Screw protection tool

A screw and tooling technology, applied in the field of screw protection tooling, to avoid loose connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

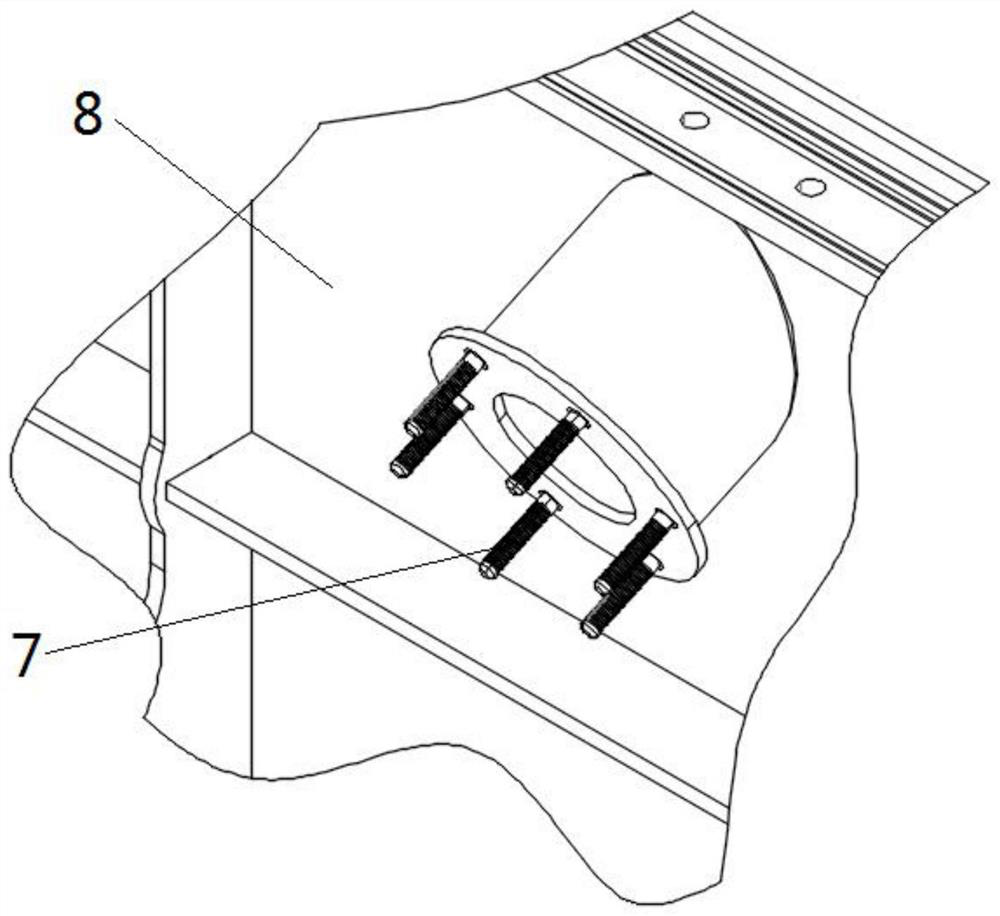

[0036] see Figure 2 to Figure 3 , a screw protective tooling, this embodiment is applied to the protection of the extension screw of the lifting seat of the transformer oil tank.

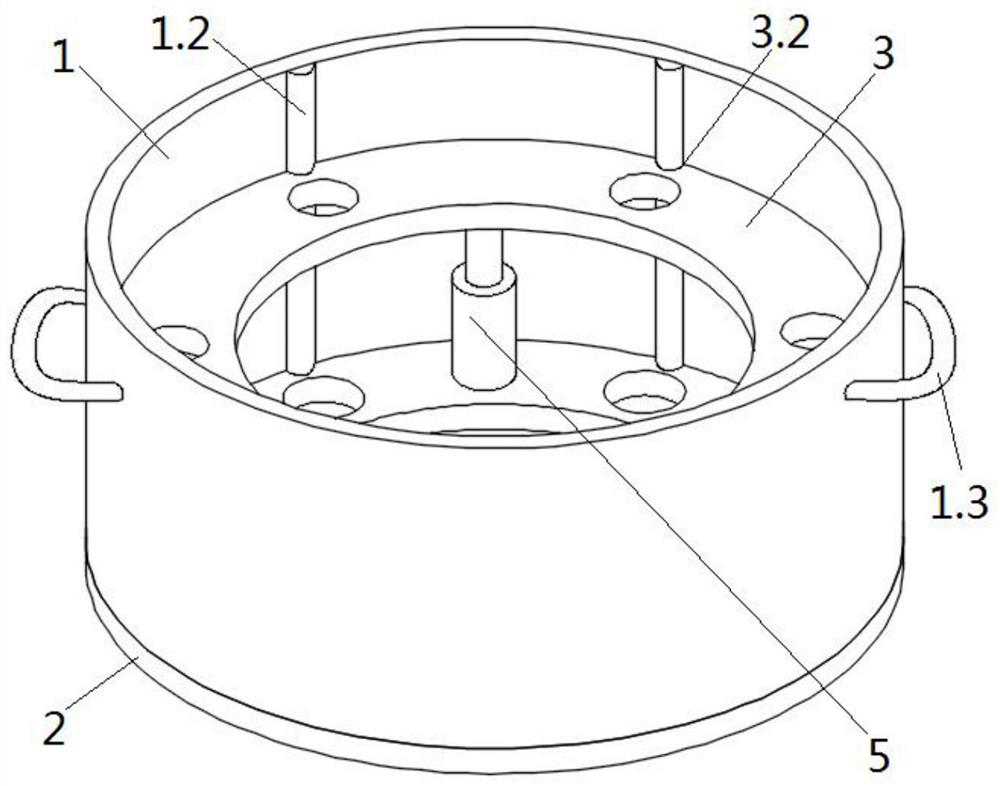

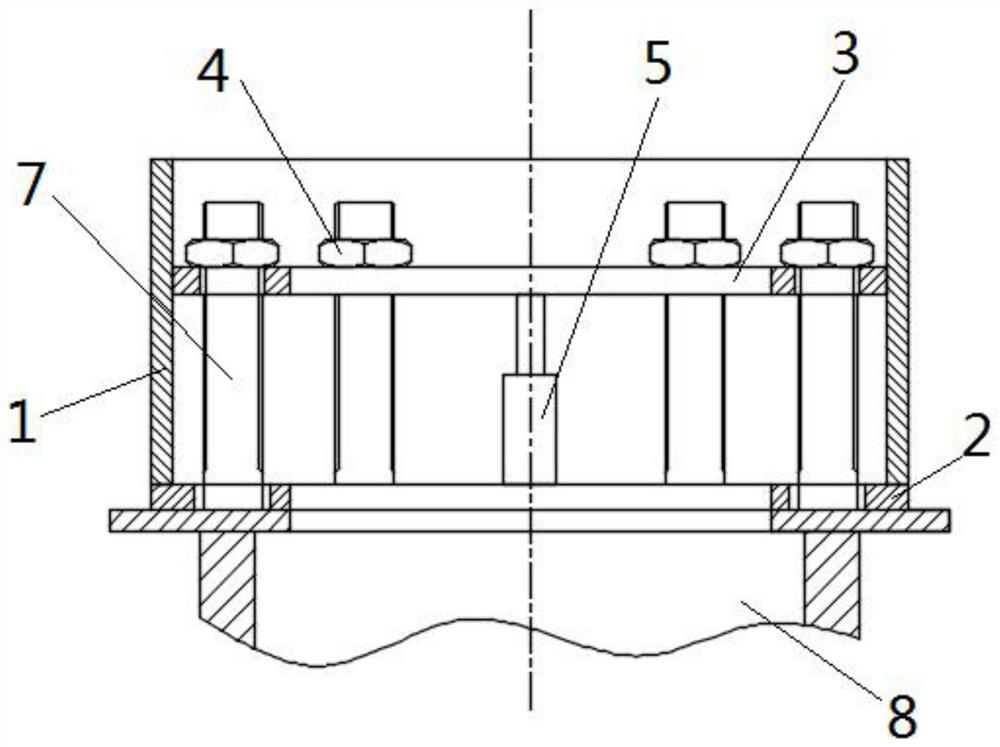

[0037] A kind of screw protective tooling, including a first casing 1, a first partition 2, a second partition 3 and a fixing nut 4 for connecting a screw 7; the first partition 2 and the second partition 3 are along the first A casing 1 is arranged in the axial direction, the plate surface of the first partition 2 is parallel to the plate surface of the second partition 3, and both the first partition 2 and the second partition 3 are provided with insertable screw rods. 7 through holes, since the number of screw rods 7 on the transformer oil tank 8 is six, the first partition plate 2 and the second partition plate 3 are provided with six through holes, and the positions correspond to the positions of the screw rods 7 to be protected one by one. ; The combination of the first casing 1, the first d...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that a chute 1.1 is provided on the inner wall of the first casing 1, and a sliding tooth 3.1 corresponding to the chute 1.1 is provided on the second partition 3, as Figure 4 shown.

Embodiment 3

[0047] The difference between this embodiment and embodiment 1 is that sliding mechanisms such as chute 1.1, sliding tooth 3.1, slide rail 1.2 and groove 3.2 are not provided between the second partition 3 and the first casing 1, and the first partition 2 and No expansion part 5 is set between the second partitions 3, and the screw protective tooling in this embodiment also includes a second casing 6, the top of the second casing 6 is connected with the second partition 3; The casing 6 is movably connected with the first partition 2, can move along the axial direction of the first partition 2, adjust the distance between the first partition 2 and the second partition 3, and realize the protection of the screws 7 with different lengths. Simultaneously, the bottom of the second casing 6 stretches into the rising seat of the transformer oil tank 8, so that the external force that the protective tooling is subjected to can be transmitted to the casing of the transformer oil tank. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com