Method, device and host computer for determining welding attitude of pipeline components

A technology for determining methods and components, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as cumbersome operations, low production efficiency, and difficulty in ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

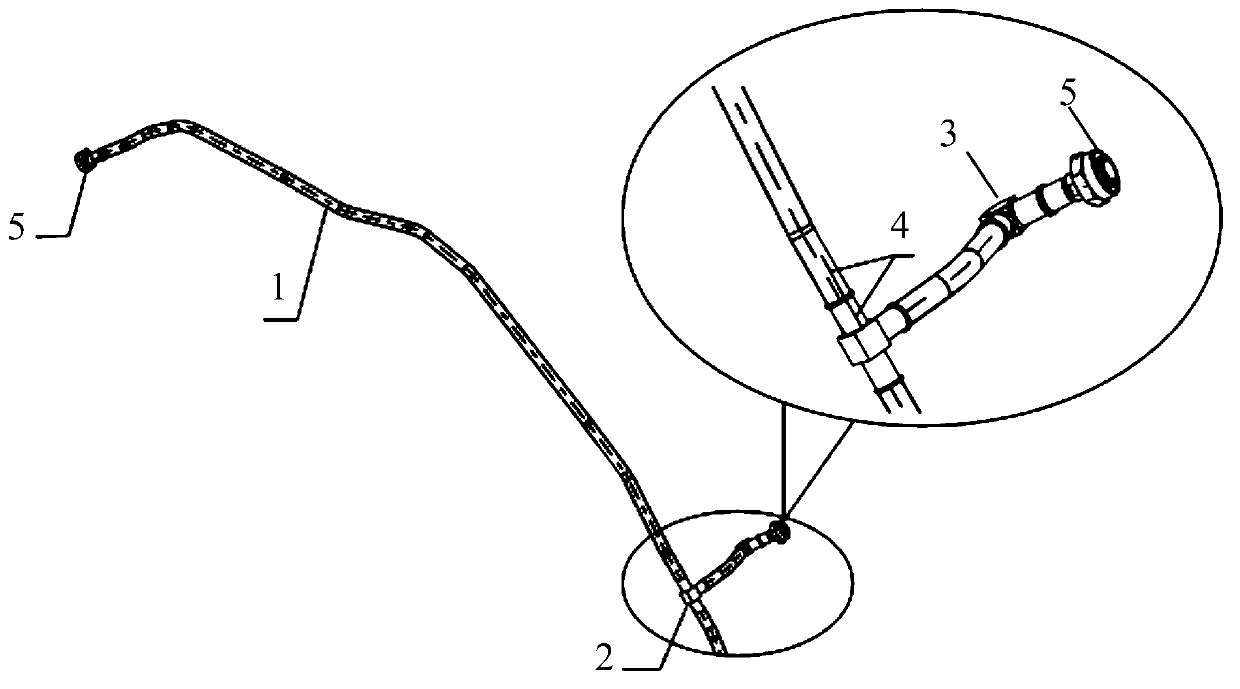

[0095] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0096] The embodiment of the present invention aims at the problems in the prior art that in the welding process of pipeline components, it is necessary to manually build and debug the combination fixture and manually score the lines, which leads to complicated welding operations, difficulty in ensuring assembly accuracy and low production efficiency, and provides a solution. A method, a device and a host computer for determining the welding attitude of a pipeline assembly make the welding operation simple, the assembly precision high and the production efficiency also improved.

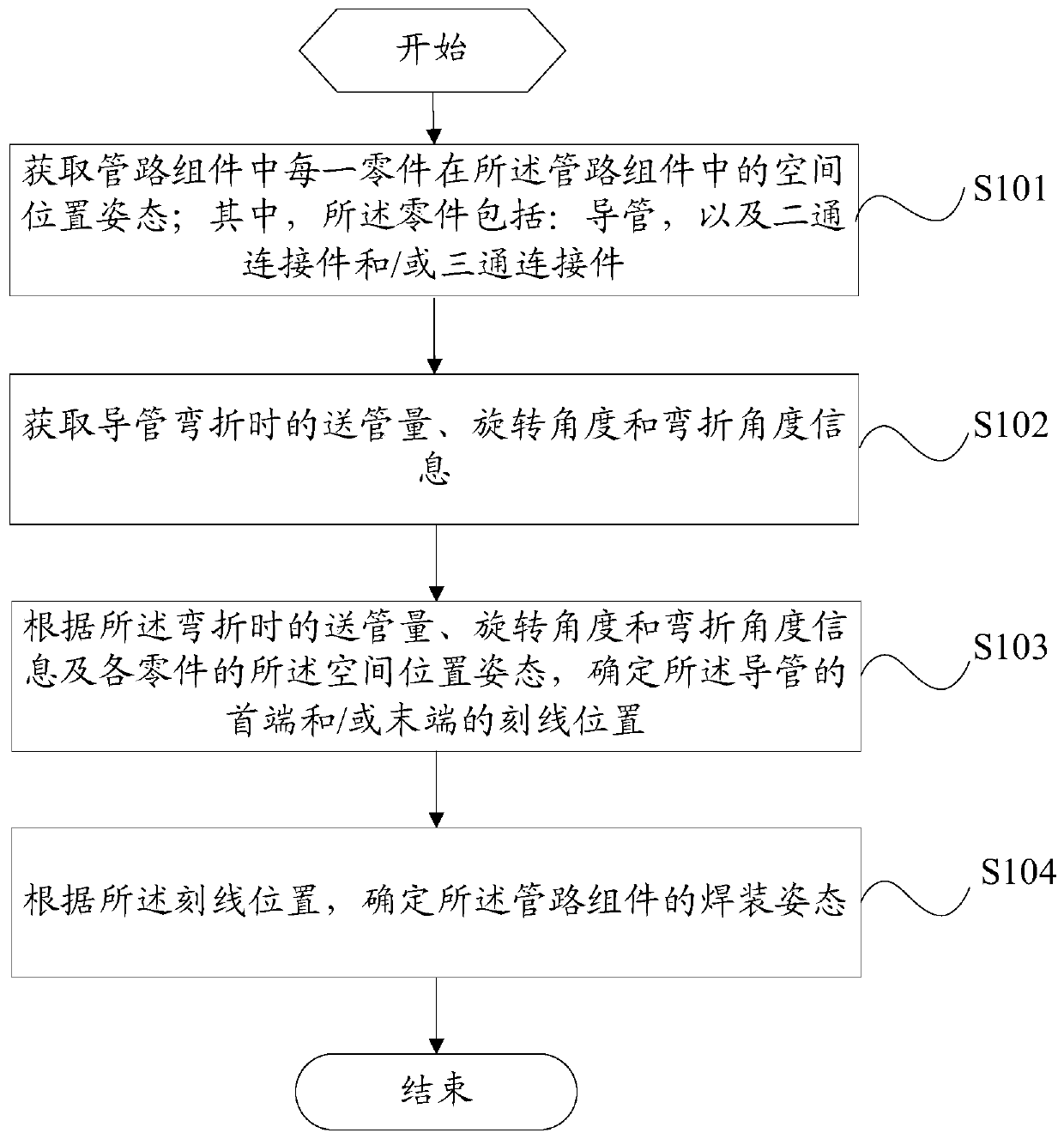

[0097] Such as figure 1 As shown, an embodiment of the present invention provides a method for determining the welding posture of a pipeline assembly, including:

[0098] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com