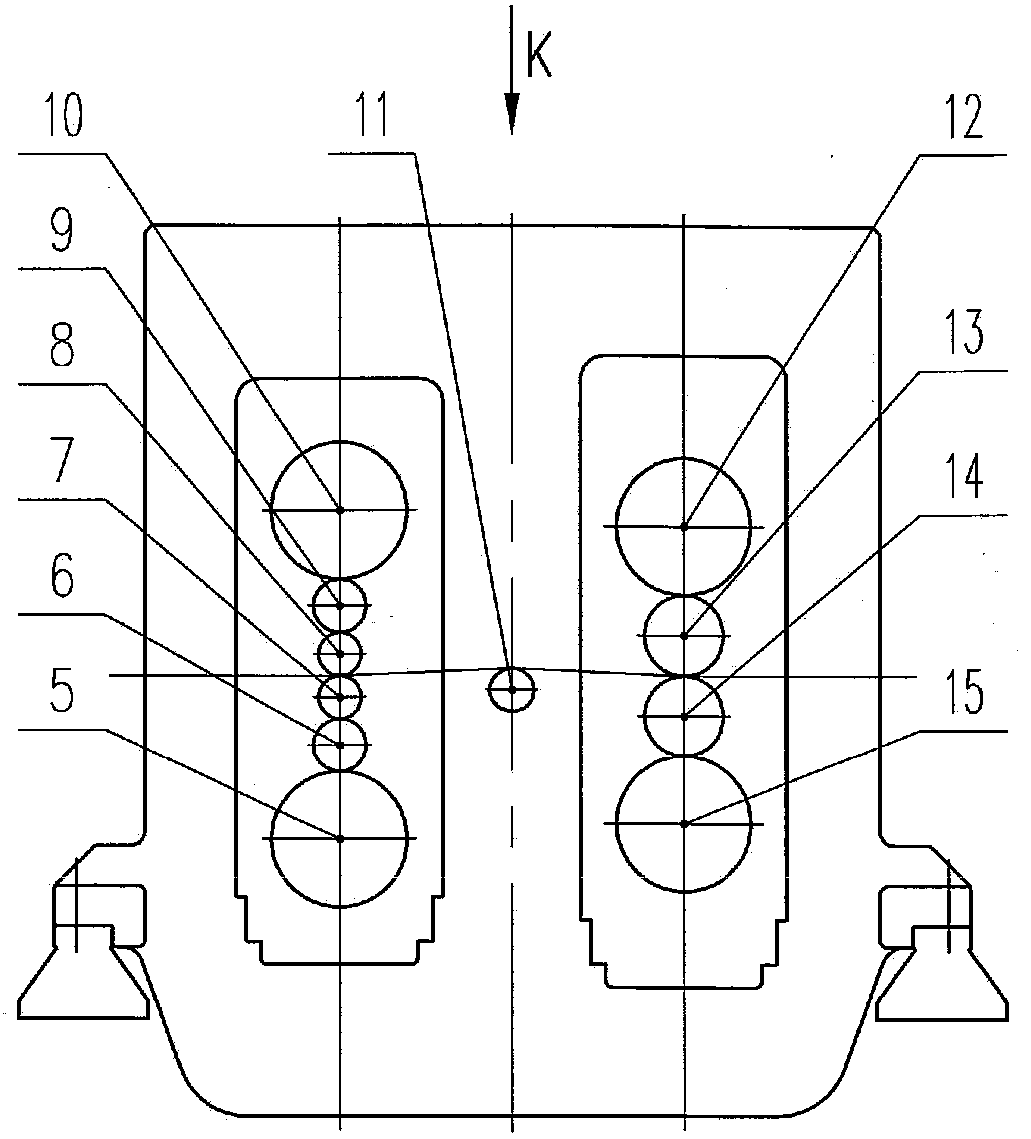

Four-roller and six-roller combined temper mill

ActiveCN102814328BIncrease production capacitySmall footprintMetal rolling arrangementsStrip steelEngineering

A four-roller and six-roller combined temper mill comprises rail chairs, cross beams, operating side machine frames, a first six roller system, a tension measuring roller and a second four roller system. The two rail chairs are fixed on a foundation of a plant. The operating side machine frames and transmission side machine frames are fixed and supported on the rail chairs, are integral steel casting parts with double windows and are connected integrally in a combined mode through four cross beams. The first six roller system and the second four roller system are respectively installed into corresponding machine frame windows, the tension measuring roller is arranged between the first six roller system and the second four roller system, is supported on a machine frame and is used for measuring rolling tension, and strip steel passes through the first six roller system, the tension measuring roller and the second four roller system to achieve secondary cold rolling and smooth temper rolling. The four-roller and six-roller combined temper mill has the remarkable advantages of being compact in structure, short in strip steel penetration time and high in unit efficiency and yield, easily ensuring overall assembly precision and the like.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

A quick connection device for off-line loading test of automobile transmission

The invention relates to a fast connecting device used for offline loading test of an automotive transmission. The fast connecting device comprises a coupling flange, a flange cover and a pin shaft extending out of the end surface of the coupling flange; a spring B is propped against the part between the pin shaft and the flange cover; a spring A is propped against the part between the flange cover and a loading transmission shaft; buffer butting between a differential mechanism connecting shaft and the loading transmission shaft is realized through the spring A and the spring B, so that the impact caused by fast butting of a hydraulic oil cylinder can be completely overcome, and adaptability to high-speed transmission can be realized; the differential mechanism connecting shaft serves as a plug for oil plugging in a differential mechanism; the differential mechanism is not needed to be provided with another plug. The fast connecting device provided by the invention is used for limiting the loading transmission shaft and the pin shaft through a central step hole and a plurality of peripheral step holes, compact in structure, reasonable in design and easier in ensuring assembly precision, has lightweight advantages, can also prevent the transmission and other related parts from impact damage while the efficiency of a whole assembly line is improved by 70 percent and can be widely applied to the fields of automobiles, new energy electric vehicles and other gear drives.

Owner:ZHUZHOU GEAR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com