Automatic bicycle hub machining system

A processing system and bicycle technology, applied in the field of automation systems, can solve the problems of increased scrap rate, unfavorable processing and assembly, and increased failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

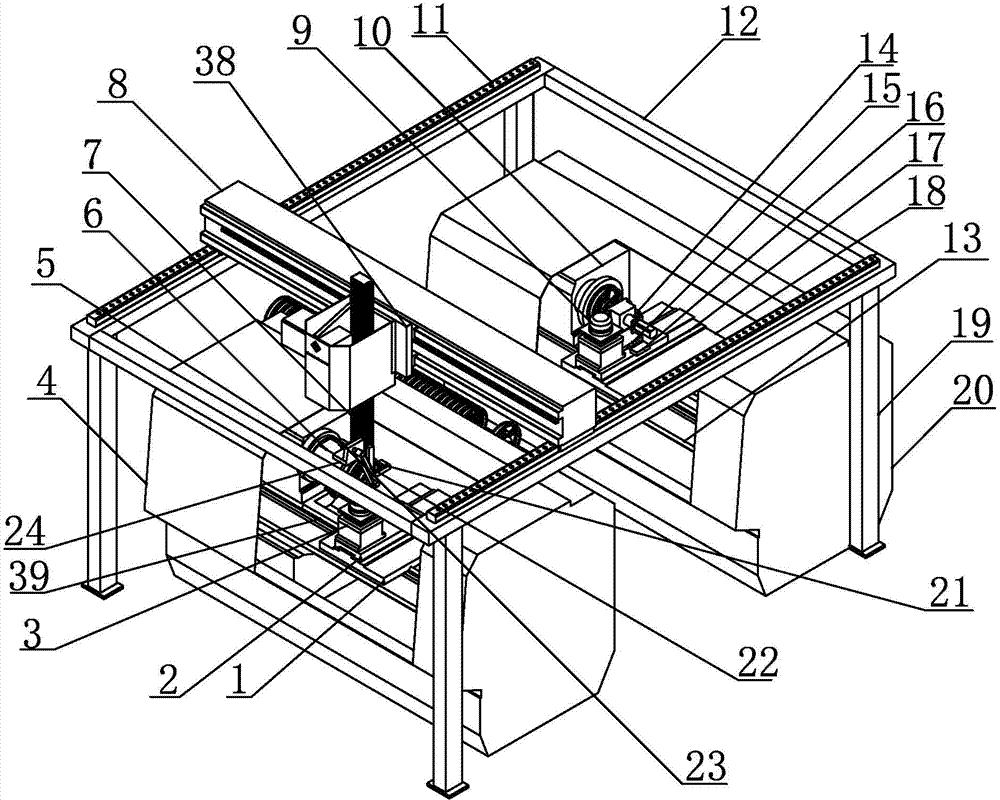

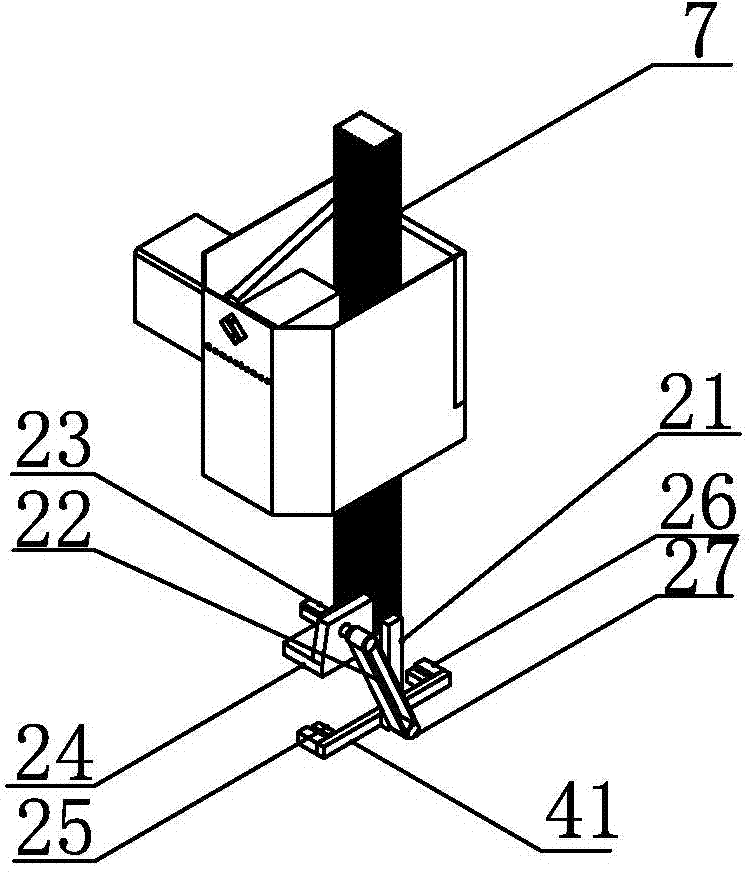

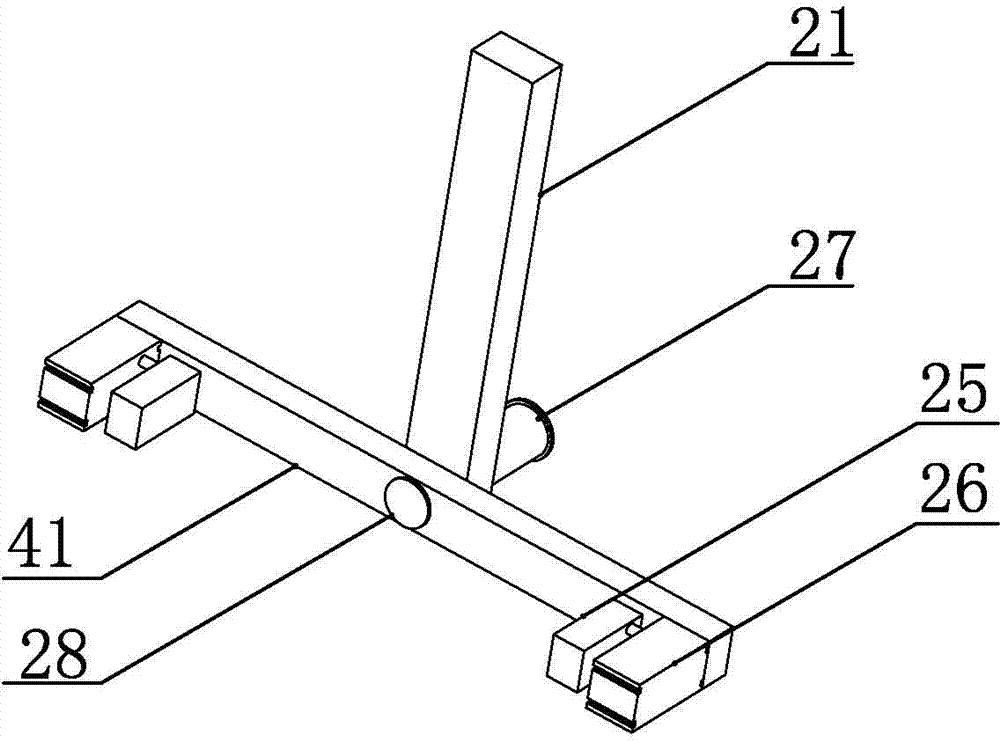

[0023] Such as figure 1 As shown, a kind of automatic bicycle hub processing system of the present invention comprises four columns 19, and a guide rail frame composed of four crossbeams 12 is installed above the column 19, guide rails 11 are installed on the guide rail frames on the front and rear sides, and guide rails 11 are installed above the guide rails. Sliding beam 8, sliding beam 8 can slide left and right on guide rail 11. A slide plate 38 that can slide back and forth is installed on the slide beam 8, and a transfer robot is installed on the slide plate 38. Such as figure 2 As shown, the handling robot includes a mechanical arm 7 that can move up and down. A motor support 24 is fixed at the lower end of the mechanical arm 7. A rotating motor 23 is installed on the motor support 24. The output shaft of the rotating motor 23 protrudes through the belt 22 and the end surface of the wheel frame 21. The cylinders 27 are connected. Such as image 3 As shown, the whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com