Self-adaptive sand-blasting polishing device for aluminium alloy bend pipe

An aluminum alloy, self-adaptive technology, applied in the direction of metal processing equipment, abrasives, spray guns, etc., can solve the problems of different brightness, affect the processing quality of aluminum alloy pipe bends, and difficult to guarantee, and achieve the effect of circumferential positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

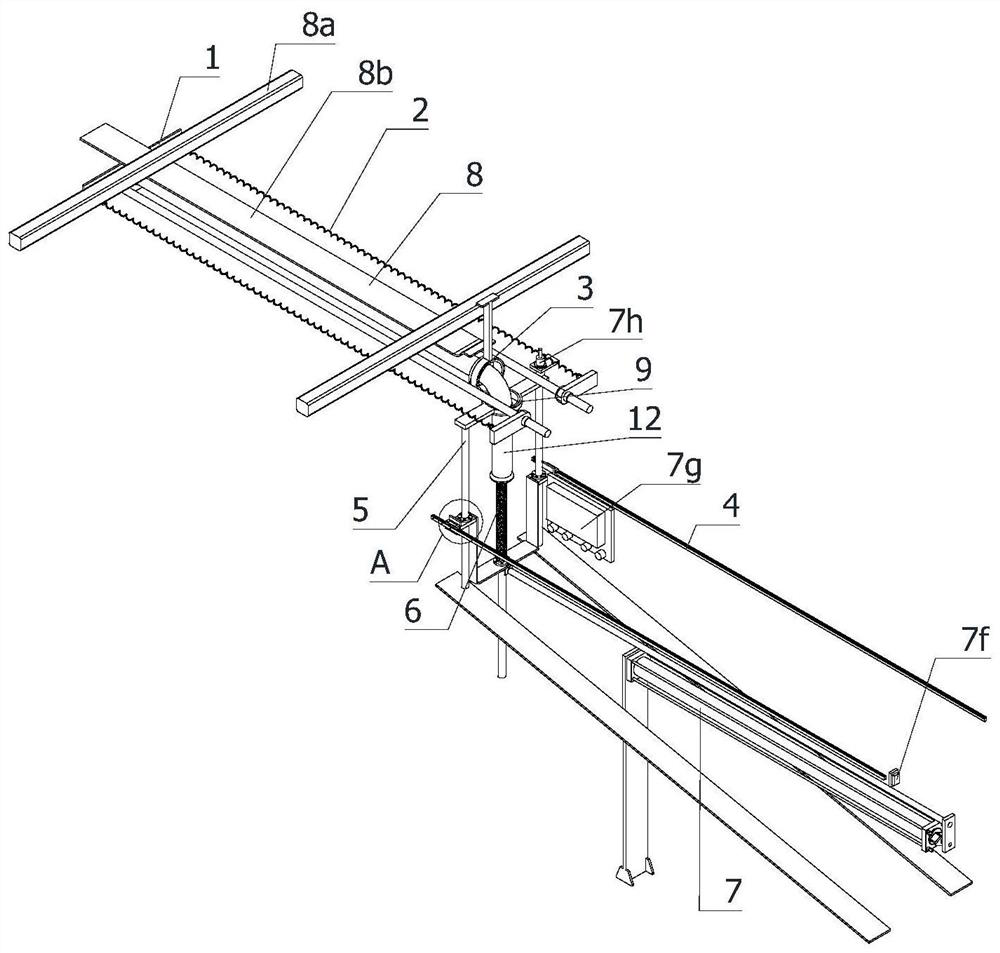

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0042] Wherein, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

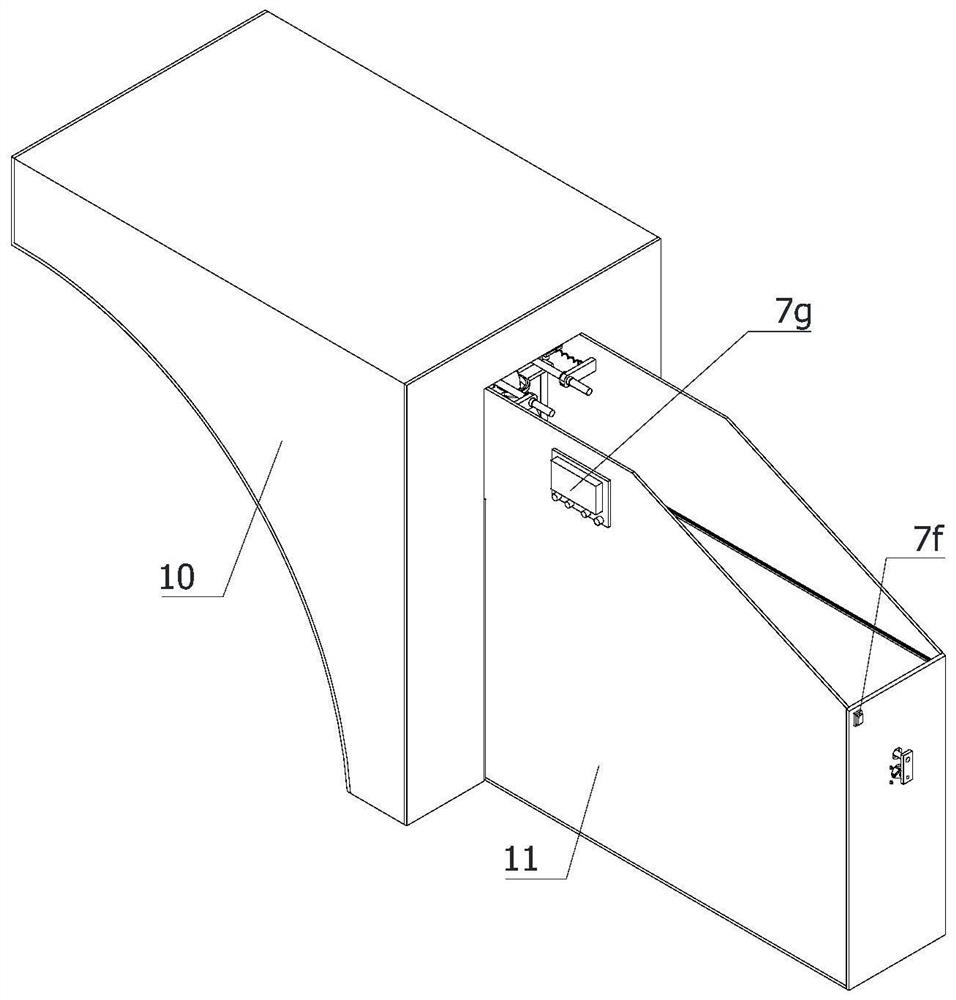

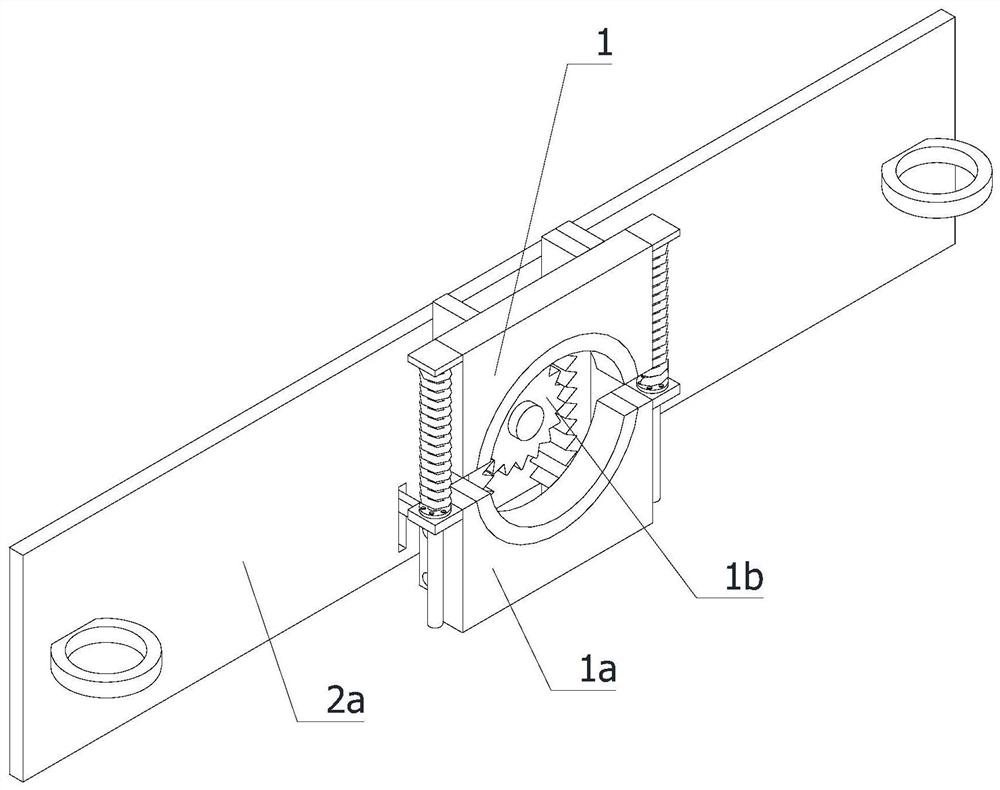

[0043] refer to Figure 1 to Figure 11 The self-adaptive sandblasting and grinding equipment for aluminum alloy elbows shown includes a centering fixture mechanism 1, a guide sliding mechanism 2, a horizontal circular sandblasting tube 3, a horizontal guide rail 4, a lifting mechanism 5, a centering seat 6, a one-way Pushing mechanism 7, pressing track 8, vertical annular sandblasting pipe 9, containing box 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com