Square tube connection method, joint used thereby and connection parts therewith

A technology of square, connecting plates, applied in the field of connecting components of square tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the following, the method of connecting aluminum square tubes to each other will be described with reference to the accompanying drawings, assuming that the metal block of the original joint is formed of aluminum, but the present invention is not limited thereto.

[0055] Example 1 (Invention A)

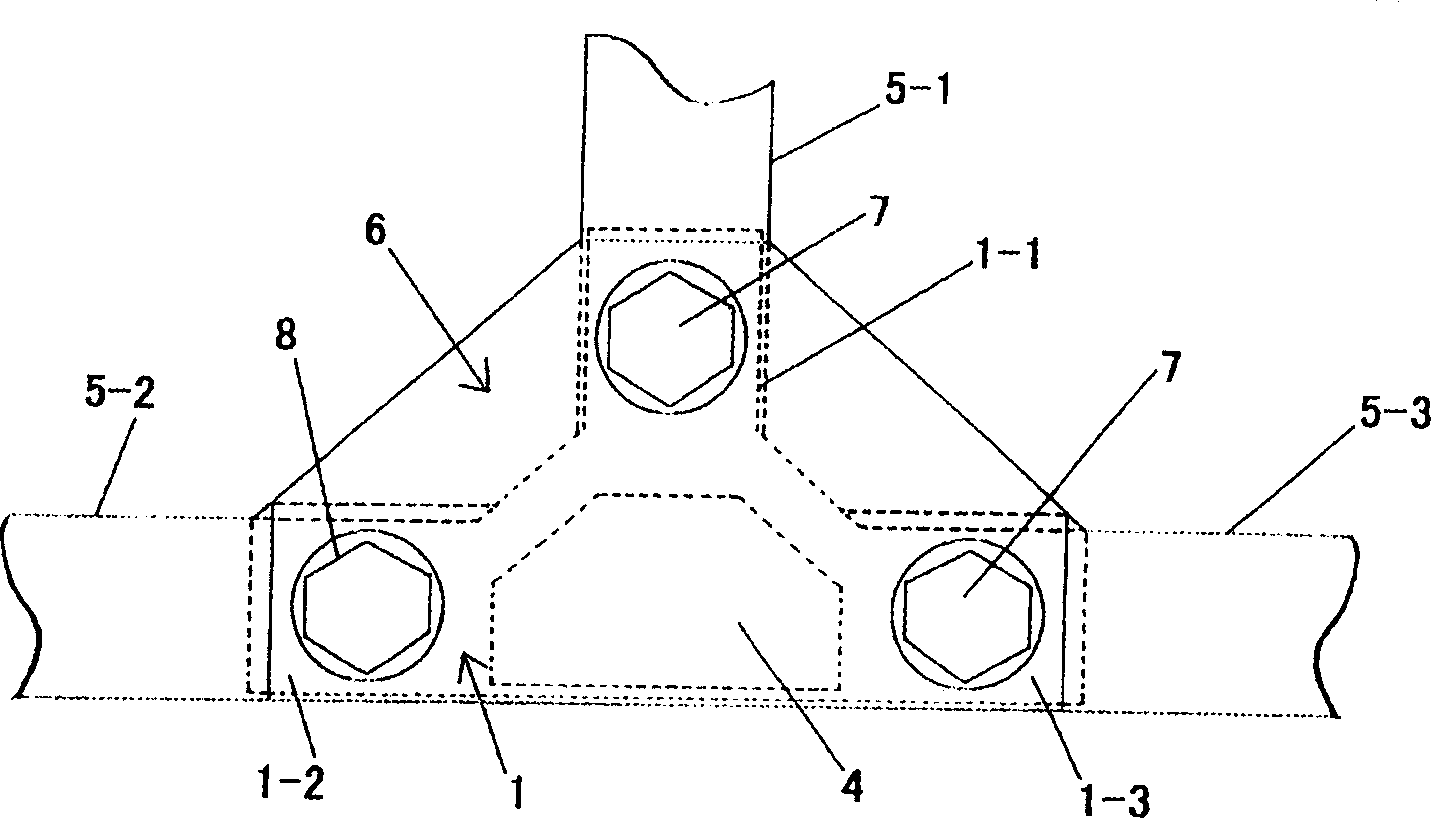

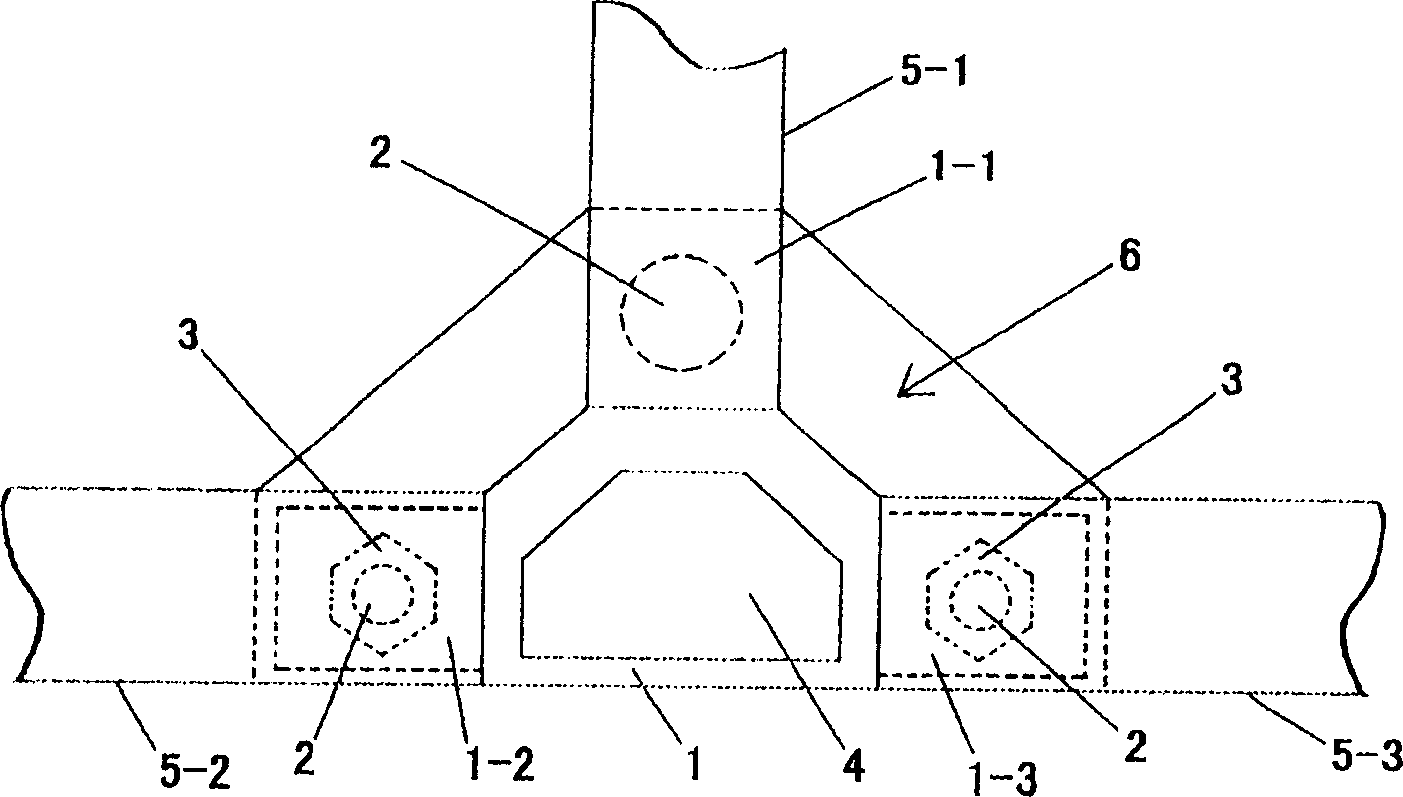

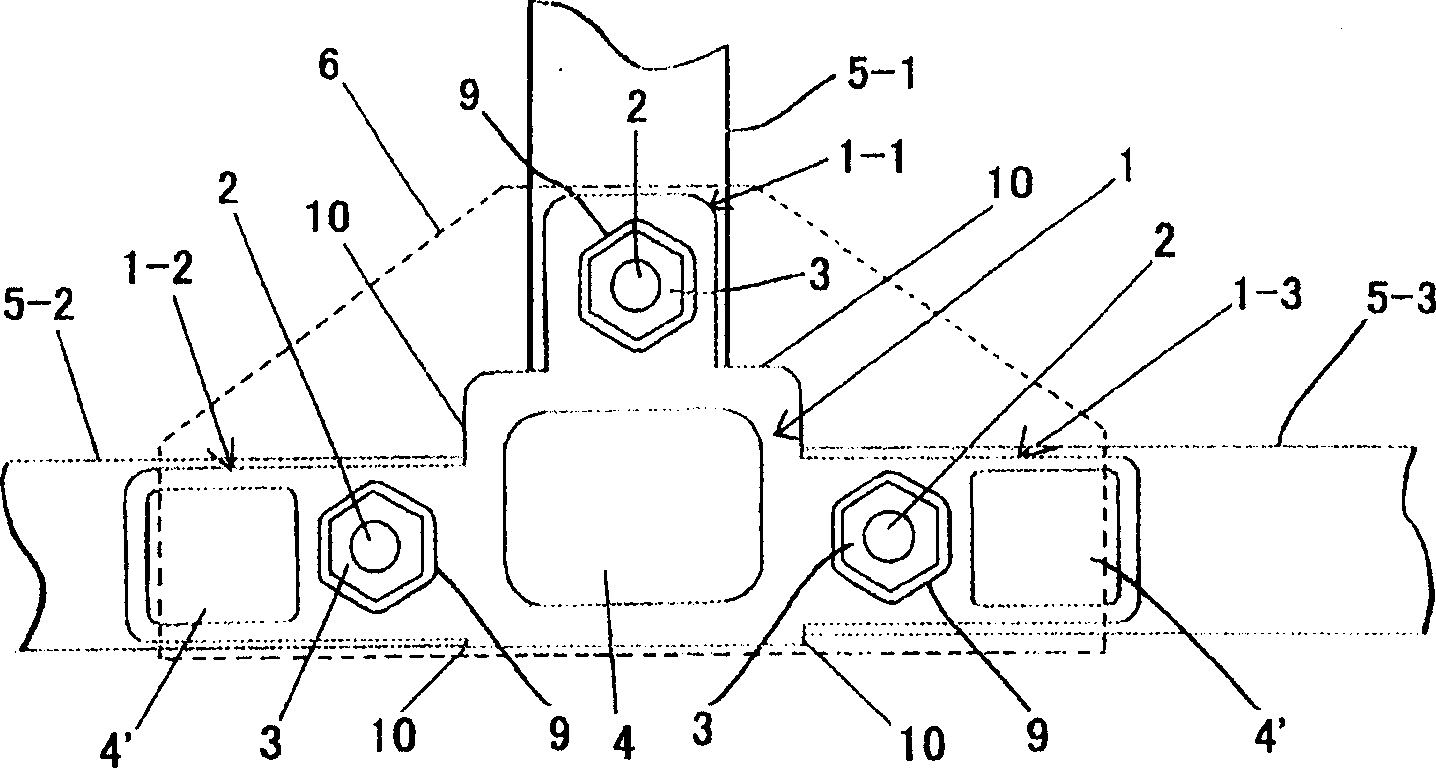

[0056] figure 1 and figure 2 Front view and rear view, respectively, which show the state in which square tubes are connected to each other by means of bolt-nut connections using front T-joints and connection plates with planes close to isosceles triangles according to the present invention .

[0057] Steel nuts 3 are respectively installed and fixed in the tee connecting arms 1-1, 1-2, 1-3 of the front T-shaped aluminum joint 1, so that the threaded hole 2 runs through from the front to the rear. Reference numeral 4 designates a cavity, which reaches from the front to the rear, for reducing the weight of the joint 1 . And, on one side of the square pipes 5-1, 5-2, 5-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com