Manufacturing process of head-hanging folding face mask

A production process and mask technology, which is applied in the field of mask machines, can solve the problem of a large number of packaging materials, and achieve the effects of improved production efficiency, accurate location, and saving packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

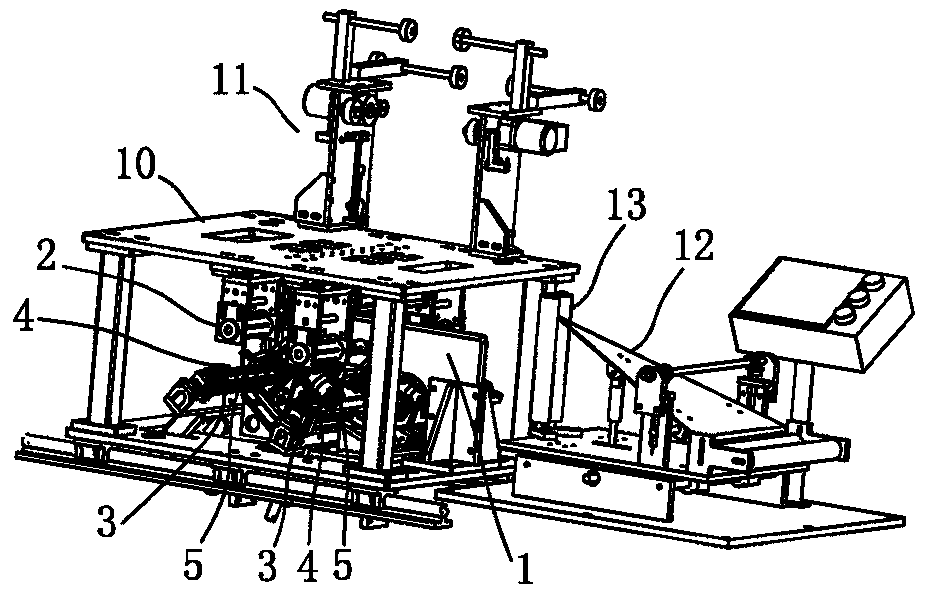

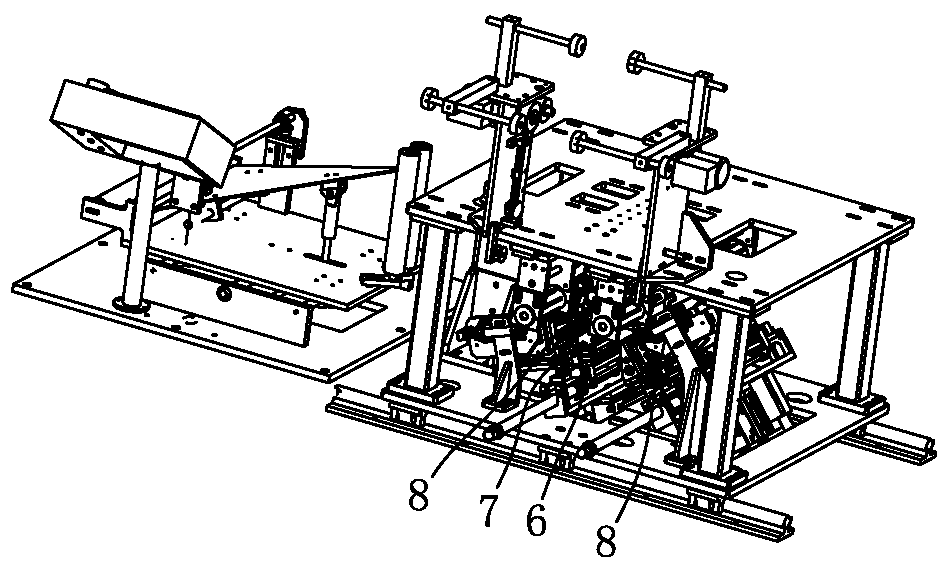

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] The production process of the head-hanging folding mask, the mask cloth is fed horizontally, and the mask is first cut to form a shape in which the front mask and the rear mask are connected in sequence, the mask is folded in half along the discharge direction, and the two ear straps of the same ear strap are separated from each other. The two sides of the mask are folded in half, and the ear straps are welded to the mask by an ultrasonic welding head, and then cut into an independent single mask.

[0023] Specifically, in the actual production application, the production equipment used and the working principle are as follows.

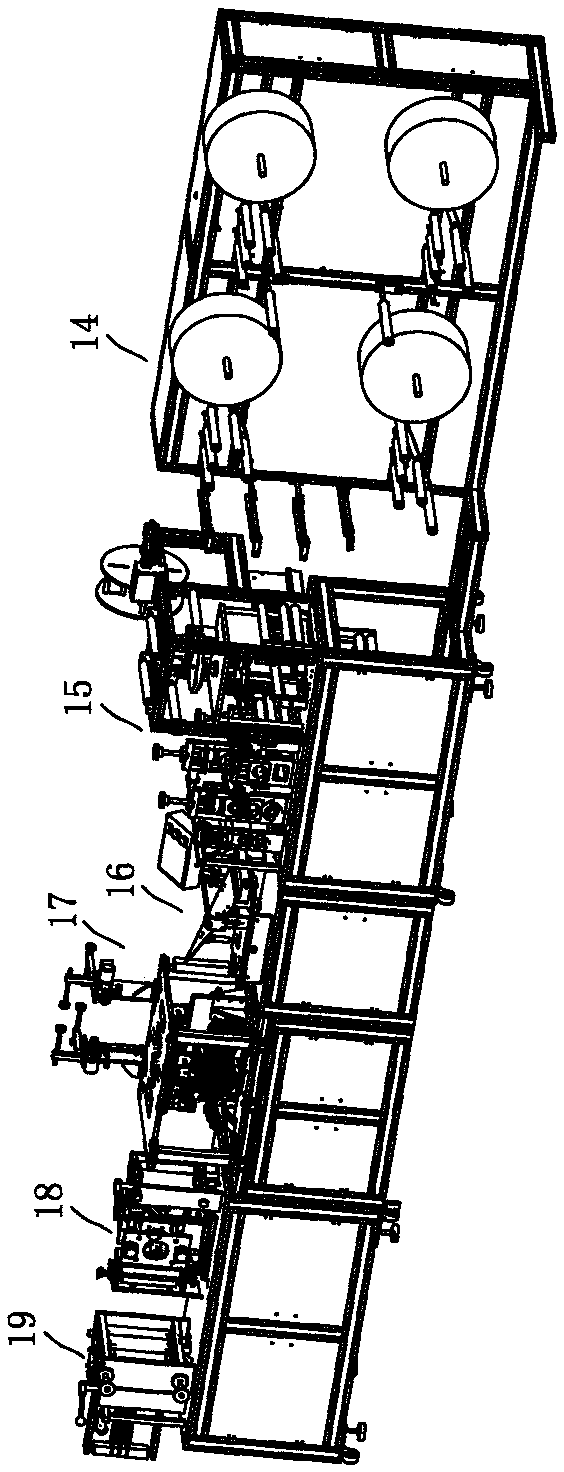

[0024] See figure 1 , the feeding rack 14 of the present invention places the mask cloth, and the mask cloth is sent into the sticking nose bridge line and the shape cutting device 15, sticks the nose bridge line on the mask cloth, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com