Hydrodynamic transmission for light vehicle

A technology of hydraulic transmission and hydraulic torque converter, which is applied in the field of hydraulic transmission for light vehicles, can solve the problems of high labor intensity, unsuitable power range, large volume and inability to install, etc., so as to reduce fuel consumption and assembly. Easy to ensure accuracy, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

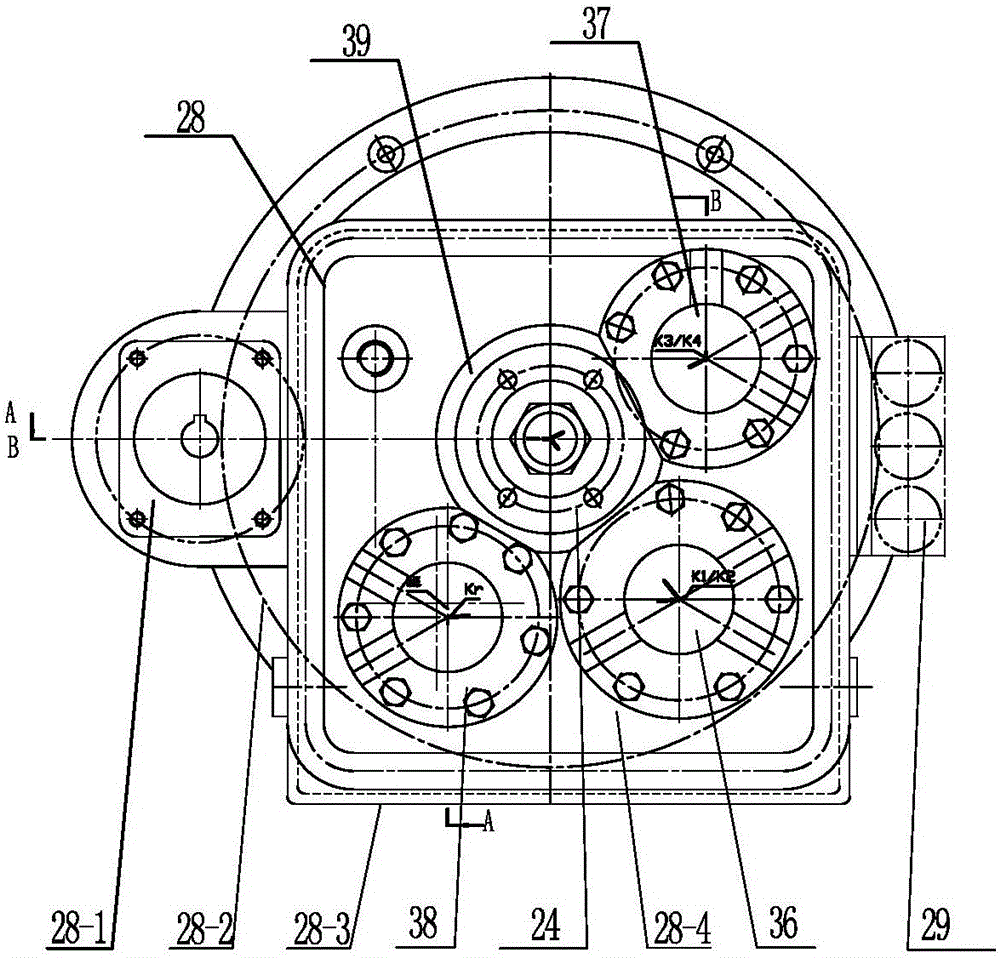

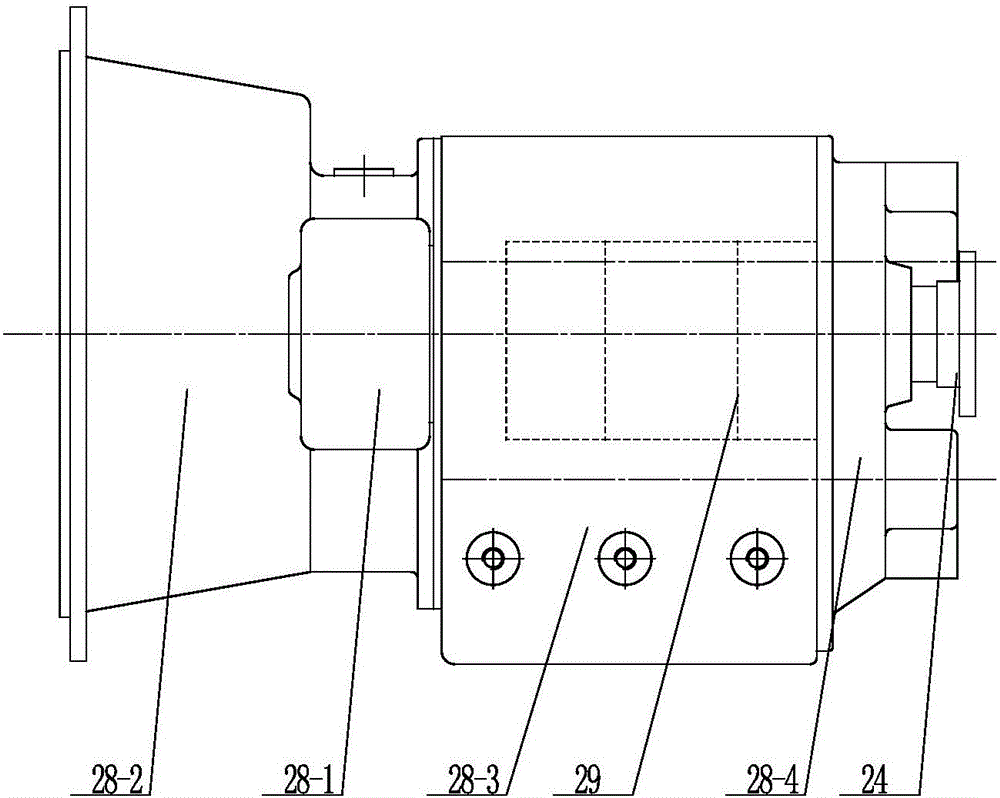

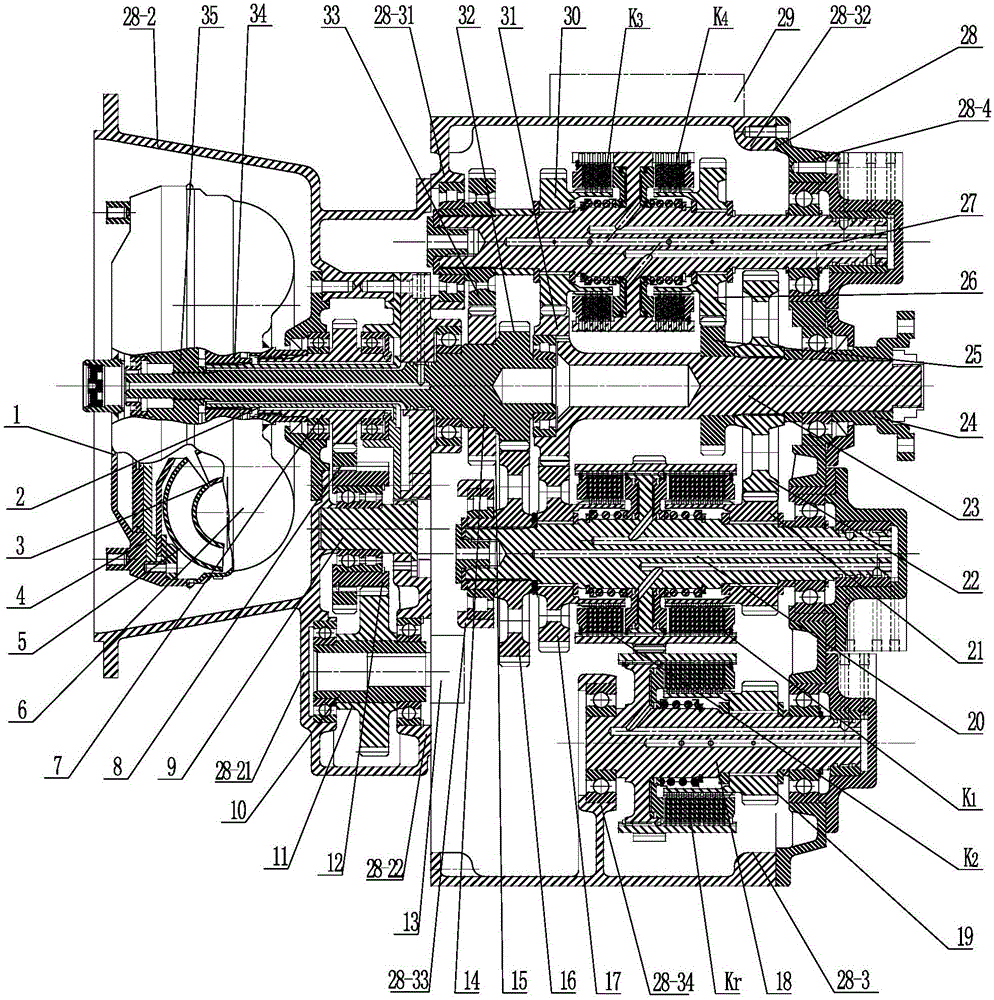

[0016] See Figure 1~3 As shown, the hydraulic transmission for light vehicles of the present invention includes a hydraulic torque converter and a transmission. The hydraulic torque converter of the present invention comprises a drive disc 1, a lock-up clutch 4, a turbine 5, a guide wheel 3, a pump wheel 6, a guide wheel seat 2 and an input shaft 14, and the drive disc 1 is connected with the pump wheel 6 through a lock-up clutch 4, The guide wheel 3 is fixed on the guide wheel seat 2 through the overrunning clutch 34 , the guide wheel seat 2 fixedly connected to the casing 28 is sleeved on the input shaft 14 , and the turbine 5 is fixedly connected on the input shaft 14 through the turbine seat 35 .

[0017] See figure 1 , 3 As shown, the oil pump drive sleeve 10 and the support shaft 9 are installed on the casing 28 of the present invention, the oil pump drive sleeve 10 is connected on the casing 28 through bearings, and the oil pump connection gear 11 is fixed on the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com