Patents

Literature

50results about How to "Achieve horizontal positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

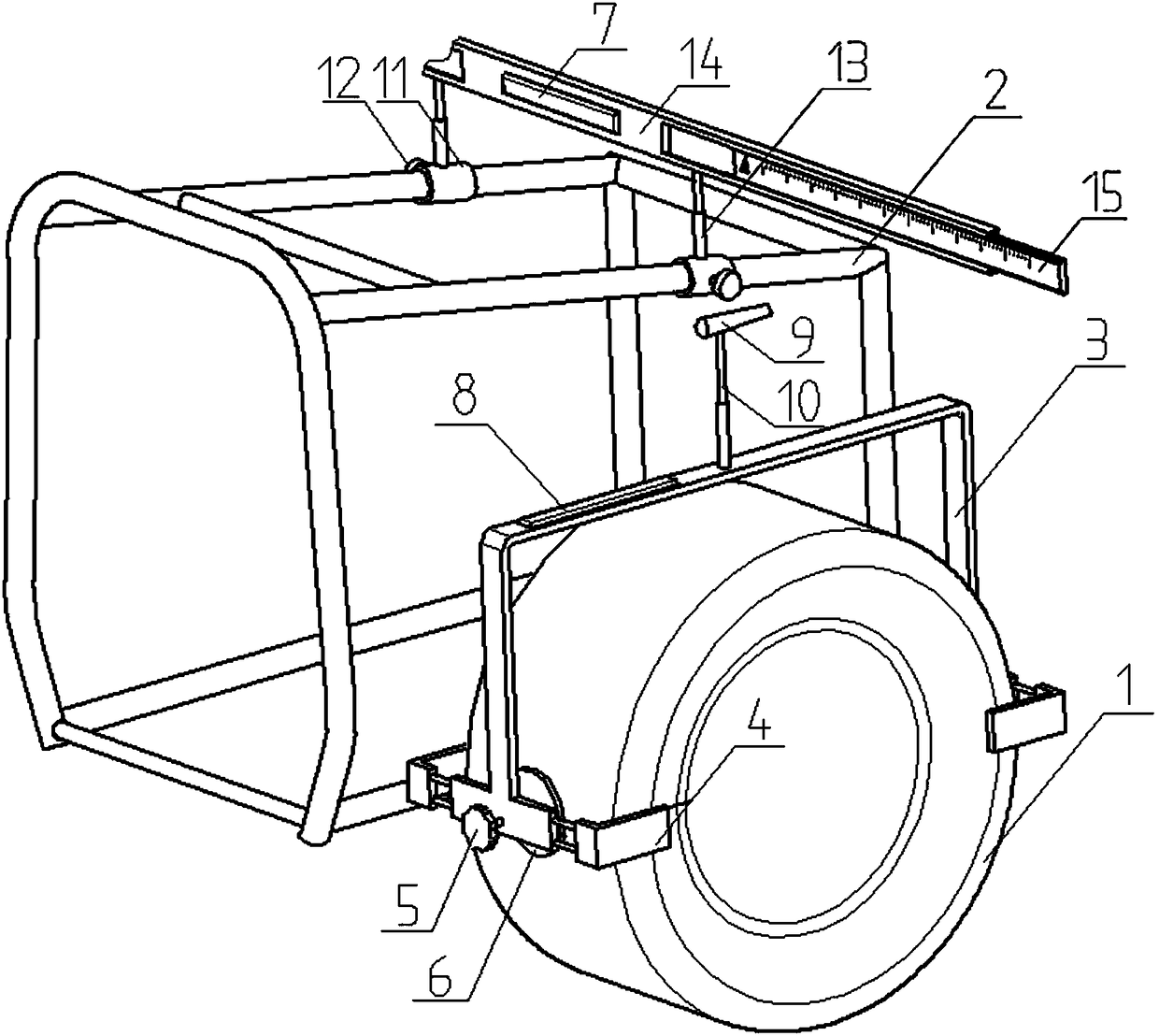

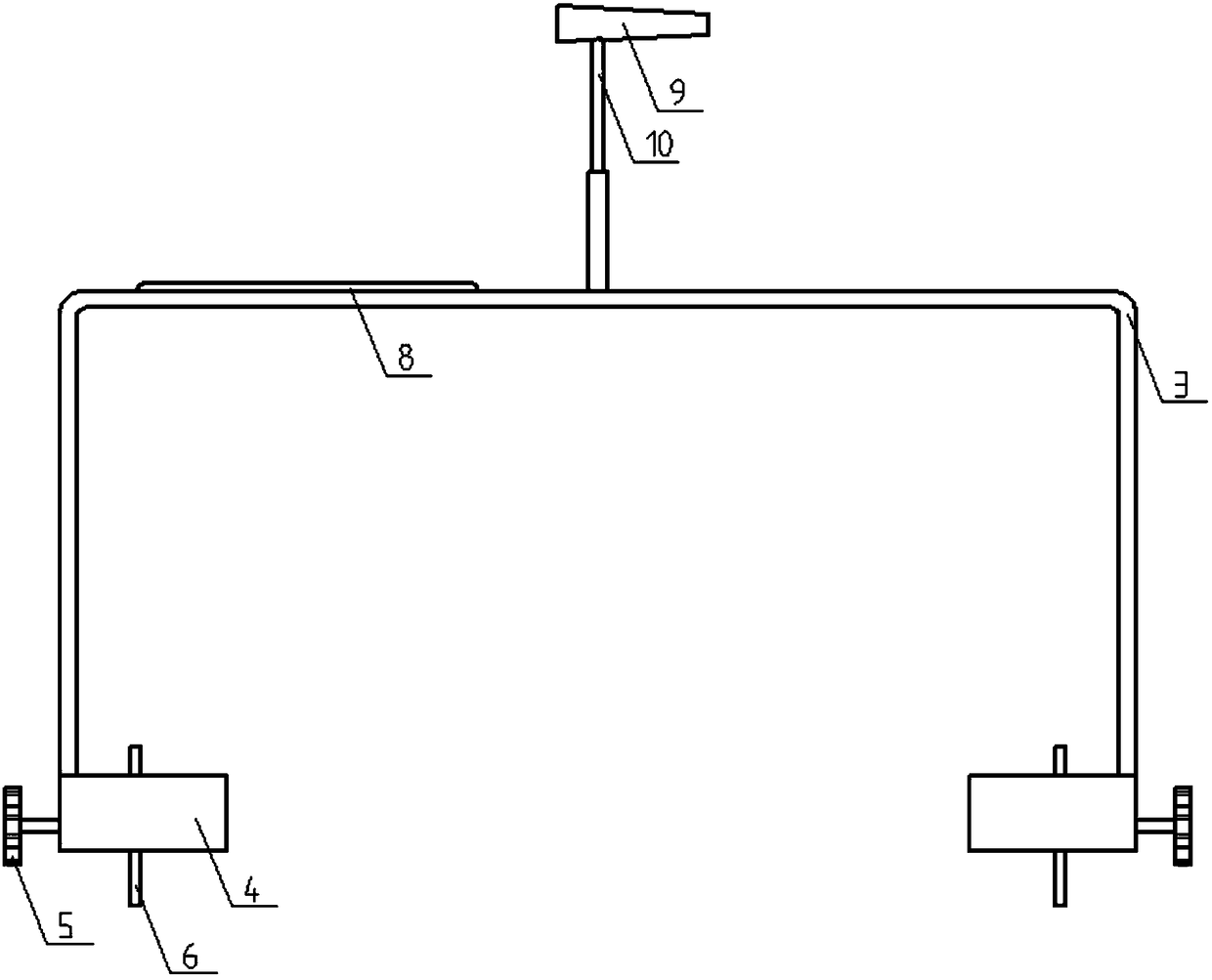

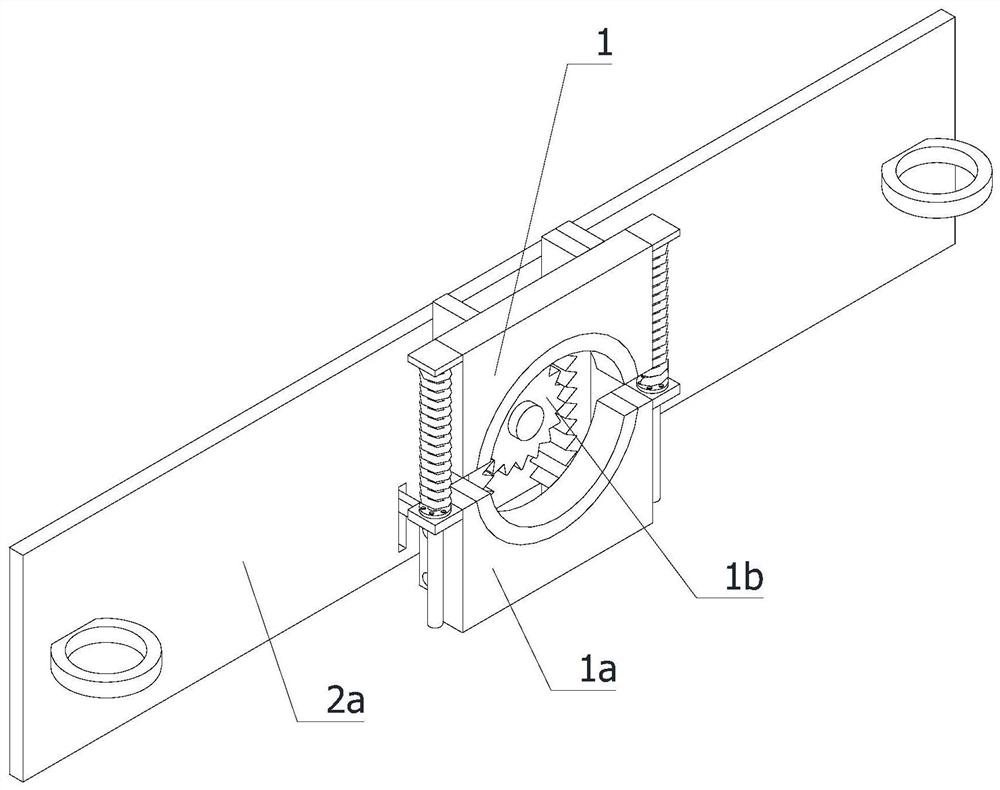

Rolling stone releasing apparatus for indoor test and rolling stone releasing test method

ActiveCN106289832ALimit the direction of motionAvoid harmStructural/machines measurementMaterials science

Owner:SHANDONG UNIV

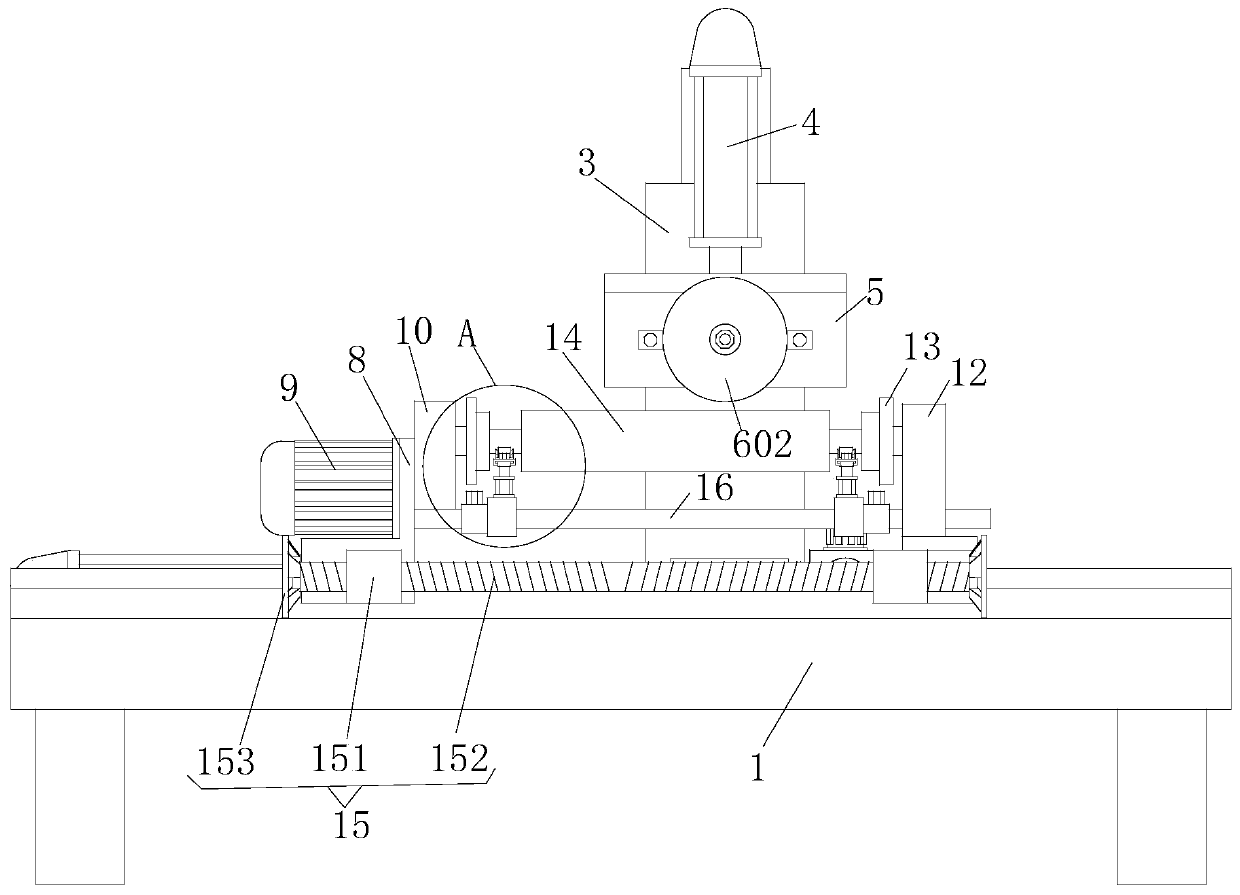

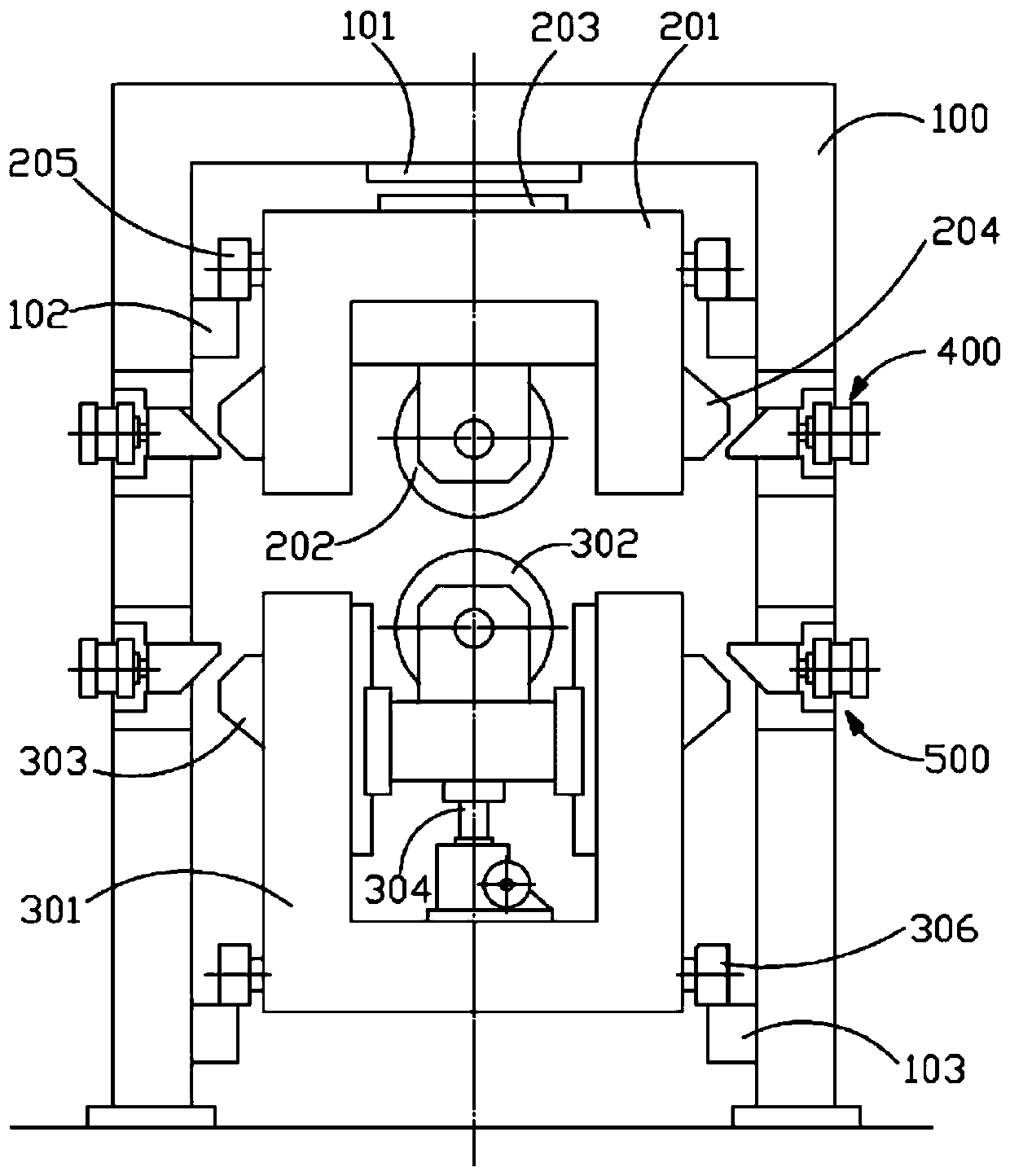

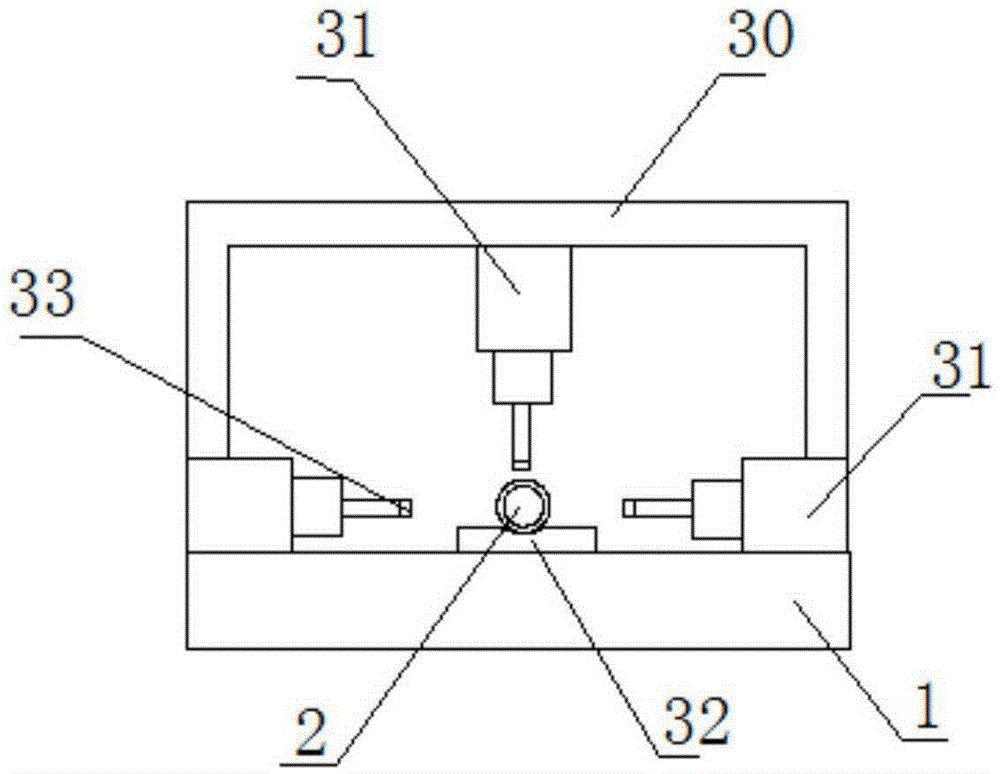

Five-axis numerical control grinding machine

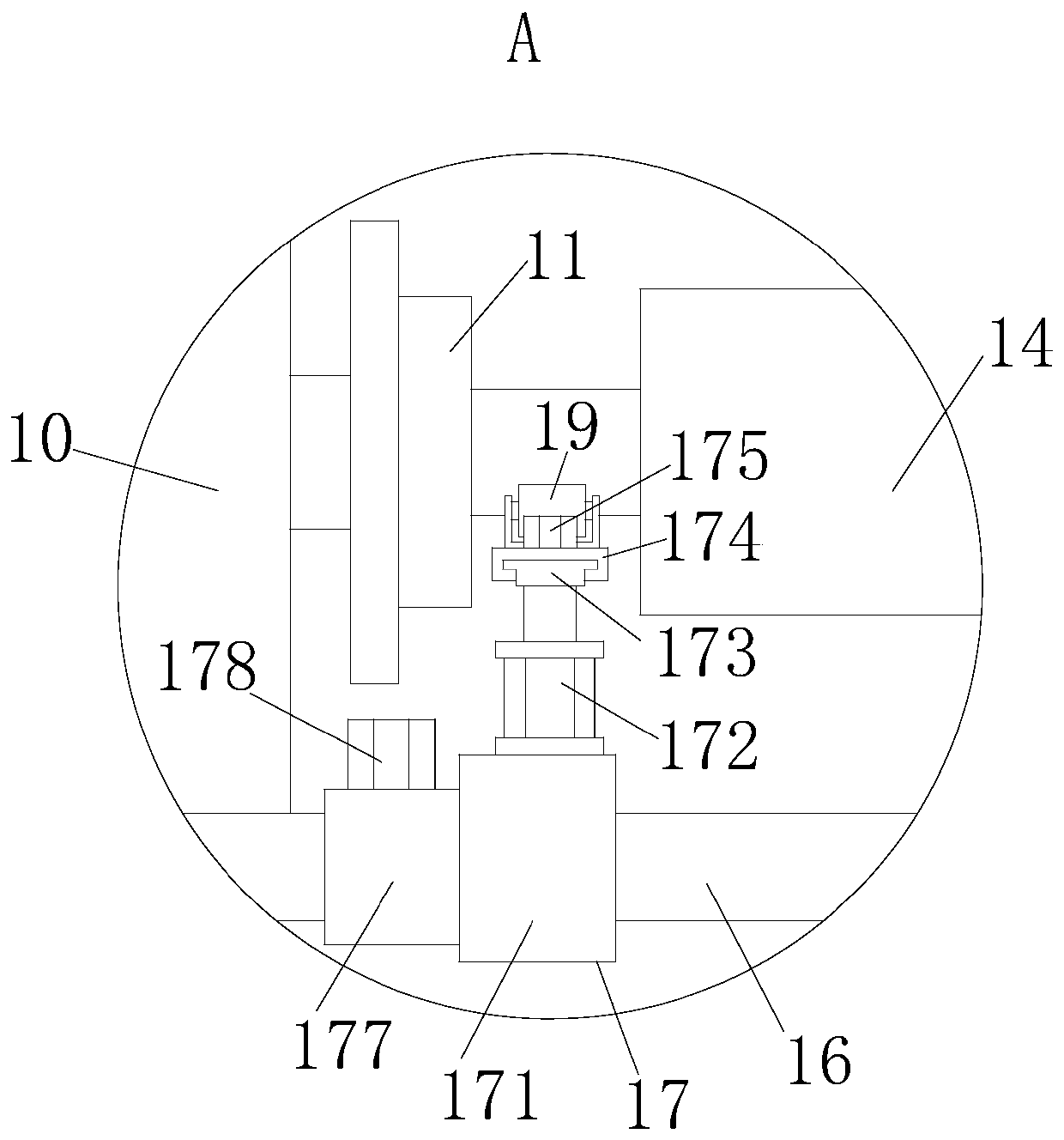

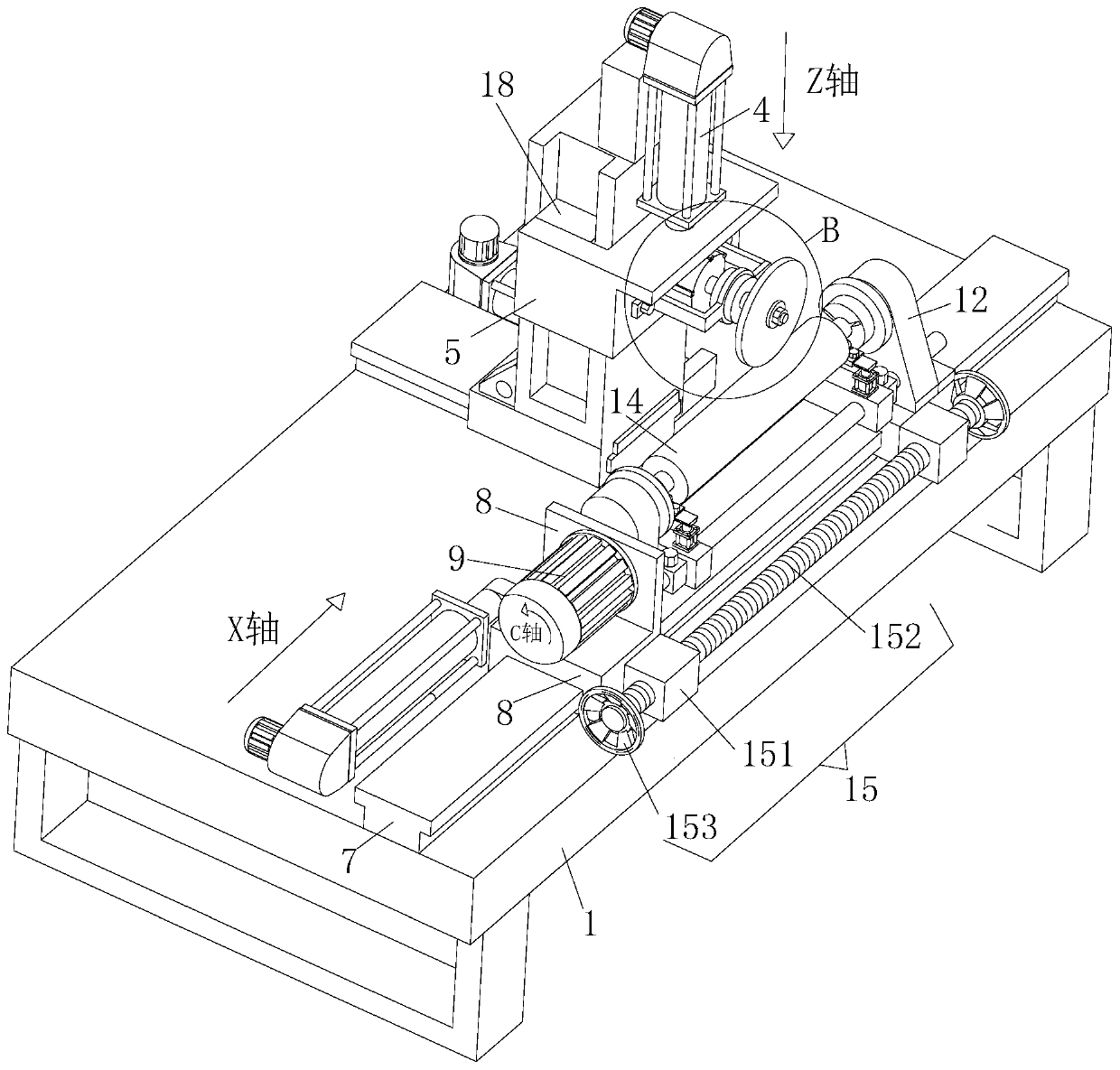

ActiveCN111451882AEasy to useTo achieve the effect of adjusting the distanceGrinding drivesGrinding machinesCnc grindingEngineering

The invention belongs to the technical field of hard alloy grinding machines, and particularly relates to a five-axis numerical control grinding machine. The five-axis numerical control grinding machine comprises an operation table. A longitudinal supporting plate is in sliding connection with the back side of the top of the operation table through a track mechanism. A second electric cylinder isfixedly connected to the top of the longitudinal supporting plate. An installing frame is fixedly connected to the bottom of an output rod of the second electric cylinder. A sliding groove is formed in the back face of the installing frame. The inner wall of the sliding groove is in sliding connection with the surface of the longitudinal supporting plate. A grinding mechanism is fixedly installedon the front face of the installing frame. By rotating a two-way screw, two reverse threads of the two-way screw can drive a first sliding block and a second sliding block to move synchronously in a face-to-face mode, and therefore the effect of adjusting the interval is achieved, and the requirement of grinding pieces of different lengths is met. The surface of a supporting roller makes contact with the surface of a grinding piece, supporting is performed, the bottom of the grinding piece is stably supported, vibration is lowered, and the problem that the grinding quality is affected by vibration is avoided.

Owner:浙江晨日智能科技有限公司

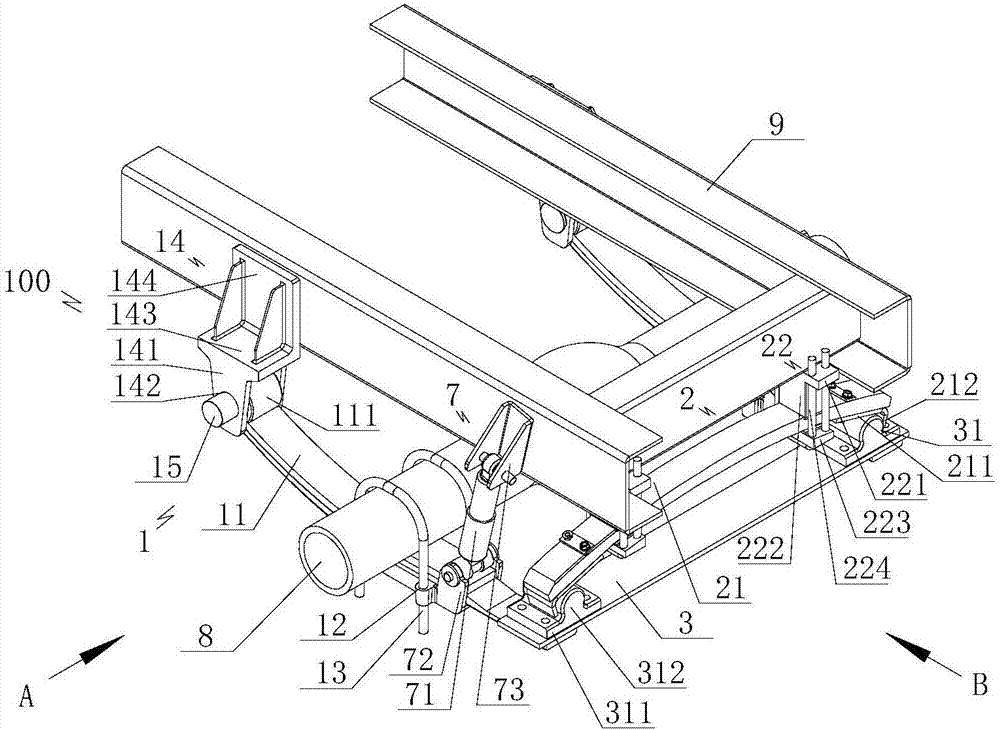

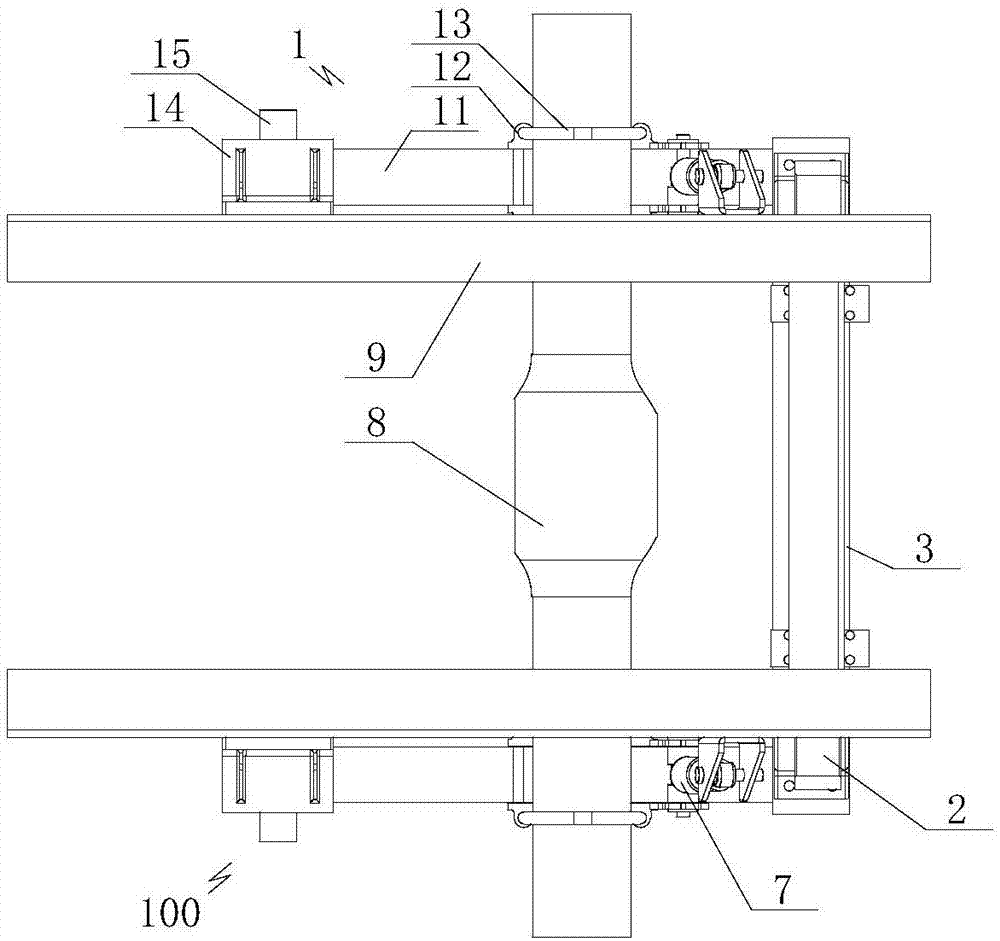

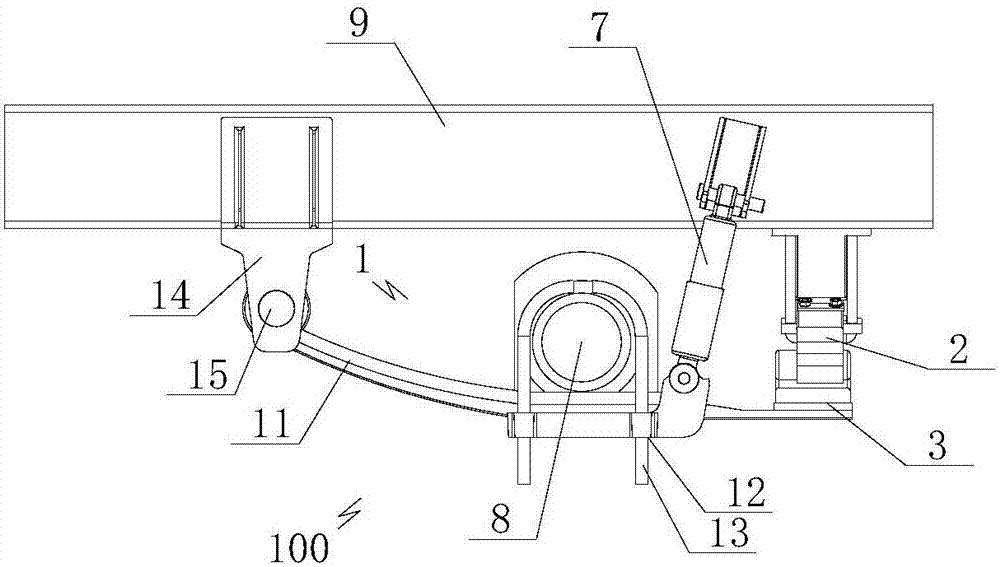

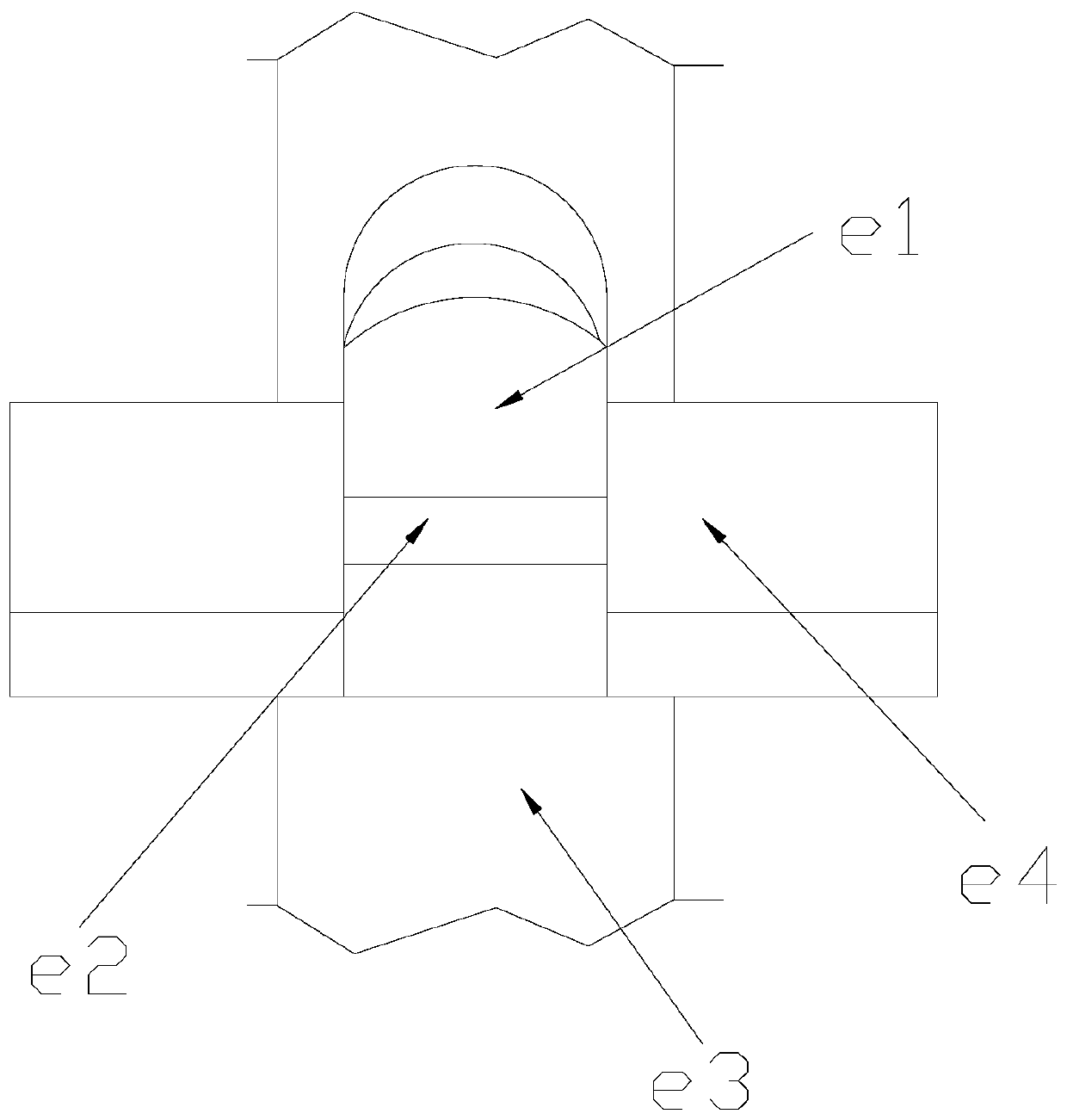

Suspension structure with transverse composite leaf spring

PendingCN107415616AReduce maintenance costsAchieve horizontal positioningLeaf springsResilient suspensionsSuspension (vehicle)Air spring

The invention relates to a suspension structure with a transverse composite leaf spring. The suspension structure comprises vehicle axle connection structures respectively arranged at two sides below a main vehicle frame, wherein the two vehicle axle connection structures are used for connecting a vehicle axle with the main vehicle frame; the longitudinal direction of the two vehicle axle connection structures is arranged in parallel with the longitudinal direction of the main vehicle frame; shock absorption structures are arranged between the two vehicle axle connection structures and the main vehicle frame; and a transverse composite leaf spring structure capable of expanding and contracting in the transverse direction of the main vehicle frame and being connected with the main vehicle frame is arranged between the opposite ends of the two vehicle axle connection structures. The suspension structure with the transverse composite leaf spring overcomes the problem that the longitudinal installation of the leaf spring in the suspension structure is limited by the space of a chassis in the prior art and the problems of high cost, short service life, hidden dangers and the like of air springs in the prior art, and has the advantages of making full use of light weight, good energy absorption capacity and other characteristics of the composite leaf spring, occupying little space on the chassis, increasing service life, effectively reducing the cost and improving the safety.

Owner:BEIJING JIAPENG MACHINERY CO LTD

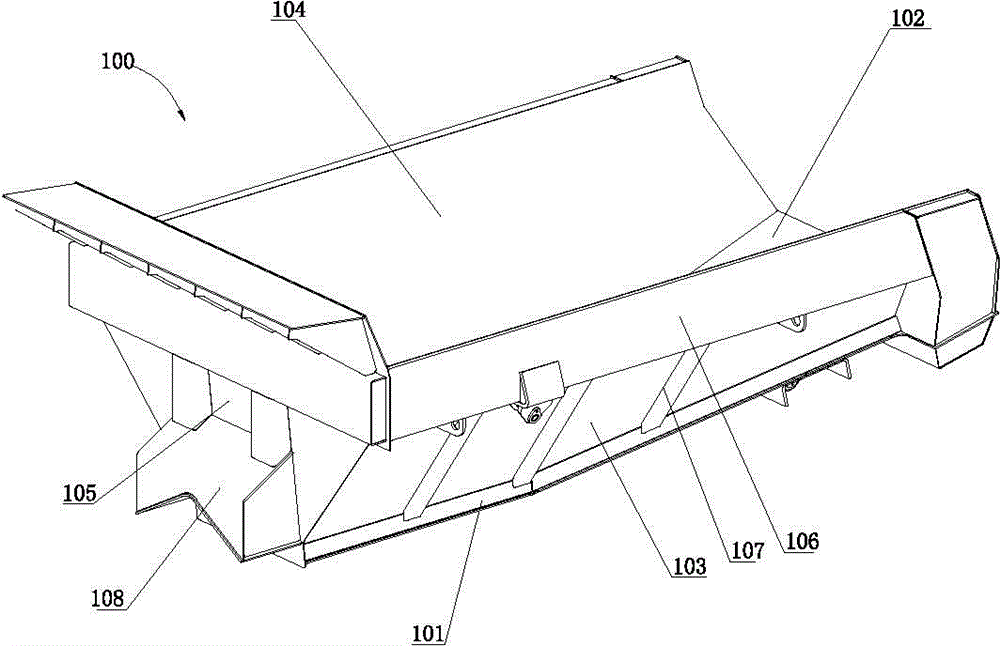

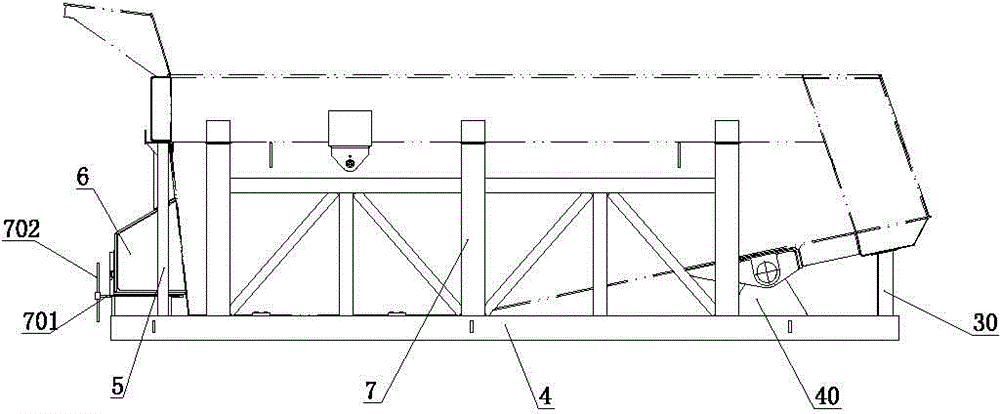

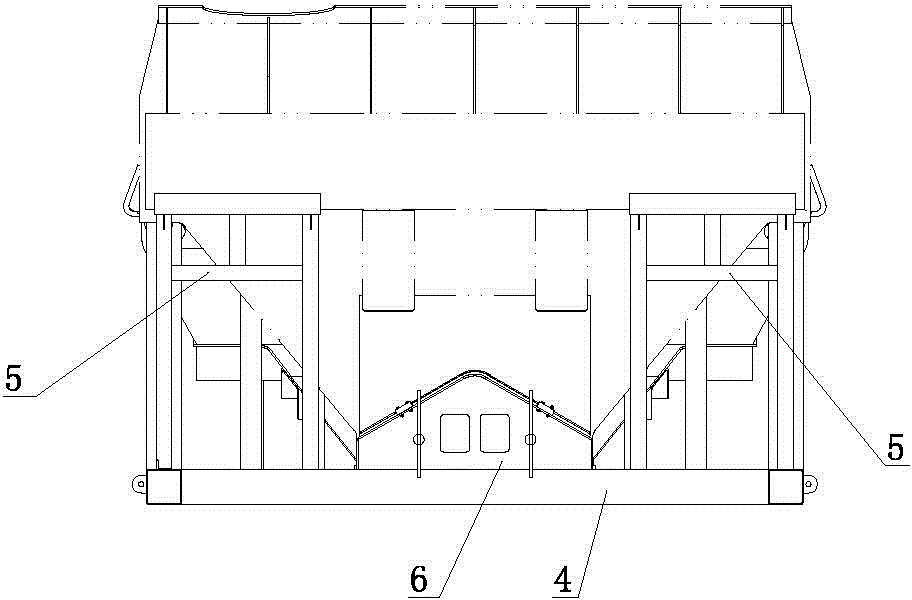

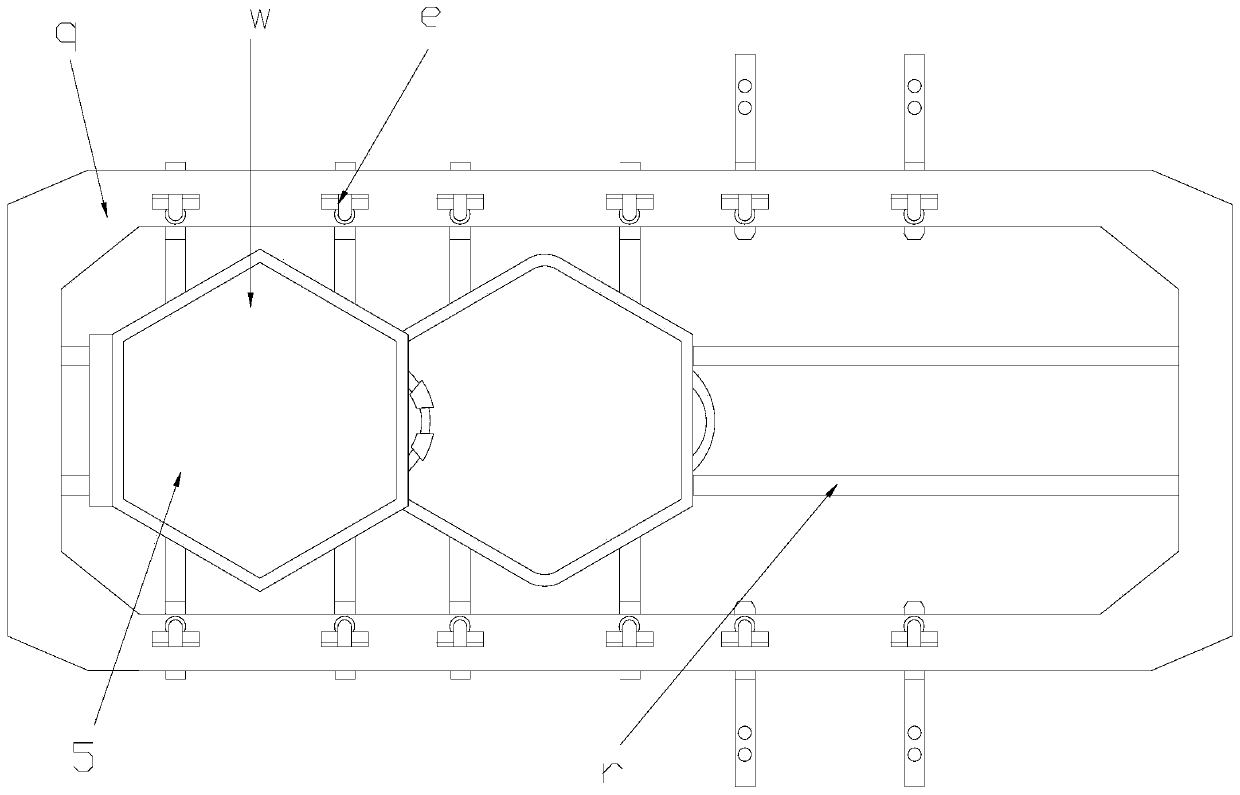

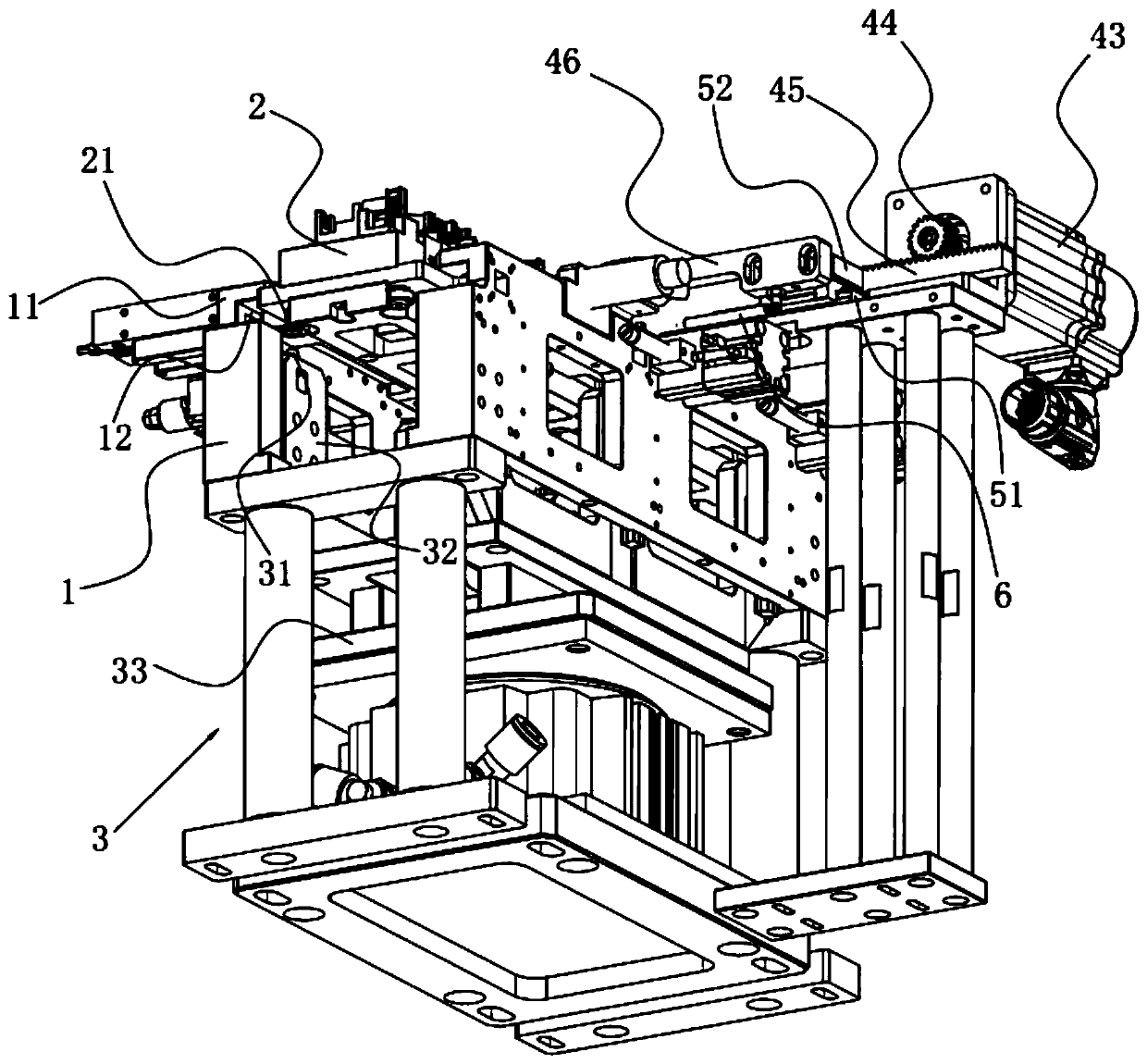

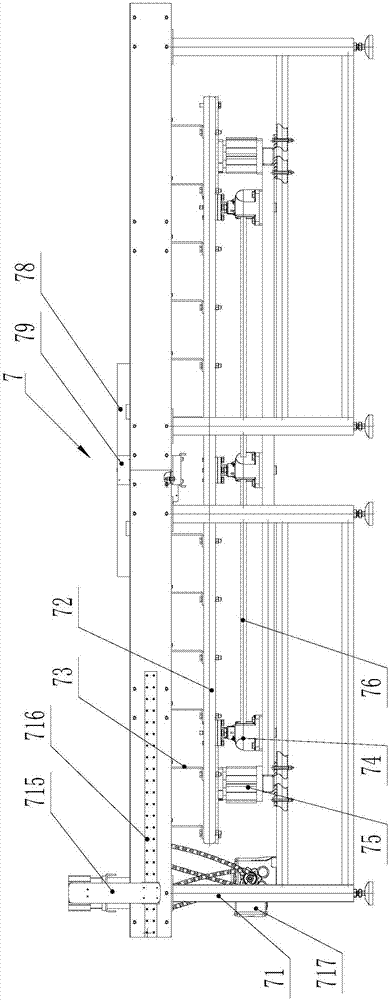

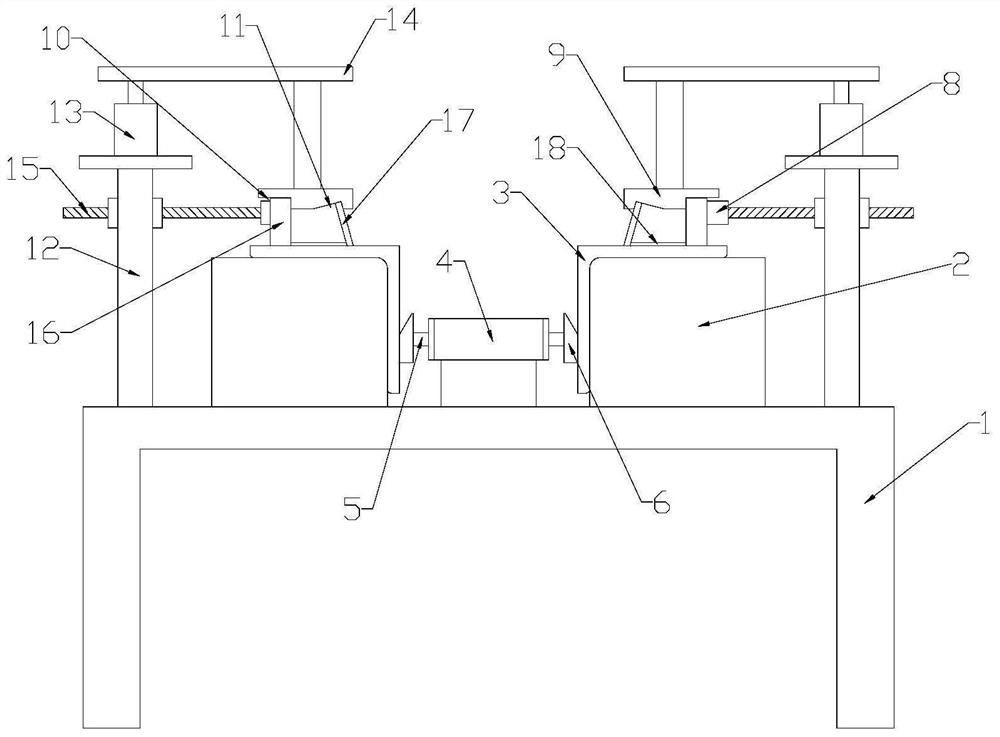

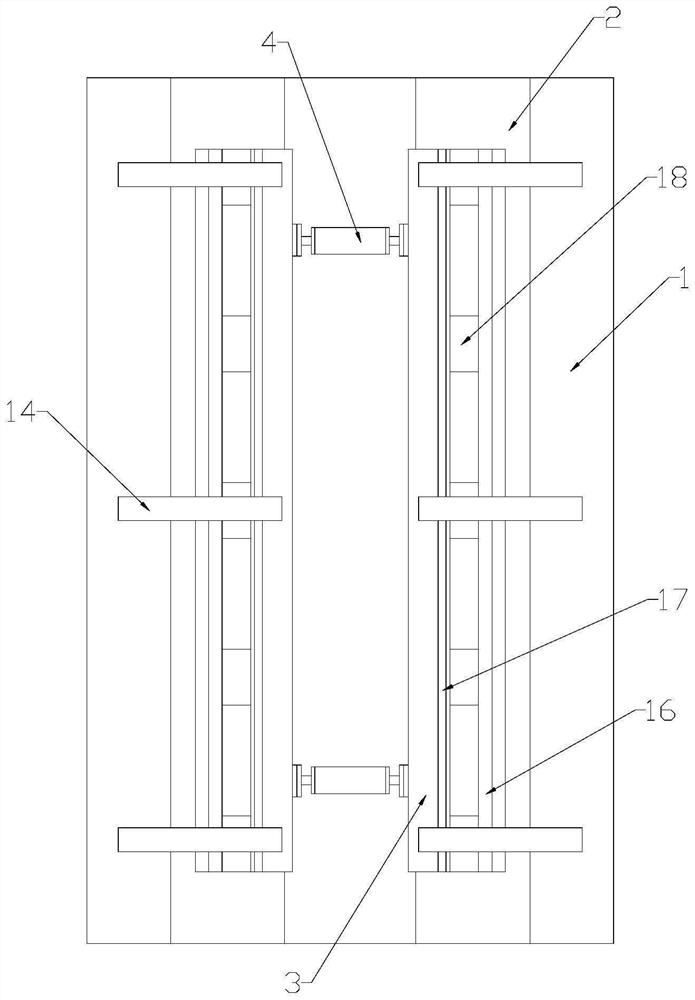

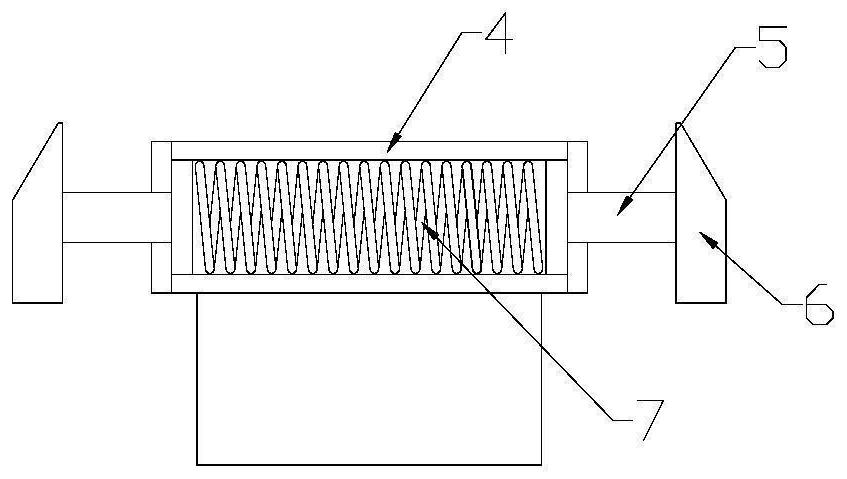

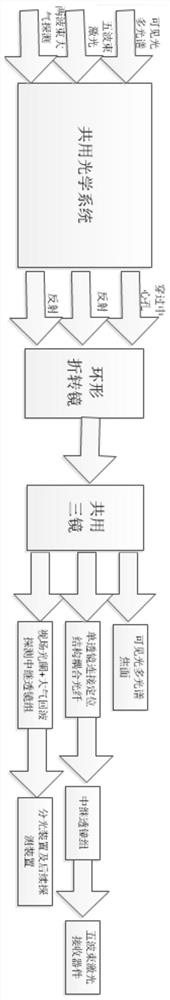

Welding assembly tool and method for electric wheel dumper cargo tank

ActiveCN104625531AEasy to disassembleHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding assembly tool and method for an electric wheel dumper cargo tank. The welding assembly tool comprises a cargo tank front plate welding assembly welding tool and a cargo tank assembly tool. The cargo tank front plate welding assembly welding tool comprises a saddle positioning base, first front plate supporting base sets, second front plate supporting bases, first pressing blocks, a fixed pressing block and a movable pressing block. The cargo tank assembly tool comprises bases, front plate welding assembly positioning frames, a saddle positioning frame, a left side plate positioning frame, a left side plate inclined supporting frame, a right side plate positioning frame, a right side plate inclined supporting frame, rear wane supporting frames, hinged bases, a saddle pressing block and bottom plate pressing blocks. The welding assembly method for the cargo tank includes the steps that a cargo tank front plate welding assembly is welded; the cargo tank is assembled. According to the structure and the method, before welding, all parts of the cargo tank can be accurately positioned, and the cargo tank can be prevented from deforming severely in the welding process.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

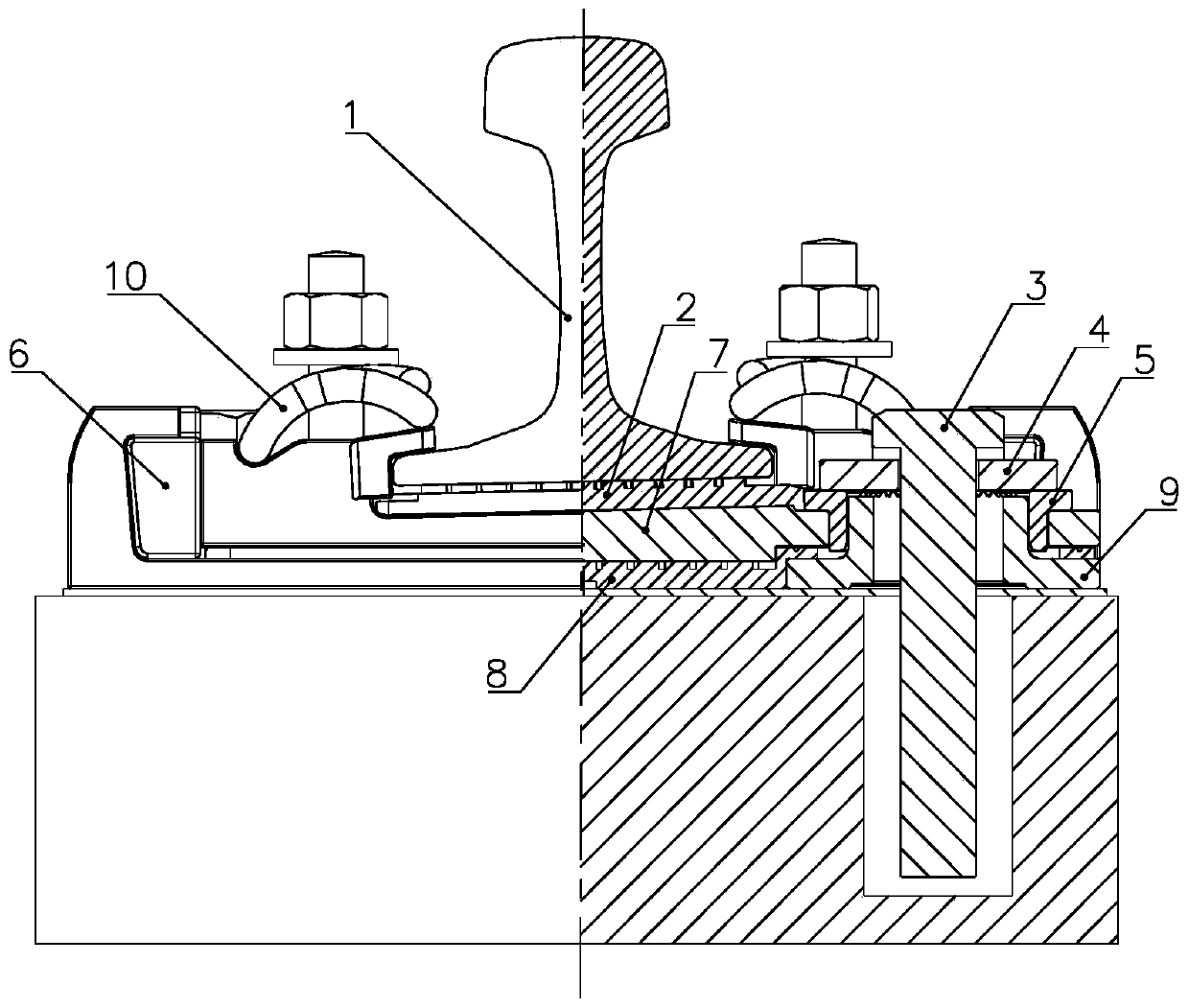

Rail damping fastener

PendingCN110863394AIncrease lateral stiffnessReduce vertical stiffnessRail fastenersClassical mechanicsEngineering

The invention discloses a rail damping fastener. The rail damping fastener comprises an upper base plate, a lower base plate, an intermediate elastic base plate and an under-rail elastic base plate, the intermediate elastic base plate is arranged between the upper base plate and the lower base plate, the under-rail elastic base plate is arranged on the upper base plate, a boss is arranged on the lower base plate, the upper base plate is externally arranged on the boss in a sleeving mode, a longitudinal first transverse limiting surface is arranged on the upper base plate, a transverse blockingshoulder extending upwards is arranged on the lower base plate, a longitudinal blocking shoulder extending towards the first horizontal limiting surface is arranged at the upper end of the transverseblocking shoulder, the rail damping fastener further comprises a transverse clamping block, and the transverse clamping block is arranged between the first transverse limiting surface and the transverse blocking shoulder. According to the rail damping fastener, by arranging a transverse blocking shoulder structure, the integration of the higher transverse stiffness and the lower vertical stiffness of the rail damping fastener can be achieved without affecting the damping effect of the rail damping fastener.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

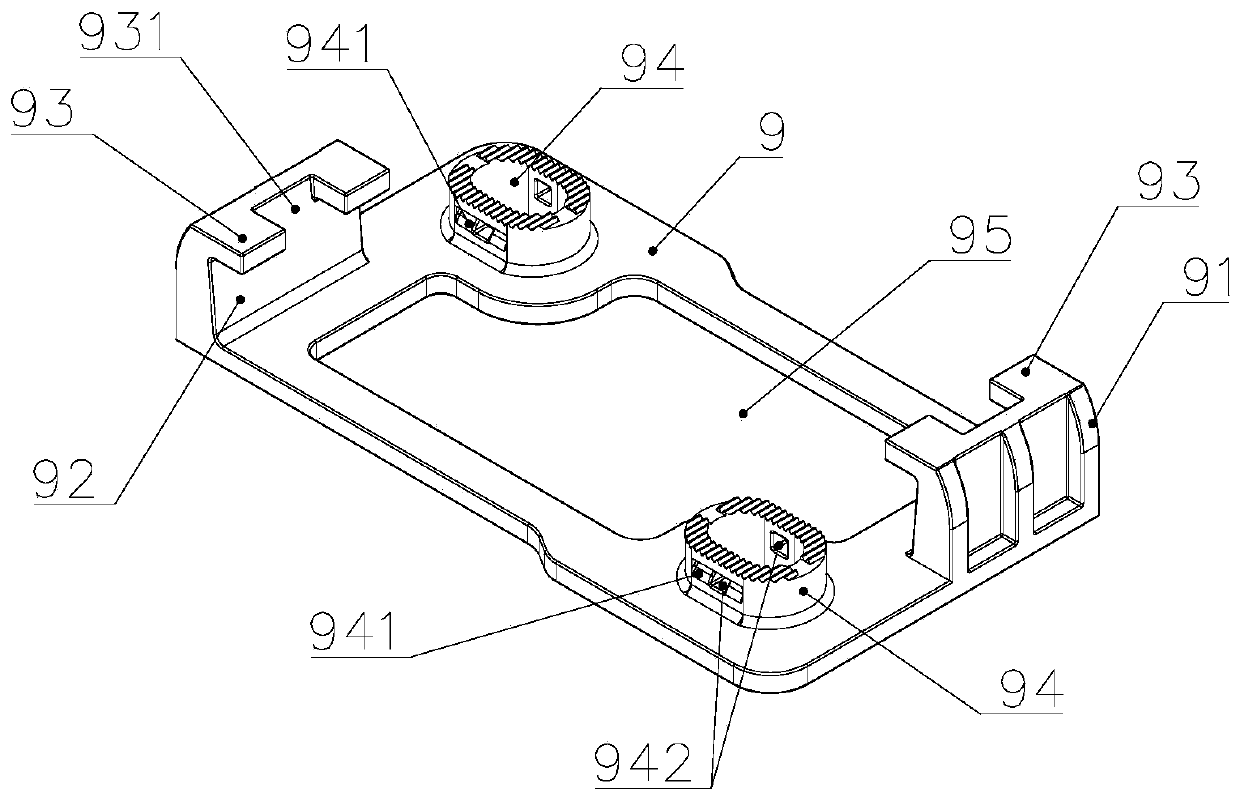

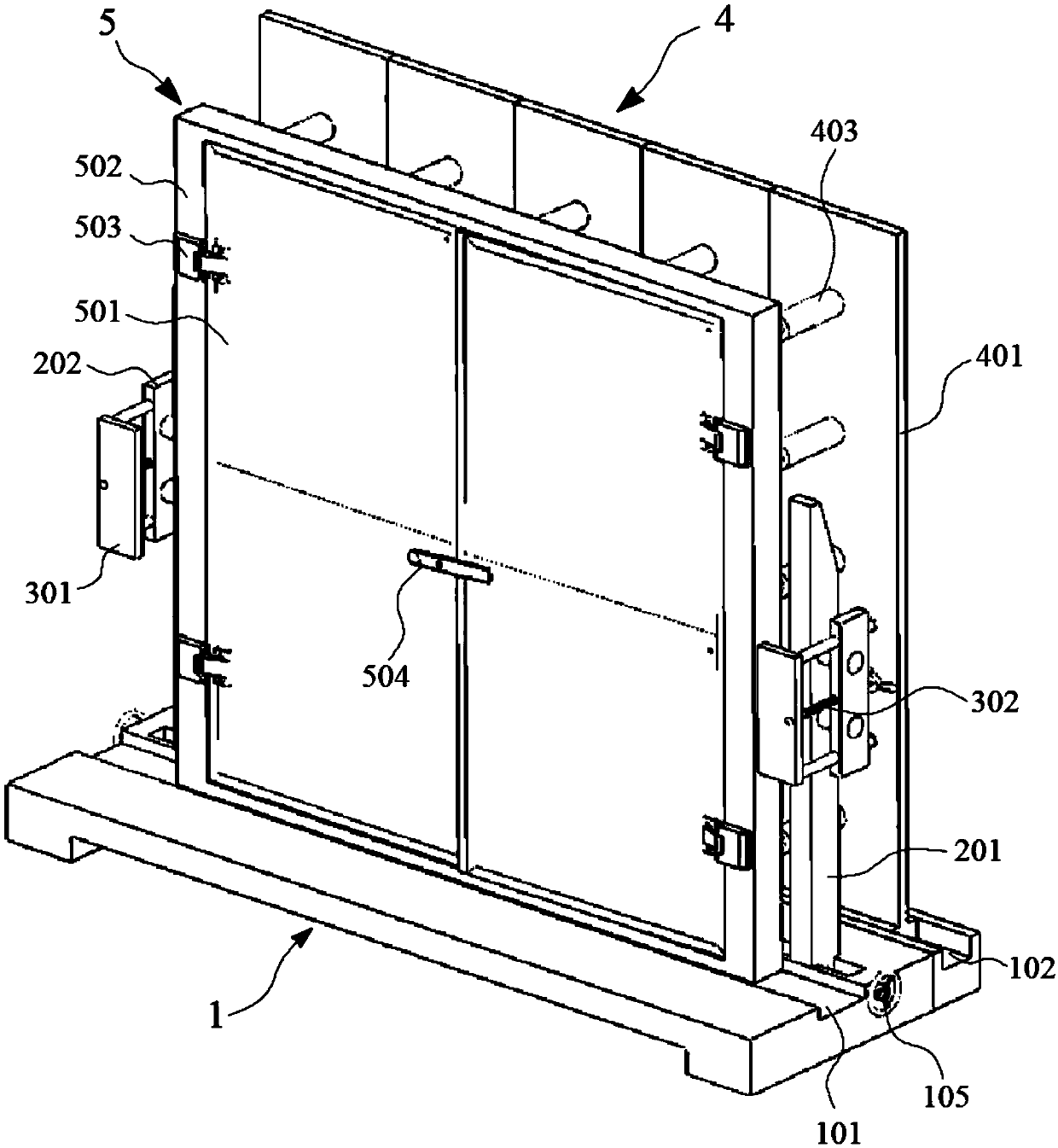

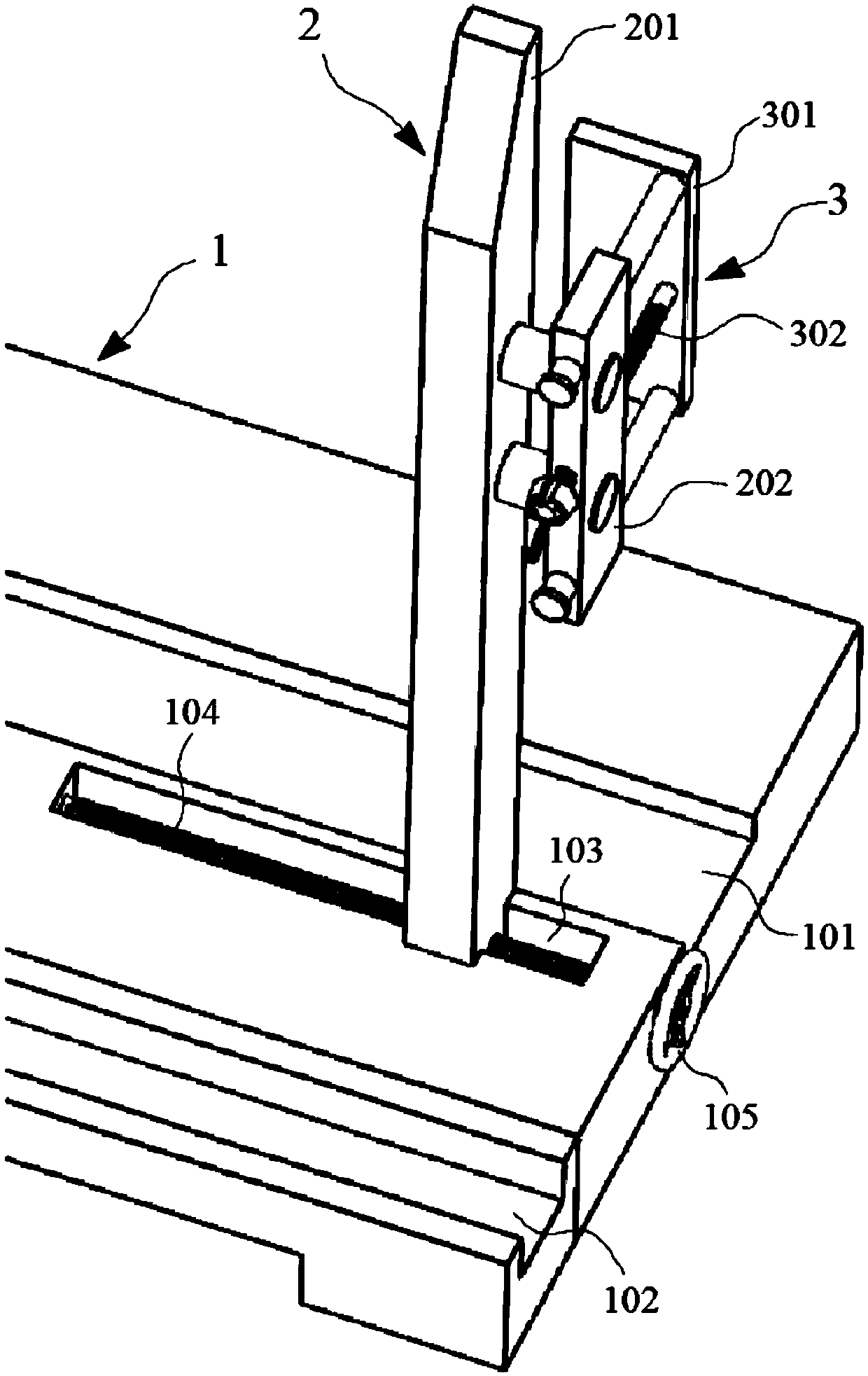

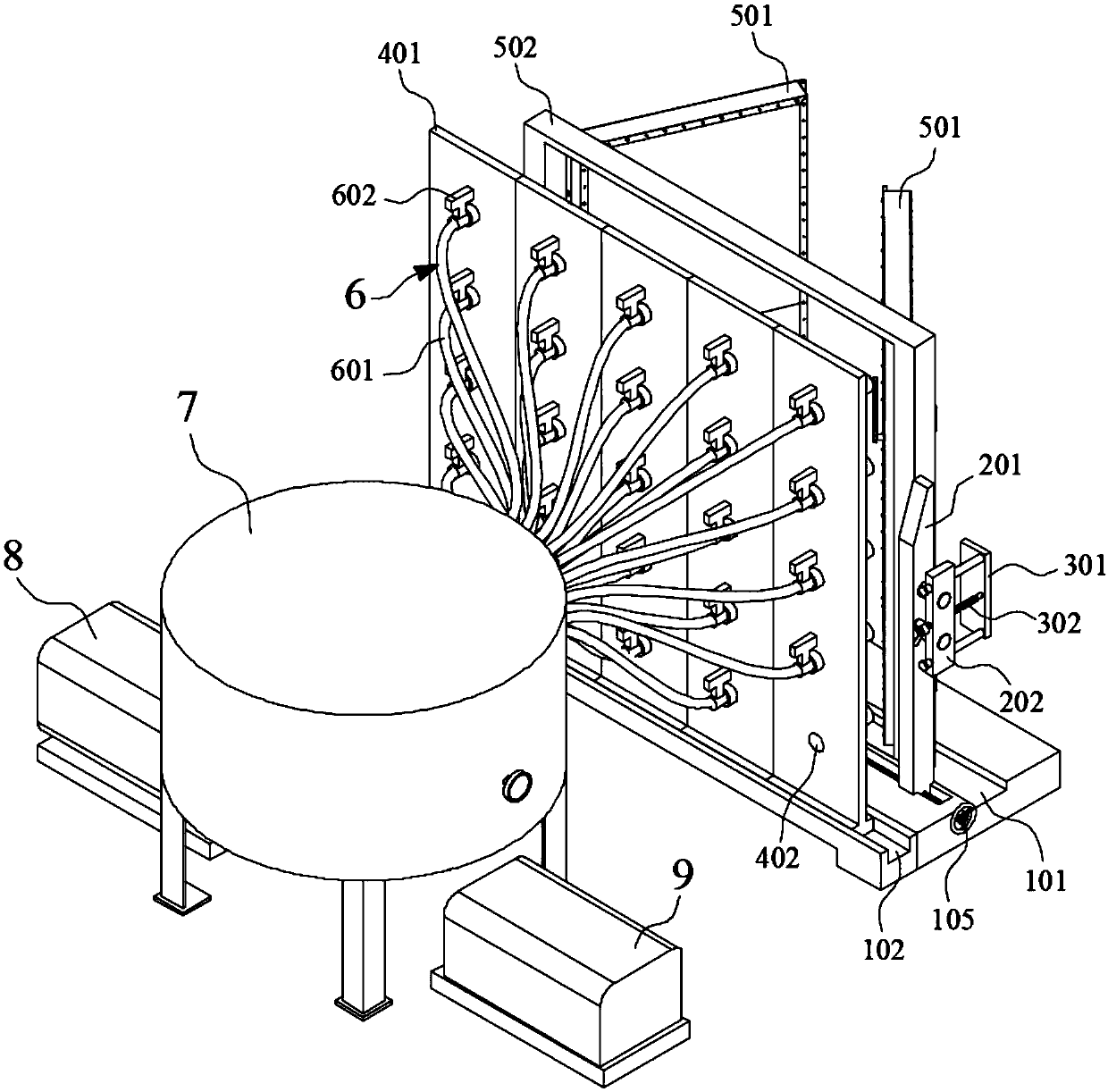

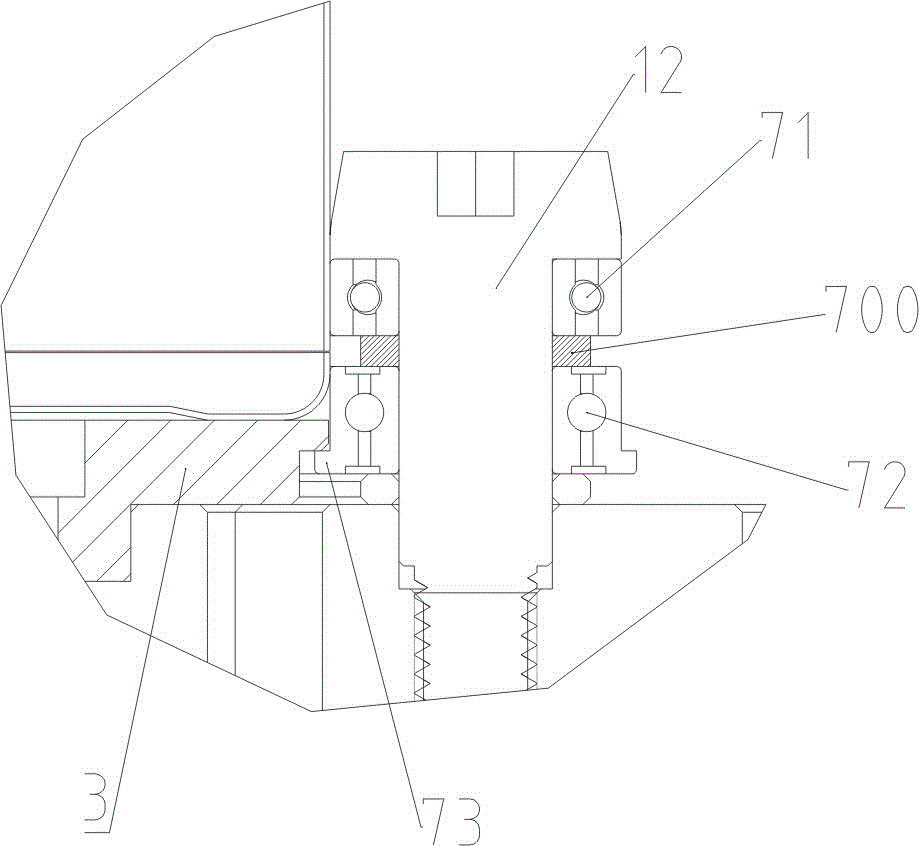

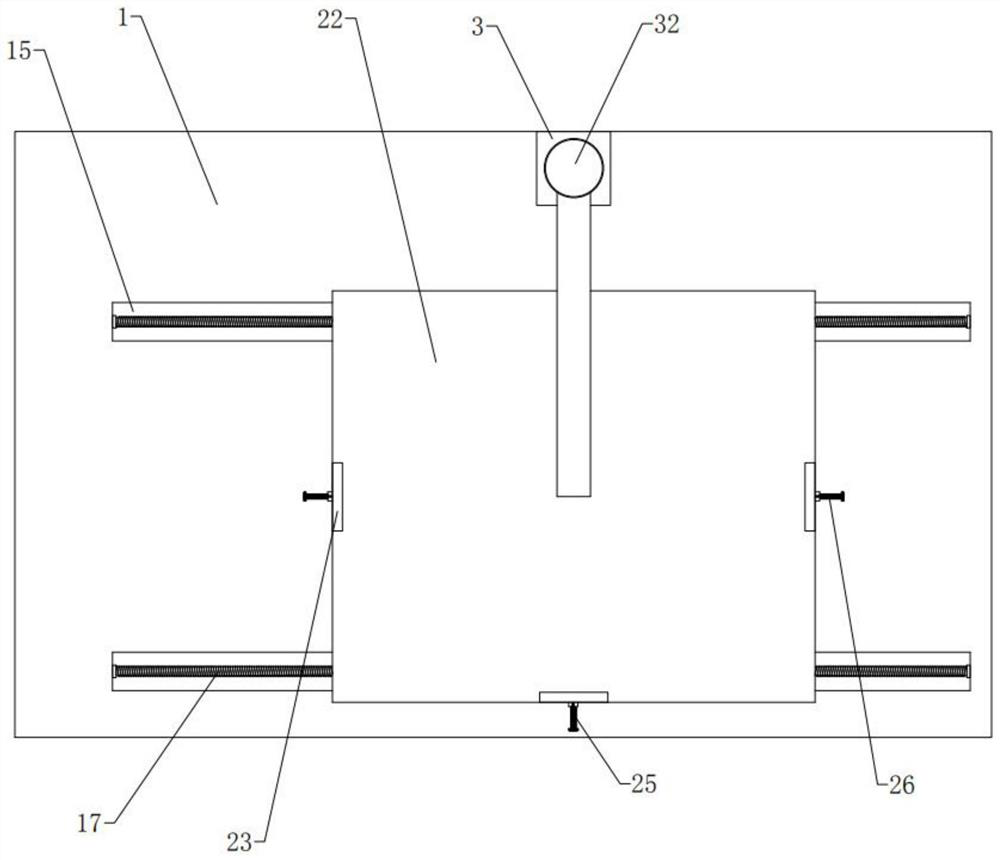

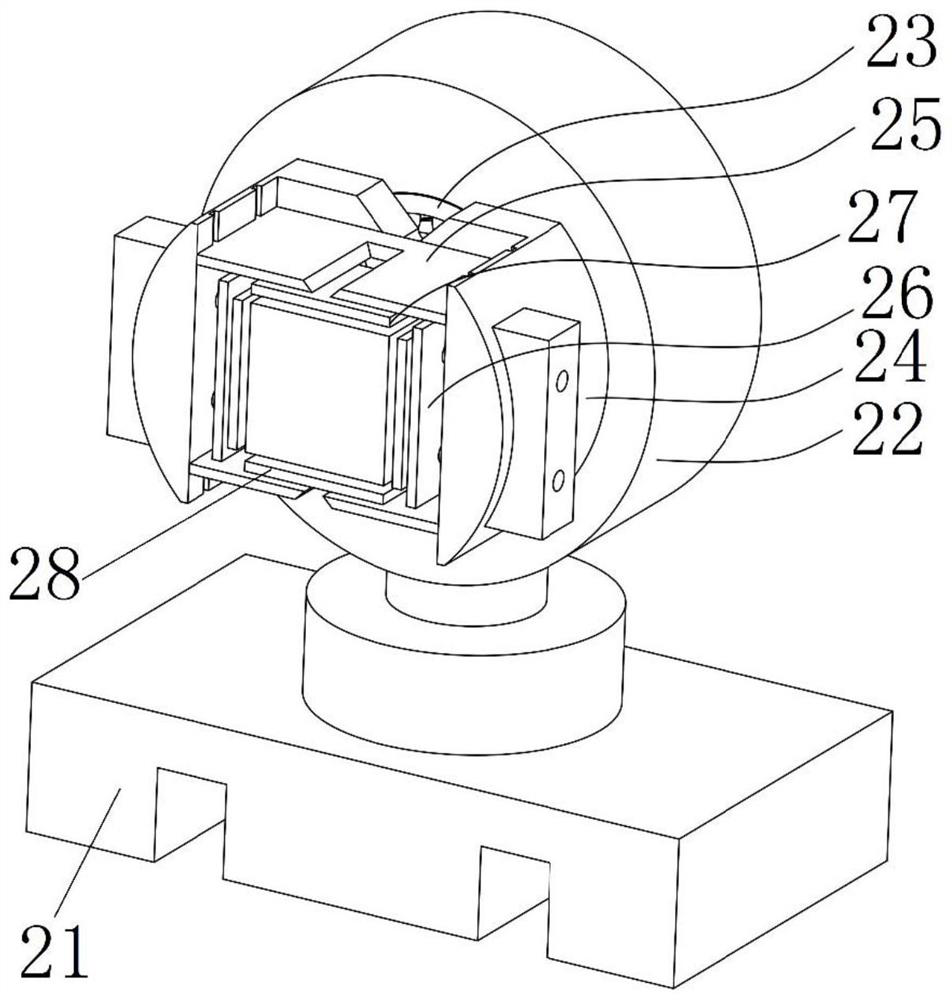

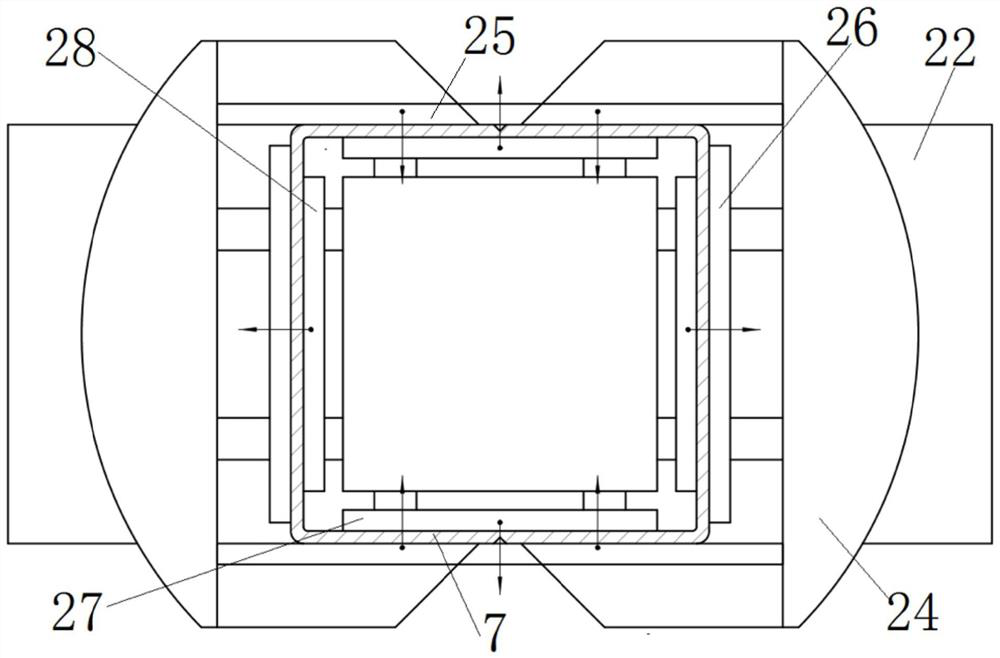

Clamping mechanism of tunnel protective door and wind pressure test device comprising clamping mechanism

PendingCN109612763AImprove loading stabilityEasy loadingMaterial strength using tensile/compressive forcesStructural/machines measurementEngineeringPressure controlled ventilation

The invention discloses a clamping mechanism of a tunnel protective door and a wind pressure test device comprising the clamping mechanism, and belongs to the technical field of tunnel protective doordetection. A transverse clamping piece and a longitudinal clamping piece are arranged on a base, so that rapid and stable loading of the tunnel protective door can be realized; and an air path assembly and a wind pressure control assembly are arranged corresponding to the clamping mechanism, so that the state of being subjected to wind pressure of the tunnel protective door in a tunnel can be effectively simulated, and thus a wind pressure test of the tunnel protective door can be accurately realized. The clamping mechanism and the wind pressure test device comprising the clamping mechanism are simple in structure and simple and convenient to control, the state of being subjected to the action of piston wind of the tunnel protective door in the tunnel can be effectively simulated, the selectivity of test schemes is high, the accuracy of test results is high, a basis is provided for structural design and matching installation of the tunnel protective door, the safety and reliability ofapplication of the tunnel protective door are improved, the application cost of the tunnel protective door is reduced, and the application popularization value is excellent.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

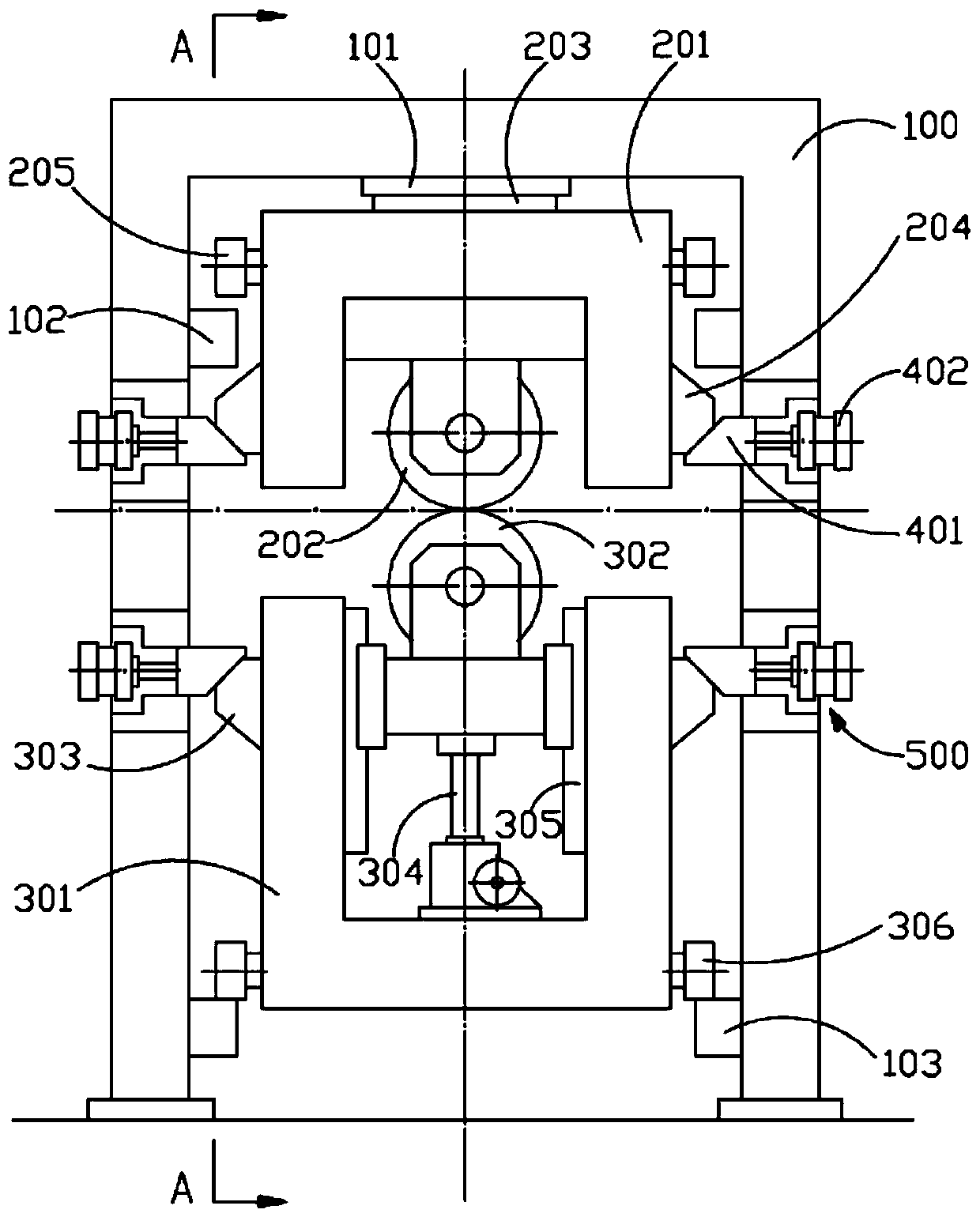

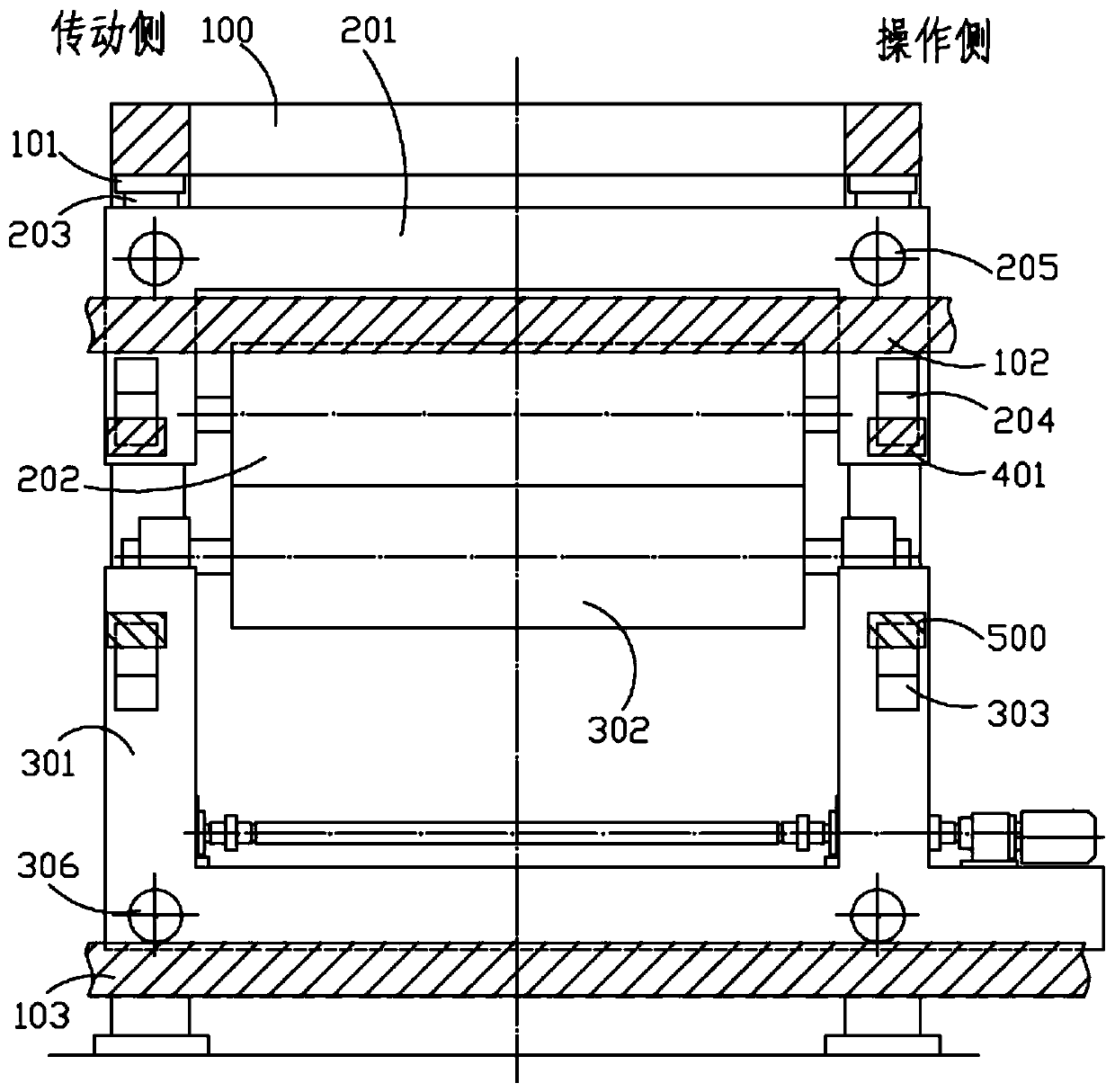

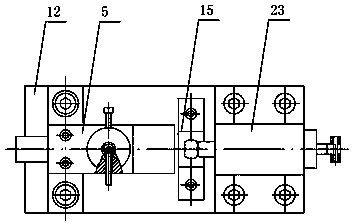

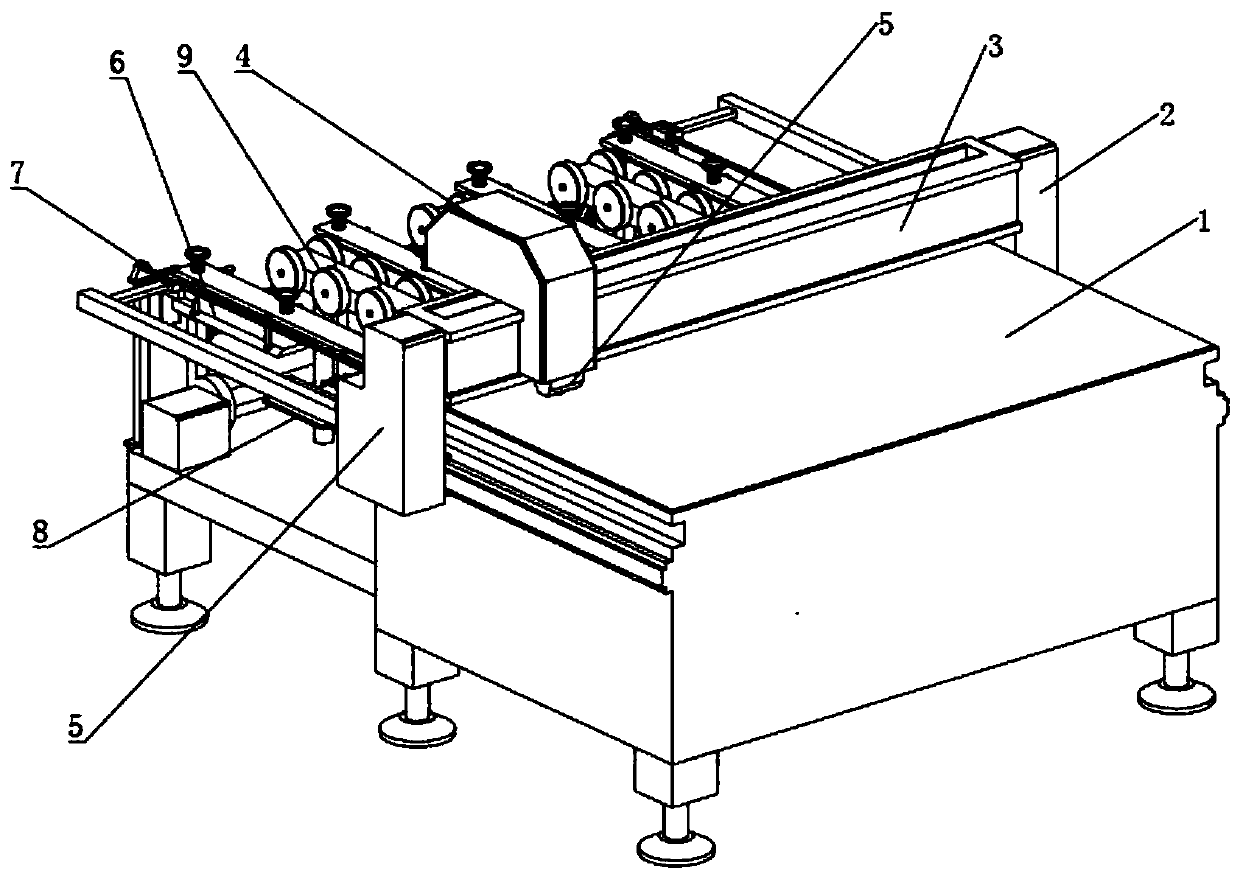

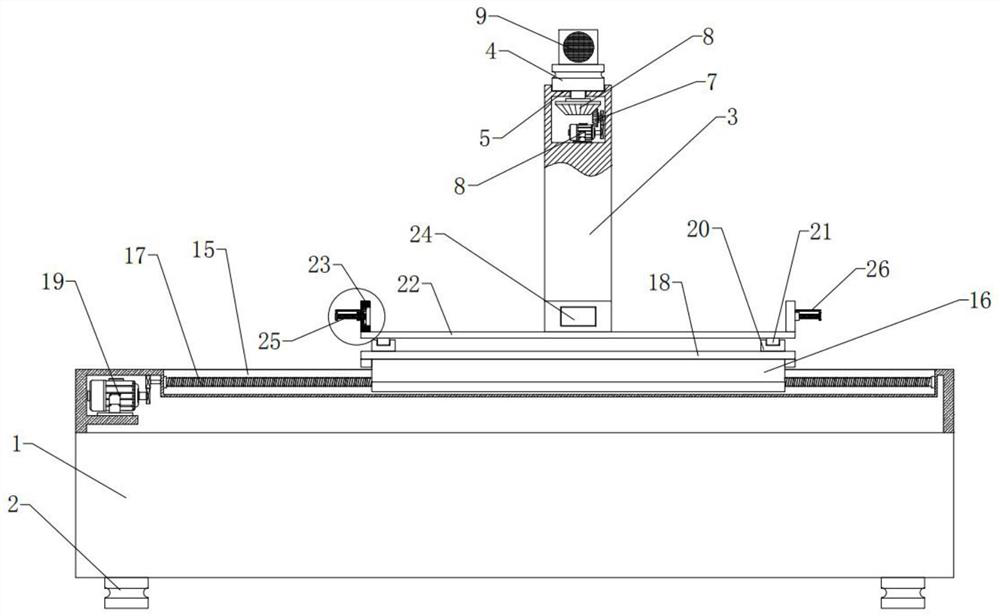

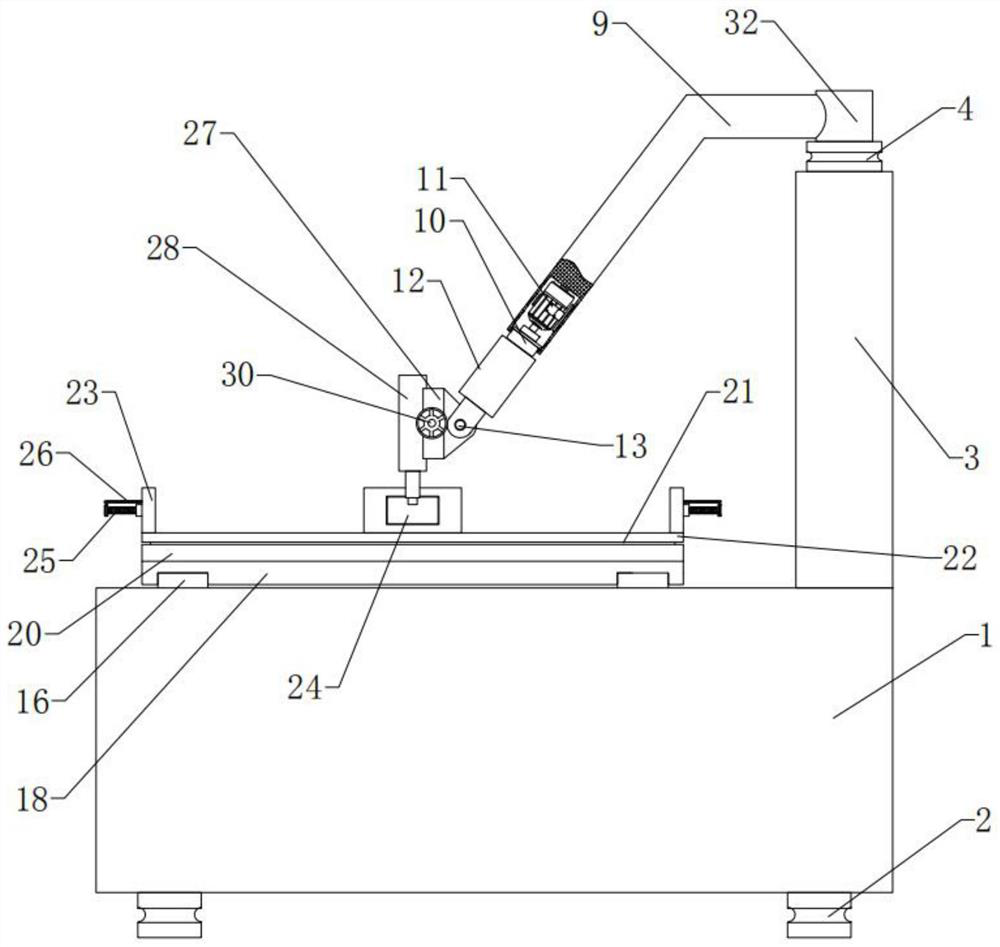

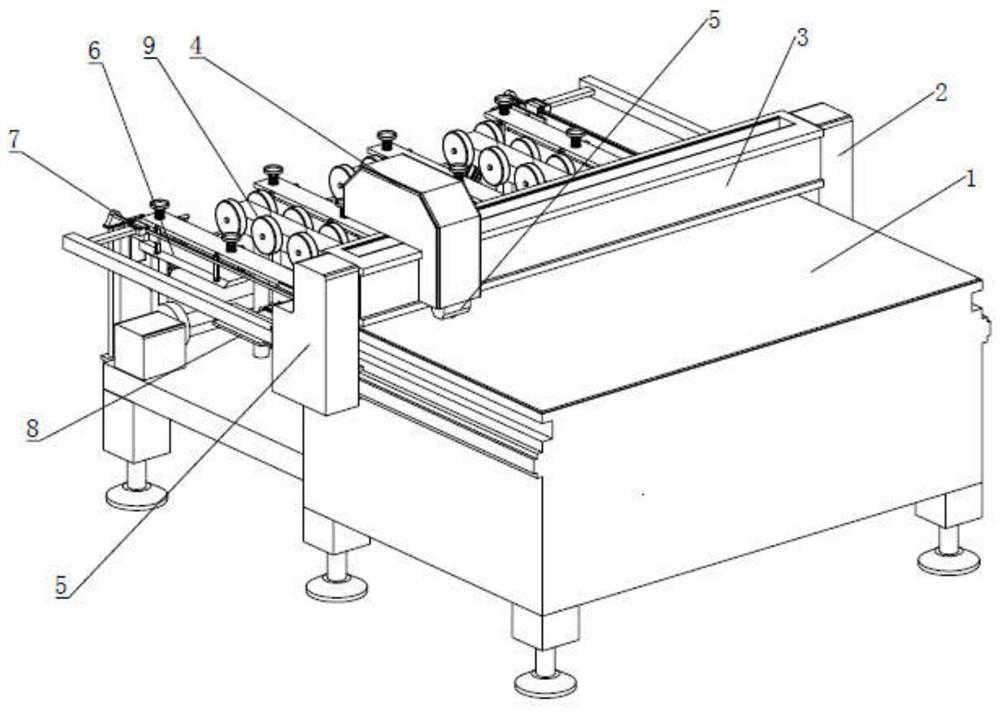

Two-roller coating machine using tapered wedge adjustment

ActiveCN110479546AAchieve horizontal positioningAchieve lockingLiquid surface applicatorsCoatingsHorizontal forceEngineering

The invention relates to a two-roller coating machine using tapered wedge adjustment. The two-roller coating machine comprises an upper roller levelness regulation mechanism and a lower roller positioning mechanism. The upper roller levelness regulation mechanism comprises a reference positioning base, a positioning table and an upper tapered wedge adjustment mechanism. The reference positioning base is arranged on a machine frame and comprises a reference positioning face. The positioning table is arranged on an upper roller frame and comprises a horizontal positioning face. The upper taperedwedge adjustment mechanism is used for driving the horizontal positioning face to abut against the reference positioning face. The lower roller positioning structure can horizontally push a lower roller frame in the length direction of the center line of a unit, can lock the lower roller frame and comprises at least one lower tapered wedge adjustment block arranged on a lower roller frame and atleast one lower tapered wedge drive unit arranged on the machine frame. By means of tapered wedge mechanisms, horizontal positioning and regulating of an upper coating roller and a lower coating lowerare achieved; and by locking the upper roller frame and the lower roller frame on the machine frame, the horizontal force borne by the coating rollers during work can be transmitted to the machine frame, precision of the coating rollers is ensured, and the coating quality is improved.

Owner:WISDRI ENG & RES INC LTD

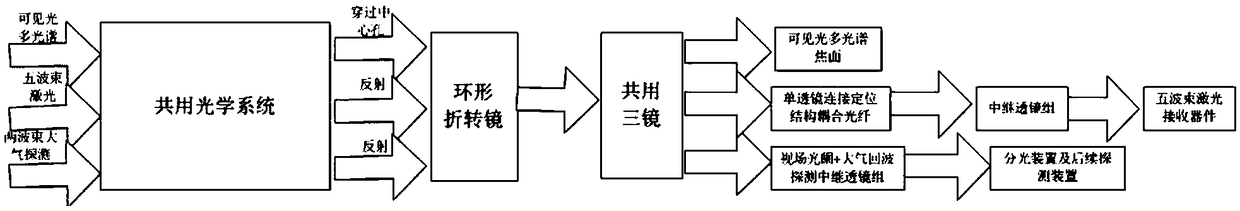

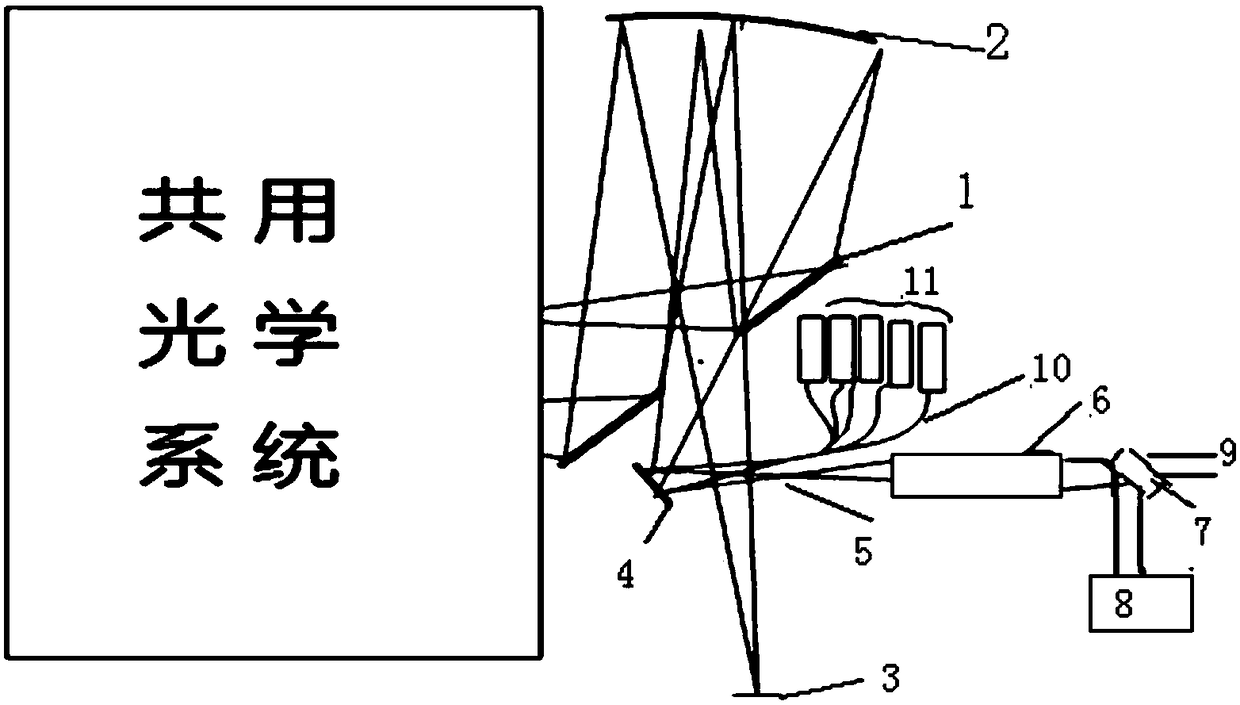

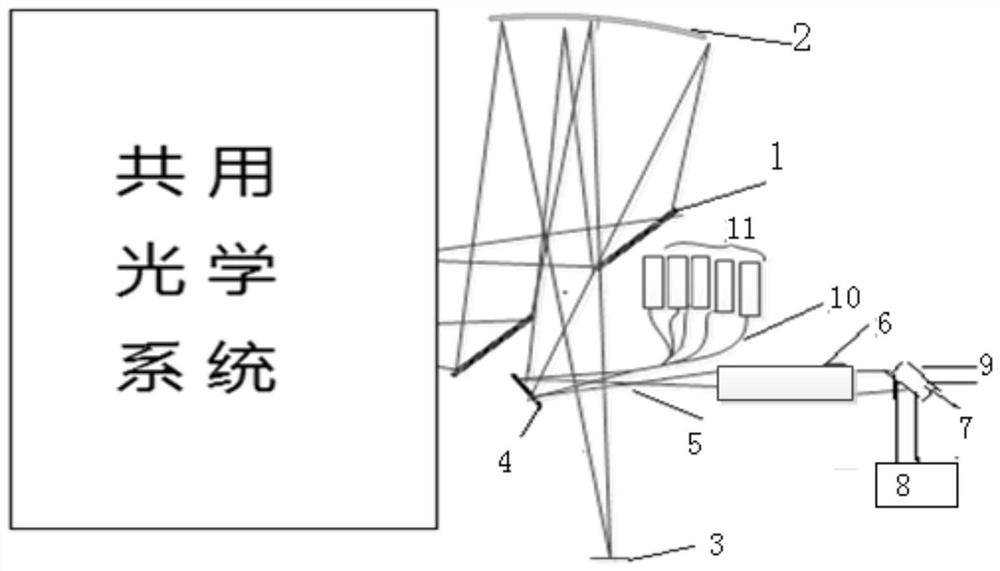

Integrated system of annular visual field

ActiveCN108845329ACompact structureSimple compositionElectromagnetic wave reradiationICT adaptationVisual field lossHigh resolution imaging

The invention provides an integrated system of an annular visual field, wherein a common main optical system, and independent subsequent elements and receiving devices are utilized, and three independent modules, namely a high-resolution imaging module, a multibeam laser echo detecting module and an atmosphere echo detecting module. The high-resolution imaging module realizes a visible light multispectral high-resolution imaging function. The multibeam laser echo detecting module realizes a five-beam laser echo receiving function. The atmosphere echo detecting module realizes an atmosphere echo receiving function. Three channels form the annular visual field through reasonable laying. The optical system according to the invention has advantages of high ray machine structure integration degree, high resolution, small size, small weight, etc. Furthermore the integrated system realizes functions of high resolution and high-precision distance measuring to large-area ground objects, cloud aerosol detection and three-dimensional plotting.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

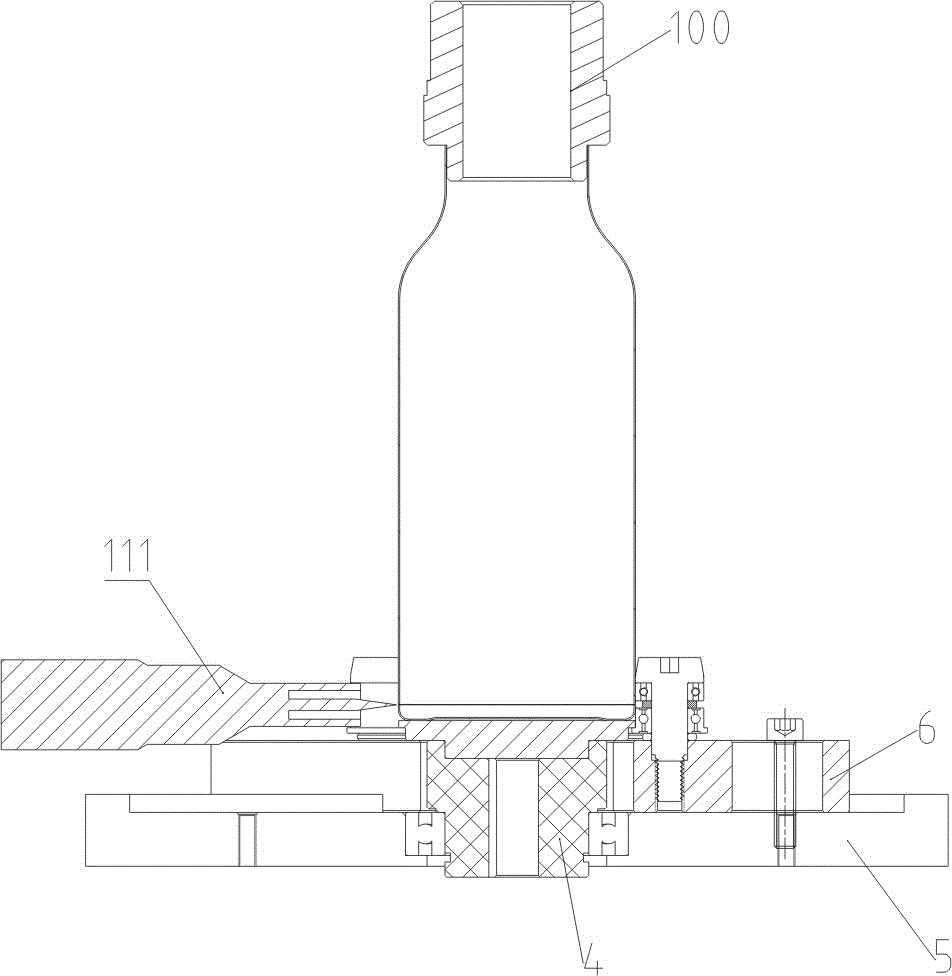

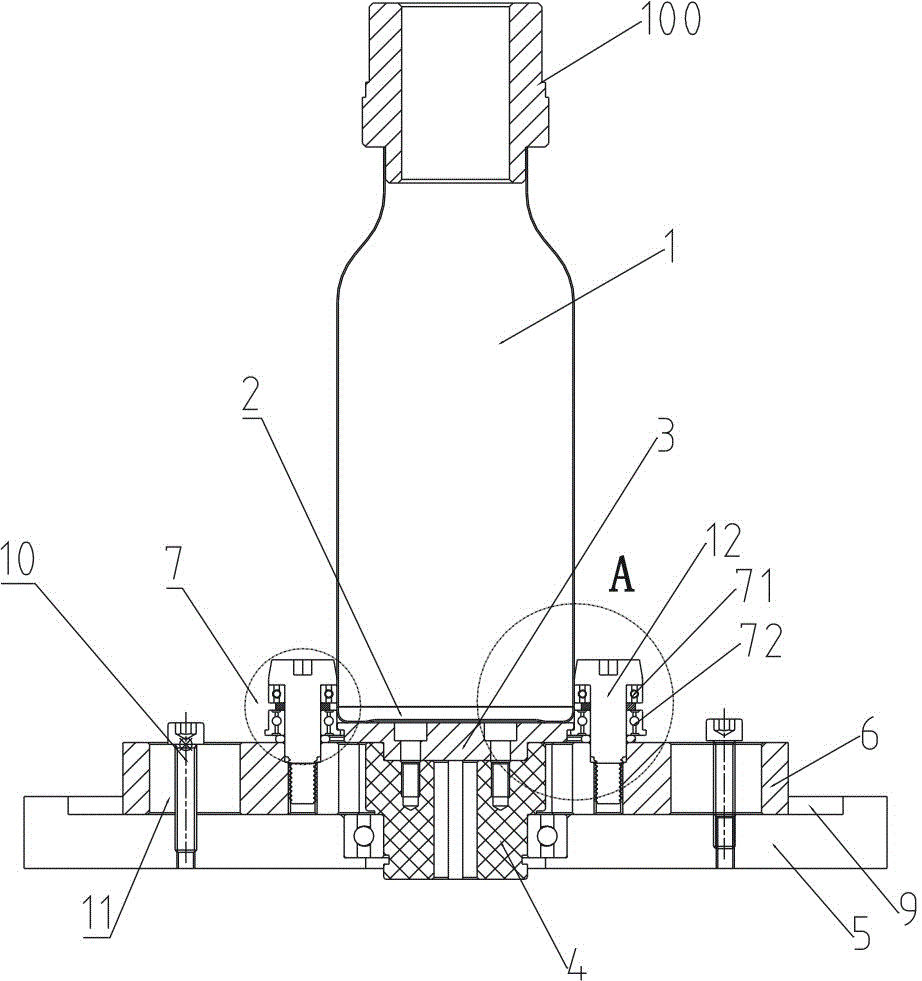

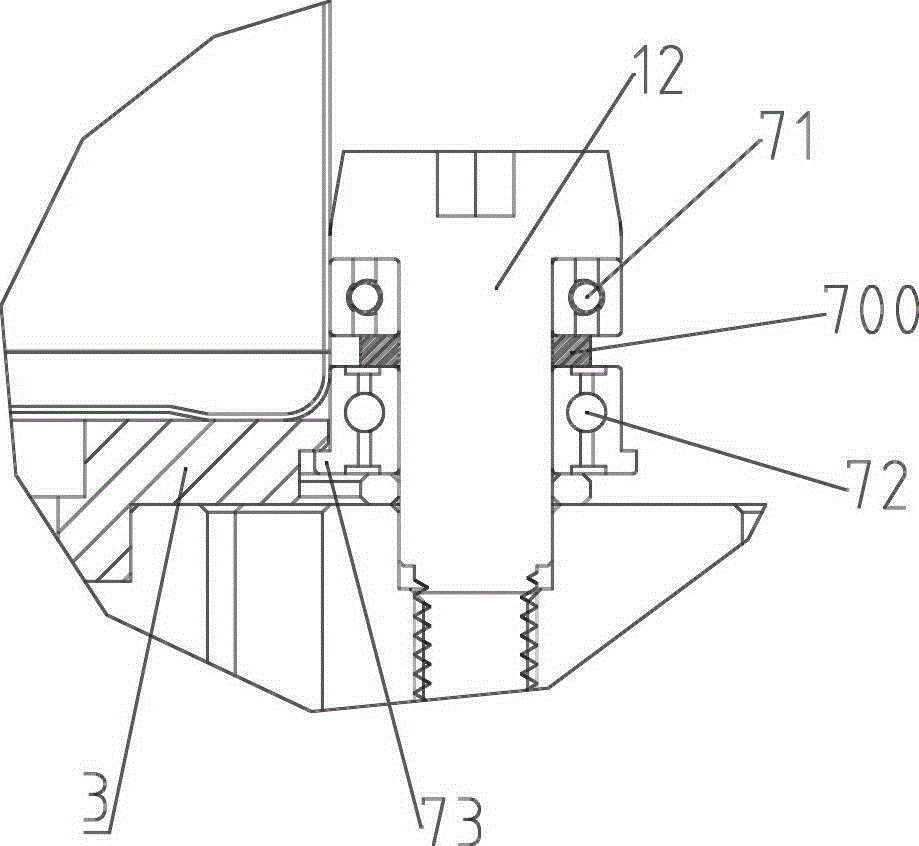

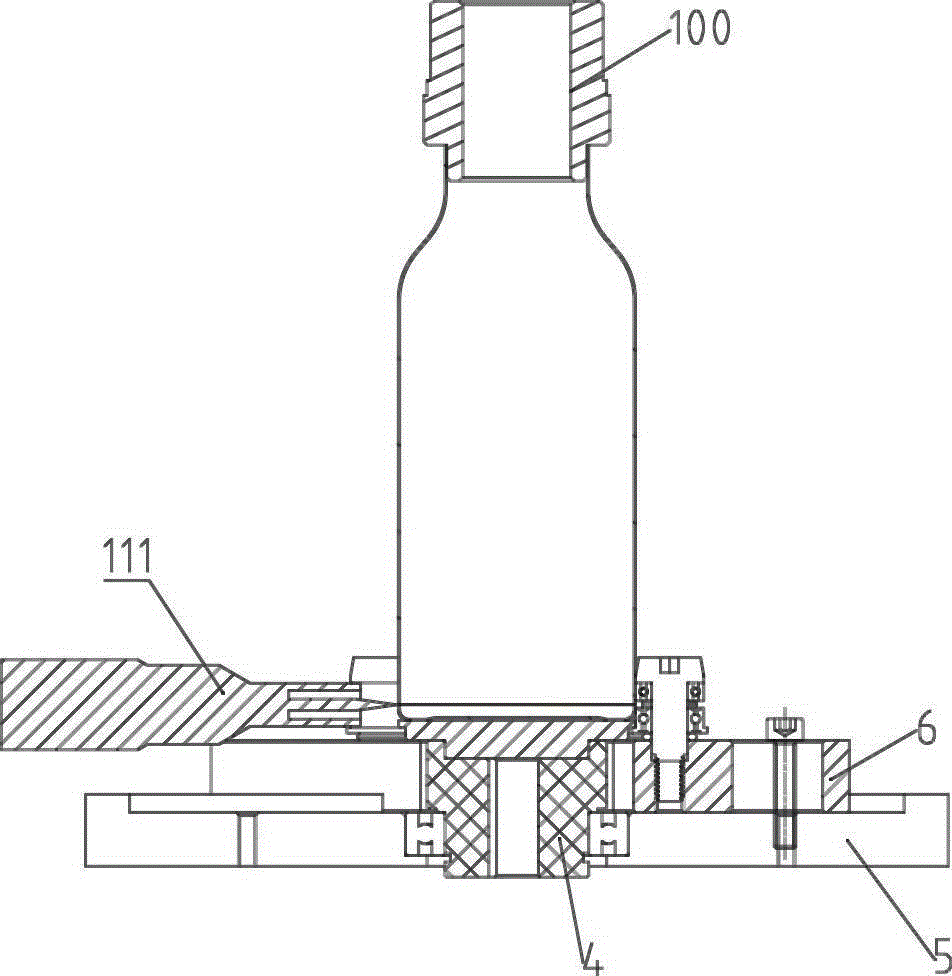

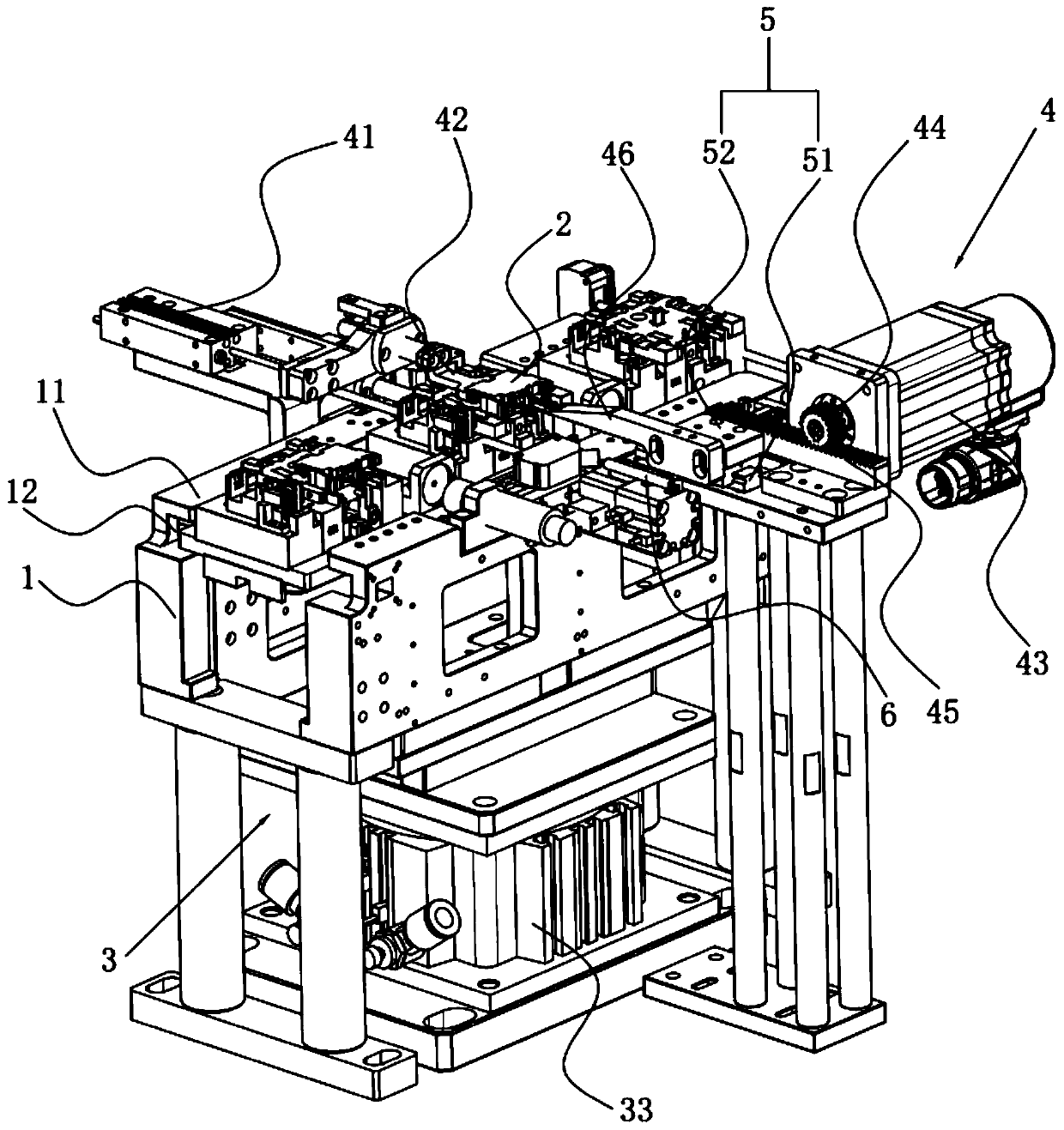

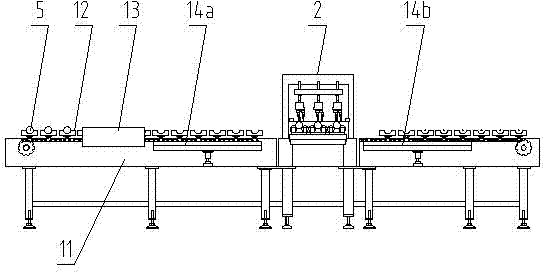

Ultrasonic welding system

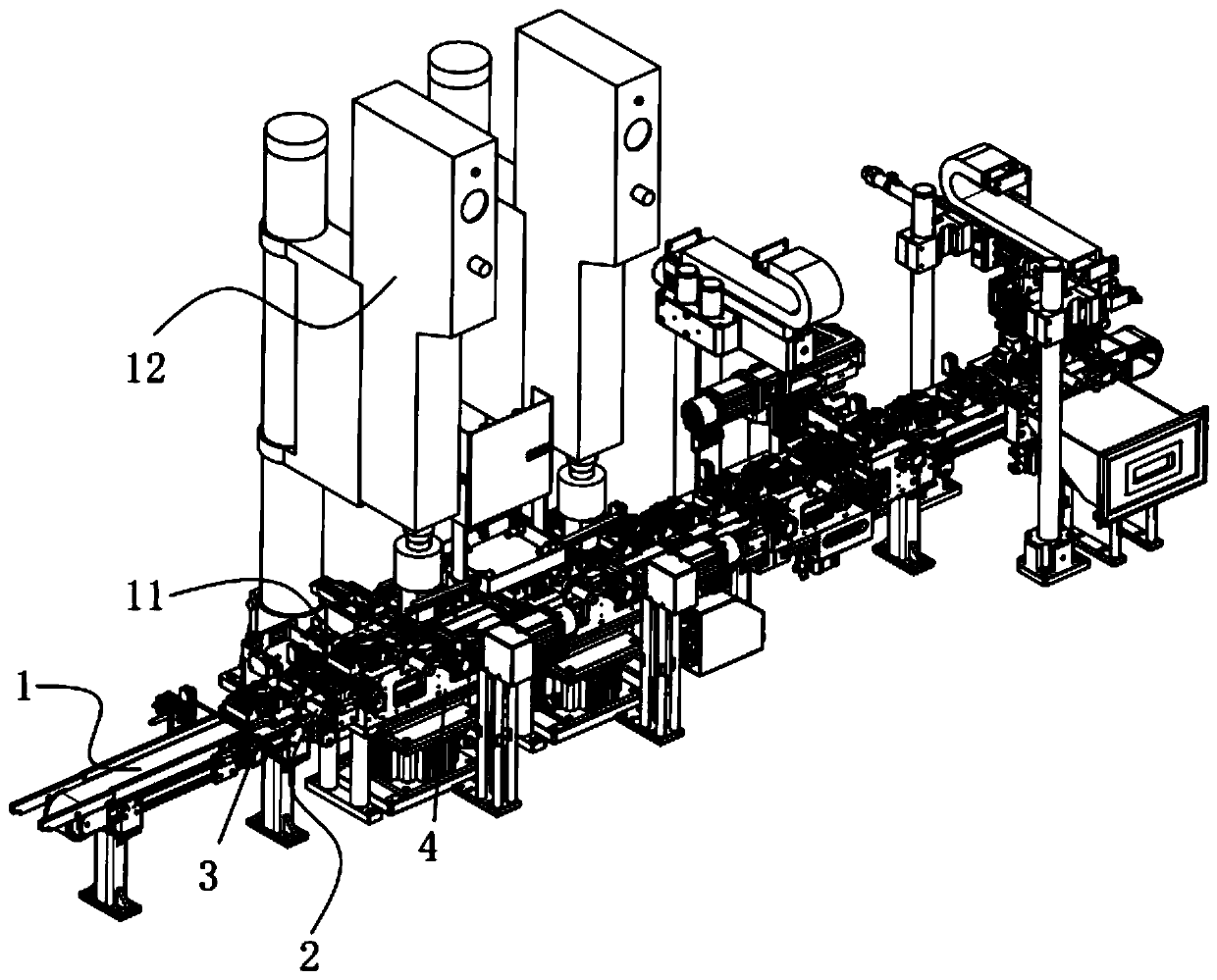

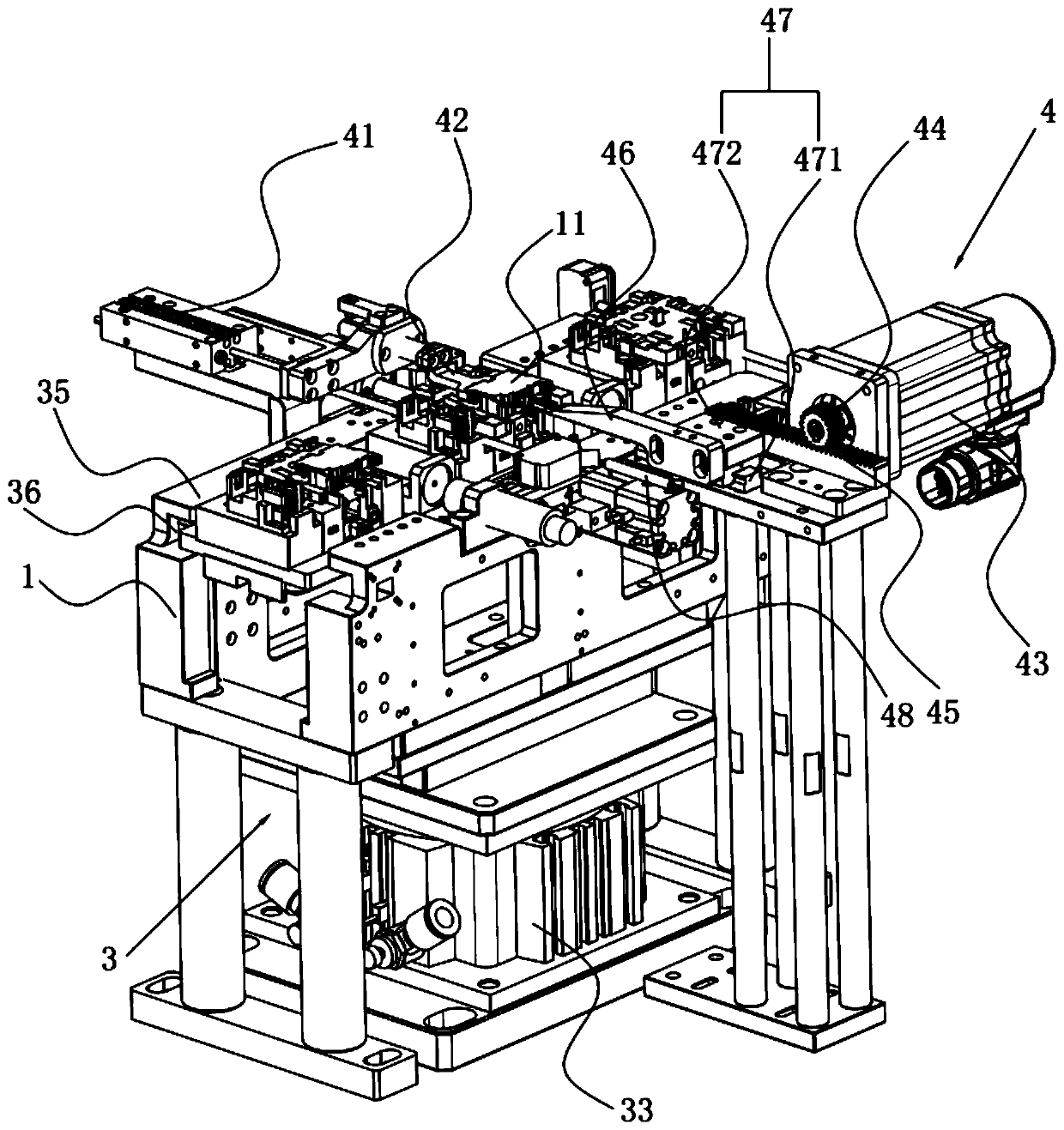

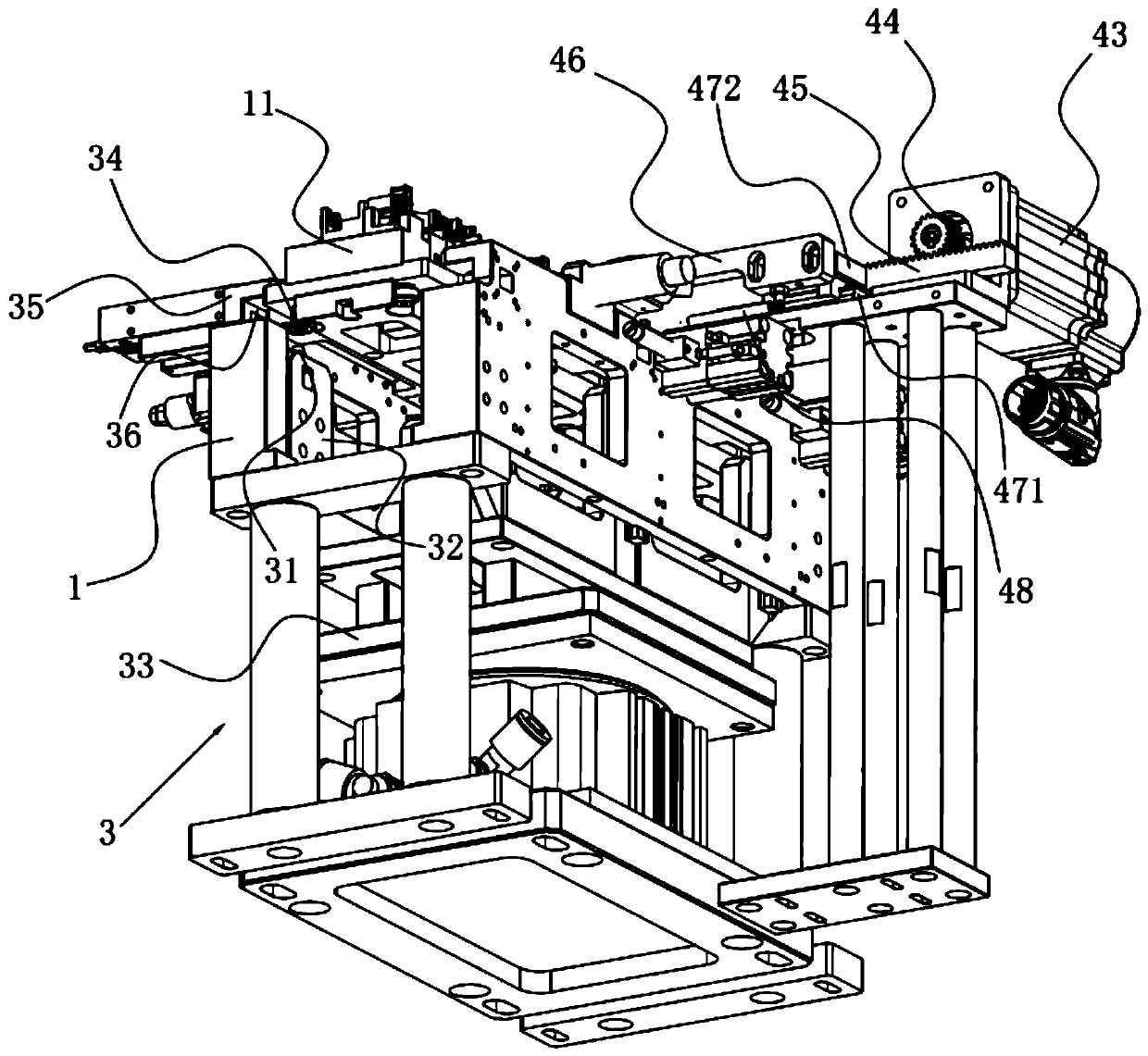

PendingCN110625243AIncrease productivityReduce labor costsNon-electric welding apparatusUltrasonic weldingDigital sensors

The invention relates to the technical field of ultrasonic welding equipment, in particular to an ultrasonic welding system. The invention aims to solve the problems of low ultrasonic welding efficiency and low welding rate in the prior art. According to the technical scheme, the ultrasonic welding system is characterized by involving a conveying belt, a double-station carrier moving in the conveying direction of the conveying belt, a welding device located on the conveying belt and a control subsystem, wherein the control subsystem comprises a plurality of groups of digital sensors arranged on the conveying belt and used for performing real-time detection feedback on the position of the double-station carrier, a first positioning mechanism arranged on the conveying belt and is used for realizing ejecting and positioning of the double-station carrier, a second positioning mechanism arranged on the conveying belt and is used for realizing horizontally positioning of the double-station carrier, and a control end being in communication connection with the digital sensors and is used for control the first positioning mechanism, the second positioning mechanism and the welding device toact. According to the ultrasonic welding system, the production efficiency can be greatly improved, and the labor cost is reduced.

Owner:SUZHOU RS TECH

Container welding positioning system

ActiveCN105397399BAchieve horizontal positioningAchieve positioningWelding/cutting auxillary devicesAuxillary welding devicesFixed positionPositioning system

The invention discloses a container welding positioning system. The container welding positioning system sequentially comprises a wall body, a container bottom cover, a lower supporting plate and a rotating connecting block. The container bottom cover is located between the wall body and the lower supporting plate. The container bottom cover is placed on the end face of the lower supporting plate. The rotating connecting block is fixedly connected with the lower supporting plate. The section of the wall body is attached to the section of the container bottom cover. The rotating connecting block is sleeved with a bottom plate. The rotating connecting block is rotationally connected with the bottom plate. The bottom plate is provided with adjusting sliding blocks in sliding connection with the bottom plate. The adjusting sliding blocks are distributed on the bottom plate in the circumferential direction. Wheel mechanisms are fixedly connected to the adjusting sliding blocks. The wheel mechanisms are rotationally connected with a container. A notch is formed in the bottom plate. The fixing position can be flexibly adjusted according to the size of the container, operation is simple, positioning is accurate, the production cost is reduced, and meanwhile the efficient welding process and the high welding quality are guaranteed.

Owner:LINGHANG IND & TRADE ZHEJIANG

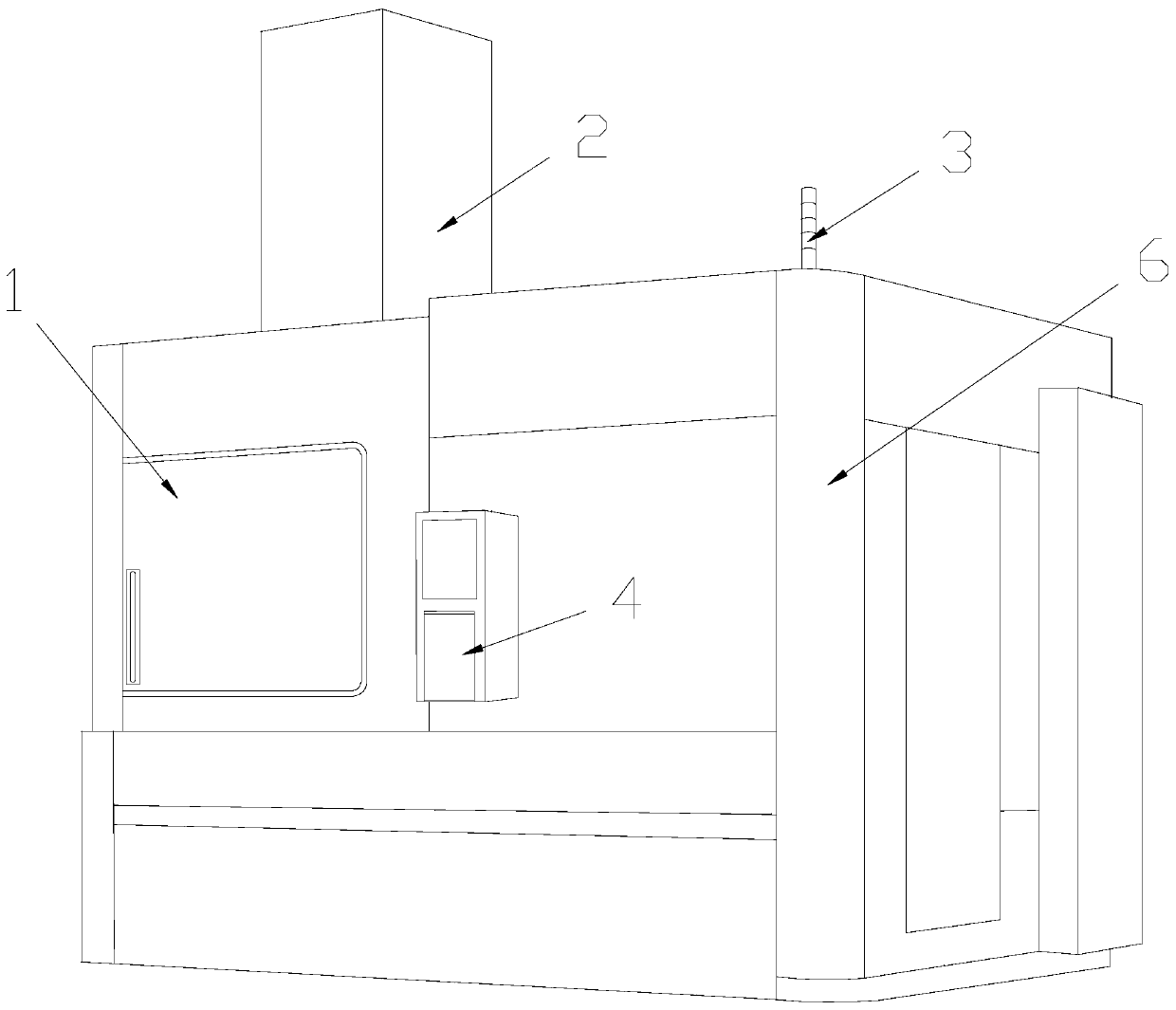

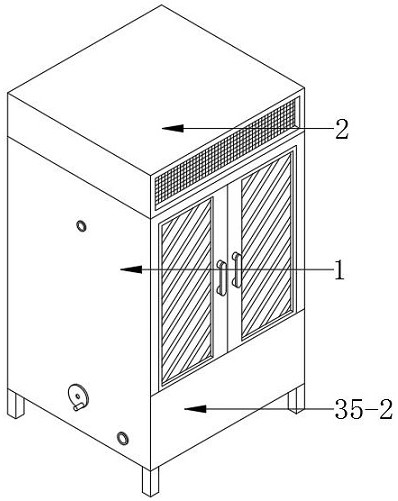

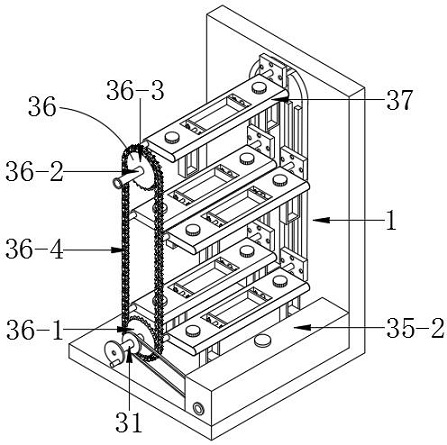

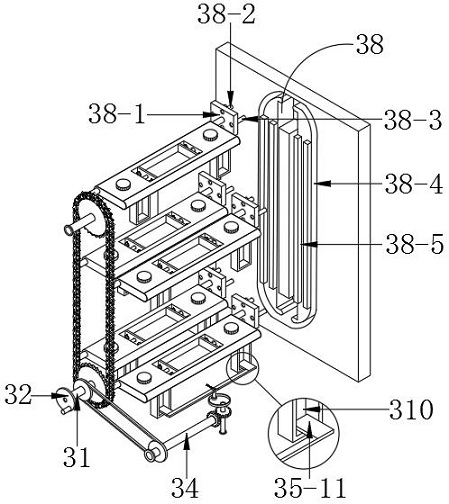

Shaft type vertical multi-spindle numerical control lathe with narrow-spacing multi-shaft station storing and extending function

ActiveCN110405228AImprove working conditionAchieve horizontal positioningAuxillary equipmentLarge fixed membersNumerical controlEngineering

The invention provides the shaft type vertical multi-spindle numerical control lathe with the narrow-spacing multi-shaft station storing and extending function. The lathe structurally comprises a protective door, a vertical lathe power column, a lathe fault alarm lamp, a turnover hidden type regulating and controlling table, narrow-spacing multi-shaft station storing and extending device and a numerical control lathe body, wherein the protective door is mounted on the left side face of the numerical control lathe body in an embedded mode, and the vertical lathe power column is arranged at thetop end of the numerical control lathe body. According to the lather, spindles and machining stations inside the numerical control lathe are arranged in a pairing mode, the stations are set as a mainstation and auxiliary expanding stations, through pulling out a station adding disc originally stored in a station disc, when the lathe carries out single-station or double-station machining under theconstraint of a reverse buckling limiting plate, chippings cut from a workpiece and cooling liquid in a machining process directly fall into a recovery area, so that a clamp on the station to be operated is prevented from being disturbed by the cooling liquid and the chippings, and the clamp can keep a good working state.

Owner:泉州台商投资区海雅达新材料有限公司

Container welding positioning system

ActiveCN105397399AFlexible adjustment of fixed positionReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFixed position

The invention discloses a container welding positioning system. The container welding positioning system sequentially comprises a wall body, a container bottom cover, a lower supporting plate and a rotating connecting block. The container bottom cover is located between the wall body and the lower supporting plate. The container bottom cover is placed on the end face of the lower supporting plate. The rotating connecting block is fixedly connected with the lower supporting plate. The section of the wall body is attached to the section of the container bottom cover. The rotating connecting block is sleeved with a bottom plate. The rotating connecting block is rotationally connected with the bottom plate. The bottom plate is provided with adjusting sliding blocks in sliding connection with the bottom plate. The adjusting sliding blocks are distributed on the bottom plate in the circumferential direction. Wheel mechanisms are fixedly connected to the adjusting sliding blocks. The wheel mechanisms are rotationally connected with a container. A notch is formed in the bottom plate. The fixing position can be flexibly adjusted according to the size of the container, operation is simple, positioning is accurate, the production cost is reduced, and meanwhile the efficient welding process and the high welding quality are guaranteed.

Owner:LINGHANG IND & TRADE ZHEJIANG

Efficient pipe fitting cutting device

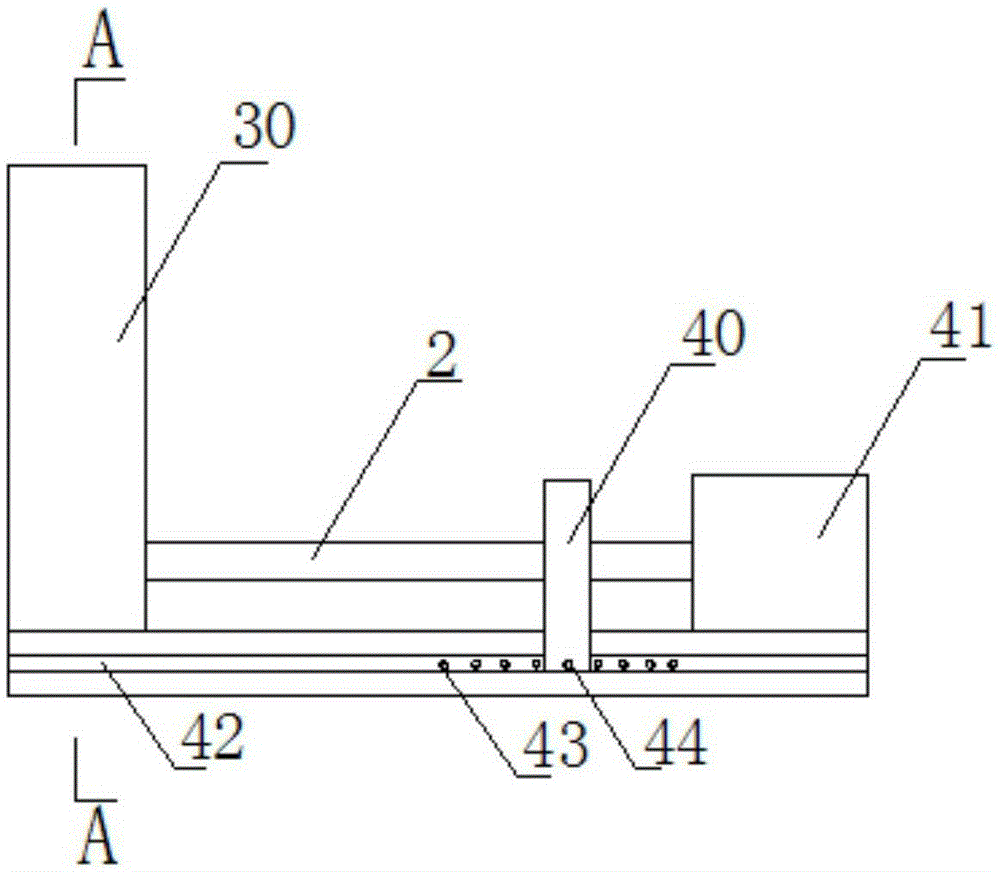

InactiveCN105382602AAvoid jitterImprove cutting accuracyPositioning apparatusMetal-working holdersPipe fittingEngineering

The invention provides an efficient pipe fitting cutting device. The efficient pipe fitting cutting device comprises a worktable, a longitudinal positioning part and a transverse positioning part; the longitudinal positioning part is arranged at one end of the worktable, and comprises a support and three longitudinal positioning cylinders; the three longitudinal positioning cylinders are fixedly connected with the support, respectively; the transverse positioning part comprises a supporting plate and a transverse positioning cylinder arranged at the other end of the worktable; a supporting plate is arranged between the transverse positioning cylinder and the longitudinal positioning part; an expansion link of the transverse positioning cylinder is fixedly connected with the supporting plate. The efficient pipe fitting cutting device is provided with the transverse positioning part and the longitudinal positioning part, respectively, thereby realizing transverse and longitudinal positioning of a machined pipe fitting at the same time; as a result, the size is accurate in the cutting process of the pipe fitting and the cutting accuracy of the pipe fitting is improved; meanwhile, the efficient pipe fitting cutting device is adaptive to cutting pipe fittings of different machined lengths.

Owner:天津建通管业有限公司

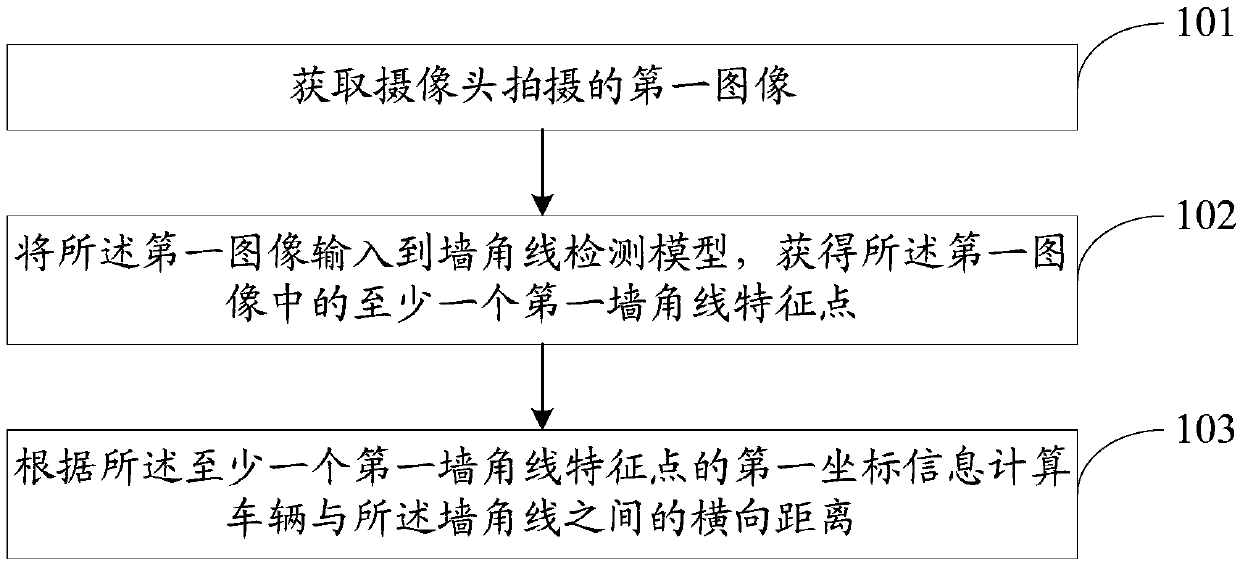

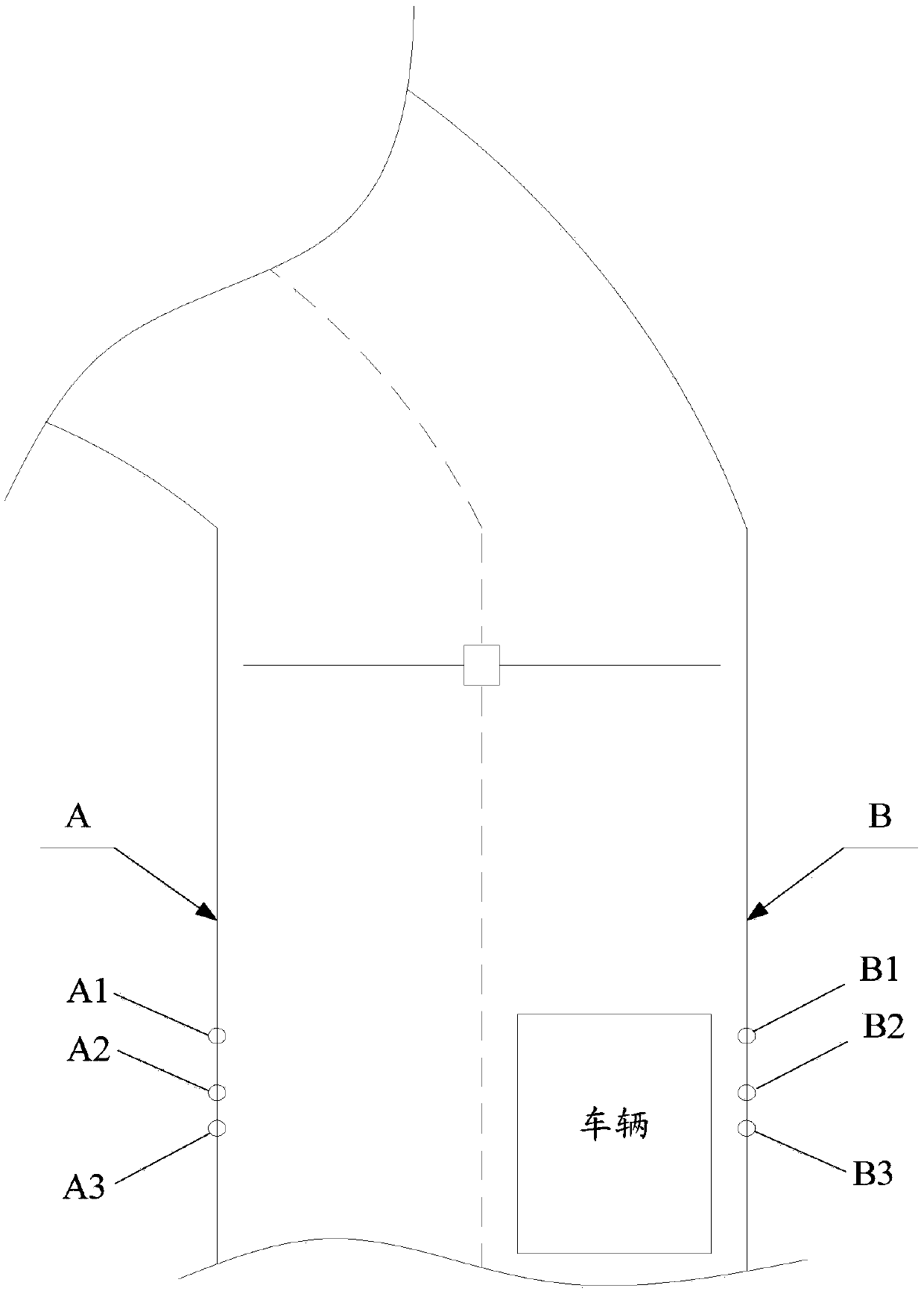

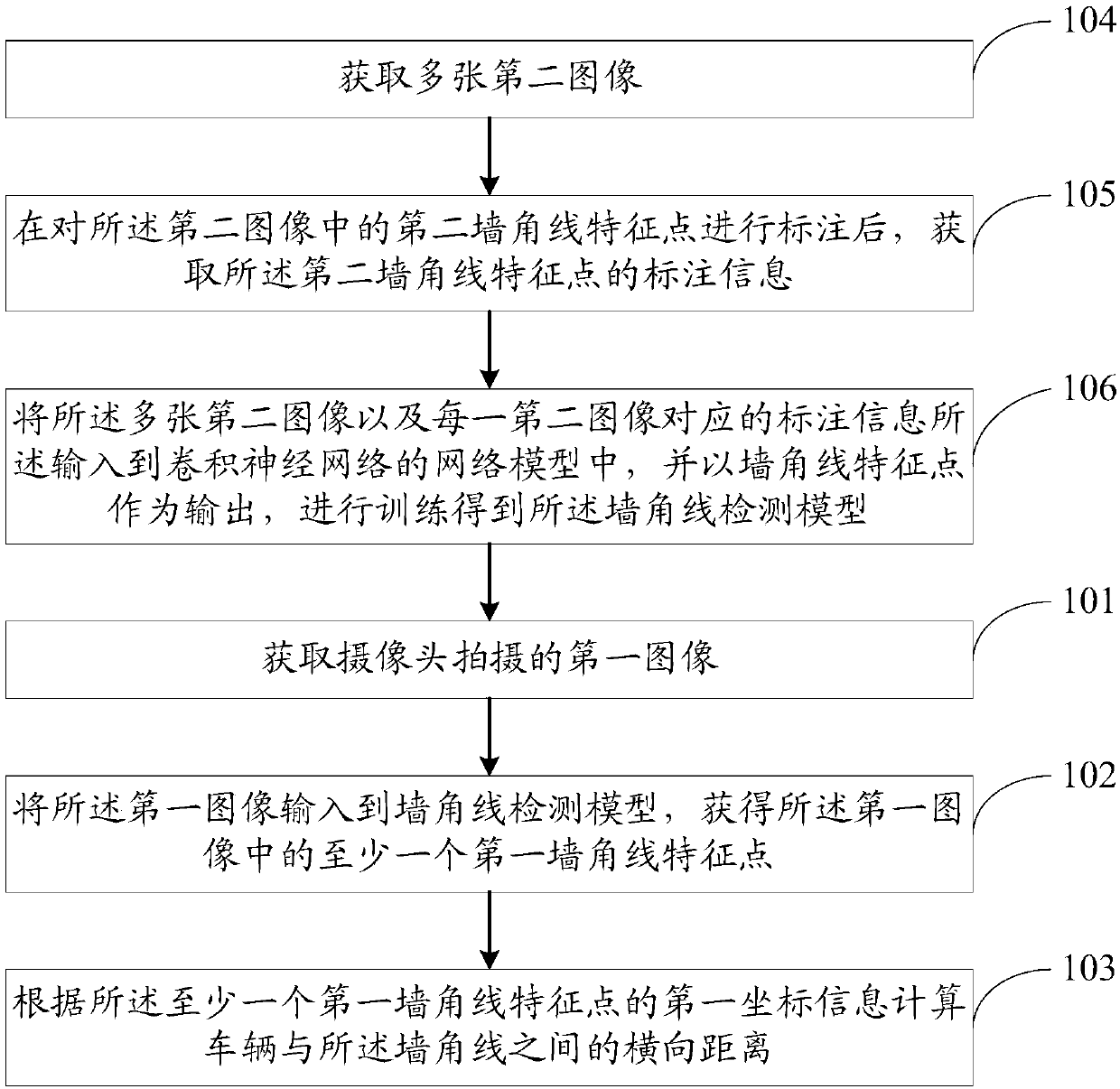

A transverse positioning method and vehicle-mounted equipment

PendingCN109685850AAchieve horizontal positioningImprove reliabilityImage enhancementImage analysisNetwork modelComputer science

The invention provides a transverse positioning method and vehicle-mounted equipment, and the method comprises the steps: obtaining a first image shot by a camera, and enabling the first image to comprise a wall corner line of at least one side of a vehicle; Inputting the first image into a wall corner line detection model to obtain at least one first wall corner line feature point in the first image, the wall corner line detection model being a network model trained by using a convolutional neural network; And calculating the transverse distance between the vehicle and the wall corner line according to the first coordinate information of the at least one first wall corner line feature point. The reliability of vehicle transverse positioning is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Horizontal positioning mechanism of ultrasonic welding equipment

PendingCN110614426AIncrease productivityReduce labor costsNon-electric welding apparatusUltrasonic weldingEngineering

The invention relates to the technical field of ultrasonic welding equipment, in particular to a horizontal positioning mechanism of the ultrasonic welding equipment. In order to solve the problems that in the prior art, a conveyor belt is used for indirect feeding, an ultrasonic welding machine needs to weld materials in the material conveying pause period, and the working efficiency cannot meetproduction requirements. The horizontal positioning mechanism is characterized by comprising a conveyor belt, a double-station carrier moving in the conveying direction of the conveyor belt is arranged on the conveyor belt, and a first positioning mechanism for horizontally positioning the double-station carrier is arranged on the conveyor belt. According to the mechanism, constant uninterrupted conveying work is kept between the input end and the output end of a base material, so that procedures matched with the ultrasonic welding machine on a production line are not affected, and the weldingquality is stable.

Owner:SUZHOU RS TECH

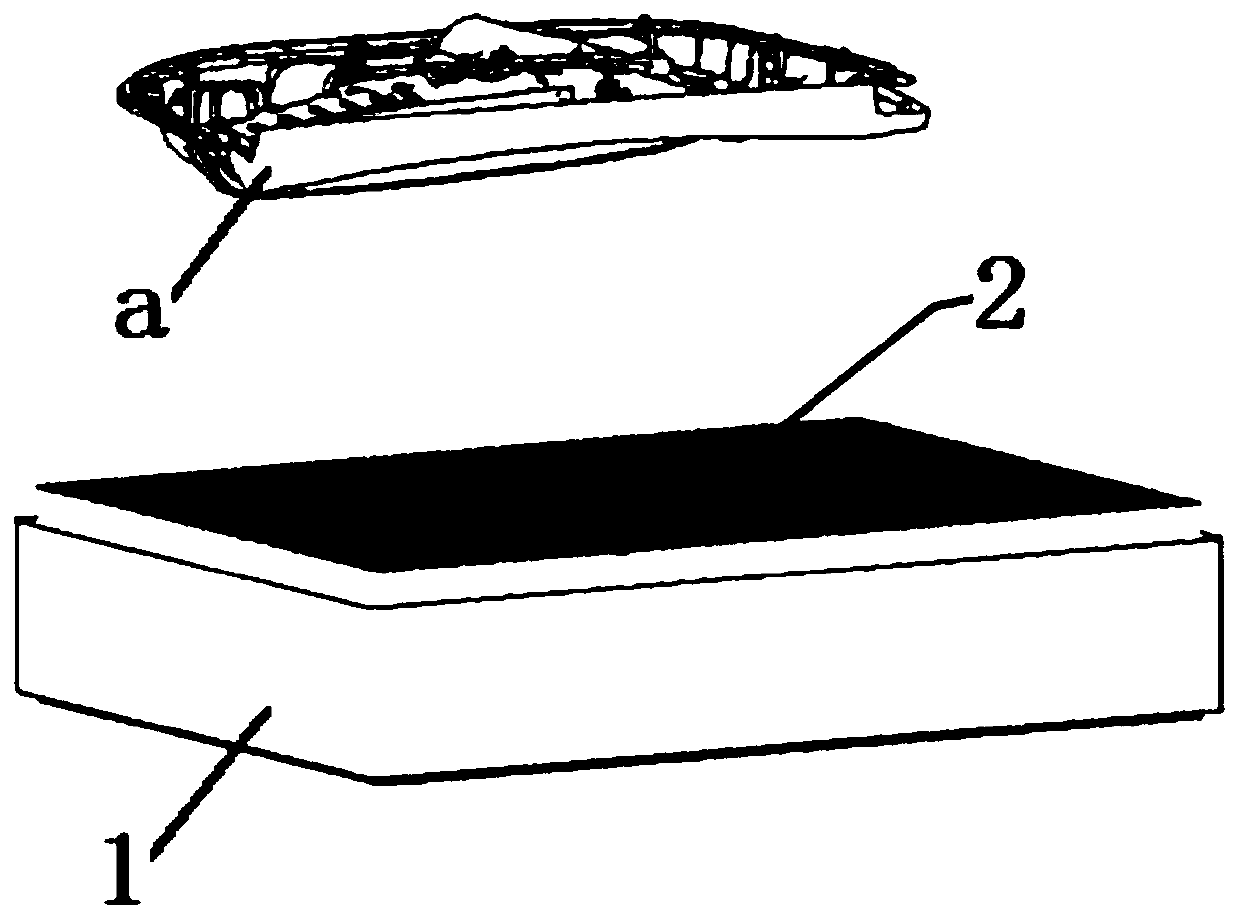

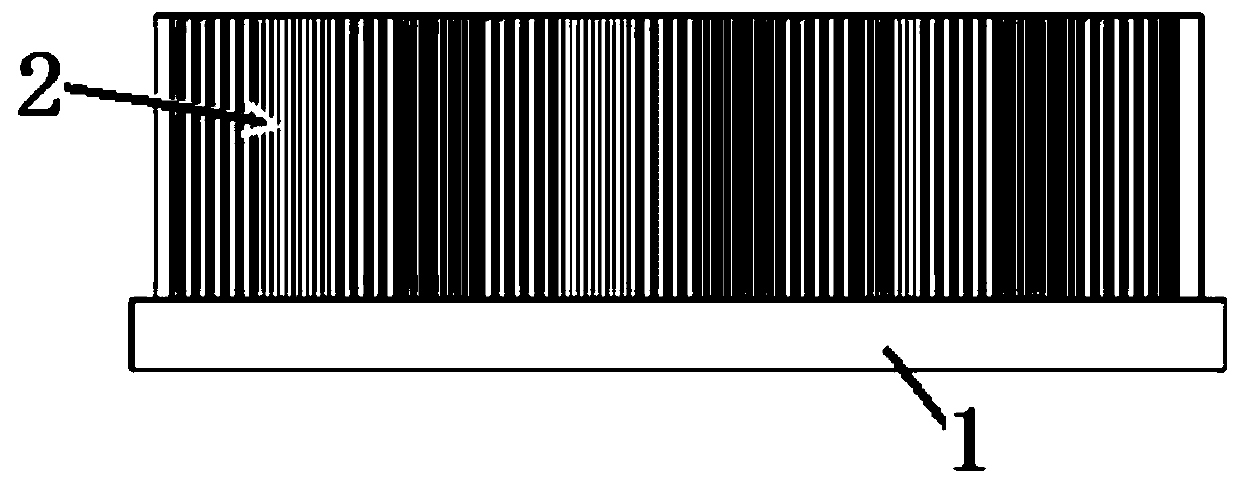

Novel universal flexible automobile door panel assembly jig

InactiveCN111318988AEasy to locateQuick switchWork holdersStructural engineeringMechanical engineering

The invention discloses a novel universal flexible automobile door panel assembly jig. The novel universal flexible automobile door panel assembly jig comprises a flexible jig body, a plurality of telescopic rods are movably inserted in the flexible jig body. The plurality of telescopic rods are movably inserted into the flexible jig body, so that when a door panel needs to be positioned, the doorpanel only needs to be placed on the telescopic rods, then the inserting height of the telescopic rods is adjusted according to the shape of the door panel, the positions of the telescopic rods are fixed after the telescopic rods are adjusted, namely the door panel can be positioned, the positioning mode of the door panel is simple and convenient, can be quickly switched among different door panel items, high in the efficiency, and can be adjusted in real time according to different shapes of door panels, so that the applicability of the door panel assembly jig is improved, waste is avoided,the manufacturing cost is reduced, and resources are saved, and the novel universal flexible automobile door panel assembly jig is suitable for automobile door panel production.

Owner:DONGFENG VISTEON AUTOMOTIVE TRIM SYST CO LTD

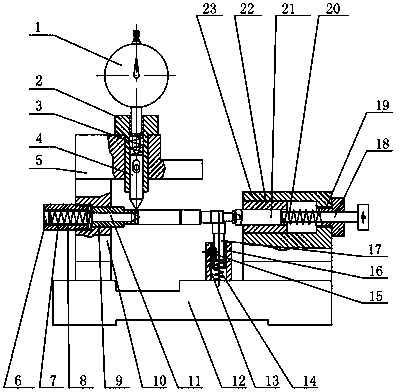

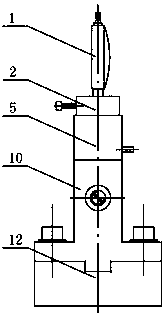

Tool structure for measuring plunger bottom clearance groove depths

InactiveCN103808237ASimple structureEasy to installMechanical depth measurementsElectrical and Electronics engineeringPlunger

The invention relates to a tool structure for measuring plunger bottom clearance groove depths. The tool structure comprises a base, a first assembling unit and a measuring unit, wherein the first assembling unit is perpendicular to the measuring unit. Second assembling units are further arranged on the base relative to the first assembling unit at intervals. The tool structure is simple and convenient to install, the first assembling unit and the second assembling units are utilized to effectively achieve horizontal positioning of plungers, standard positioning of the plungers is achieved by arranging flat position columns, accuracy in plunger bottom clearance groove measurement is guaranteed, and the tool structure is flexible and convenient to adjust and effectively achieves depth measurement of massive plunger bottom clearance grooves of different sizes.

Owner:无锡威孚马山油泵油嘴有限公司

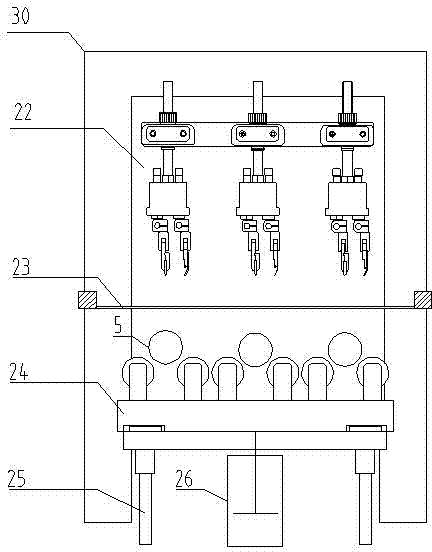

Device for curved surface printing and working method thereof

ActiveCN104118200AAchieve high positioningRealize the height positioning of the workpieceRotary pressesWorking setPrinting ink

The invention discloses a device for curved surface printing. The device comprises a rack, and the rack is provided with a conveying device, a multi-station automatic curved surface screen printing machine and a printing ink solidifying device. The multi-station automatic curved surface screen printing machine comprises an upper curved screen printing device and a lower auxiliary printing device which is matched with the upper curved screen printing device. The upper curved screen printing device comprises a fixing rack arranged on the rack, and a printing mechanism and a net plate are sequentially arranged on the front portion of the fixing rack from top to bottom. The lower auxiliary printing device comprises a workpiece bracket arranged on the rack, a riding wheel set is arranged on the upper portion of the workpiece bracket, and a bracket guide mechanism and a bracket driving mechanism are arranged on the lower portion of the workpiece bracket. The device for curved surface printing further comprises a positioning device arranged on the multi-station automatic curved surface screen printing machine. By means of the device for curved surface printing, one-time multi-workpiece printing can be achieved, and production efficiency is improved; multi-workpiece automatic continuous printing is achieved, production labor is reduced, and the production efficiency is improved; on-line operation of printing and other production processes is realized.

Owner:四季沐歌(洛阳)太阳能有限公司

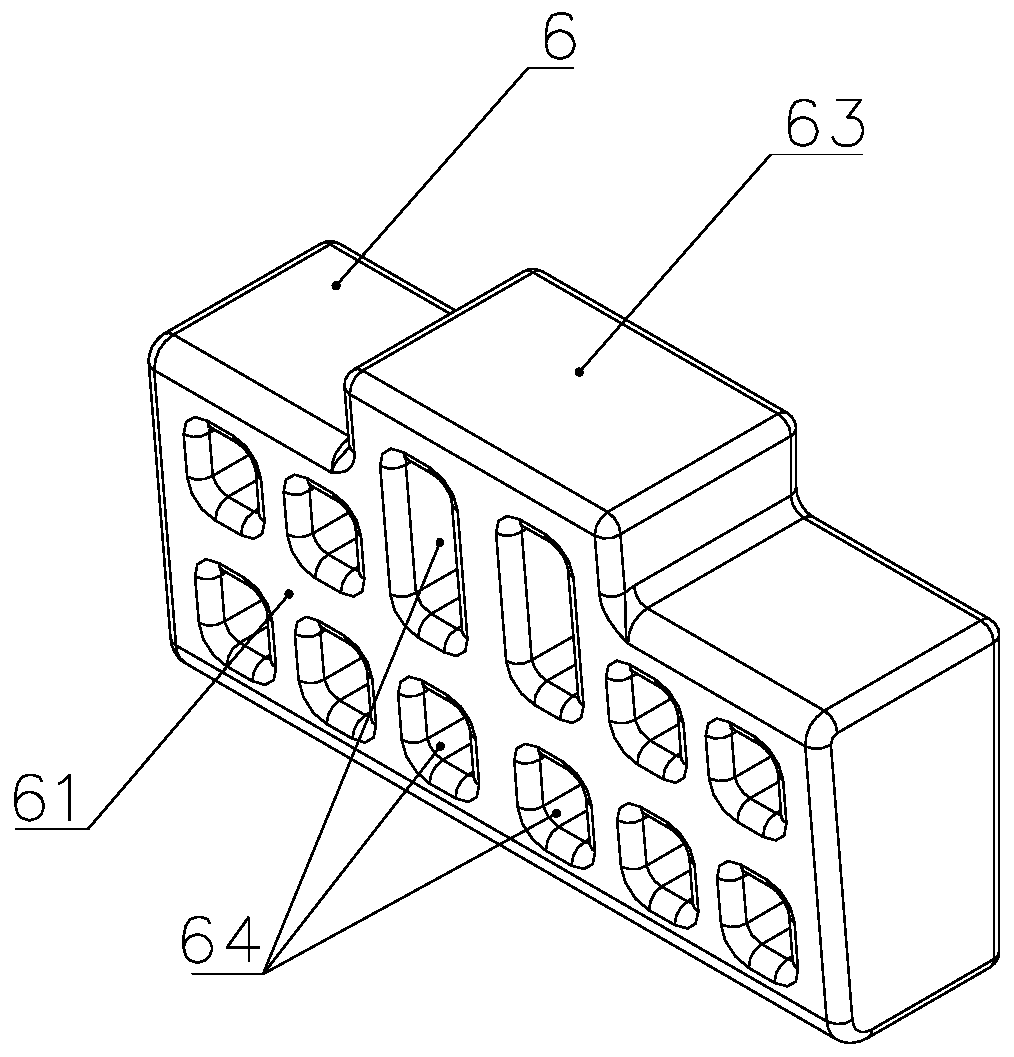

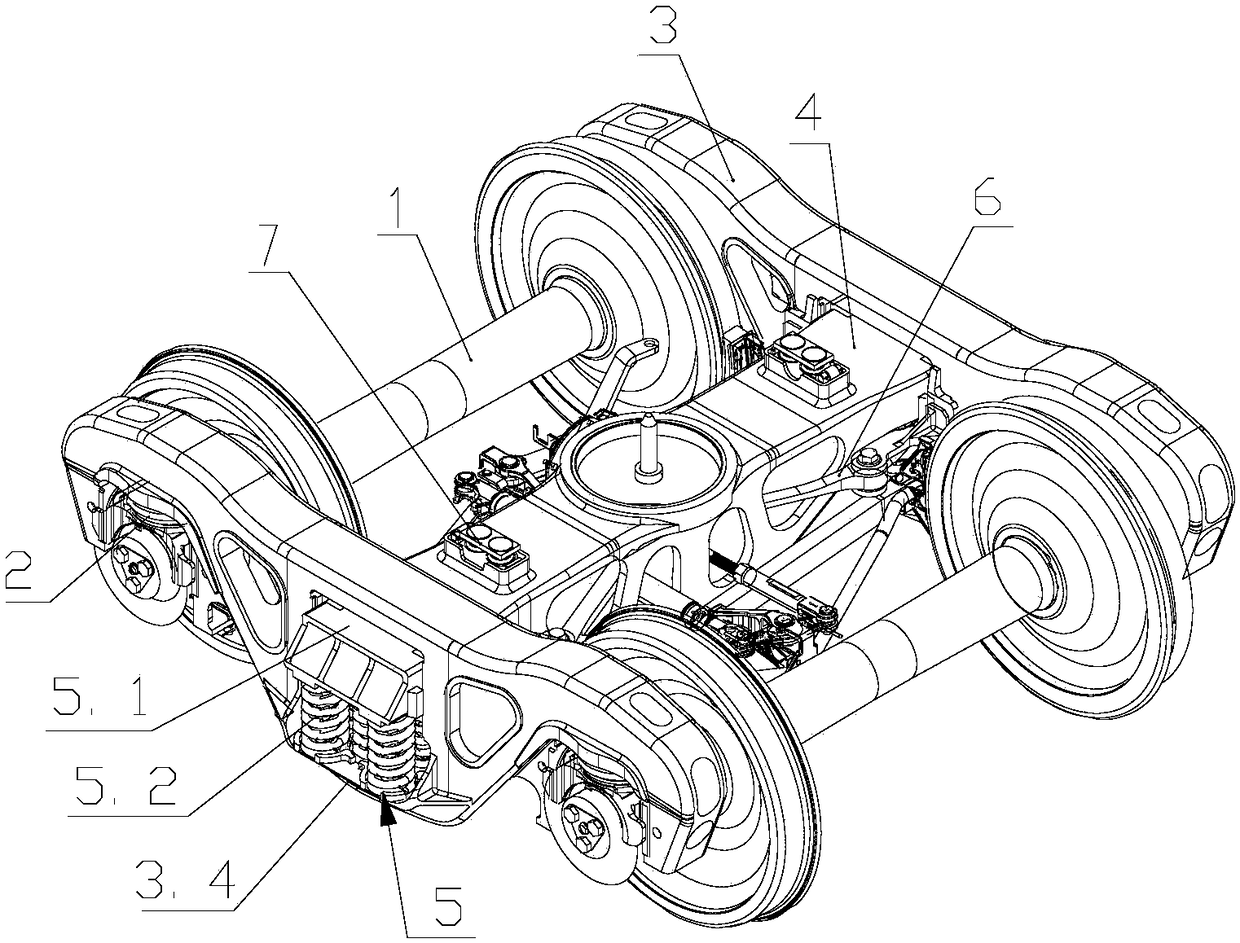

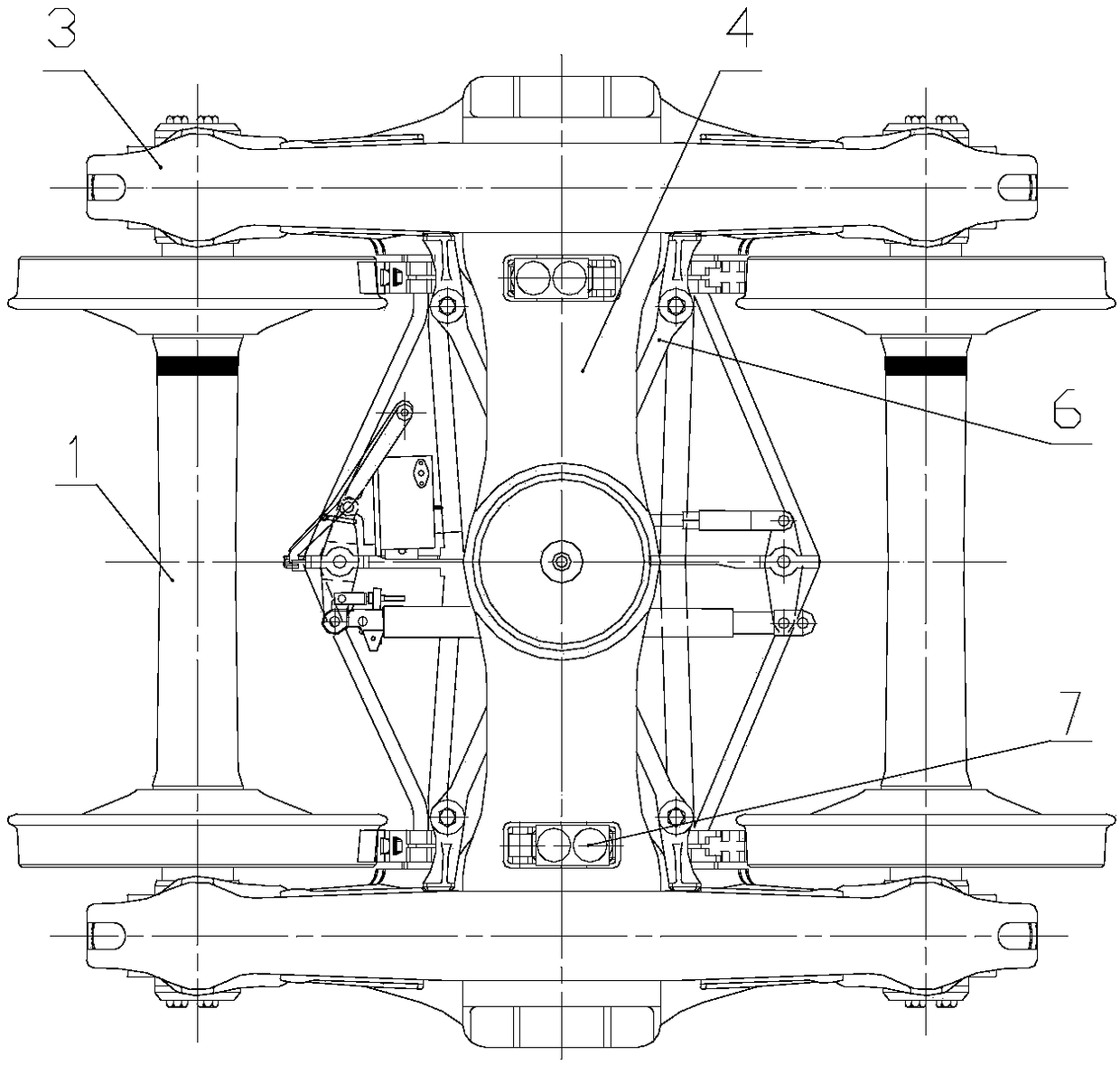

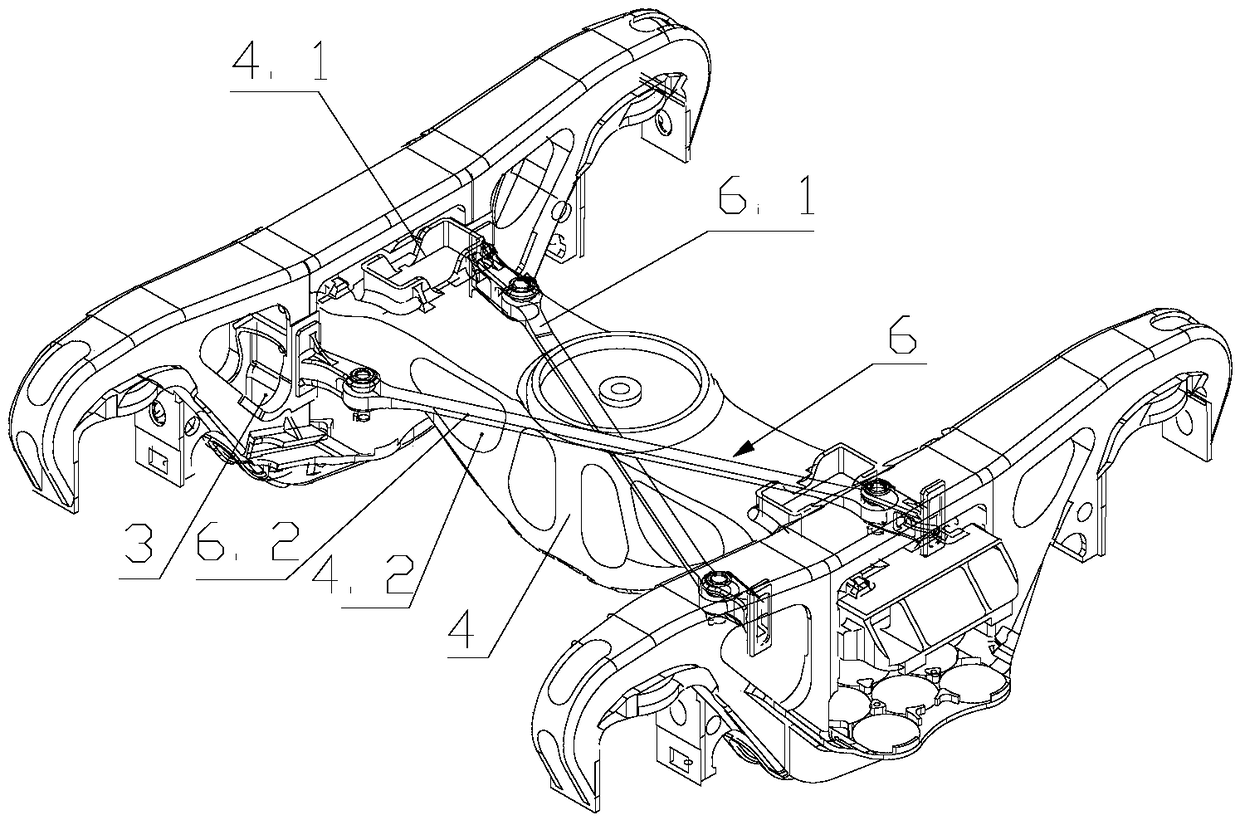

Flexible axle boxes and assembling method thereof, and bogie

InactiveCN108238061AAchieve horizontal positioningEasy to installBogie-underframe connectionsAxle-boxes mountingBogieInstability

The invention discloses flexible axle boxes and an assembling method thereof, and a bogie. The bogie comprises two sets of wheel pairs; the flexible axle boxes are symmetrically arranged on the two sides of each set of wheel pair; each flexible axle box comprises a flexible axle box body, side beam compositions are arranged on the two flexible axle box bodies on the same sides, and cross beam compositions perpendicular to the side beam compositions are arranged between the side beam compositions on the two sides; the two ends of the cross beam compositions are arranged in the middles of the side beam compositions through central damping suspension devices; X-shaped connecting rods are arranged below the cross beam compositions; and the two axial ends of the X-shaped connecting rods penetrate through webs on the two sides of the cross beam compositions correspondingly to be fixedly connected with the side beam compositions. According to the flexible axle boxes and the assembling methodthereof, and the bogie, the X-shaped connecting rods are arranged below the cross beam compositions, the two axial ends of the X-shaped connecting rods penetrate through webs on the two sides of the cross beam compositions correspondingly to be fixedly connected with the side beam compositions, and in the running process of a vehicle, the X-shaped connecting rods can effectively control mutual movement of the two side beam compositions on the left and the right, thus the purpose of inhibiting hunting movement of the bogie is achieved, and the instability critical speed of hunting movement is increased.

Owner:CRRC YANGTZE CO LTD

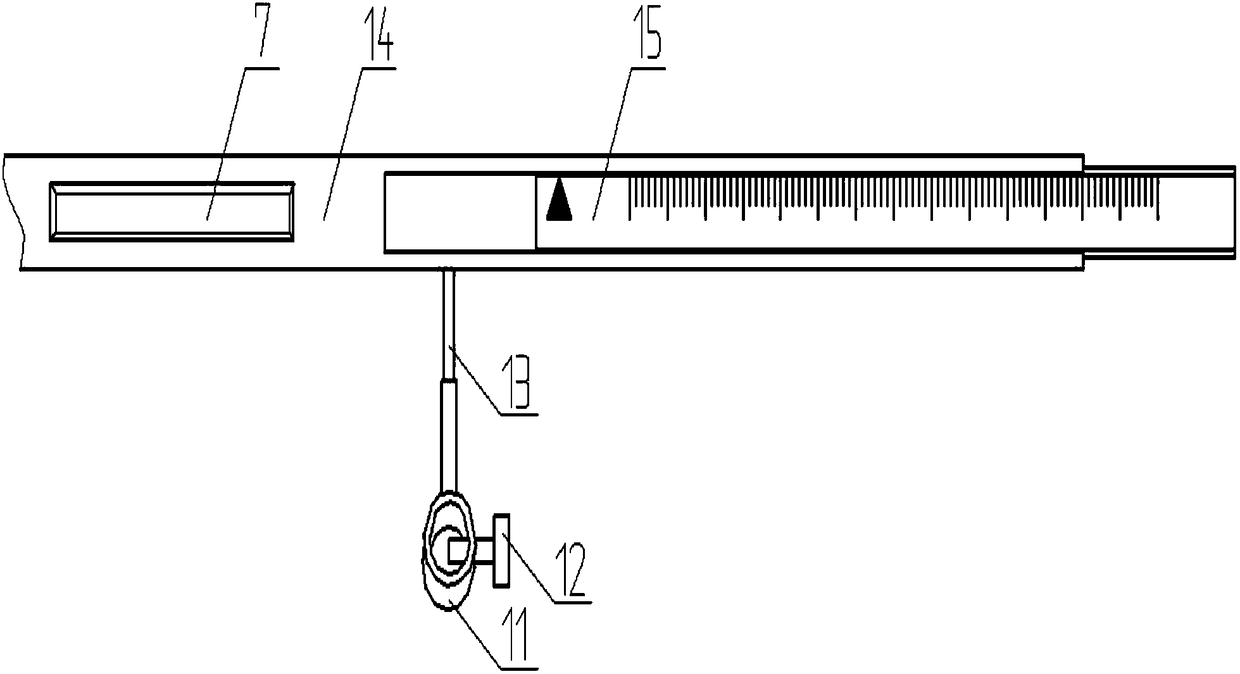

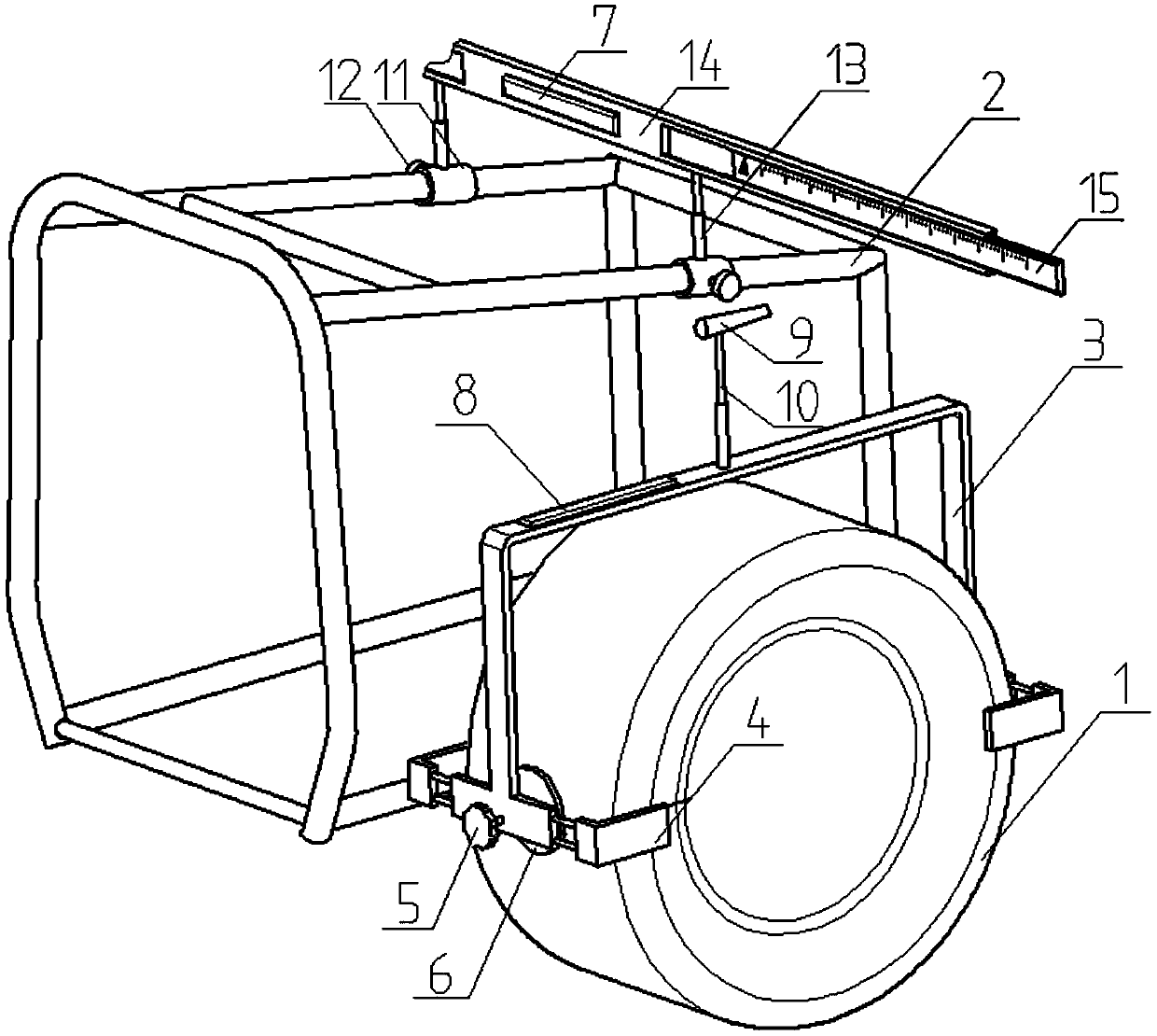

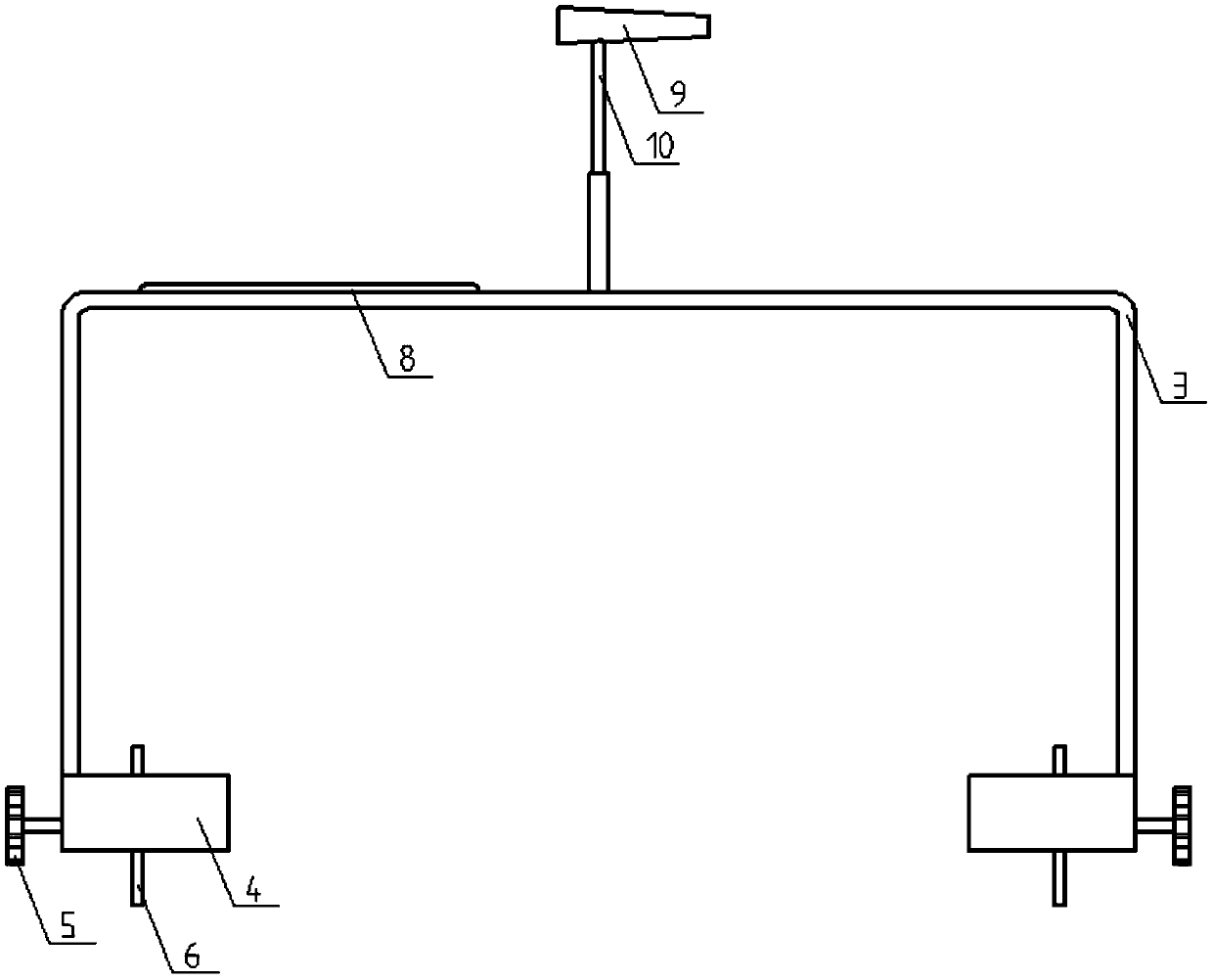

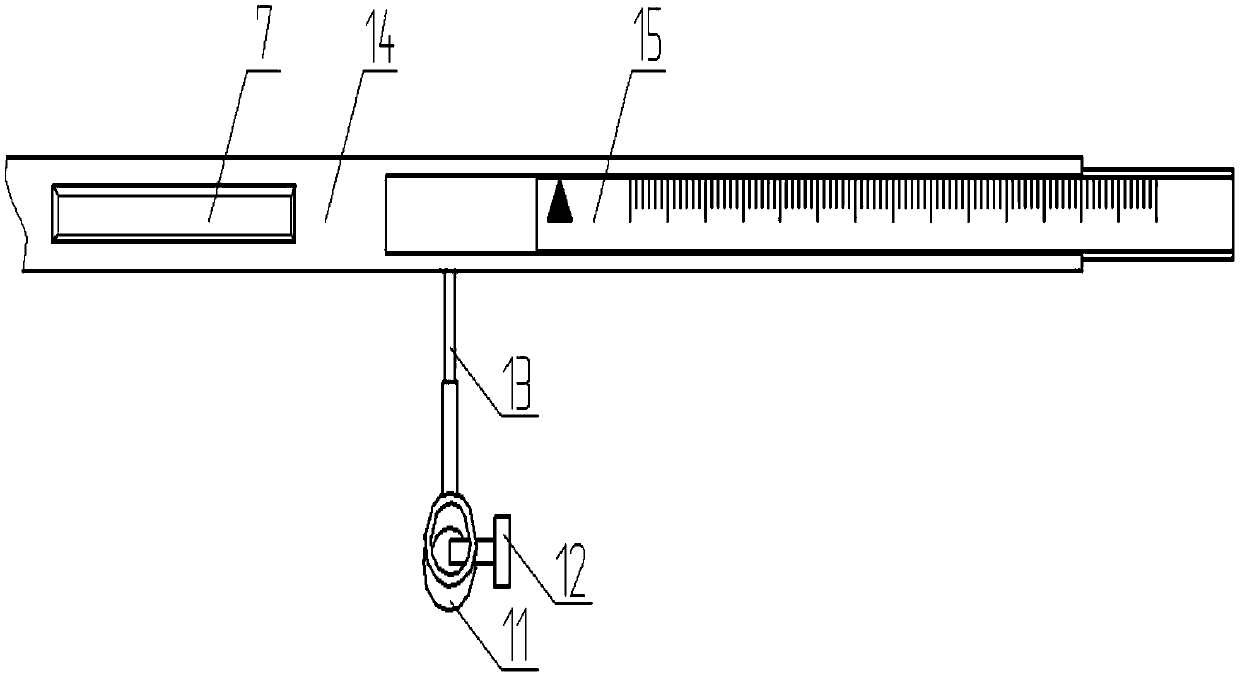

Toe-in angle measuring device of wheel of formula racing car

ActiveCN108844487ALarge adjustable rangeLarge measuring rangeAngles/taper measurementsUsing optical meansSteel tubeVehicle frame

The invention discloses a toe-in angle measuring device of a wheel of a formula racing car, and relates to the field of vehicle detection and positioning. The device comprises a frame, a wheel fixingpedestal, an automatic positioning and clamping device, a horizontal calibrator, a laser emitter and an adjustable calibrated scale with a slide rail; the wheel fixing pedestal with the laser emitteris mounted on the wheel to be measured, and the automatic positioning and clamping device can position the laser emitter in the center of the wheel accurately; and the adjustable calibrated scale withthe slide rail is mounted on a steel pipe in the upper of a car frame, and the calibrated scale on the slide rail is adjusted to measure and position the toe-in angle of the wheels, with different wheelspans, of the formula racing car. The device can carry out measurement without changing a suspension arrangement form, and the wheels, with different wheelspans, of the formula racing car can be measured. Compared with the prior art, the device only measure the wheel of 1 / 4 suspension, a measuring process is simple, accurate and efficient.

Owner:JIANGSU UNIV

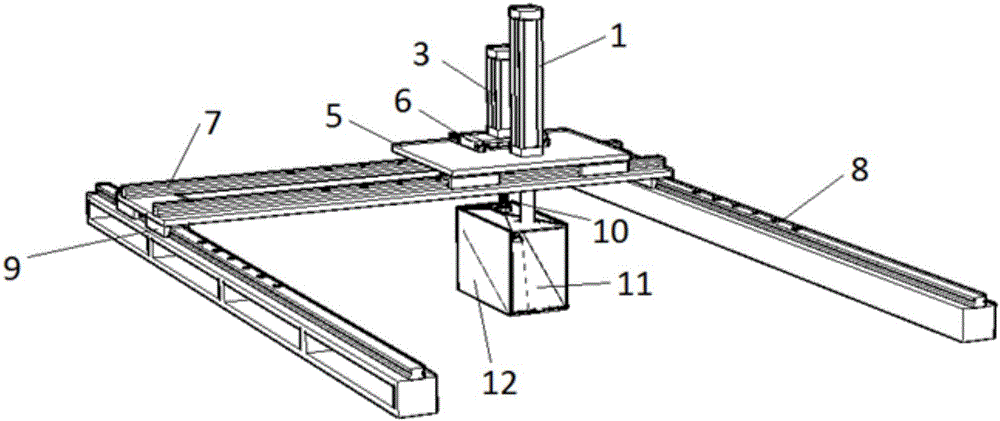

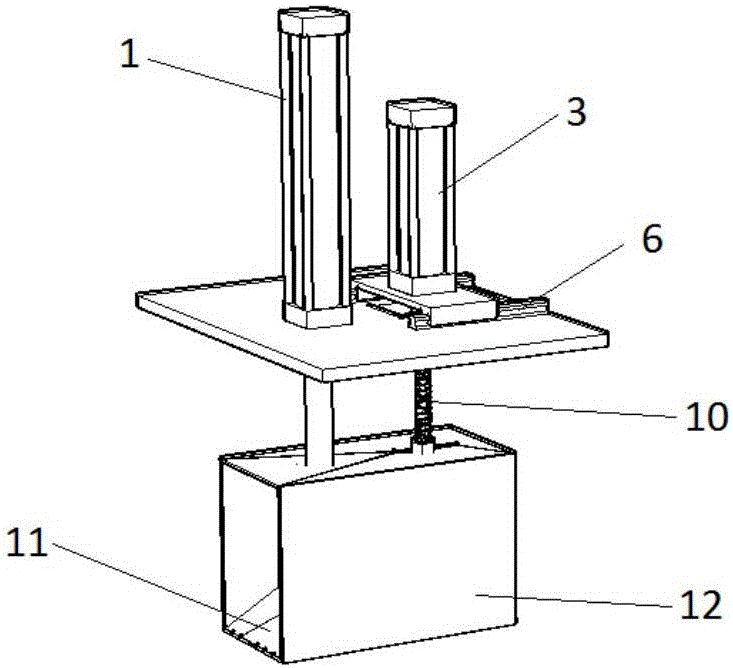

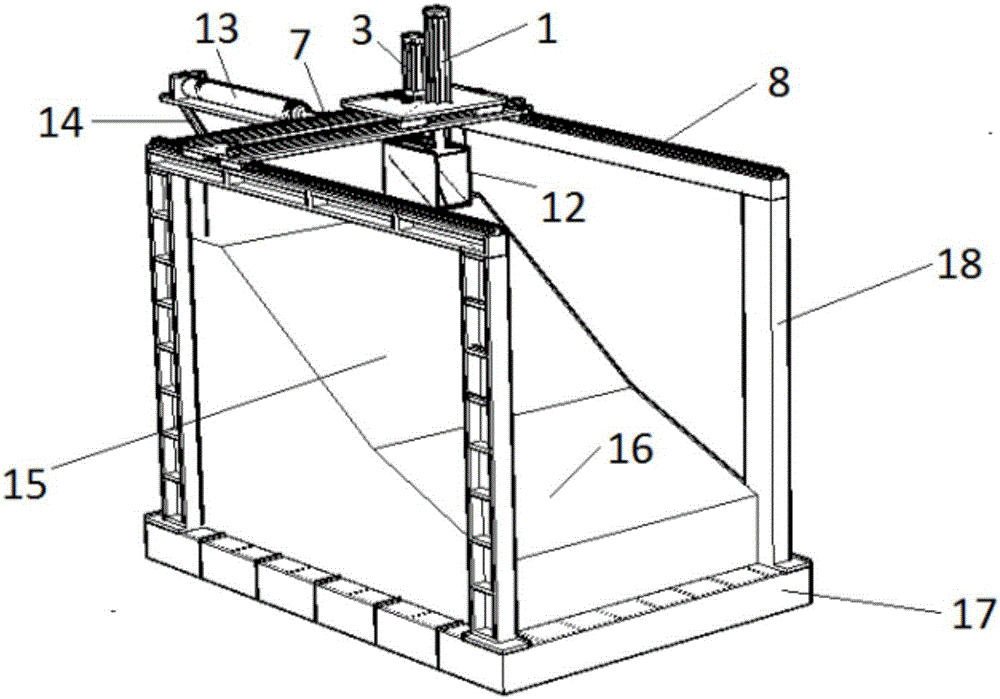

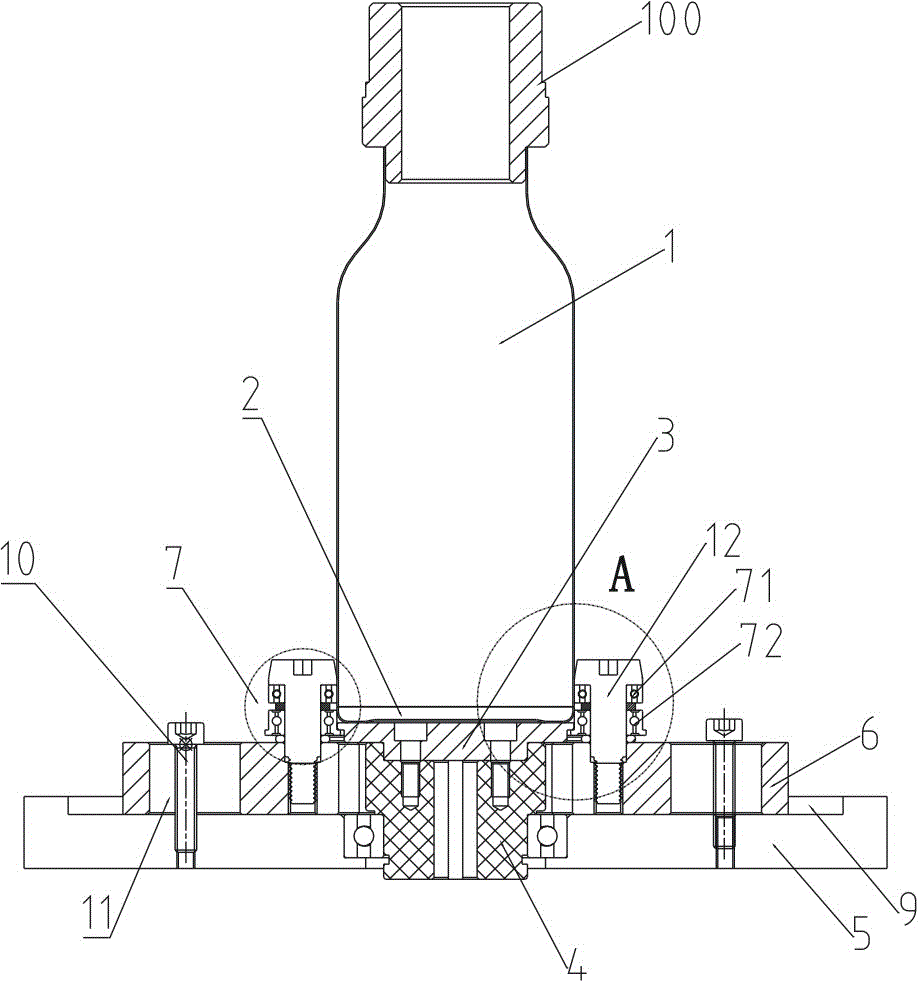

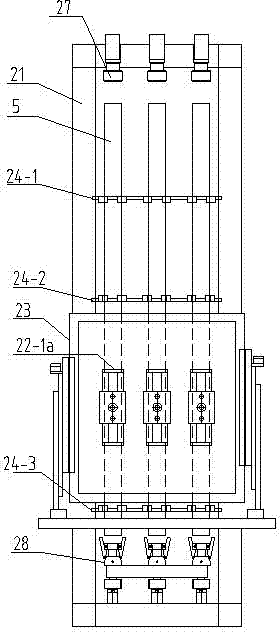

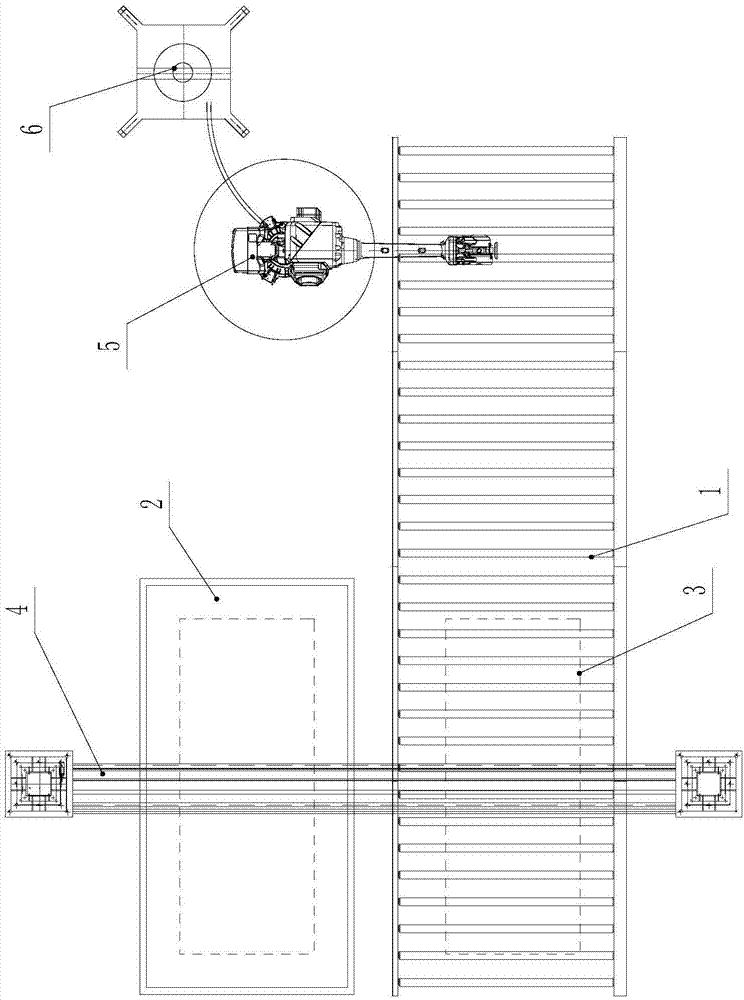

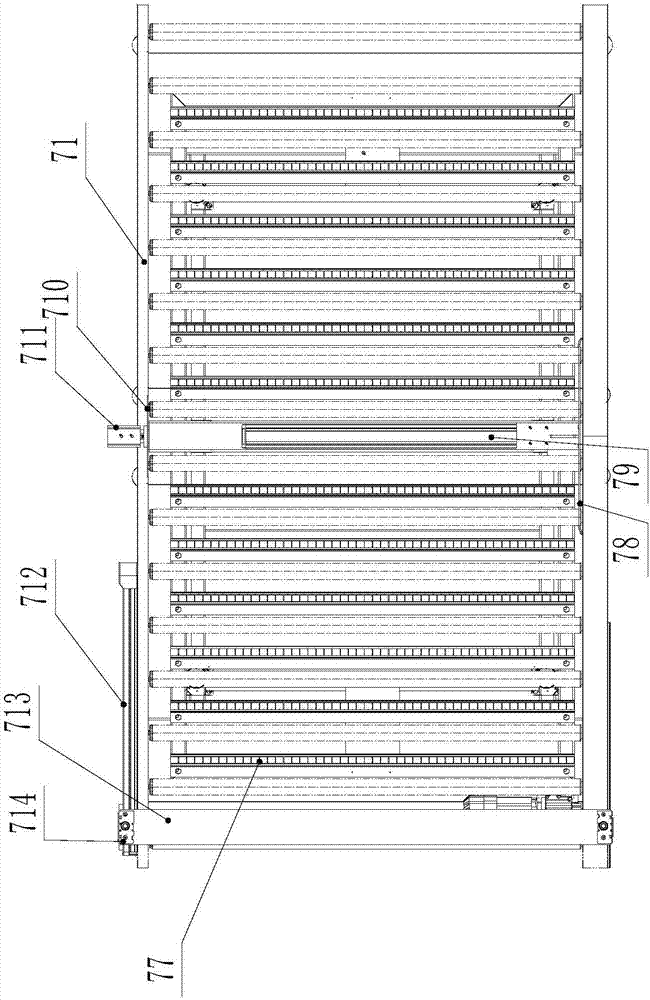

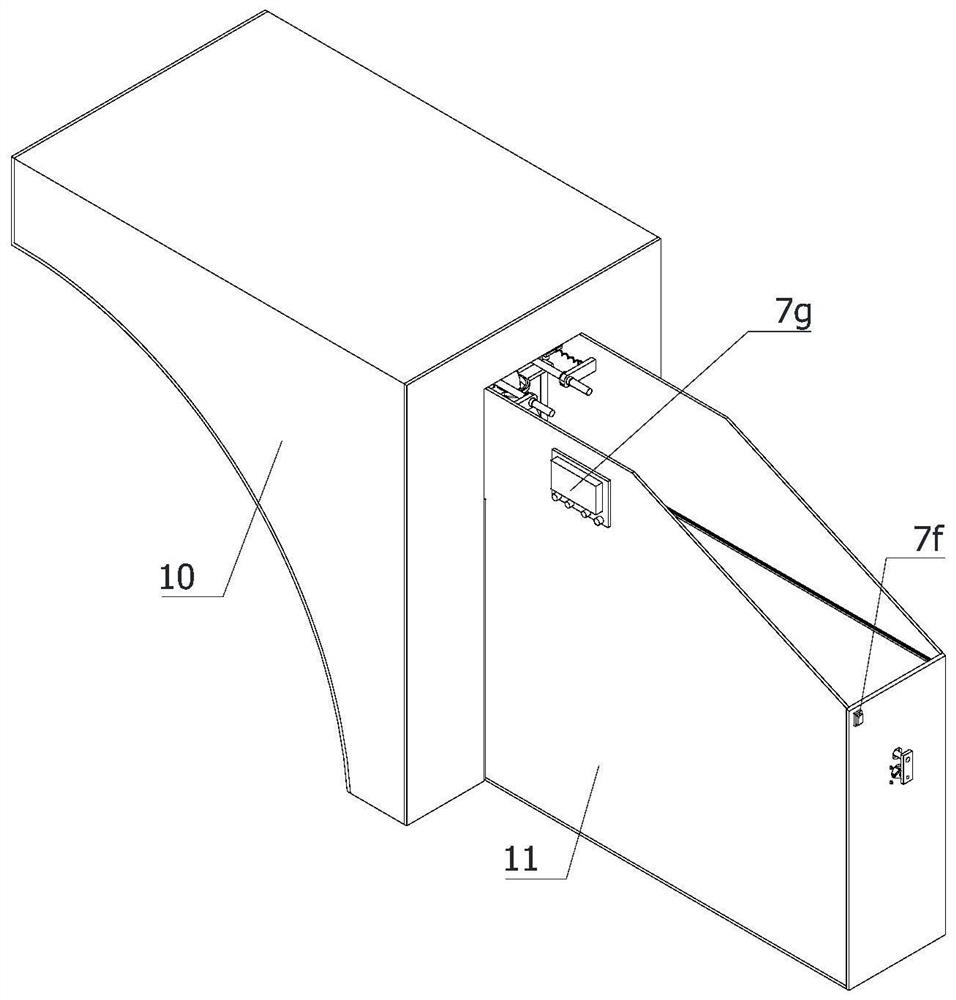

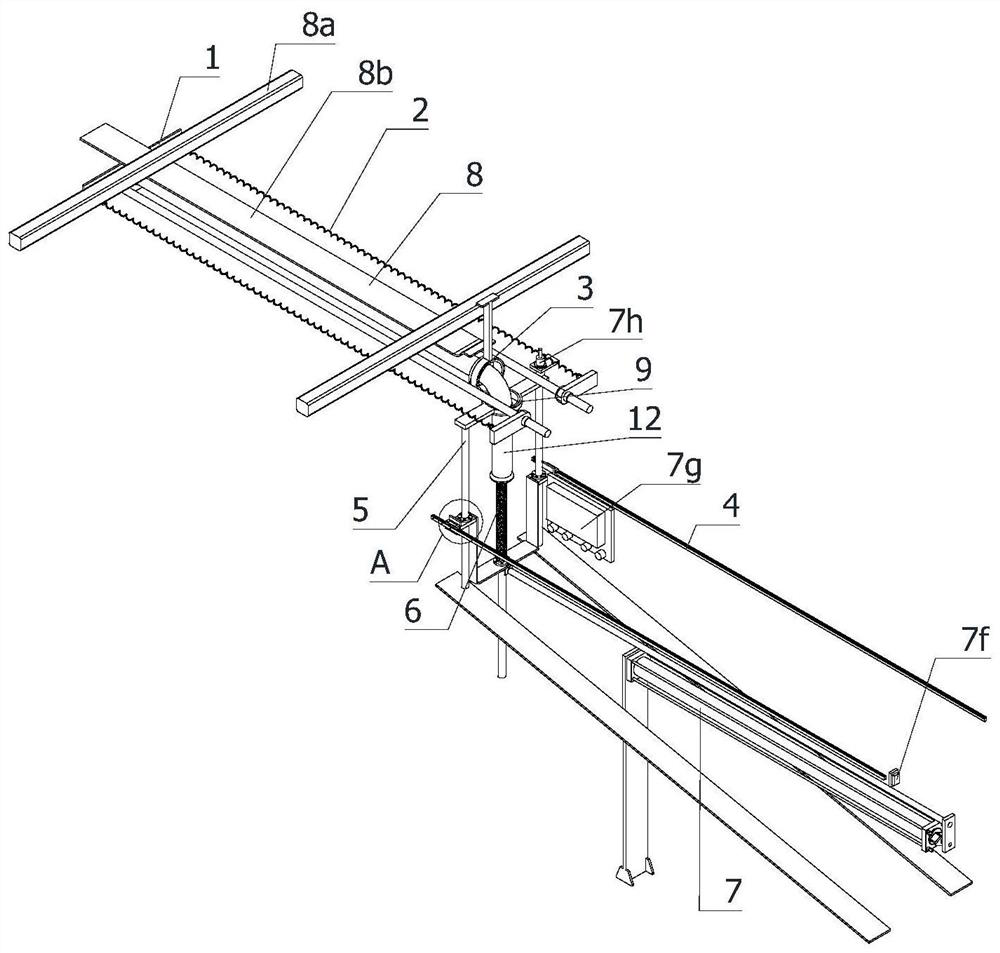

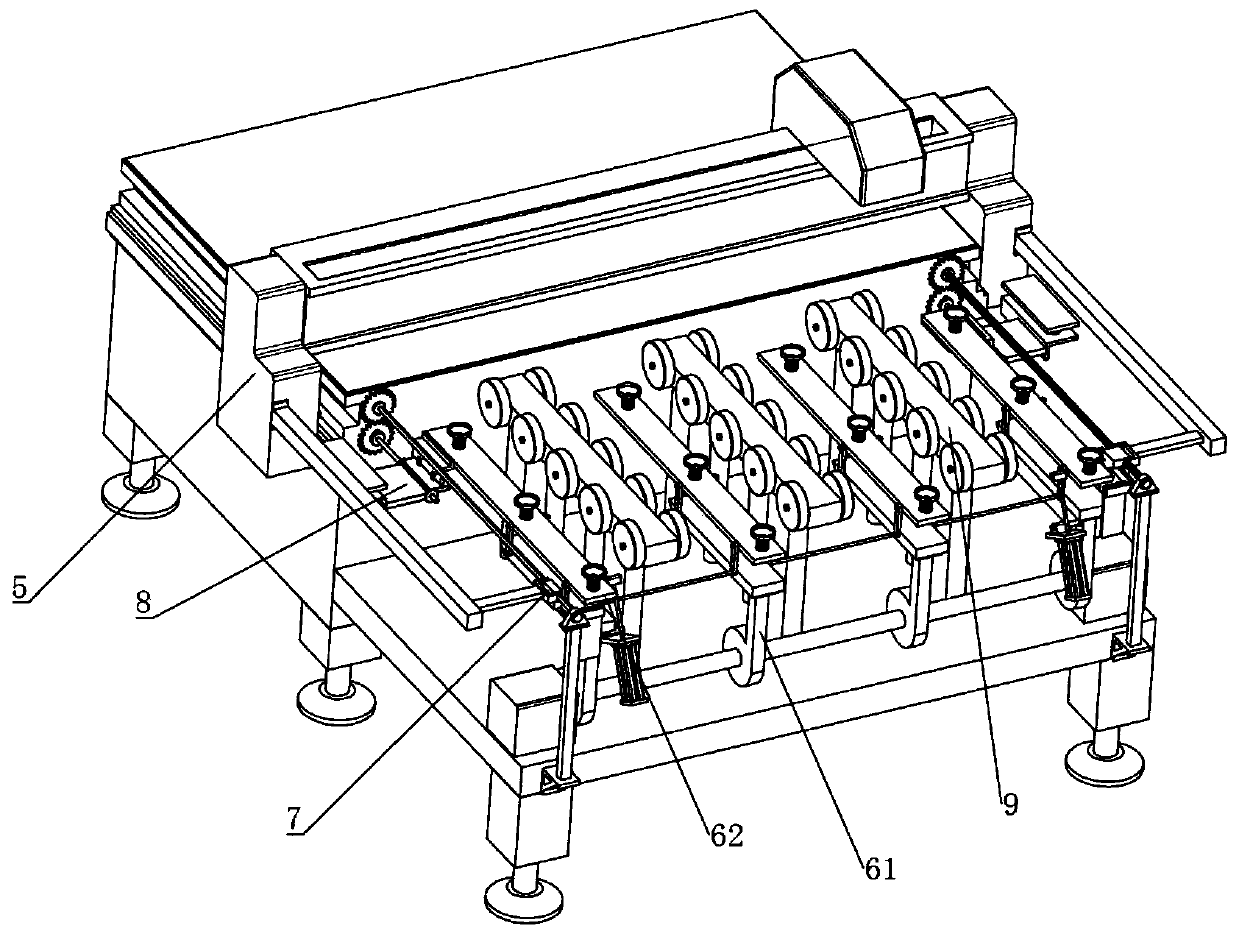

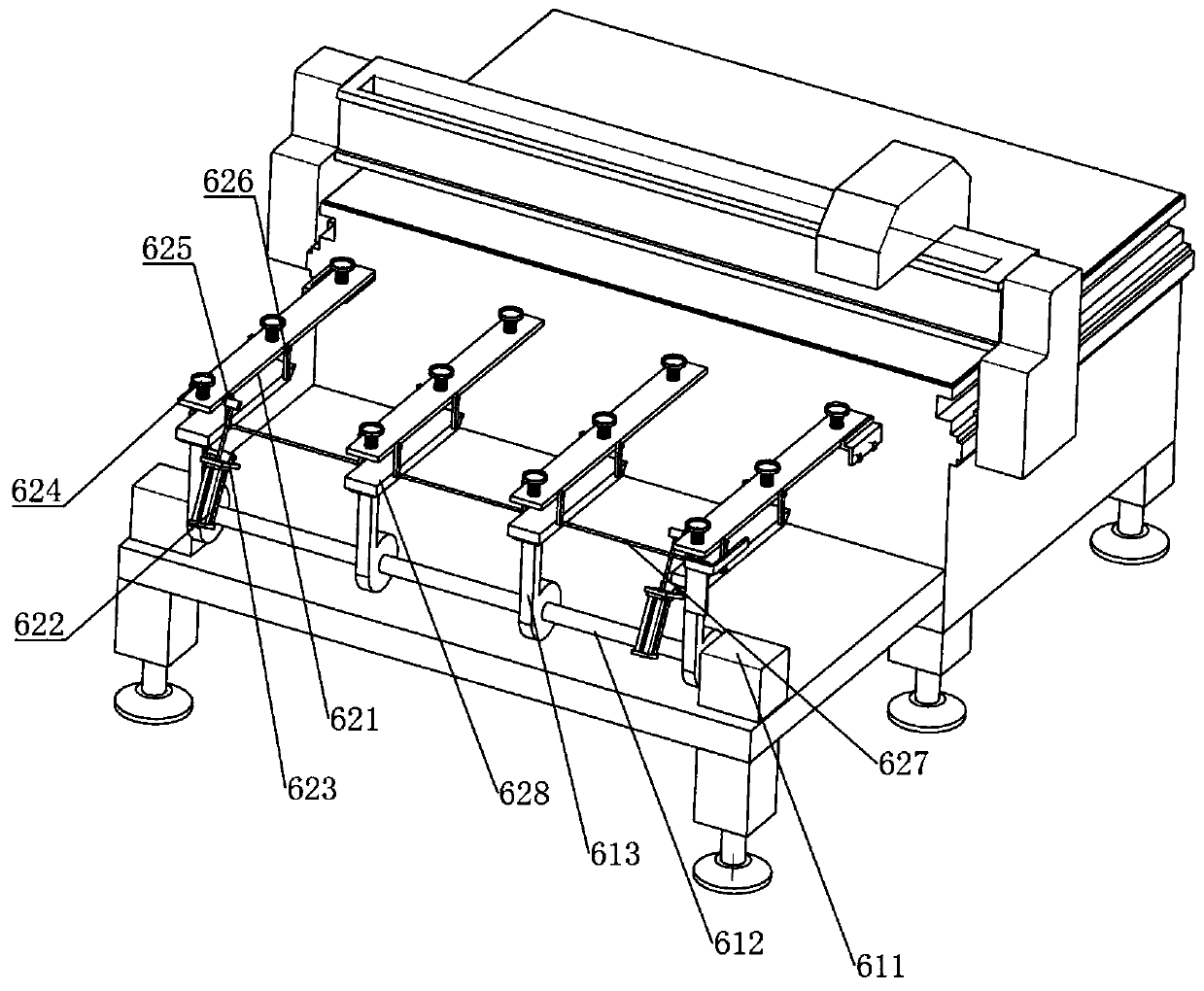

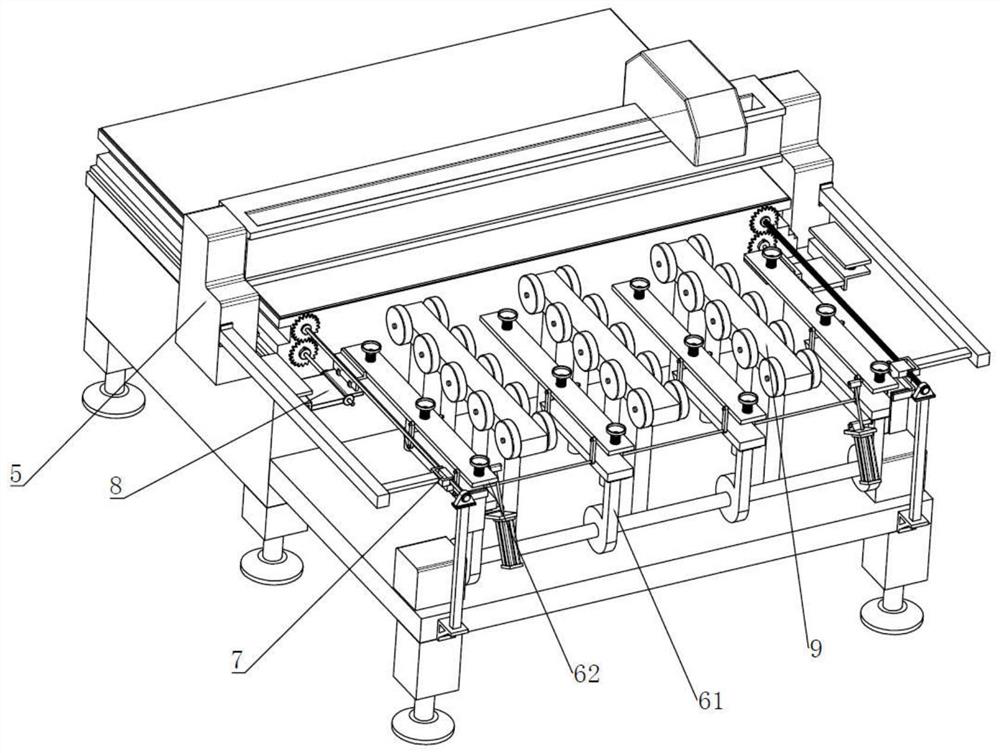

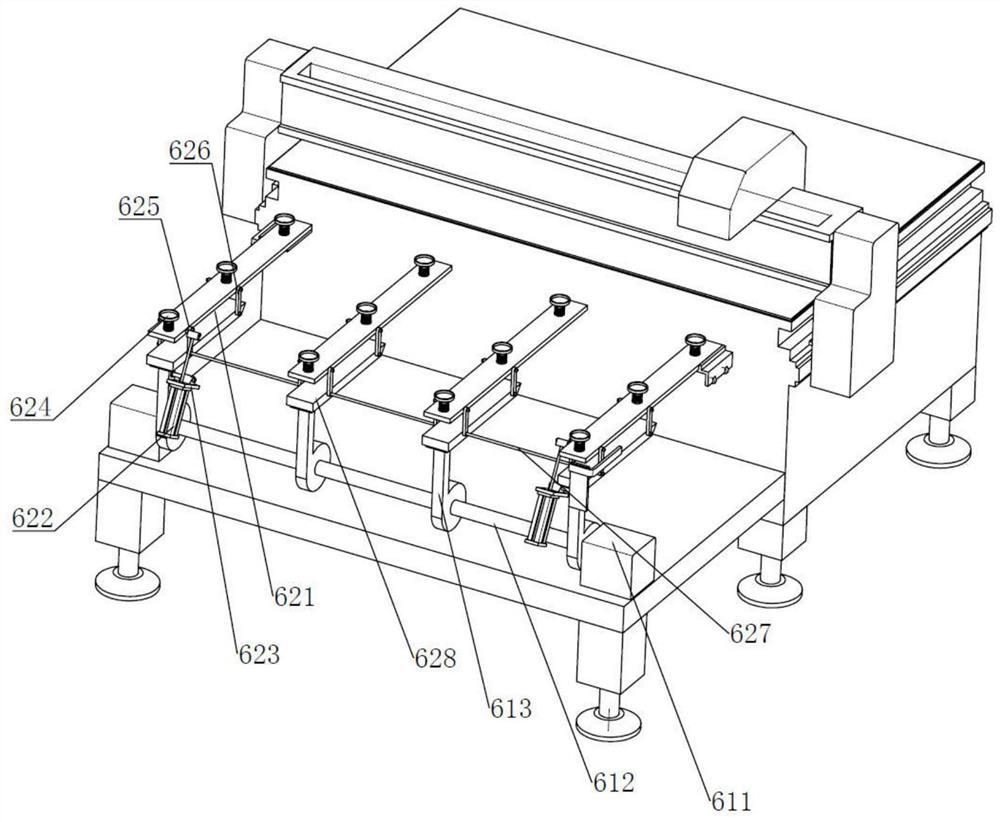

Automatic insulated cotton feeding robot for producing solar collector

PendingCN107243896AAchieve horizontal positioningRealize accurate feedingProgramme-controlled manipulatorMetal working apparatusAgricultural engineeringCollector device

The invention discloses an automatic insulated cotton feeding robot for producing a solar collector. The automatic insulated cotton feeding robot comprises a rack, wherein a main conveying roller group is installed on the rack, an assembling and positioning station is formed on the main conveying roller group, and an insulated cotton storage station is formed on one side of the assembling and positioning station; an insulated cotton stacking platform is arranged at the insulated cotton storage station, an assembling and positioning device is arranged at the assembling and positioning station, and a straight moving device which is used for moving insulated cotton to the assembling and positioning station from the insulated cotton storage station is arranged between the assembling and positioning station and the insulated cotton storage station. According to the automatic insulated cotton feeding robot, the automatic feeding of the insulated cotton can be realized, and the feeding accuracy and the feeding efficiency are increased.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

Self-adaptive sand-blasting polishing device for aluminium alloy bend pipe

InactiveCN111975651AEqual grinding forceEqual distanceBlast gunsAbrasive machine appurtenancesSand blastingWork time

The invention relates to the field of aluminium alloy bend pipe polishing, in particular to a self-adaptive sand-blasting polishing device for an aluminium alloy bend pipe. The device comprises a centering fixture mechanism, a guiding sliding mechanism, a horizontal ring-shaped sand-blasting pipe, a horizontal guiding rail, a lifting mechanism, a centering base, a one-way pushing mechanism, a pressing rail, a vertical ring-shaped sand-blasting pipe, a containing box body, and a pushing box body. The self-adaptive sand-blasting polishing device for the aluminium alloy bend pipe realizes the automatic clamping of the aluminium alloy bend pipe, ensures the equal distance between the outer wall of the aluminum alloy bend pipe and the inner side of the horizontal ring-shaped sand-blasting pipe,and ensures that the brightness of the external wall of the aluminum alloy bend pipe is basically the same after polishing, so that the device can polish all aluminum alloy bent pipes with differentheights, and polish both sides of the aluminum alloy bent pipe simultaneously, so as to improve the working efficiency of the device and reduce the working time of a worker.

Owner:孔霄

Civil air defense door machining device and method capable of reducing deformation

PendingCN114850713ASmall overall deformationGuaranteed connection strengthWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringConstruction engineering

The civil air defense door machining device comprises a machine frame, longitudinal supporting rods are arranged on the two sides of the upper end of the machine frame and used for supporting reversely-buckled angle steel, and an angle steel side end positioning mechanism is arranged on the portion, between the two longitudinal supporting rods, of the machine frame. An angle steel upper end positioning mechanism is arranged above the longitudinal supporting rod and used for pressing and positioning the bearing plate and the inclined flat steel to the upper side of the angle steel. The multiple connecting plates are fixed to the lower side between the bearing plate and the inclined flat steel at intervals in the longitudinal direction, the connecting plates are fixedly connected with the angle steel in a welded mode, the sides, away from the connecting plates, of the bearing plate and the inclined flat steel are fixedly welded to the angle steel, the welding positions are dispersed, and the connecting strength of the bearing plate, the inclined flat steel and the angle steel is guaranteed; and meanwhile, the problem that the angle steel is greatly deformed due to concentrated welding positions is also avoided.

Owner:河南鼎力人防设备有限公司

An integrated system with a circular field of view

ActiveCN108845329BCompact structureSimple compositionElectromagnetic wave reradiationICT adaptationHigh resolution imagingEngineering

The invention provides an integrated system of an annular visual field, wherein a common main optical system, and independent subsequent elements and receiving devices are utilized, and three independent modules, namely a high-resolution imaging module, a multibeam laser echo detecting module and an atmosphere echo detecting module. The high-resolution imaging module realizes a visible light multispectral high-resolution imaging function. The multibeam laser echo detecting module realizes a five-beam laser echo receiving function. The atmosphere echo detecting module realizes an atmosphere echo receiving function. Three channels form the annular visual field through reasonable laying. The optical system according to the invention has advantages of high ray machine structure integration degree, high resolution, small size, small weight, etc. Furthermore the integrated system realizes functions of high resolution and high-precision distance measuring to large-area ground objects, cloud aerosol detection and three-dimensional plotting.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

A Formula Racing Wheel Toe Angle Measuring Device

ActiveCN108844487BAccurate measurementAvoid negative influenceAngles/taper measurementsUsing optical meansLaser transmitterVehicle frame

The invention discloses a toe-in angle measuring device of a wheel of a formula racing car, and relates to the field of vehicle detection and positioning. The device comprises a frame, a wheel fixingpedestal, an automatic positioning and clamping device, a horizontal calibrator, a laser emitter and an adjustable calibrated scale with a slide rail; the wheel fixing pedestal with the laser emitteris mounted on the wheel to be measured, and the automatic positioning and clamping device can position the laser emitter in the center of the wheel accurately; and the adjustable calibrated scale withthe slide rail is mounted on a steel pipe in the upper of a car frame, and the calibrated scale on the slide rail is adjusted to measure and position the toe-in angle of the wheels, with different wheelspans, of the formula racing car. The device can carry out measurement without changing a suspension arrangement form, and the wheels, with different wheelspans, of the formula racing car can be measured. Compared with the prior art, the device only measure the wheel of 1 / 4 suspension, a measuring process is simple, accurate and efficient.

Owner:JIANGSU UNIV

A storage device suitable for white latex

ActiveCN114313746BStorage storage implementationEasy to storeStorage devicesInternal fittingsNO storageLatex rubber

The invention discloses a storage device suitable for white latex, which comprises a storage box. The top of the storage box is fixedly equipped with heat preservation equipment. The inside of the storage box is provided with an annular circulation mechanism. The annular circulation mechanism includes a rotating rod and rotates One end of the rod penetrates and extends to the outside of the storage box and is fixedly connected with a rotating disc. The invention relates to the technical field of latex storage. This is suitable for white latex storage and storage devices. By providing a circular circulation mechanism, the rotation of the rotating rod can not only drive the circular rotation of the placement plate, but also rotate the transmission shaft to realize the movement of the moving plate inside the moving groove and make the movement After the plate and the square frame are clamped, the height of the plate is positioned, and the limit component is used to limit the transmission operation, which is convenient for the storage of white latex, and there will be no rotation and no excessive storage position. Advanced problems, so as to better realize the storage of white latex.

Owner:合肥皖维化工有限公司

Slitting machine for glass product

ActiveCN110217978AAchieving lateral positioningAchieve horizontal positioningGlass severing apparatusInductorEngineering

The invention discloses a slitting machine for a glass product, wherein the rear side of a machine table is further provided with a roller supporting mechanism, a lateral locating mechanism and a longitudinal uploading mechanism; a sucker moving mechanism comprises mounting battens for mounting suckers, and the bottoms of the mounting battens located at two sides are provided with pressing platesextending towards the outer side; and the lateral locating mechanism comprises a locating rotating shaft rotatably mounted at the rear side of the machine table, the locating rotating shaft is fixedlyprovided with a rotating flat plate and an L-shaped locating mounting plate, the rotating flat plate extends towards the inner side of the slitting machine, and the L-shaped locating mounting plate extends towards the outer side of the slitting machine, the pressing plates press against the rotating flat plate to make the locating rotating shaft rotate when the mounting battens are descended, theend of the L-shaped locating mounting plate is fixedly provided with a lateral locating assembly, and a locating surface of the lateral locating assembly is parallel to the rotating flat plate. By using the slitting machine, the transverse location of glass can be realized during automatic feeding in glass cutting, so that locating steps are reduced, and the slitting machine is not easily affected by faults of an inductor.

Owner:安徽大河镜业有限公司

Auxiliary positioning mechanism for industrial welding machine

PendingCN112658558ASimple structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural composition

The invention discloses an auxiliary positioning mechanism for an industrial welding machine. The mechanism comprises a mounting base, two pairs of supporting legs and a supporting frame, the two pairs of supporting legs are arranged on the bottom face of the mounting base, the supporting frame is arranged on one side of the top face of the mounting base, a welding mechanism is arranged on the supporting frame, and a steering movable structure is arranged between the supporting frame and the welding mechanism. A plane shaft sliding positioning mechanism is arranged on the mounting base. The auxiliary positioning mechanism for the industrial welding machine has the beneficial effects that the auxiliary positioning mechanism is simple in structure and convenient to operate, horizontal adjustment of materials is achieved through a plane sliding structure, then horizontal positioning of the materials can be achieved, as for curved-surface materials, the angle of the welding mechanism is adjusted through the steering movable structure, flexible positioning in curved surfaces can be achieved, the overall structural composition is simple, automatic positioning is adopted, the precision is high, positioning can be conducted on the horizontal plane, and the positioning functions of the curved surfaces can be diversified.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

A cutting machine for glass products

ActiveCN110217978BAchieving lateral positioningAchieve horizontal positioningGlass severing apparatusStructural engineeringMachine

The invention discloses a slitting machine for glass products, wherein the back side of the machine table is further provided with a roller support mechanism, a side positioning mechanism and a longitudinal film loading mechanism. The bottoms of the mounting strips on both sides are installed with pressing plates that protrude toward the outside. The side positioning mechanism includes a positioning shaft that is rotatably installed on the rear side of the machine table. The positioning shaft is fixedly installed with a rotating plate and an L-shaped. Positioning and mounting plate, the rotating flat plate protrudes toward the inside of the slitting machine, the L-shaped positioning mounting plate protrudes toward the outside of the slitting machine, and the pressing plate presses against the rotating flat plate when the mounting strip is lowered The positioning shaft rotates, and a side positioning assembly is fixedly installed at the end of the L-shaped positioning and mounting plate, and the positioning surface of the side positioning assembly is parallel to the rotating plate. The invention can realize the lateral positioning of the glass during automatic feeding of glass cutting, reduces the positioning steps, and is not easily affected by the failure of the sensor.

Owner:安徽大河镜业有限公司

Assembling and welding mould for thin-wall rectangular beam and using method thereof

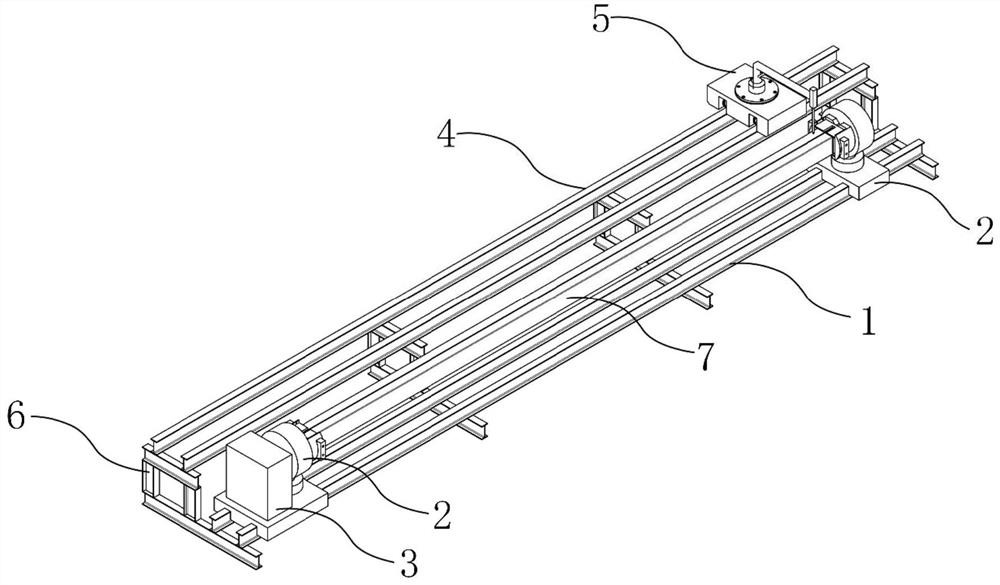

InactiveCN111940975AFast solderingPrecision weldingWelding/cutting auxillary devicesAuxillary welding devicesWeldingThin wall

The invention discloses an assembling and welding mould for a thin-wall rectangular beam and a using method thereof. The assembling and welding mould comprises chuck guide rails, the chuck guide railsare horizontally arranged in parallel with a welding machine guide rail, and two chucks are symmetrically arranged on the chuck guide rails; a to-be-welded workpiece is horizontally arranged betweenthe two chucks, and the chucks are used for clamping the end of the to-be-welded workpiece and can drive the to-be-welded workpiece to rotate around the axes of the chucks; and a welding machine is arranged on the welding machine guide rail in a sliding manner and used for welding the to-be-welded workpiece. According to the assembling and welding mould, the two chucks are used for clamping the to-be-welded workpiece, so that transverse positioning of the to-be-welded workpiece is achieved, and the positioning process is simple, rapid and accurate; the chucks drive the to-be-welded workpiece to rotate, so that the whole workpiece is stably overturned, and cracking, deformation or positioning failures of the workpiece in the overturning process is avoided; and the welding machine is arranged on the welding machine guide rail in the sliding manner, so that rapid welding of the to-be-welded workpiece is achieved through movement of the welding machine, the welding efficiency is high, andthe assembling and welding yield is high.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com