Locknut

A technology for locking nuts and nuts, applied in the directions of nuts, screws, bolts, etc., can solve the problems of bolt connection failure, complex processing technology, and high production costs, and achieve the effects of avoiding accidents, prolonging fatigue life, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

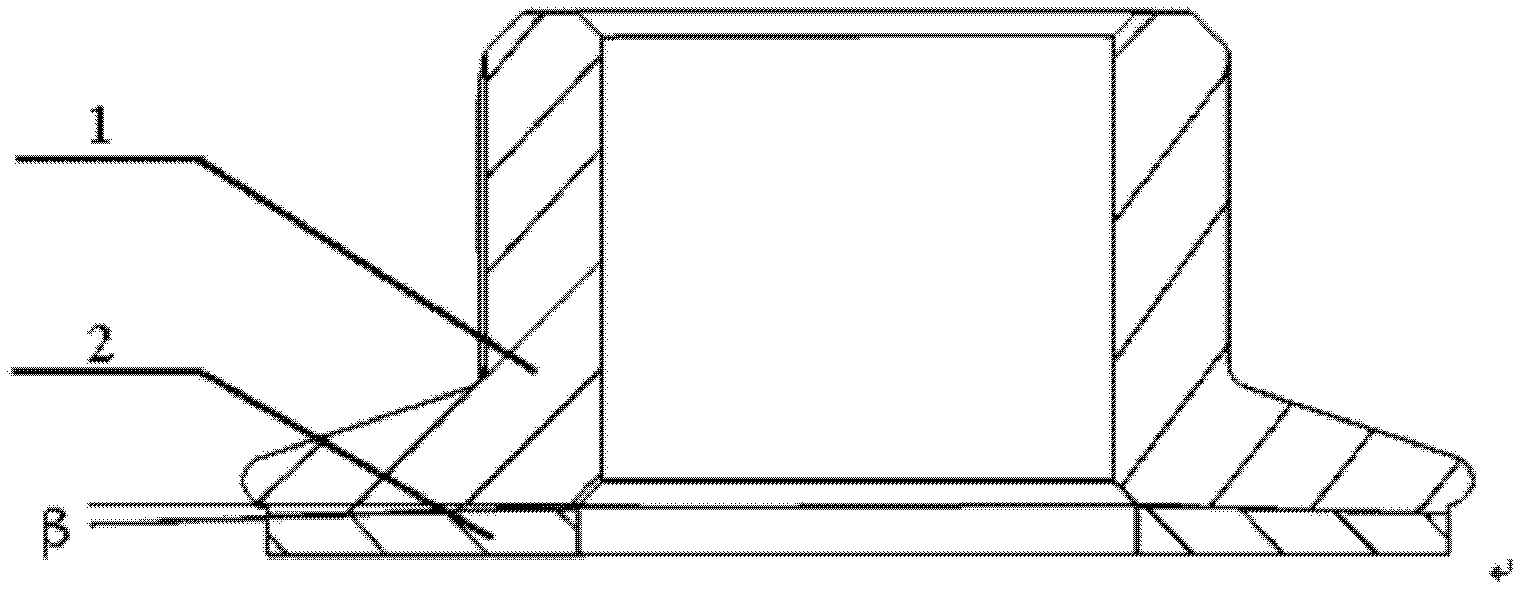

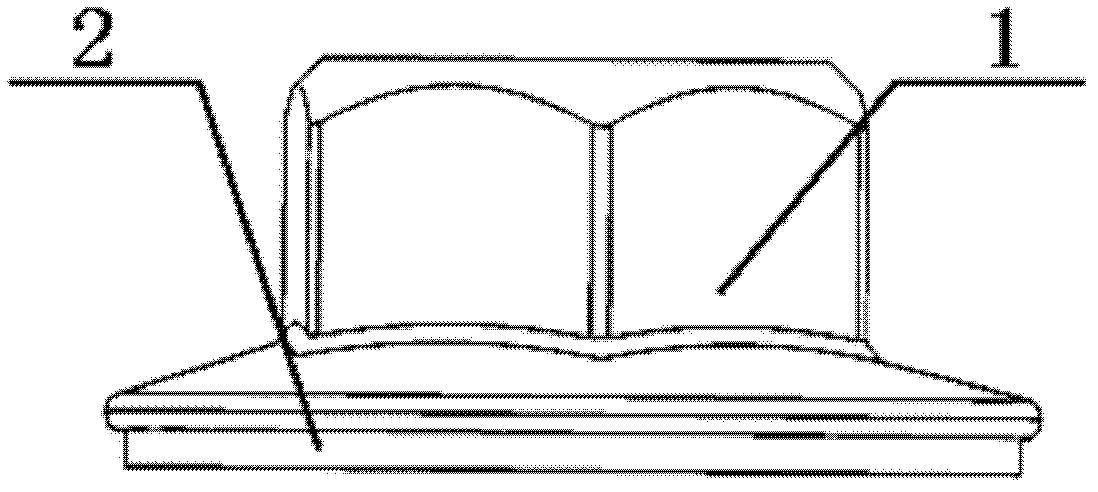

[0018] Such as figure 1 As shown, the lower end surface of the present invention is a concave trumpet-shaped inclined-plane structure, and the connected part has an inclination angle β; a rubber gasket 2 is arranged between the nut 1 and the connected part, thereby realizing Anti-loosening function of the nut.

[0019] Compared with conventional nuts, the nut 1 and the connected part of the present invention adopt a slope structure, the inclination angle between the end surface of the nut 1 in contact with the connected part and the plane of the connected part is β, and the angle of β is 0.3 degrees about. The advantage of this structure is that after the pre-tightening force is applied to the bolt, the outer edge of the nut 1 is the first to contact the connected part. After pre-tightening, the pressure at the edge is the largest. Relatively speaking, the force arm from the action point to the center of the bolt is the smallest. Long, the bolt works best. In addition, a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com