Civil air defense door machining device and method capable of reducing deformation

A technology for processing devices and civil air defense doors, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve problems such as deformation of angle steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

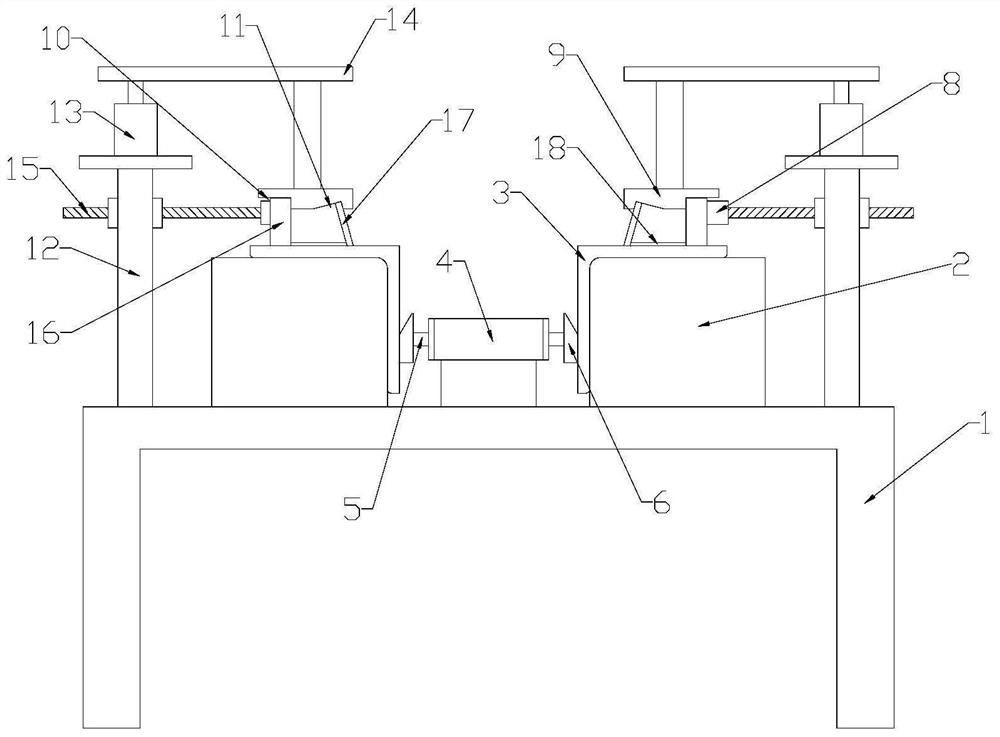

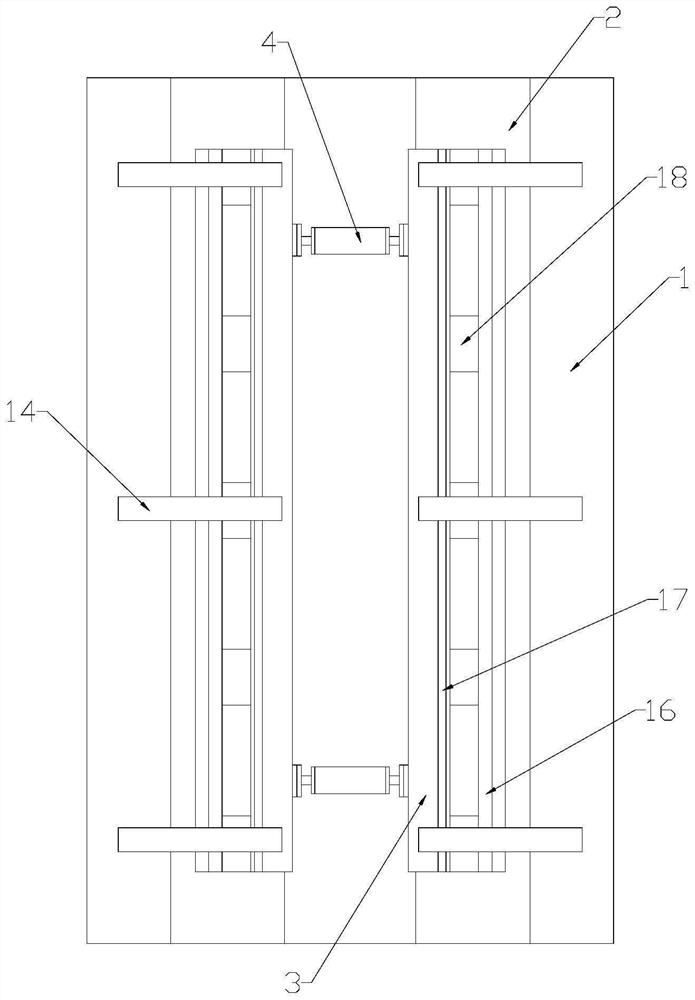

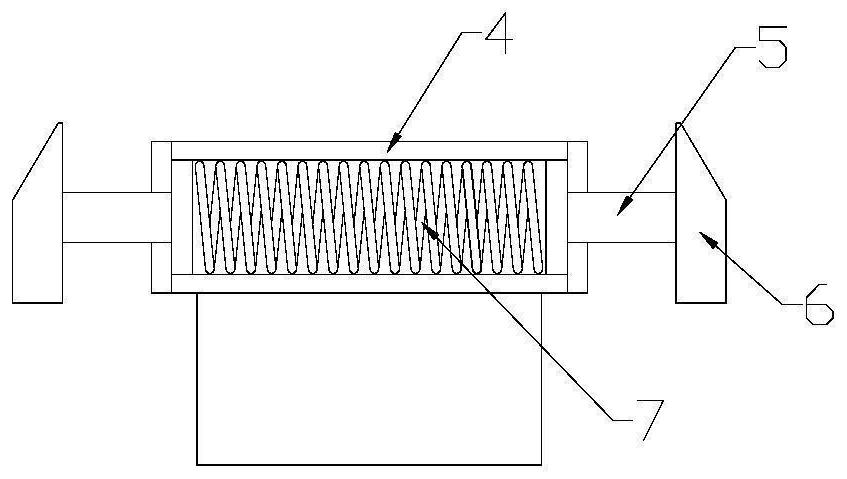

[0026] like Figure 1-3 As shown, a civil air defense door processing device includes a frame 1, and longitudinal support rods 2 are fixed on both sides of the upper end of the frame 1. The longitudinal support rods 2 are rectangular rods, which are used to support the inverted angle steel 3, and the two longitudinal support rods are The frame 1 between the rods 2 is provided with an angle steel side end positioning mechanism. The angle steel side end positioning mechanism includes two, which are located at both ends of the longitudinal support rod 2 respectively. The hollow cylinder 4, both ends of the hollow cylinder 4 are provided with a mandrel 5, one end of the mandrel 5 is slidably placed in the hollow cylinder 4, and the other end is fixed with a top plate 6, and the upper end of the top plate 6 is provided with an inclined side near the longitudinal strut 2. On the downward guide surface, a compression spring 7 is arranged in the hollow cylinder 4 between the two eject...

Embodiment 2

[0029] This implementation is basically the same as Embodiment 1, except that: figure 1 and 2 As shown, the upper end positioning mechanism of the angle steel includes a horizontally moving side pressure plate 8 and a vertically lifting upper pressure plate 9, the upper pressure plate 9 is located just above the longitudinal support rod 2, and the lower end of the upper pressure plate 9 is provided with a pressure bearing plate 16 corresponding to the first plate 9. In the lower pressure groove 10 and the second lower pressure groove 11 corresponding to the inclined flat steel 17, the side pressure plate 8 is located on the side of the upper pressure plate 9 away from the top plate 6, and the side pressure plate 8 is used to press the bearing plate 16 laterally. The second lower pressure groove 11 is a V-shaped groove with its opening facing downward. One side of the V-shaped groove is in contact with the side of the oblique flat steel 17 away from the pressure bearing plate 1...

Embodiment 3

[0033] A kind of civil air defense door processing method that can reduce the amount of deformation, adopts the processing device shown in Embodiments 1 and 2, and comprises the following steps:

[0034] (1) A plurality of connecting plates 18 are fixed at the lower side between the bearing plate 16 and the oblique flat steel 17 along the longitudinal interval. One end of the connecting plate 18 is connected to the bearing plate 16 by welding, and the other end is connected to the oblique flat steel 17 by welding. ;

[0035] (2) Buckle the angle steel 3 upside down on the side of the longitudinal support rod 2 close to the top plate 6, the top plate 6 presses the side wall of the angle steel 3 on the longitudinal support rod 2, and the step (1) is connected to the pressure bearing by the connecting plate 18. The plate 16 and the inclined flat steel 17 are placed on the upper side of the angle steel 3, and the pressure-bearing plate 16 and the inclined flat steel 17 are pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com