A Supporting Rod System with Continuously Changing Height

A technology for supporting rods and rod systems is applied to supporting rod systems. It can solve the problem that the bracket is difficult to meet the working conditions of different heights, and achieve the effect of simple structure, convenient installation and disassembly, and good stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

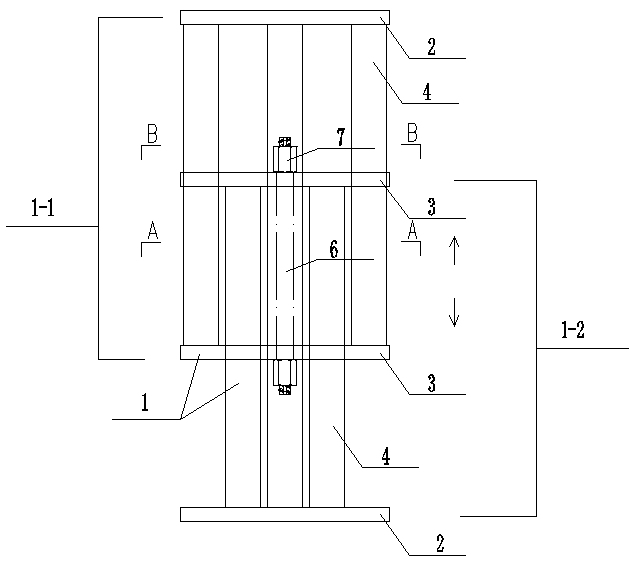

[0021] Embodiment 1: A support rod system whose height can be continuously changed, including two rod systems 1 arranged up and down, the two rod systems 1 are an upper rod system 1-1 and a lower rod system 1-2, and the rod system 1 includes the second A steel plate 2 and a second steel plate 3, the first steel plate 2 and the second steel plate 3 are connected by a support rod 4, the second steel plate is provided with a support rod groove 5 and a screw hole 8, the upper rod system 1-1 and the lower rod The line 1-2 is horizontally symmetrically arranged and the second steel plate 3 is located in the middle of the upper bar system 1-1 and the lower bar system 1-2, and the screw rod 6 and the nut 7 are passed between the upper bar system 1-1 and the lower bar system 1-2. , the screw hole 8 is connected, and the support rod 4 cooperates with the support rod groove 5.

Embodiment 2

[0022] Embodiment 2: There are several intermediate rod systems between the upper rod system 1-1 and the lower rod system 1-2. The intermediate rod systems include two second steel plates 3, and the two second steel plates 3 are supported by The rods 4 are connected, and the two adjacent intermediate rod systems are connected by a screw 6, a nut 7 and a screw hole 8.

[0023] Other structures are with embodiment 1.

Embodiment 3

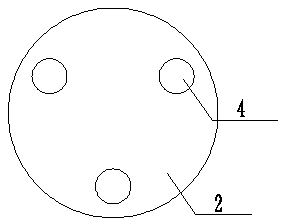

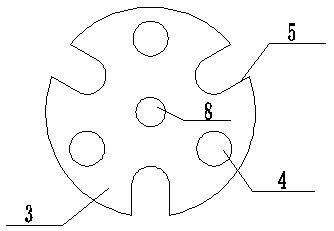

[0024] Embodiment 3: The first steel plate 2 and the second steel plate 3 are circular plates.

[0025] The support rod groove 5 is a U-shaped groove.

[0026] The support rod 4 is arranged at the edge of the first steel plate 2 and the second steel plate 3, and the connection between the support rod 4 and the first steel plate 2 forms an equilateral triangle, and the connection between the support rod 4 and the second steel plate 3 forms an equilateral triangle. An equilateral triangle, the supporting rod groove 5 encloses an equilateral triangle matched with the supporting rod 4 .

[0027] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com