High speed train set axle box device used for accurate-wide track gauge transformation

A high-speed EMU and wide-gauge technology, applied to axle boxes, tracks of different widths, transportation and packaging, etc., can solve the problems of low operating efficiency, long time consumption, increased manpower and material costs, etc., to improve operational efficiency, The effect of reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

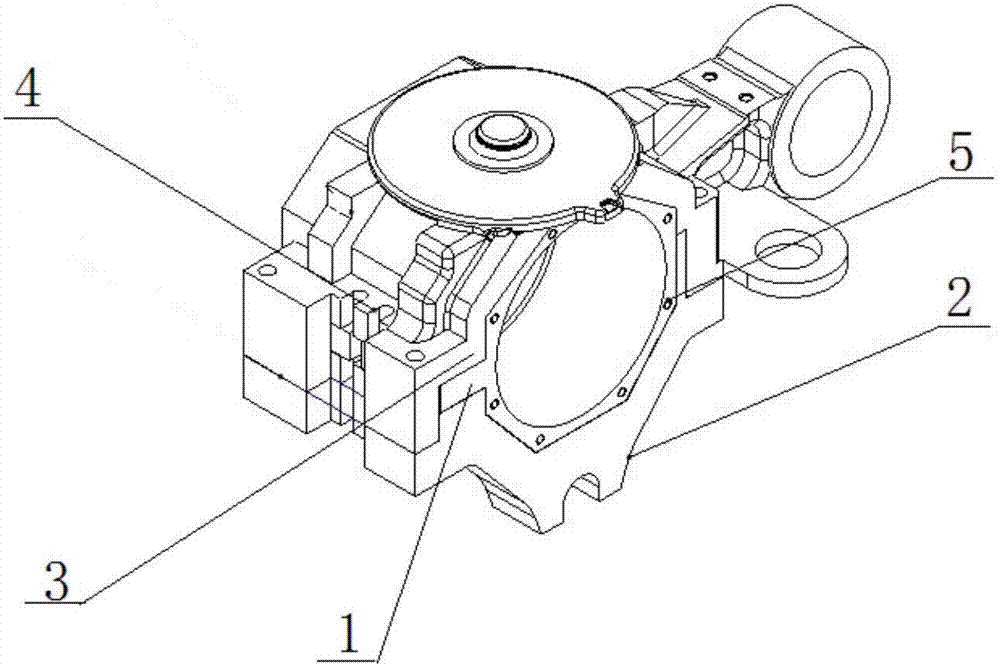

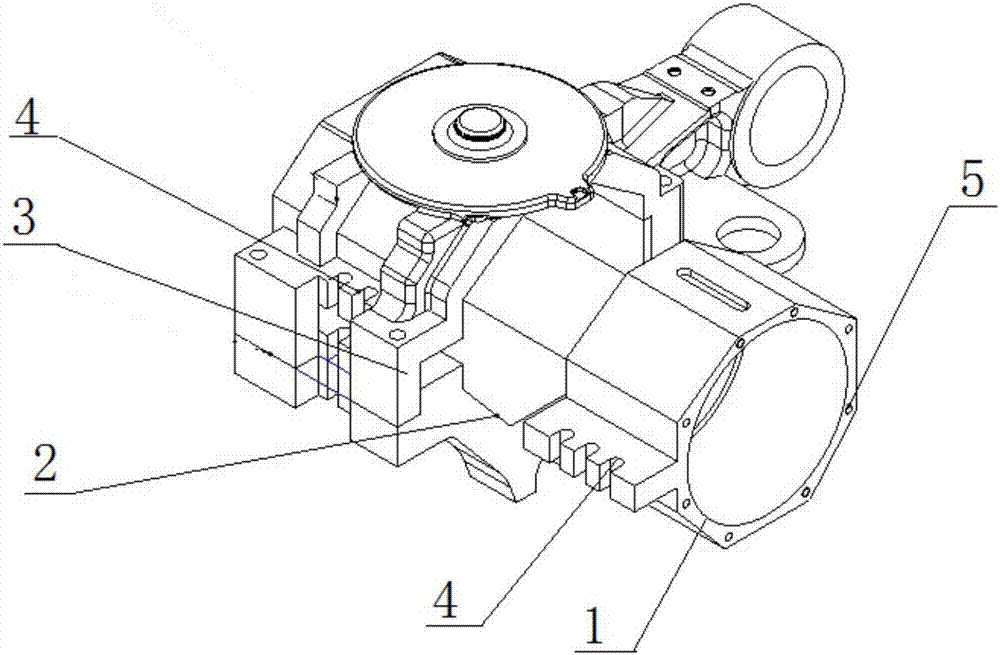

[0011] refer to figure 1 , figure 2 , the present invention comprises axlebox body 1, pivoting arm hoop 2 and axlebox pivoting arm beam 3, and axlebox body is arranged in the inner cavity that axlebox pivoting arm beam, pivoting arm hoop constitute and cooperates with the inner cavity clearance, axlebox body, The cross section of the pivot arm beam and pivot hoop of the axle box is a corresponding octagonal cross section, which prevents the circumferential rotation of the axle box due to the inertia of the axle rotation, and the multi-plane cooperation of the octahedral structure can realize circumferential positioning , and can disperse the vertical force borne by the axle box, improving the service life of the axle box. There are corresponding locking keyways 4 on the sides of the axle box body 1, the pivoting arm hoop 2 and the axlebox pivoting arm beam 3 as the installation interface of the locking mechanism to ensure the installation and positioning of the locking mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com