TOFD ultrasonic non-destructive testing self-positioning fixture of welded rotor

A technology for welding rotors and non-destructive testing, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc. Small space and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

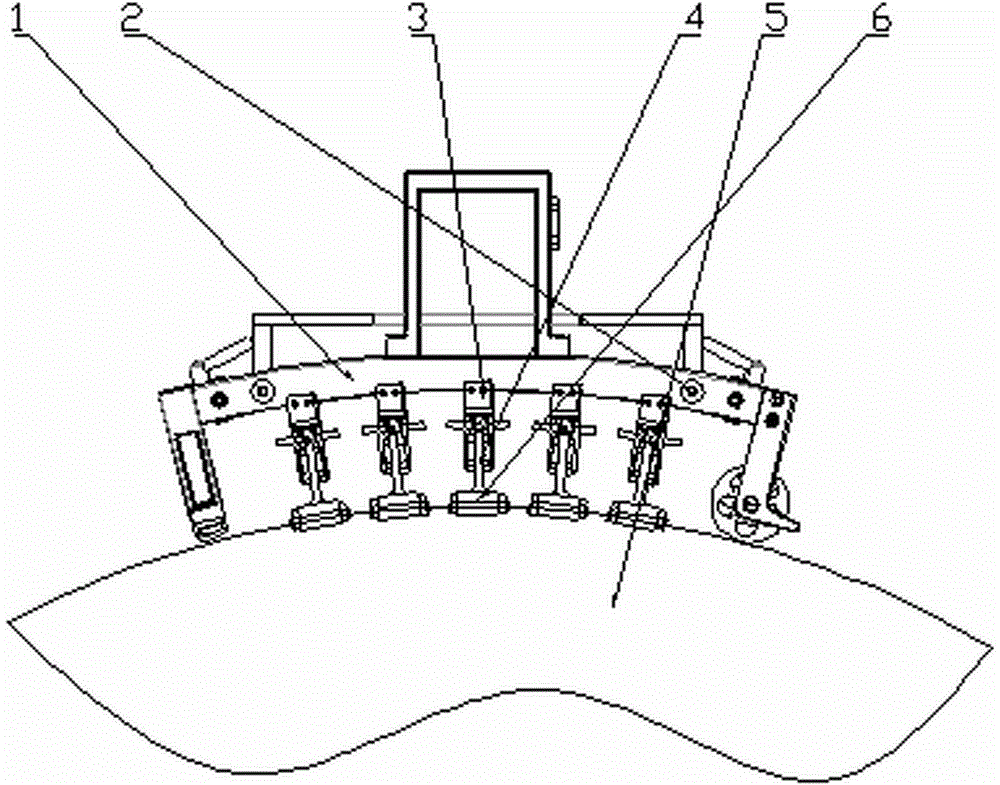

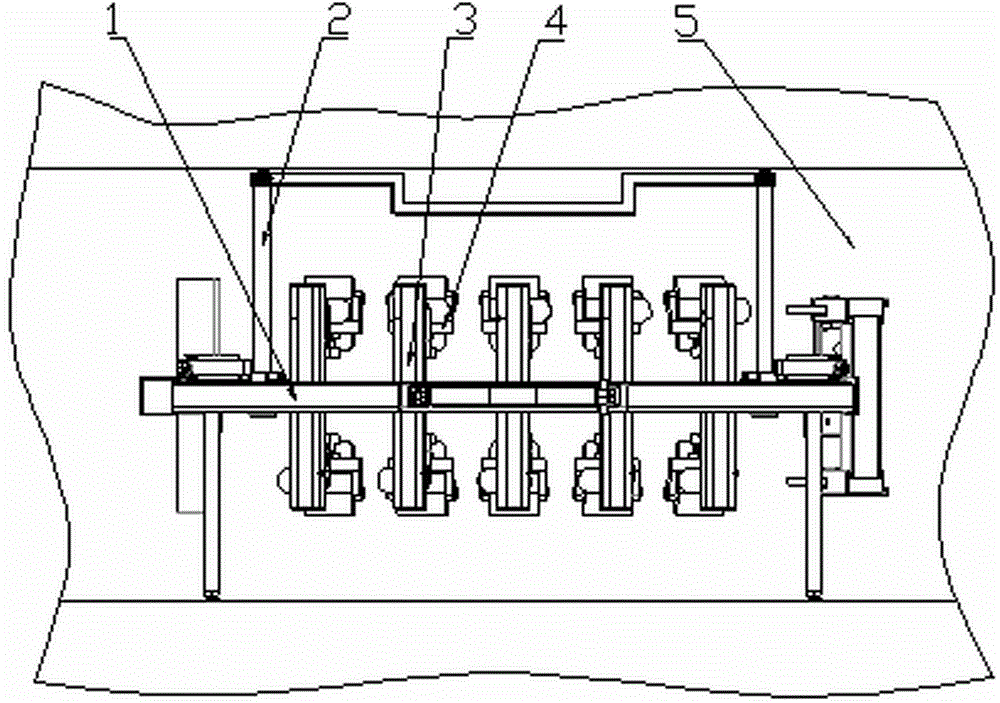

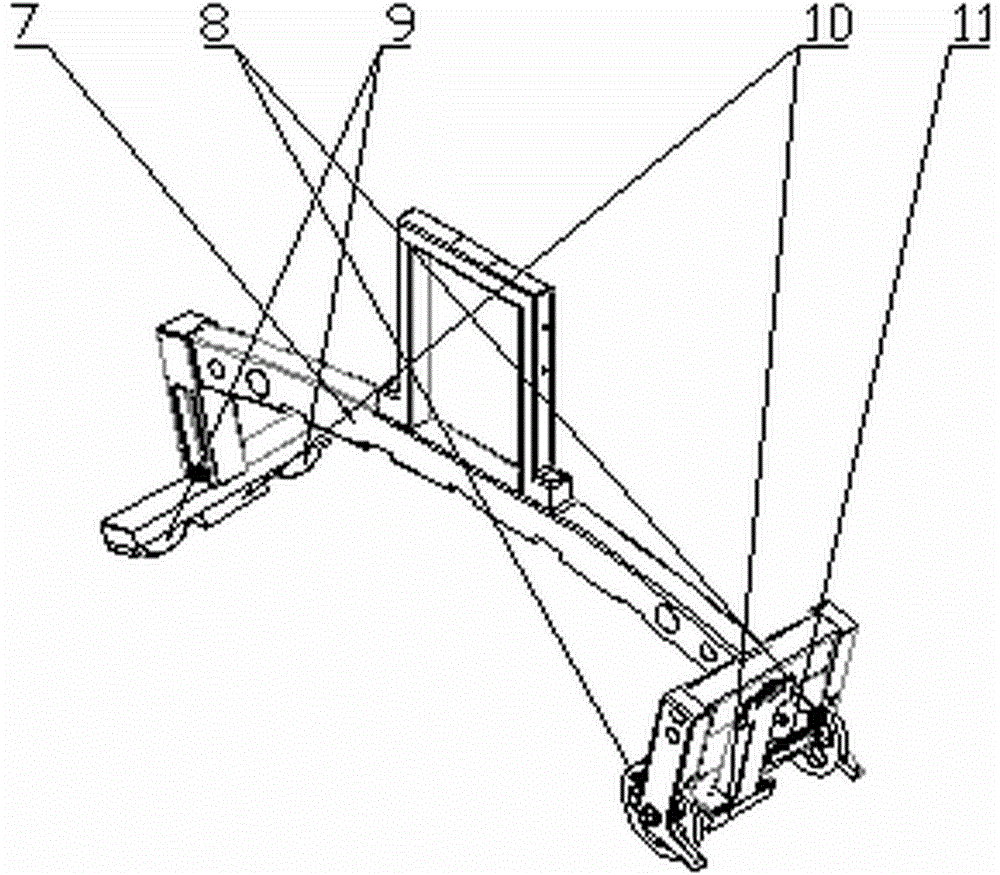

[0032] like figure 1 , figure 2 As shown, the welding rotor TOFD ultrasonic non-destructive testing self-positioning fixture is composed of an adsorption mobile platform 1, a positioning system 2, a fixture slide rail 3 and an adaptive fixture 4. The adsorption-type mobile platform 1 is adsorbed on the surface of the welding rotor 5, and can slide freely along the circumferential direction of the welding rotor 5; , to achieve axial positioning; the number of the fixture slide rails 3 is 5, which are respectively fixed on the adsorption mobile platform 1, and have a chute structure that can fix the self-adaptive fixture; the described self-adaptive fixture 4 has 10 , every two are symmetrically installed in the chute of a fixture slide rail, and clamp the TOFD detection wedge 6, making it contact with the surface of the welded rotor 5 for detection.

[0033] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com