Automatic welding machine of rocking chair iron frame

An automatic welding machine and iron frame technology, applied in the field of machinery, can solve problems such as inaccurate welding positions, unreliable quality, and high labor intensity, and achieve the effects of high welding quality, good positioning effect, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

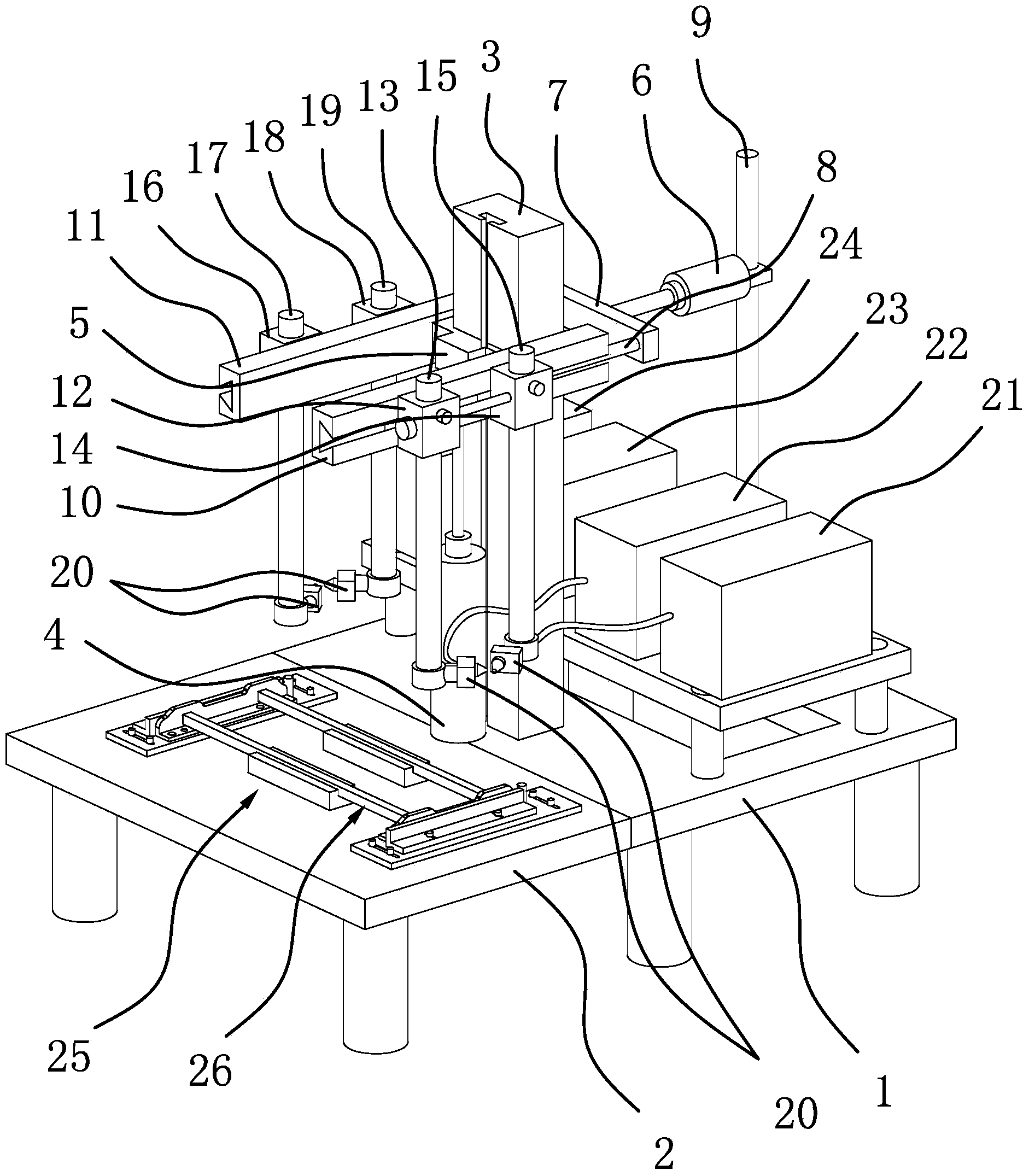

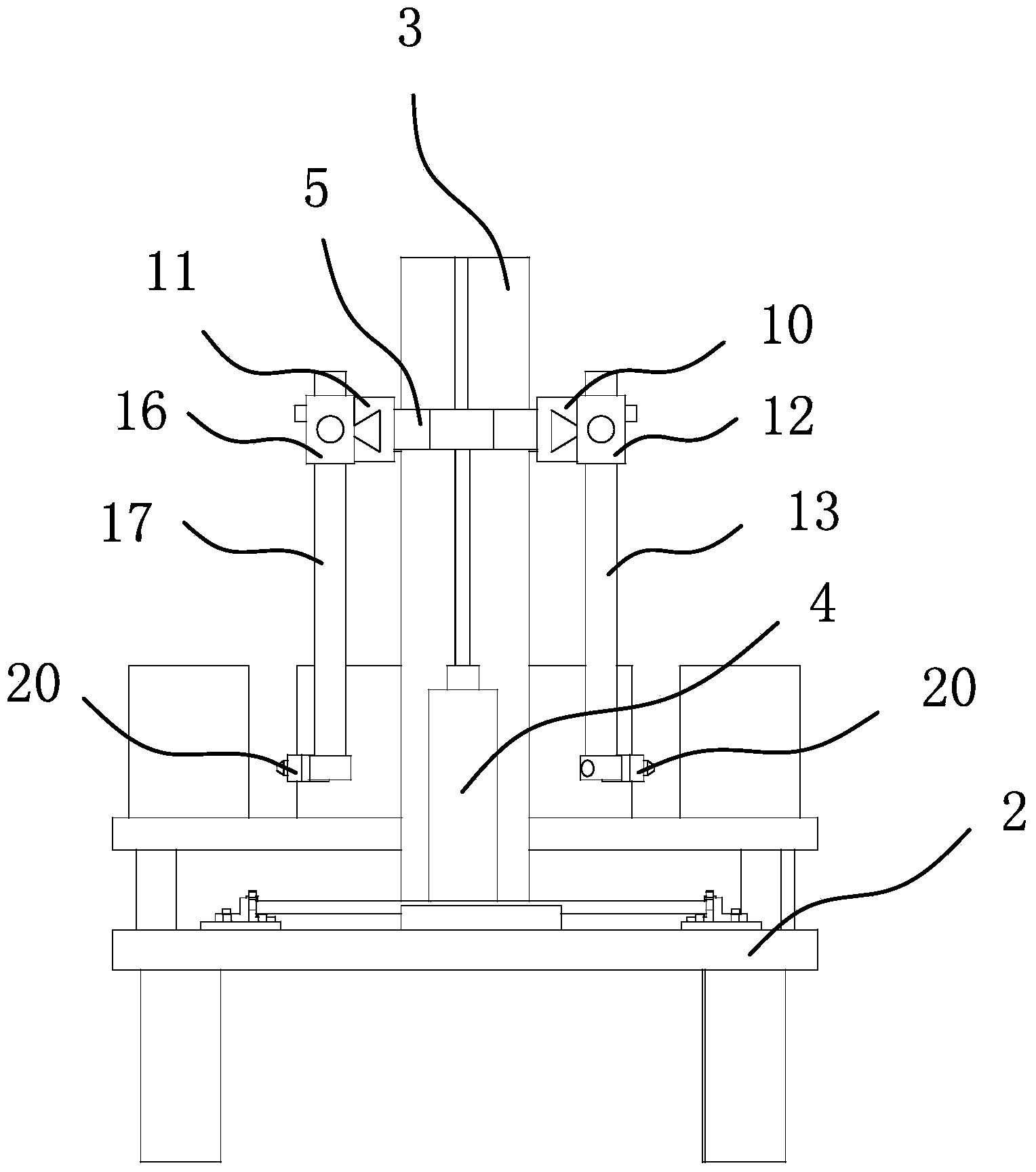

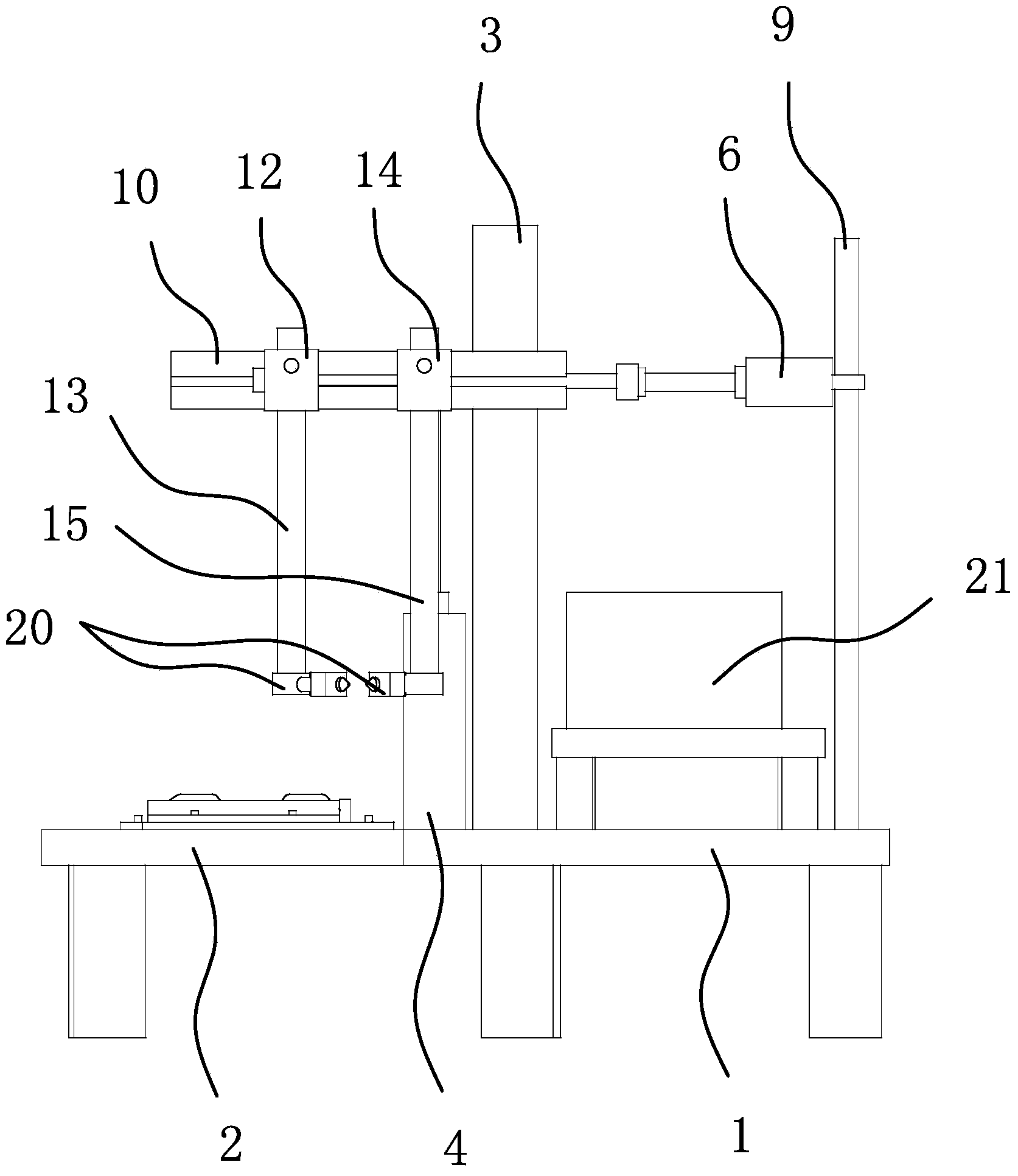

[0029] Such as figure 1 , 2 , 3 and 4, a kind of automatic welding machine of rocking chair iron frame, comprises frame 1, has the working platform 2 that places horizontally on the frame 1, is vertically fixed with column 3 on the working platform 2, and column 3 is provided with The lifting block 5 that can be lifted up and down along the column 3, the two ends of the lifting block 5 are respectively fixed with a mounting plate 10 and a mounting plate 11, and the mounting plate 10 is provided with a slide block that can move back and forth along the mounting plate 10 One 12 and slide block two 14, slide block one 12 is fixed with vertical installation rod one 13, and the end of installation rod one 13 is hinged with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com